powered rotary table quotation

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

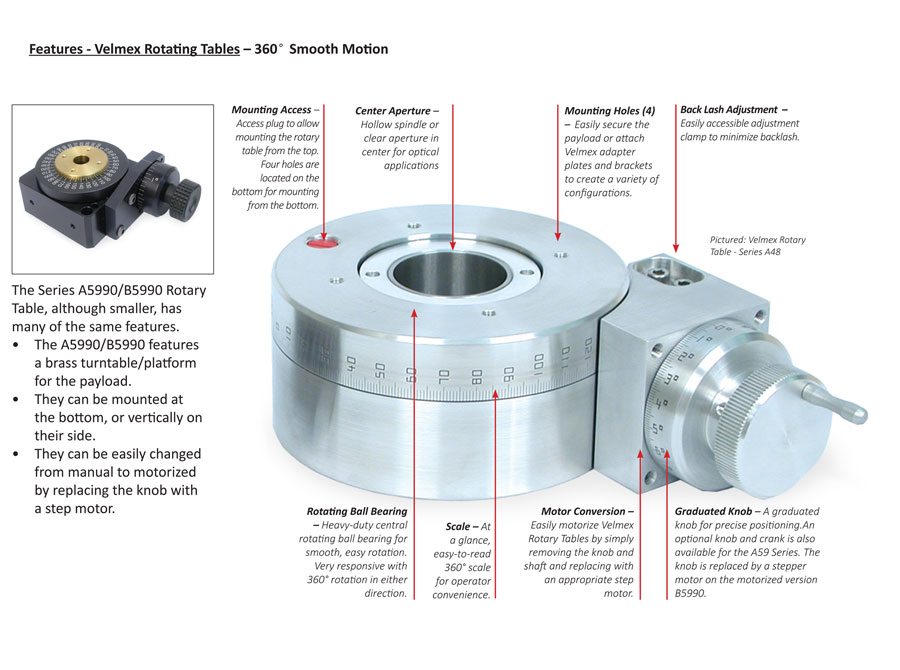

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

RotoRingrotary tables provide superior angular positioning and are designed to eliminate backlash, friction and wear problems associated with worm, gear and belt drives.

Radially distributed brushless RotoLinear motoring modules provide high positioning stiffness during rotary indexing and when installed on moving XY tables.

RotoRingsfeature "large open center design".In general automation applications large open center offers the opportunity to access parts from inside and outside of the table simultaneously.

This feature allows robotic devices, pick and place and ancillary tooling to be mounted inside the table, saving floor space and reducing parts handling with increased productivity.

The T1191 manual was written by our U.S. based Technical Documentation Department and is packed with useful information. The complete and easy-to-read manual makes it easier to assemble and maintain your rotary table.

The Grizzly Customer Service and Technical Support Teams are U.S. based. Parts for the rotary table may be available online and shipped from the Grizzly parts warehouse in Springfield, MO.

The T1192 manual was written by our U.S. based Technical Documentation Department and is packed with useful information. The complete and easy-to-read manual makes it easier to assemble and maintain your rotary table.

The Grizzly Customer Service and Technical Support Teams are U.S. based. Parts for the rotary table may be available online and shipped from the Grizzly parts warehouse in Springfield, MO.

PI’s direct-drive rotary tables with frictionless, brushless, closed-loop torque motors provide the best combination of high accuracy, high velocity, and maximum service life. PI provides closed-loop direct drive rotary tables with both mechanical bearings and air bearings. Stage models with large apertures and low profile are available. The stage design is optimized for high speed, stiffness, and high load capacity. If completely friction-free and maintenance free motion with virtually unlimited lifetime is required, air bearing rotation tables are recommended. These ultra-precision, high-speed rotary tables provide vibration-free motion with extremely high accuracy and negligible runout, wobble and eccentricity errors. The lack of lubricants makes these also clean room compatible and ideal for any high-performance metrology application in optics, photonics, and semiconductor manufacturing, test and metrology related projects.

In contrast to worm gear driven rotary stages or belt-drive rotation stages, torque-motor direct drive stages eliminate play in gears, couplings or flex in drive belts, providing motion with zero backlash and excellent constancy of velocity, while achieving higher speed than worm-gear drives.

PI’s precision direct-drive, positioning tables can be used in high performance factory automation, research, semiconductor, and laser processing applications. Due to the use of brushless high-torque, motors with direct metrology position feedback, backlash is completely eliminated, and reliability is greatly improved.

With modern direct-metrology rotary encoders, sensor resolution down to 1/100th of a microrad is available on select models with large rotary table platforms, using the high interpolation factors

Based on the high encoder resolution and powerful servo controllers, the direct-drive rotary tables also provide excellent velocity control, which is required in automation applications including high-speed laser processing, indexing, and semiconductor wafer inspection.

Most Direct Drive Rotation stages can be mounted horizontally and vertically, and with combinations all 3 rotary degrees of freedom (3DOF, pitch, yaw, and roll) can be addressed.

The KP1-V single-axis turntable with vertical rotational axis is used for direct workpiece positioning or as a modular base. It is available with a payload capacity of 500 ...

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits into the CM-1 or larger machines. It is ideal for smaller ...

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version ...

Our redesigned TRT160 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater mounting flexibility than its predecessor. ...

The rotary table TP 004 is a simply designed turning unit of high-quality gear and drive motor as a main component. It is equipped with an inductive reference ...

... Its modular design allows the positioning table to be combined with accessories of its category. The radial play of the rotary shaft is less than 0,015 mm, where as the axial play of ...

The horizontal rotary tables of the RCH series with bearings on one side are directly driven, maintenance-free precision axes. They use water-cooled ...

JVL introduces a highly effective, modern turntable that can be fully integrated in modern automation systems. TurnMaster Turntable is supplied with integrated electronic control and ...

Bearing assemblies with direct drive are suitable for applications where high performance and low space requirements are important criteria. The integration ...

... products are motorized rotary stages with built-in controllers. Rated for 2.25 N-m of torque, speed up to 75 rpm, and a load capacity of up to 20 kg, these stages are ...

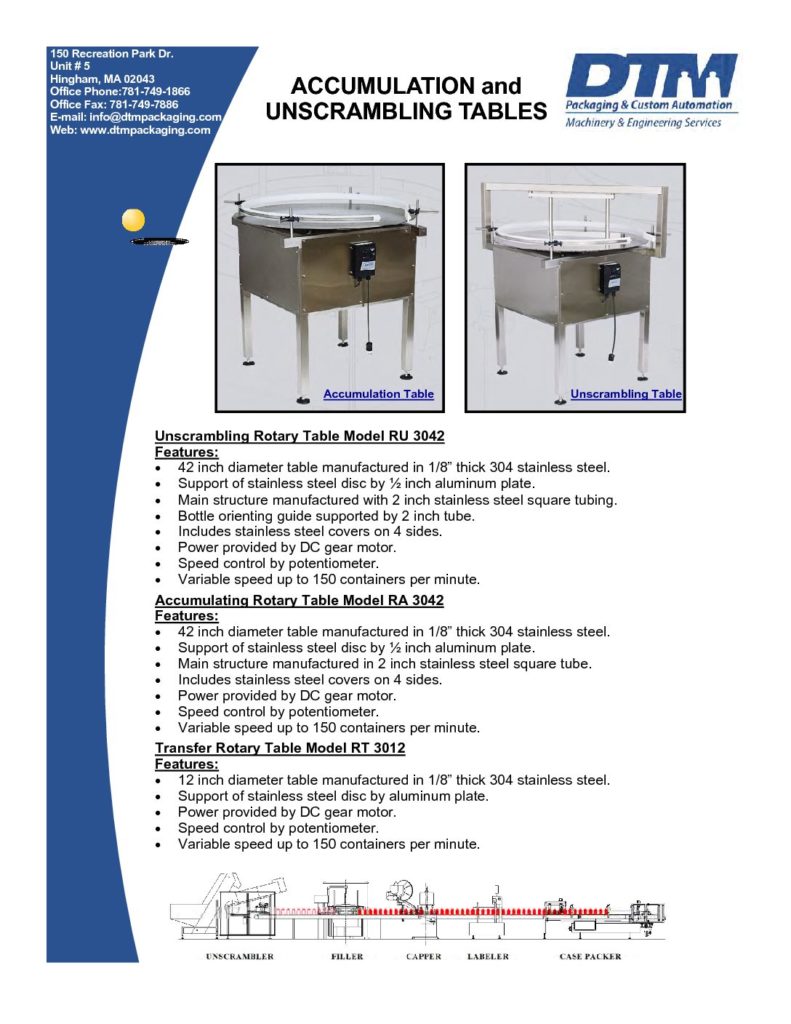

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

... turning table is equipped with motorized roller conveyors. It is used in conveying systems for changing the direction of the package units, without difference in the forward front. In addition, it is also utilized in ...

Unimec SA conceived these electric rotating tables for an integration in automatic rotating machines, for transport and assembly where precision and dynamism are asked.

Microplan"s TR rotating tables are designed and manufactured out of 2 granite disks each, moving on pressure/vacuum air bearings in ways to obtain highest possible stability. These apparatuses exhibit ...

Compact package and Superior design of the AccuRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

The Compact Clean room rotary table PSX Series is manufactured by ITALPLANT. The product is made of plastic, making it very light. It is suitable for corrosive and explosive environmental conditions. ...

Our FÖRSTER swivel welding tables offer maximum working comfort for all-round welding of complex assemblies. Ideal for all tasks due to a variable arrangement of our patented T-slot system.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

This is an accurate designed table for milling, boring and other machine tools. This table allows indexing, facing and other work to be carried out rapidly with extreme precision. Tiliting range 0-90 degrees fromread more...

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

Located at the entrance of a conveyor belt, or directly to the machine that has to feed, performs the function of “station of accumulation and distribution”. The products can be loaded manually or by conveyor belt. The adjustable deflectors allow you to sort and align products to the food evenly and without interruption the machine that receives them. Positioned at the exhaust of a conveyor belt or in the output of a packaging machine, filling machine, labeling etc., Performs the collection and accumulation of products function. The rotary tables are equipped with a speed variator to adapt to the various needs. The rotating disc may be provided in a slippery plastic material or stainless steel.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

This machine is normally used with a horizontal glass conveyor leading to a castor top assembly table. The units are pushed across onto the sealing table in its lowered position. The table then lifts pneumatically to allow rotation clearing the table.

American Block offers a complete line of drilling rotary tables that range from 17 ½ to 60 ½ . These tables are designed to withstand the harshest drilling conditions. All rotary tables feature a fabricated frame, heavy duty main thrust bearing and precision machined spiral bevel gear that results in superior strength, toughness and durability.

American Block can also provide unitized rotary table assemblies (IRD). Our unitized skid packages are ideal for new builds or can be retrofitted to existing rigs. Featuring a heavy-duty oilfield skid and an extend life transmission. The rugged design ensures that when the equipment is mounted it remains rigid during operation and rig moves. Other rotary table options include hydraulically operated tables and high torque tables (25% more torque), which are ideally suited for top drive operation.

8613371530291

8613371530291