micro rotary table quotation

The basic version, M-035.50 rotating table, is equipped with a micrometer drive and a zero-backlash magnetic coupling. The micrometer provides a positioning range of ±9.5 degrees.

The versions M-035.PS and M-035.P0 feature additional piezoelectric fine adjustment over a range of ±520 µrad. They also allow dynamic operation such as scanning or tracking. The .PS version is equipped with a closed loop feedback piezo drive (model P-841.30), while the .P0 version has an open loop piezo drive (model P-840.30). Both drives provide a linear range of 45 microns and sub-nanometer linear resolution (see "PZT Actuators" section for further details and recommended drivers).

The continuous need for miniaturization in industry and research requires smaller precision motorized rotation stages for many alignment applications in optics, photonics and medical design. Motorized miniature rotary stages from PI are available with different motor drive principles to suit various requirements. For the smallest size, closed-loop piezo motors are integrated into the miniature rotation stages. These direct-drive motors provide high speed and repeatability and are free of backlash. A direct measuring encoder for position feedback is integrated in the miniature rotary table body for high position accuracy. Depending on the technology used, table diameters are as small as 18.5mm. The more traditional mini rotation stages use stepper motors and closed-loop servo motors driving the rotation platform via a worm gear that increases motor torque and resolution. It also locks the rotary platform into place when the motion controller is turned off. The stepper motor rotary stages can provide resolution in the arcsecond range when driven with a micro-stepping motor controller such as the Mercury compact, low cost single axis stepper motor controller.

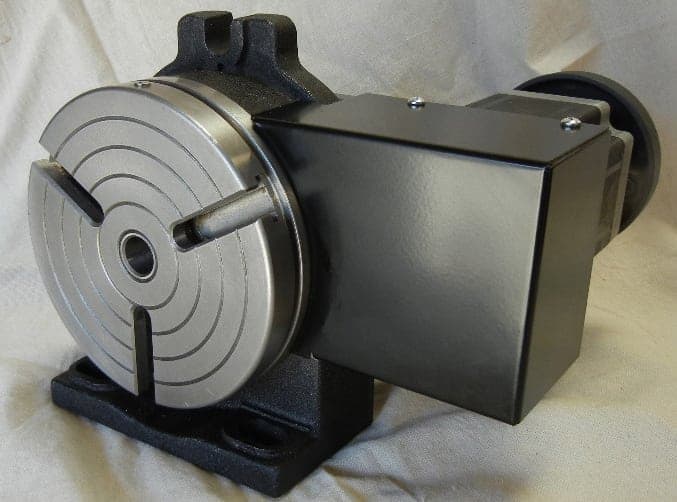

The TR160 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. Scale feedback on the ...

The TR160-2 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. The dual-spindle design ...

The TR200Y is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. Scale feedback on the ...

The base and circular positioning tables are made out of anodized aluminium alloy. The self-locking spindle is made from steel and its slide bearing is maintenance-free. The table has ...

... X-RSW-E Series products are motorized rotary stages with built-in controllers. Rated for 2.25 N-m of torque, speed up to 75 rpm, and a load capacity of up to 20 kg, these stages are ...

... Series feature a 120 mm diameter table with a 50.8 mm (2 inch) aperture, and the ease of a built-in controller and motor encoder. With a compact footprint, low profile and load capability of 60 kg, these ...

... versions of TRV rotary table involve electric rotation via double Brushless motor with precision reducer instead. In these big TRV tables position and rigidity are granted by Hirth coupling ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on their small ...

The EGD series is a globoidal rotary table that has a rated repeatability and angular accuracy of 20 seconds. The unit has a zero backlash positioning function, and has an utmost load ...

The table top center bearing is extremely precise: concentricity is less than .0004 inches, typically as small as .0002 inches. This gives you ultra center positioning, makes your parts very ...

Mini-Mover Rotary Table Accumulators (RTAs) were originally designed for the metalworking marketplace to promote unattended machine operation and separation of sensitive parts after machining.

Our RTA units are well suited for various applications in assembly and packaging, such as cycle tolerance inspection, surge table on production lines and staging for manual or pick & place case packing.

Parts are delivered to table via part chute or conveyor. Parts are stopped by in-feed cushion. As table rotates, parts are directed away from part drop area by the diverter fence and accumulate at the table center.

Manufacturer of linear slides, linear positioning stages & rotary positioners with tandard & custom models available. Linear slides & stages are available with ball screw, linear motor or lead screw actuation, flanged or sealed. Specifications include maximum load capacity ranging from 395 kg to 2187 kg, travel from 25 to 2000 mm & width from 50 to 600 mm. Miniature linear stages are available with nano step positioning with maximum load capacity of 544 kg, travel of 15 mm to 160 mm, lengths from 44 mm to 200 mm & width from 50 mm to 150 mm. Rotary positioners are available with direct & worm drive actuation with specifications including length from 130 mm to 410.7 mm, maximum load capacity of 250 or 460 kg, 360 degrees travel & width from 100 mm to 300 mm. Industries served include packaging, food, semiconductor, automotive & aerospace, medical, factory automation, bottling & high speed milling machining. ISO 9001:2000 certified, RoHS & DFARS compliant, Lean Manufacturing.

With proper selection and integration of high-performance brushless DC servo motors ABTech’s air bearing rotary tables provide ultra-smooth and precise rotary motion. With high torque, high performance motor drives, our motion experts will gather your specific requirements and work closely with our motor suppliers to create/select a motor drive that suits your specific application. Whether you need sub-micron position accuracy with minimal settle time and stringent following error specifications, high-speed constant motion, or a combination of both there is an ABTech rotary table that will meet your needs.

The motor drives are designed to accommodate a wide range of precision motion applications such as optical metrology; circular geometry gages; and micro machining with ultra-precision scanning, velocity control, speed regulation and precision indexing.

ABTech’s modular design approach facilitates multiple system configurations to optimize the price-for-performance required in your application. This approach allows the user to define the level of control desired for the most cost-effective solution. Our complete engineering services allow us to respond quickly to provide a solution to your O.E.M. requirements for ultra-precision rotary motion.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

One of the earliest designs for accumulation or unscrambling is the rotary table. Both configurations can handle multiple container sizes and materials. The rotary design is flexible and effective. Standard (non-custom) diameters are 36", 48" and 60”. Top discs are stainless steel with machined backer plates for trueness. Accumulators are usually supplied with an enclosed cabinet and variable speed controls, using either DC or VFD controllers. Infeed and discharge conveyors are recommended to be designed with a close interface for smooth transfers. A smooth edge bowl top is available for hand packing applications.

Technitron has been integrating rotary tables and accessories on machine tools since 1992. Over the past 30 years Technitron has pioneered new technology and techniques to allow us to set the industry standard for rotary table and accessory integrations. By utilizing our vast experience, we have been able to meet and exceed our customers’ expectations. No other company has our experience on a variety of machines and controls.

Technitron is dedicated to supplying high quality Integration Services to the Machine Tool Industry. Our Turn-Key Integration Services are designed to enhance the productivity from both new and existing machine tools. We have installed more than 3500 rotary tables to date.

The resolution of 0.0015 degrees is achieved with a 10 micro-steps per step stepper motor driver. This rotation stage is also available with a servo motor

The T25937 manual was written by our U.S. based Technical Documentation Department and is packed with useful information. The complete and easy-to-read manual makes it easier to assemble and maintain your rotary table.

The Grizzly Customer Service and Technical Support Teams are U.S. based. Parts for the rotary table may be available online and shipped from the Grizzly parts warehouse in Springfield, MO.

8613371530291

8613371530291