precision rotary table manufacturer

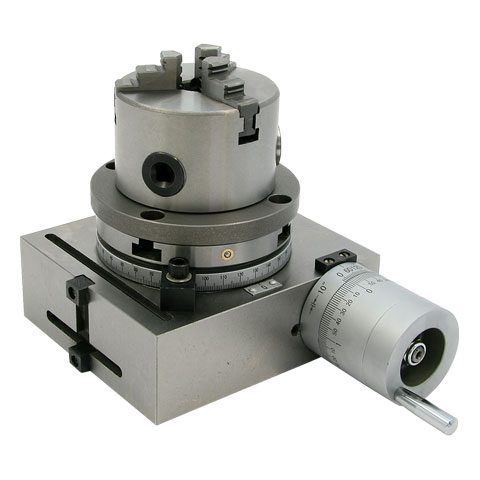

Penn Tool Co. has a variety of precision rotary tables for sale. Simplify your production work with a rotary table that can be used for many different machining applications. In production, it is essential that jobs are done quickly, efficiently, and precisely. In the industry of intricate metalworking, precision matters and can make all the difference. All of the parts should look identical in the end, and our tools can help you do just that. To ensure quality and durability, we only carry top-rated, premium brands you can trust including Vertex, Harig and Phase II. With an easy-to-operate precision rotary tablefrom Penn Tool Co., get the accuracy you need and a timely, beautiful end result. Browse our collection, and order today!

Tsudakoma had been providing best-in-class rotary tables for over 100 years, offering multiple models and configurations to ensure seamless integration with your machining centers. Koma Precision has been distributing Tsudakoma’s tables for over 40 of those years and our North American sales team and in-house engineers will work with you to determine which model best suits your machining needs.

The 200RT Series Rotary Tables are designed for precise motor-driven rotary positioning and indexing. These tables are designed to function independently or in conjunction with linear tables used for precision automation applications. Their low profile design minimizes stack height in multi-axis configurations and enables them to fit in many places where other motorized rotary devices cannot. Models are available in 5, 6, 8, 10, or 12 inch diameters and are offered with four gear ratios making it convenient to match size, speed, and load requirements. They can be selected in either English or metric mounting. They are found in virtually all industries where intermittent part indexing, part scanning, skew adjustment, or precise angular alignment is required. At the heart of these tables is a rugged main support bearing which is comprised of two preloaded angular contact bearing races. It is designed for high load capacity and smooth, flat rotary motion. The drive is a precision worm gear assembly which is preloaded to remove backlash. The top and base are constructed of high quality aluminum with an attractive black anodized finish. The top and bottom mounting surfaces are precision ground to assure flatness.

The assembly tables with reciprocating movement rotate on the horizontal plane. They are used to equip semi-automatic or automatic loading stations. Incorporated fine pitch stop screws made of hardened ...

... SA conceived these electric rotating tables for an integration in automatic rotating machines, for transport and assembly where precision and dynamism are asked.

... X-RSW-E Series products are motorized rotary stages with built-in controllers. Rated for 2.25 N-m of torque, speed up to 75 rpm, and a load capacity of up to 20 kg, these stages are ...

RTGA Series motorized rotation stages provide precision angular positioning accuracy combined with high load capacity. There are three stage sizes with center aperture ...

Velmex Rotating Tables deliver precise, continuous rotating motion for scanning, assembly, testing and production. They are a convenient, accurate method of quickly positioning or rotating ...

For the past fifty years, TRT has been the most frequently used rotary table. TRTs are electric, driven by fully CNC Brushless motor with precision reducer. Position and rigidity are ...

Jenaer Antriebstechnik GmbH"s HRT-100 Series of hollow-shaft rotational tables feature n x 360° rates, mechanical and electrical connection readiness, and integrated ES Series motors. They feature hole ...

The Rotating rotary table DSH-S Series is manufactured by Isel Germany. The product has a compact and durable design; it is made of stainless steel that has protection class of IP 65. ...

The RT series of our precision rotation stages is used where rotation-symmetric components and assemblies are measured with highest accuracy or for positioning. The free from float pre-stressed ball bearings ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

... acoustics Remote-operated Turntable HRT I is used for automated orientation-dependent acoustic measurements, allowing to rotate the device under test to specific angles in the measurement field.

This is the Hollow Rotary Table model number GSN60-05K-SV with table size 60mm gear ratio 1:5 for servo motor. GIGAGER Hollow Rotary Table also called ...

Rusach International has continued an on-going program of design and development, benefiting from years of experience in the design of special purpose Rotary Tables, Pallet Automation Systems and Metrology Products,from our Eimeldingen years. An increased product range through acquisitions and product development has enhanced the company"s work on high accuracy rotary tables. A natural progression was the introduction of retrofitting pallet automation systems in 1976. These have subsequently been supplied in "stand alone" and FMS form to suit a wide range of machining applications, also over the last few years supplying rotary and tilt CNC tables fully integrated onto slideways or as full bases for various machines.

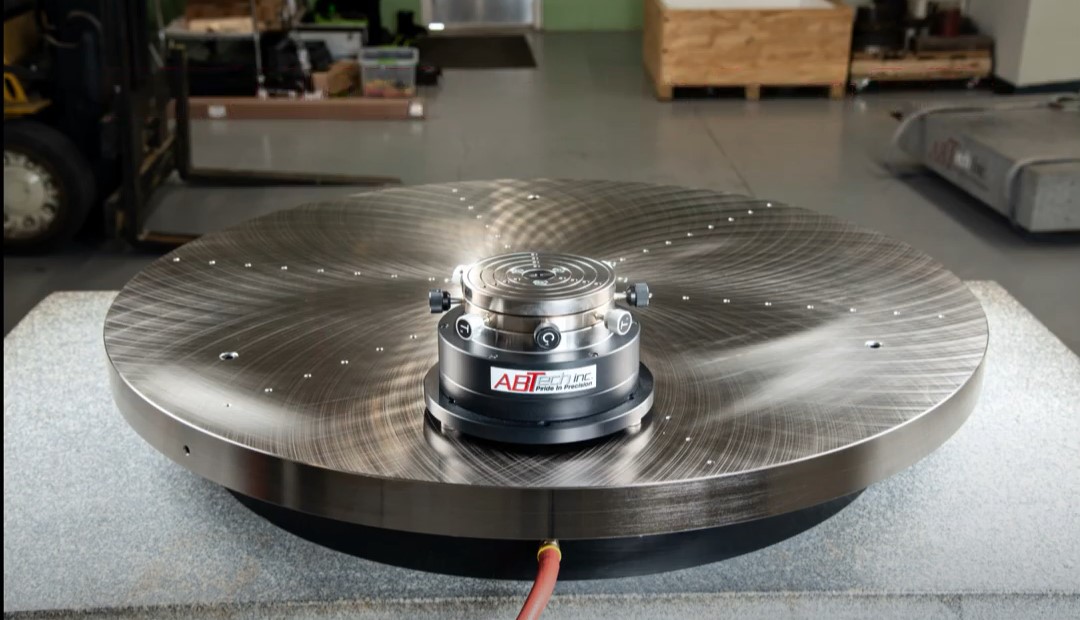

Designed and manufactured to the highest level of quality, our rotary tables feature distortion-free active clamping with roller bearings for high-resolution rotation. The rigid design and solid components make loading capacities of up to 100+ tons possible.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

PI’s direct-drive rotary tables with frictionless, brushless, closed-loop torque motors provide the best combination of high accuracy, high velocity, and maximum service life. PI provides closed-loop direct drive rotary tables with both mechanical bearings and air bearings. Stage models with large apertures and low profile are available. The stage design is optimized for high speed, stiffness, and high load capacity. If completely friction-free and maintenance free motion with virtually unlimited lifetime is required, air bearing rotation tables are recommended. These ultra-precision, high-speed rotary tables provide vibration-free motion with extremely high accuracy and negligible runout, wobble and eccentricity errors. The lack of lubricants makes these also clean room compatible and ideal for any high-performance metrology application in optics, photonics, and semiconductor manufacturing, test and metrology related projects.

In contrast to worm gear driven rotary stages or belt-drive rotation stages, torque-motor direct drive stages eliminate play in gears, couplings or flex in drive belts, providing motion with zero backlash and excellent constancy of velocity, while achieving higher speed than worm-gear drives.

PI’s precision direct-drive, positioning tables can be used in high performance factory automation, research, semiconductor, and laser processing applications. Due to the use of brushless high-torque, motors with direct metrology position feedback, backlash is completely eliminated, and reliability is greatly improved.

With modern direct-metrology rotary encoders, sensor resolution down to 1/100th of a microrad is available on select models with large rotary table platforms, using the high interpolation factors

Based on the high encoder resolution and powerful servo controllers, the direct-drive rotary tables also provide excellent velocity control, which is required in automation applications including high-speed laser processing, indexing, and semiconductor wafer inspection.

Most Direct Drive Rotation stages can be mounted horizontally and vertically, and with combinations all 3 rotary degrees of freedom (3DOF, pitch, yaw, and roll) can be addressed.

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

Before Roto Tech and Roto Technology, Roto-Grind Precision Rotary Grinding Tables were manufactured by M&M Precision Systems in Dayton, Ohio. M&M Precision Systems (later purchased by Gleason Corporation to become Gleason M&M Precision Systems Corporation) developed the first full CNC gear metrology system, positioning it as the global leader in precision motion and metrology systems for specialized inspection and gear manufacturing process control needs as well as precision rotary grinding tables which were at that time a critical portion of the gear inspection systems.

The sophisticated versatility of those early Roto-Grind Rotary Tables are still available today and updated for precision finishing of today"s more exotic manufacturing materials.

TANSHING products can be selected depending on different machining conditions. A wide range of models, such as the type of high load, high rigidity, high speed, high precision, long life span, zero backlashes, ultra-high load 10-60 tons large precision rotary table, and hydrostatic table can be customized. In addition, there is a variety of new 5 axis rotary tables, swing head rotary, etc. The complete series is available in our product line.

TANSHING’s R&D team is capable of dealing with a variety of machining requirements, such as speed and load capacity improvement. Any customized accessories can be planned and designed quickly. The same type of rotary table with a direct drive motor has been widely installed at domestic and foreign machine tool manufacturers. Our techniques for the function application of product, assembly, and testing are well-developed. We welcome machine tool manufacturers and machining shops to contact us for any kind of inquiry.

The Sauter rotary table is ideal for machines designed for complete machining. Our tables can be used for milling or grinding machines as a base for the main spindle or the workpiece carrier an allowing easy access from any position.

Our design for the B-axis rotary table focused on flexibility, precision, and robustness. This was achieved by means of:Backlash-free pre-loaded gear train

PARKSON enthusiastically develops our innovative researches and productive technologies for cooperating with clients to respond to the quick changing demands in industry and designs the rotary tables with digital control that comply with the demands by clients, demonstrating the capabilities of PARKSON in terms of research, innovation, and production.

For a long time, PARKSON has persisted in the foundation of a manufacturer, which is design developments and engineering technologies and has followed the operational principles: “Quality to accomplish future; no ending for innovation” to market internationally with the brand of PARKSON. For many years, we have developed many high-precision rotary tables together with domestic and foreign manufacturers of machine tool for satisfying different territories of machining.

Moore Tool manufactures a complete line of high precision, CNC positioning and contouring rotary tables from 12 inches (305 mm) to 96 inches (2.4 m) in diameter. We also offer service and remanufacturing services on tables that we have built.

The Moore 1440 Precision Index is a serrated-tooth circle divider of highest accuracy using two face gears of identical shape and pitch. During operation, the table is displaced axially to disengage the teeth and radially to the desired angle. The instrument is guaranteed to be accurate to within ±0.1 second of arc at any of the 1440 indexed positions

Many rotary table manufacturers outsource gear fabrication to lower costs. While that strategy may offer short term cost savings, Index Design’s American made rotary tables are built with gears cut in house. This is the only way to closely monitor and control tolerances, consistency and performance.

Our rotary tables incorporate large diameter high tensile bronze worm gears mated against hardened steel drive shafts. The combination of metal gives superior wear properties for long lasting operation. As the rotary table is run, the properties of a tin bronze gear develops a low friction deposit on the mating steel drive shaft. These deposits fill in microscopic pores of the mating surface. Over time, as these deposits are embedded on the surface, wear decreases followed by a reduction in frictional forces within the gear assembly.

Final inspection and verification of specification performance is done with precision calibration equipment capable of measure tolerances of +/- 1 arc second in any position. Any deviations from specified angular positions are corrected so our customers can be assured that they are receiving the performance we guarantee.

In addition, the data gathered from our automated calibration procedure allow our engineers to assess, monitor and improve the static and dynamic performance of prototype rotary tables during the design phase.

Our engineers have a long and rich history in the machine tool business, they combine decades of both CNC machine tool and rotary table manufacturing experience with the latest design tools to produce rotary tables with superior performance and dependability.

Our CAD/CAM software is used to analyze displacement and stress for each component, sub-assembly and total assembly. However, the best software and technology is worth next to nothing if no one understands the craftsmanship. This is particularly true when manufacturing precision rotary tables which involves many steps. Despite all the modernization and automation available, a large part of the manufacturing process is still completed by hand. At Index Designs, we understand and appreciate craftsmanship, It is designed and built into our products.

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

For machining conditions involving high load, high rigidity, and high speed, or requiring high precision, fine tolerances or hydrostatic rotary tables, HOSEA provides customized products for complete solutions.

Yukiwa precision rotary tables and index tables are high-speed indexing tables which have the built-in precision couplings. They are most suitable for precision machining for the automobile parts, etc., interlocking with the machining centers and the special purposes machines.

8613371530291

8613371530291