rotary table with dividing plates free sample

The H7527 manual was written by our U.S. based Technical Documentation Department and is packed with useful information. The complete and easy-to-read manual makes it easier to assemble and maintain your rotary table.

The Grizzly Customer Service and Technical Support Teams are U.S. based. Parts for the rotary table may be available online and shipped from the Grizzly parts warehouse in Springfield, MO.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

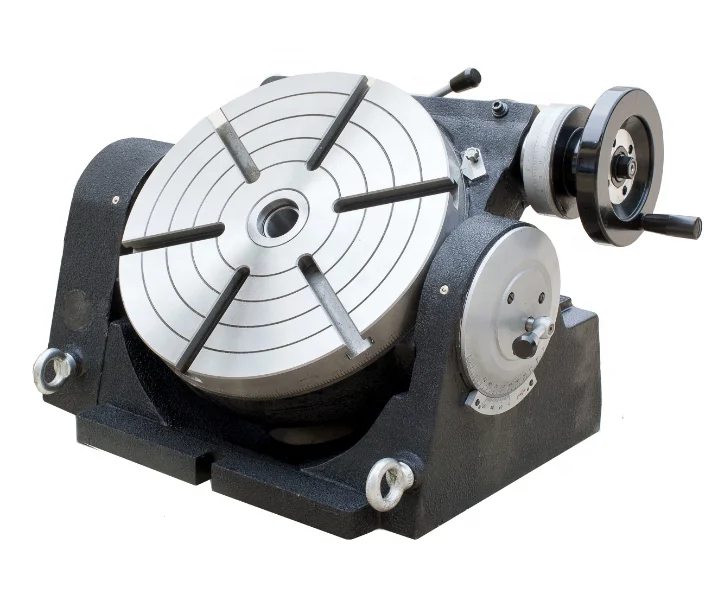

The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from casting with high quality, can work with a set of dividing plate.

Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part.

Three dividing plate set(Plate "A" - 15, 16, 17, 18, 19, 20 Plate "B" - 21, 23, 27, 29, 31, 33 Plate "C" - 37, 39, 41, 43, 47, 49). A set of wrench and screws are free for you with your installation.

One of the programs included with the DIVHEAD archive on my webpage allows you to calculate the hole plates required for any number of divisions up to an input maximum. Below are the results of that program for rotary table gear ratios of 40, 80 and 90 assuming one wants the ability to make all divisions up to 50.

These solutions are minimum hole drilling solutions so it"s possible that some of the lower number divisions could be accomplished with a single circle of holes at the expense of drilling more holes. For example, the 4 and 6 hole circles in the 40:1 solution could be accomplished with a single hole circle of 12 holes or some integer multiple of 12 holes.

If your table has a ratio of 90:1 then you will have to turn the dial 90 turn to make the table go around once. That means that you divide 360 degrees by 90 turns and you get 4 degrees per turn. Simple enough.

Now lets say that you want to cut something that has 4 slots in it. Divide 360 by 4 cuts. That gives you 90 degrees per cut. So haw many turns to make 90 degrees? Divide 90 by 4 degrees and you get 22 1/2 turns. (90 turns divided by 4 will give you the same results) You could do this one by sight but it gits harder when you are cutting gears or something with odd numbers and lots of teeth.

So here is what you do. This is where the plates come in! This example is easy but the theroy is the same. You only need a plate with two holes but since there is no such thing you will use any plate that the row of holes you want to use will divide by 2 since you need half turns. Set your index arms so that the pin on your arm falls inside the dividing arms. Set them so that you can find the next hole of the same count. IE: If you used a 24 hole plate then you will have 12 holes between the arms thus giving you half turns each time you index.

The number of full turns has nothing to do with the plate hole count. Only the remaining partial turn needs to be indexed. You have to count the full turns youself. Using the RT degree scale helps make sure you counted correctly if you get interputed. It happens!

A rotary table can be divided automatically, according to the size of the table. Secondly, a kitchens can benefit from longevity and convenience. It is easy to use, a spice rack can help to organize items andlyize accordingly.

A server rotary plate can be used as an alternative to a standard rotary plate. It is easy to operate as a server rotary plate, it can be easily moved to the objects by rotating on them. The kitchenware can benefit from the different benefit of a rotary table dividing plate as it is easier to operate. It is environmentally friendly, dishwasher safe and drying, and can benefit from the advantage of a rotary table dividing.

This website uses cookies, which are necessary for the technical operation of the website and are always set. Other cookies, which increase the usability of this website, serve for direct advertising or simplify interaction with other websites and social networks, will only be used with your consent.

The handle can be removed easily by releasing the caphead bolt. The handle being located with a keyway. This then allows the dividing plates and crank to be fitted in place of the free-rotating handle.

The crank handle is held in place with a grub screw – ensure this is tight and that the handle and pin are at 90° to the crank plate before trying to fit the crank to the table.

12 divisions is achieved with 7.5 turns – so 7 complete turns of the handle and then with a 20 division plate the dividers are set at 10 + 1 holes apart.

A very small 12 tooth gear made with a cutter designed for a larger number of teeth and hence the undercut on the teeth – the wall is rather thin at the centre, but this was a trial to see how the rotary table works when being used as a divider – aim is to make more gears for my Wood and Metal Clock.

A freely available spreadsheet that has the full dividing plate and rotary table calculations. You can set it up for your specific table and print off the sheets. You just need to know the worm drive ratio.

You remove the nut holding the hand wheel on and pull the handwheel off. They are usually on a keyed shaft that also has two flats on it. Behind this are three tapped holes to take one of the three plates you should have with the table.

Most popular dividing heads use a 40:1 ratio and the tables published reflect this. Rotary tables are usually 90:1 or 60:1 so you will need a set of tables to cover this ratio. This is why you need to choose which plate you use carefully as you need a plate with a row of holes to match your divisions at the required 60 or 90:1 ratio.

The Motion Index Drives RT Series Fixed Rotary Index Tables encompass a large range of sizes, ranging from our model RT100 up to our RT1250. In addition, special cam-driven devices can be custom made to order for your automation needs. RT Series Fixed Station Rotary Table are offered in a fixed number of stations or as a flexible turntable with a servo motor or standard AC brake motor with encoder. With the addition of Motion’s patented NANO Indexer Technology, the RT Series Fixed Station Rotary Table becomes the world’s most accurate barrel cam indexers.RT Series indexing tables are constructed with strength and reliability in mind. Robust design and components ensure this device will maintain precision in intense factory settings.

8613371530291

8613371530291