harbor freight rotary table free sample

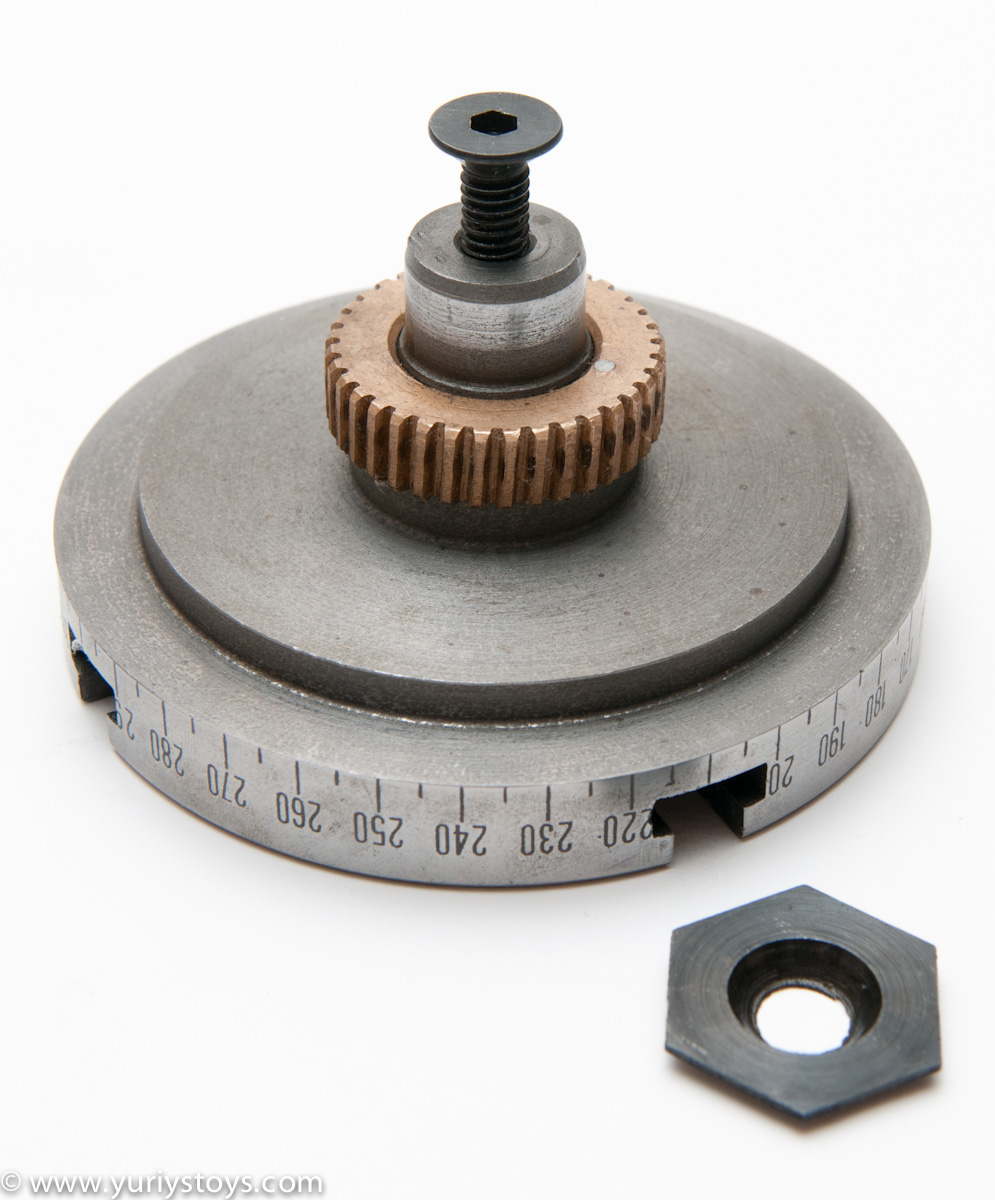

There are no locking bolts in the Grizzly model table. There is a ball bearing that is pressed onto the table shaft. On mine, it isn"t a tight fit and is easily removed with slight pressure. It isn"t easy to hold the casting while pressing on the table shaft, but it is fairly easy to remove, once you remove the worm gear.

The screw in the bottom is used to adjust the spacing between the edge of the table and the casting. I tighten it until it barely moves, back off the screw about 1/8 turn and smack it with a brass hammer.

One note, there is a slight bit of space between the side of the table and the base casting, so if you plan on using the locking screw, center the table with the screw tight. It can make a thousandths or two difference.

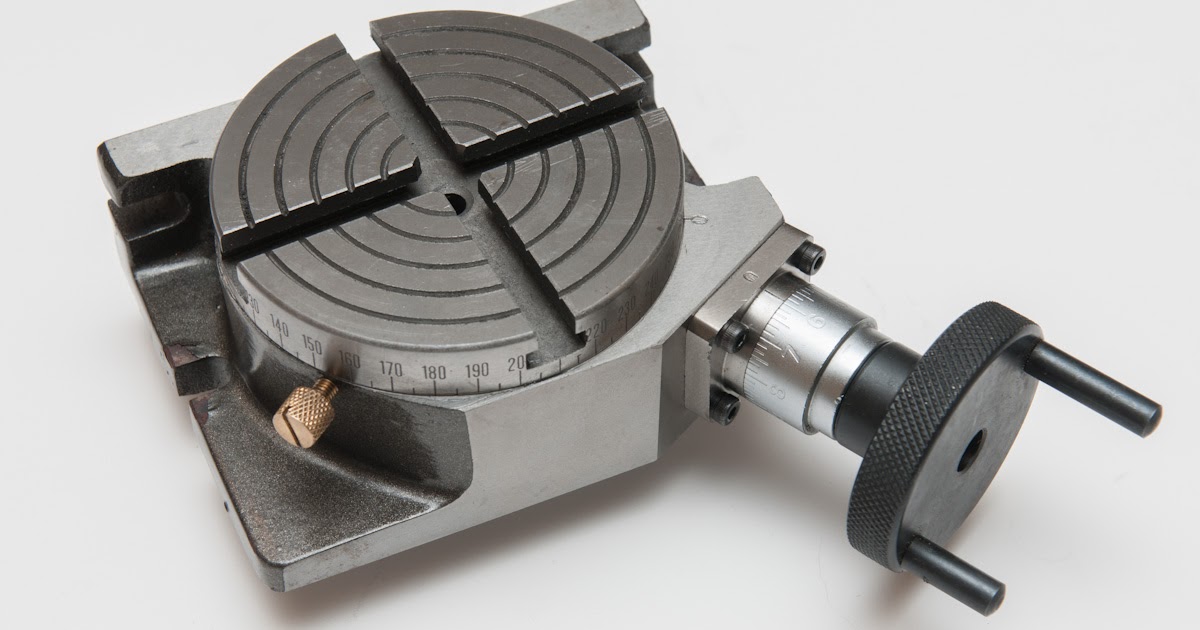

Here is a close-up of one of the two clamps provided. These fit in the t-slots on the rotary table. As can be seen, these are just stamped out metal pieces, screws, and T-nuts.

I have a mill made by Little Machine Shop. It is very similar to others such as those offered by Micro Mark, Harbor Freight and Grizzly, and - perhaps not in the same class - the Proxxon FF230. But just the same: they all have one thing in common: they use metric threads and that can cause some problems when interchanging accessories with those made on the basis of the US standard threads (for example Sherline).

After looking at the various options offered by Grizzly (their ‘two inch self-centering vise’), and the rotary table sold by Micro Mark at a much higher price, I went with the 4 inch rotary table and tilting table made by Sherline. The rotary table is a high quality tool and the tilting table is ok, but nothing fancy. However, the combination of the two gives me a lot of possible machining options.

I need to use metric bolts and T-nuts to hold the tilting table to my mill bed. But since the holes in the tilting base are US standard and don’t align with the mill table slots, I had to drill new holes in the tilting table base so it would. The four new holes are clearance holes for 6 mm cap screws and are spaced 1.78 inches apart.

The rotary table is designed to clamp to the tilting table, so now I can use it without having to make new adapters to mount it to my mill table. So, far so good.

How about chucks for the rotary table. You can buy them from Sherline, but I also have a mini lathe that has a three and a four jaw chuck. Again they are metric and that is where the rub lies. I don’t use the four jaw chuck very often and decided to make an adapter plate that would allow me to bolt the chuck to the rotary table. I used a ¼ inch thick aluminum plate and drilled the holes as shown in the drawing below.

The reason for the slots is that the hole-pattern in the Sherline table is all screwy and not spaced uniformly across the base plate. The two threaded holes used for the brackets to the rotary table could have been moved to 1.29 inches from center (the same as those to the right) instead of the 1.16 inch as it appears now.

·Mount the rotary table and tilting table along with one of the two chucks (three or four jaws). This is where the adapter plate comes into the picture.

·To machine horizontal slots in shafts, spars or other parts I can take the tilting table (with chuck mounted) and tilt it to 90 degrees. Sherline makes a tailstock for their mill to do just that (it mounts on their mill bed, not mine). I like to keep my 4 inch vise where it is and I think I can make an adapter to serve as the ‘tailstock’ using wood. Besides, how often would I need that?

To read the table position, the operator turns a micrometer knob to center one of the circle graduations in an aperture that appears to be 3 times or so the width of the circle line. Once the graduation is centered in the aperture, the circle degree value is read, and then the subsidiary value -- usually expressed in arcminutes and arcsecond is read from a micrometer-knob display.

I"ve used rotary tables having this type of display made by Leitz and by Heidenhain, on rotary tables made by Eimeldingen, Troyke, and an Italian-made table that had only an importer"s name. If I"m remembering right, the Leitz system position-measurement uncertainty was +/- 2 arcsecond, the Heidenhain uncertainty +/- 3 arcsecond if properly installed.

Both glass- circle and Inductosyn scale systems require that their circle graduations be very well centered on the rotary axis. This need for precise centering has been their marketplace downfall, as their correct alignment at installation is a painstaking and time consuming process.

In contrast, the "optical encoder" systems are easier and much faster to install. Of course, early optical encoders had their own weakness, readhead lamps. In the mid 1980s, my employer was in the market for a new rotary table that would take a 10,000+ pound workpiece. Having been very satisfied with a 1 meter Eimeldingen rotary table, we inquired of Eimeldingen. Eimeldingen told us that neither the Leitz nor Heidenhain glass-circle systems were still available, and they were reluctant to fit an Inductosyn system. Instead, the recommended using a Heidenhain ROD / RON 700 angle encoder.

We ended up buying a 48 inch Knight rotary table, which had a 50,000 pound capacity and an Inductosyn scale system. (For what it"s worth, the Knight table"s weakness was it Compumotor electricals. After a couple of years we replaced the Compumotor equipment, and lived well.)

Today"s encoders use LED illumination, which has substantially eliminated the lamp-failure concern. If buying a new rotary table today, even I would choose an angle-encoder position sensor.

As for the term "hinge", I made that up. The one I am thinking of is still called a rotary table; there are two parts ... the rotary table, and then the base. The two are connected on one side by the hinges (just two tabs with holes, a rod, and the horizontal hole in the base that the rod goes through). The tab parts fit over the edges of the base and the rod slides through the tab holes and the horizontal hole in the base.

Even with a rotary table that is not hinged, you can mount it vertically and in that position you might call it a dividing head because you can usually buy a tailstock for it, and, for certain ones the dividing plates.

I"ve been a customer of Harbor Freight for several years. On 11/19/20 I decided to take a chance on an expensive purchase. I bought a $10,000.00 ICON tool box suite with side and upper lockers. The manufacturer sent the items to Harbor Freight"s Oxnard store, which they use as a warehouse until a contract company picks it up and delivers it to the customer.

A month later, the Items were finally found their way to me; however, I still haven"t been credited with my returned locker. Also, one of the pieces had minor damage. I was ultimately given a Harbor Freight gift card for the damage, which I thought would take longer to resolve. In the intervening months, I"ve been on the phone for hours trying to get through to someone who can help. Their customer service literally blocks you from getting to the proper person. One fellow went so far to say that he didn"t know who he reported too, usually you just get the run-around and with no other option than leaving an unanswered message. Interestingly, the Camarillo store manger left me to handle the problem myself.

This is the king of experience you might expect from some kind of rip-off mail order business not a large company like Harbor Freight. I"m really disappointed with them and can"t fathom the level of their poor service. The Icon tool box on the other hand is a quality item.

Harbor Freight’s Black Friday ad is thick with sales. But to be perfectly real with you, a lot of those sales are prices you can catch throughout the year. While some of the deals are winners for the holiday season, others aren’t anything to get excited about. The Harbor Freight Black Friday ad is here, and we dove right into to find the best deals for you. Note that these deals don’t start for the public until Friday, Nov. 25, and you have to be a paid member to get the pricing now (Nov. 21 – Nov. 23). If you’re curious, a one-year subscription is $29.99.

Let’s delve into which Harbor Freight Black Friday sales are and aren’t worth it, along with some Early Black Friday deals you can score between now and then.

The Harbor Freight Black Friday ad is here! You can check out the member deals here and start shopping them if you are paid member. We found the best deals and listed them below!

There will be a Harbor Freight Black Friday sale on US General carts again this year. But the deal’s not anything to write home about. Black Friday pricing is:

8613371530291

8613371530291