fanuc rotary table supplier

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Whether your CNC control has AC or DC drives, uses Fanuc, Mitsubishi, Yaskawa, Glentek, Siemens, Baldor, etc. we can build your rotary table with a compatible motor for just about any 4th axis-ready machine on the market! If you need help getting a machine 4th axis ready, we also supply the parts you need; such as amplifiers, drives, cables and connectors. If your application does not require simultaneous 4th axis cutting, we offer an easy-to-program, single-axis control box that can be M-function interfaced to your CNC machine. The control box can either be programmed directly or fed data via RS-232 for fast, accurate indexing to any angle.

Need to get a down FANUC-controlled CNC machine up and running fast? Looking for control or integration advice on a CNC machine purchase or upgrade you are thinking about? Our engineers are here to help.

With 400 combined years of experience with FANUC controls and expertise in control, electrical and mechanical aspects of CNC integration, we can help you quickly find answers to your questions.

Our engineers have built an extensive library of FANUC manuals and other documentation to help you. Our collection of Case Studies & Tech Resources includes videos and other content to answer the most common questions we hear. And live support is just a few clicks away.

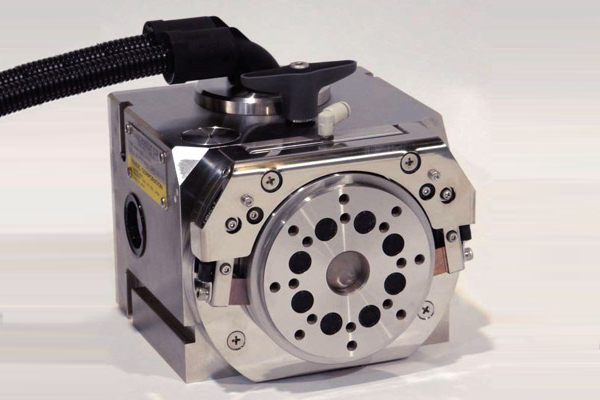

The innovative rotary table incorporates a fully-closed feedback loop system using Fanuc servo motor and rotary encoder, making it the ideal addition to Fanuc EDM machines. As the CCR table is designed and manufactured by Fanuc, solely for the RoboCut EDM machines, it costs up to 50% less than a table from a third-party supplier and it has considerably more functionality built in.

The CCR table is equipped with a sensor that triggers a servo motor and an encoder alarm that sounds if a seal ruptures and water gets into the compartment where both are located. As a safety measure, this shuts down the machine and drains the water tank. This built-in technology minimises the potential for expensive water-related repairs to the motor and encoder.The robust 16kg CCR has a compact area of 155 by 170 by 130mm (LXWXH) that enables the operator to retain the spacious work envelope of the machine. The precision of the CCR is demonstrated by an indexing accuracy of 12 seconds and a repetition accuracy of +/-2 seconds. Despite its lightweight and highly accurate frame, the CCR permits a maximum workpeice weight of 40kg.

For some time, EDM customers have been adding rotary tables to their machines to accommodate the range of motion required to conduct work in high-tech markets such as the aerospace and medical sectors. This new CCR rotary table will now provide customers with this range of movement whilst adding speed, precision rigidity to the EDM process.

Rotary tables also have an economic impact on the manufacture of cutting tools, especially when paired with the relatively high production speeds of some Fanuc EDM machines. An example of this is the production of rotary PCD (polycrystalline diamond) tipped tool bodies where the CCR will deliver astounding benefits.

Table Model • Several options available for motor mounting position, including right side, left side, back and top • Highest weight load capacity in its class Table Model • Compact design • Suitable for a wide range of applications from small machines with simple indexing to full CNC integration for production application • Excellent full 5 axis contouring capabilities • Compact design Table Model • Suitable for a wide range of applications from small machines with simple indexing to full CNC integration for production application Table Model NIKKEN KOSAKUSHO EUROPE LTD - PRECISION HOUSE -...

The Perfect Solution for Your Manufacturing Needs Nikken’s Rotary Tables are known worldwide for their longivity, rigidity and quality. Our range of rotary tables are designed and built to provide extreme accuracy and to increase your work productivity. Fanuc Robodrill is an intelligent high-speed CNC drill with versatility which offers application solutions to meet a wide variety of machining needs. Nikken’s Rotary Tables seamlessly become part of the machine to create the perfect solution for each and every manufacturing requirement. The result is simple: maximum productivity and...

Designed to enhance the productivity of your FANUC ROBODRILL across an enormous range of applications, FANUC’s range of options give you the freedom to tailor your machining processes to your needs precisely. Like all FANUC products, FANUC accessories exhibit world-beating reliability, are simple to use and have been designed to help you get the most out of your ROBODRILL. Using them will allow you to increase output and maintain exacting quality standards regardless of how challenging your machining processes might be.

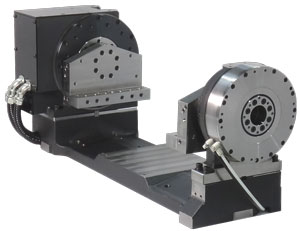

Thanks to its direct drive motor and improved rigidity for more accurate machining, the FANUC ROBODRILL DDR makes the perfect additional axis for your ROBODRILL. It"s direct drive and non-backlash structure enabling high speed and high precision machining. Benefits include an extremely fast indexing and clamping speeds. Extremely precise and reliable, the DDR offers the best value for your money.

Depending on the application, we can equip your ROBODRILL with an extremely rigid DDR-T trunnion system that features all the benefits of the DDR rotary table and includes a support spindle and L-brackets. Its improved rigidity ensures even higher degrees of machining accuracy. All you need to do is add the fixture plate. The DDR-T"s practical design ensures that the existing X-axis travel remains the same as on the 3-axis design.

FANUC ROBODRILL offers a wide variety of spindle options in order to meet the optimum performance standards to a customer"s requirements and application.

FANUC’s all new ROBODRILL DiB Plus is a vertical machining center available in standard as well as advanced small, medium and large models. The ROBODRILL Plus offers the versatility to handle a wide range of machining applications for large or small manufacturers. It’s ideal for high-volume manufacturing production environments – from automotive to medical to jewelry. It’s also a great solution for low-volume work such as mold and tool making.

The FANUC ROBODRILL Plus combines ultimate flexibility along with the accuracy and robust construction to provide the highest reliability in vertical machining.

In addition, the ROBODRILL PLUS offers the speed, precision, and ease of use to help you maximize productivity. Plus…if you’re looking to automate, it’s never been easier to quickly integrate a FANUC robot.

Fitted with a standard bed, the machines are the ultimate all-rounders, helping increase productivity for a wide range of milling and drilling tasks requiring maximum precision, versatility and reliability. Multipart clamping makes them highly adaptable.

Now, FANUC CNCs have the ability to control connected FANUC robots providing machine tending or other assistance through FANUC’s Quick and Simple Startup of Robotization (QSSR).

Spreading your machining across several ROBODRILLs instead of relying on a dedicated transfer machine allows you to benefit from cheaper production and higher flexibility in the face of changing production numbers. Inherently adaptable, FANUC ROBODRILL also represents a great addition to your production facilities since you can use it to absorb extra demand, thereby freeing up your larger vertical machining centers for bigger jobs.

ROBODRILL’s compact design and easy accessibility from all sides make it ideally suited for trouble free machine tending. Adding machine tending robots is easy thanks to our Quick and Simple Startup Packages. All FANUC products speak the same language and share common servo and control platform – something that makes learning and operation extremely easy.

FANUC’s new flexible solutions for light component manufacturing is the perfect system for all of your repetitive manufacturing needs. It is able to make nearly any part with high-speed and accuracy!

FANUC America partners with Methods Machine Tools, the industry leader in machine tool distribution, for ROBODRILL sales and integration. Methods Machine Tools pairs FANUC ROBODRILL with strategic engineering and automation to deliver solutions for precision manufacturers. Choose FANUC ROBODRILL for your next machining project to leverage our powerful partnership with Methods Machine Tools.

With FANUC’s world-renowned reliability, the next generation ROBODRILL Plus features easy preventative maintenance procedures to keep downtime to an absolute minimum for an unbeatable return on investment.

8613371530291

8613371530291