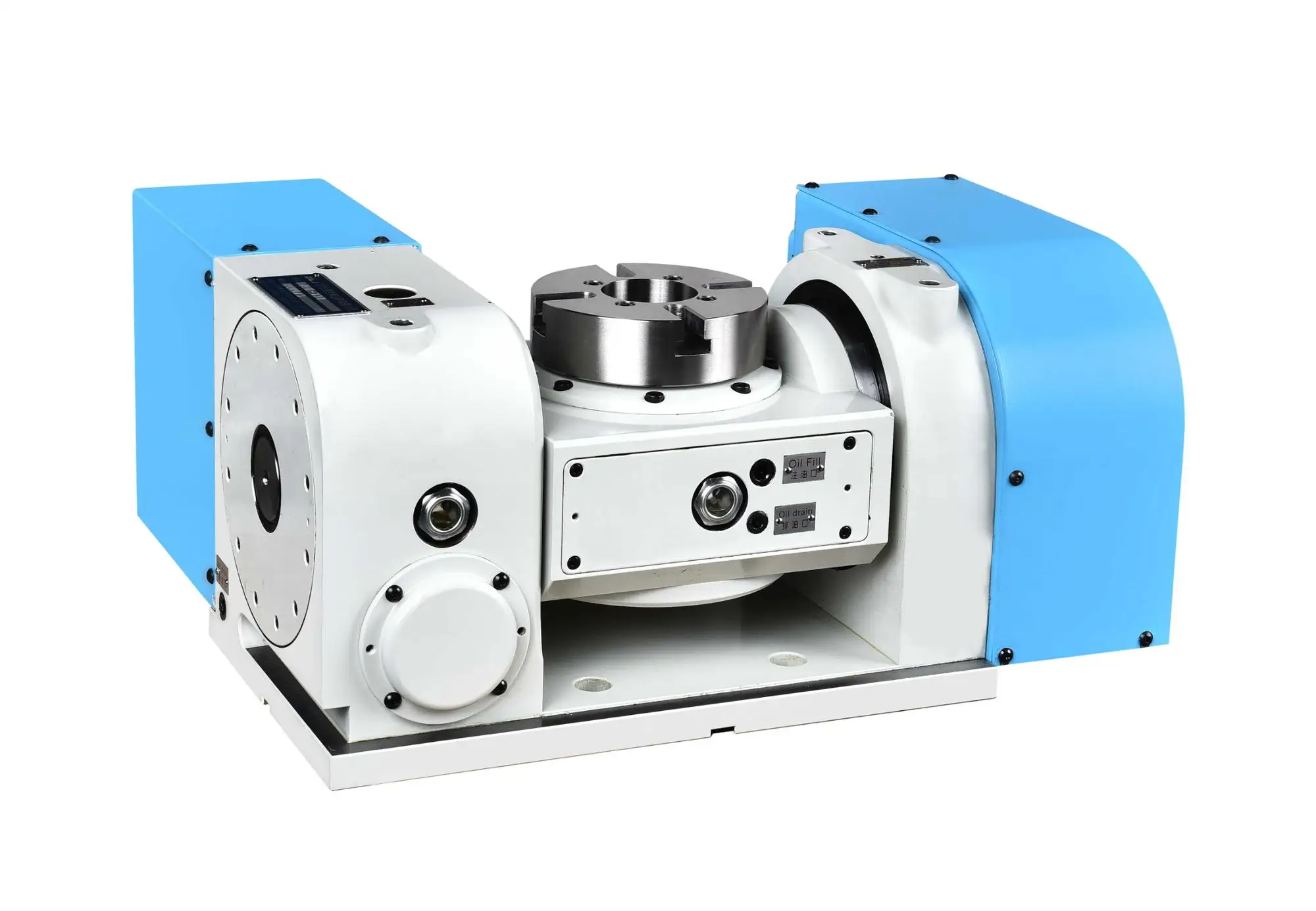

fanuc rotary table made in china

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Japan: Fanuc, Nikken, Tsudakoma, Kitagawa and Sankyo are major brands. They are mainly configured on machine tools of some Japanese brands. Some factories will also be equipped with them when machining precision parts. Fanuc has the largest market share with, because robodrill is most widely used in 3C industry in china, so many factories are equipped with its DDR

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

Designed to enhance the productivity of your FANUC ROBODRILL across an enormous range of applications, FANUC’s range of options give you the freedom to tailor your machining processes to your needs precisely. Like all FANUC products, FANUC accessories exhibit world-beating reliability, are simple to use and have been designed to help you get the most out of your ROBODRILL. Using them will allow you to increase output and maintain exacting quality standards regardless of how challenging your machining processes might be.

Thanks to its direct drive motor and improved rigidity for more accurate machining, the FANUC ROBODRILL DDR makes the perfect additional axis for your ROBODRILL. It"s direct drive and non-backlash structure enabling high speed and high precision machining. Benefits include an extremely fast indexing and clamping speeds. Extremely precise and reliable, the DDR offers the best value for your money.

Depending on the application, we can equip your ROBODRILL with an extremely rigid DDR-T trunnion system that features all the benefits of the DDR rotary table and includes a support spindle and L-brackets. Its improved rigidity ensures even higher degrees of machining accuracy. All you need to do is add the fixture plate. The DDR-T"s practical design ensures that the existing X-axis travel remains the same as on the 3-axis design.

FANUC ROBODRILL offers a wide variety of spindle options in order to meet the optimum performance standards to a customer"s requirements and application.

FANUC has a tremendous reputation for building reliable controls, motors and drives in the machine tool industry. Most people do not realize FANUC also builds machine tools to bring out their new technology. When the new FANUC 31i CNC controller was brought out, it was first brought out on their ROBOCUT and ROBODRILL.

In the EDM world, there has been a void of submersible rotary tables with a compact footprint. FANUC saw this void and developed their own submersible rotary tables for their EDMs. By developing a product for your own use, details can be given to needs instead of designing a one size fits all approach.

Submersible rotary tables are not new, but traditionally the design has been to build a table out of stainless steel that meets the demands of the majority. Before FANUC"s CCR was unveiled, the choices were limited as well as bulky and expensive.

FANUC C-iA wire EDMs use the powerful 31i-WB control, capable of fully integrating single and two axis rotary tables. The CCR tables are lightweight, compact and high precision using a full enclosed feedback loop system with a FANUC servo motor and rotary encoder. Fully submergible with water leakage detect function

NIKKEN WORLD WIDE SALES BRANCH LOCATIONS KOREA NIKKEN (KOREA) ★ : Sales office with Service Engineer PROCOMO-NIKKEN (FRANCE) : Sales office : Service office NIKKEN SCANDINAVIA (SWEDEN) HEAD OFFICE & FACTORY There are overseas Sales Branch office in 14 countries. Each sales branch office has stocks for toolings and CNC Rotary Tables, and service engineers look after the maintenance and service operation of our products. In the other region, e.g. East-South Asia, Oceania, South America, Africa, etc., there are some distributors. At the production line abroad, as there are many requirements for special tools and CNC Rotary Table to suit the special specifications, please ask us or distributors for spare tools and maintenance parts in advance. NIKKEN CHINA (CHINA) NIKKEN DEUTSCHLAND (F.R.GERMANY) NIKKEN KOSAKUSHO WORKS, LTD. OSAKA, JAPAN. 5-1, 1-chome, Minamishinden, Daito-shi, Osaka-fu, Japan. Telephone:072-869-5820 Telefax:072-869-6220 U.S.A GERMANY ITALY SWITZERLAND SCANDINAVIA SWEDEN SPAIN & PORTUGAL LYNDEX-NIKKEN 1468 Armour Boulevard, Mundelein, ILLINOIS 60060 Tel.+1-847-367-4800 Fax.+1-847-367-4815 HERRAMIENTAS LYNDEX-NIKKEN S.A.de C.V. Av. Hercules #401-13, Fracc. Poligono 3 Santa Rosa Jauregui, Queretaro 76220 Tel.+52-55-8421-8421 PROCOMO-NIKKEN S.A.S 6, avenue du 1er Mai-Z.A.E.Les Glaises 91127 Palaiseau Cedex Tel.+33-(0)-1-69.19.17.35 Fax.+33-(0)-1-69.30.64.68 NIKKEN KOSAKUSHO EUROPE LTD. Precision House, Barbot Hall Industrial Estate, Rotherham, South Yorkshire, S61 4RL Tel.+44-(0)-1709-366306 Fax.+44-(0)-1709-376683 NIKKEN DEUTSCHLAND GmbH Eisenstraße 9c, 65428 Rüsselsheim Tel.+49-(0)-6142-550600 Fax.+49-(0)-6142-5506060 VEGA INTERNATIONAL TOOLS S.P.A Via Asti N 9 10026-Santena(TORINO) ・ Tel.+39-011-9497911 Fax.+39-011-9456380 NIKKEN SWITZERLAND AG Sumpfstrasse 32-CH-6300-Zug Tel.+41-(0)-41-748-5000 Fax.+41-(0)-41-748-5001 NIKKEN SCANDINAVIA AB Bultgatan 13b, 44240 Kungalv Tel.+46-(0)-303-440-600 Fax.+46-(0)-303-58177 CUTTING TOOL S.L(TOOLING) PORTUETXE 16, BARRIO IGARRA E-20018 DONOSTIA-SAN SEBASTIAN Tel.+34-(0)-902-820090 Fax.+34-(0)-902-820099 UTILLAJES OLASA,S.L.(CNC ROTARY TABLE) Tel.+34-(0)-669-603433 NIKKEN KESICI TAKIMLAR SAN. VE ULUSLARARASI TIC. A. S E5 Uzeri Kucukyali Yanyol Irmak Sok. Kucukyali Sanayi Sitesi A Blok No:5 Maltepe 34852 Istanbul Tel.+90-(0)-216-518-1010 Fax.+90-(0)-216-366-1414 KOREA NIKKEN LTD. 90B-11L, Namdong Industrial Complex, 170, Namdong-Daero, Namdong-Gu, Incheon, Korea 405-819 Tel.+82-(0)-32-763-4461 Fax.+82-(0)-32-763-4464 SHANGHAI ZHONG YAN TRADING CO., LTD. BUILDING 1/F, #54, No.1089 QINZHOU RD. (N) , SHANGHAI, CHINA Tel.+86-(0)-216210-2506 Fax.+86-(0)-216210-2083 NIKKEN KOSAKUSHO ASIA PTE, LTD. 186, WOODLANDS INDUSTRIAL PARK E5 #04-01 M SINGAPORE 757515 Tel.+65-6362-7980 Fax.+65-6362-7980 SIAM NIKKEN Co., LTD. 127 Moo5 Gauwungsai-Bangturie Road Tambon Tanokkard Ampher Muangnakhonpathom Nakhonpathom 73000 Thailand Tel.+66(02)178-0503 Fax.+66(02)178-0504 http://www.nikken-kosakusho.co.jp/en e-mail : export@nikken-kosakusho.co.jp/en Please contact to the following agent. NIKKEN KOSAKUSHO WORKS, LTD. D.LK.0.5 Specifi

The rotary table is an accessory for the CNC floor type boring and milling machine. It can be working together with the floor type boring milling machine for milling angle, reverse boring, polyhedral machining, and other complex machining processes. It could do five sides machining if the main machine equipped the angle milling head.

CNC rotary table is a common part of CNC milling machine, often used as a servo axis of CNC milling machine, namely C axis of vertical CNC milling machine and B axis of horizontal CNC milling machine. The CNC rotary table includes the foot of the turntable, a round turntable surface, four rolling bearing parts arranged on the upper surface of the foot of the turntable, and a center with a self-aligning bearing installed at the center of the upper surface of the foot of the turntable. Support, each rolling bearing component includes a rolling bearing and a support that supports the rolling bearing through the axle. The center of the lower surface of the turntable is provided with a vertical downward axle. The turntable is installed on the foot of the turntable. The inner ring of the self-aligning bearing is fixed, and the rotating surface of the rolling bearing is in rolling contact with the lower surface of the turntable surface.

The CNC rotary table has an inclinometer with two orthogonal test axes as the test tool. The inclinometer is set at the center of the turntable surface to be leveled, so that the two orthogonal test axes of the inclinometer are parallel to the turntable surface, by adjusting the milling machine turntable. The leveling mechanism under the base makes the tilt angle value output by the two test shafts of the inclinometer turntable in the leveling state.

CNC rotary table and swing head are the key components of multi-coordinate CNC machine tools. Traditional rotary tables and swing heads using high-precision worm gears and other transmissions are not only difficult to manufacture, costly, but also difficult to achieve the speed and accuracy required for high-speed machining. Therefore, it is necessary to develop a new electromagnetic drive system for the CNC milling machine turntable and swing head in a different way to realize the zero-drive drive of the rotational motion coordinates of the CNC machine tool.

1. The CNC turntable uses modular design technology. The PAN turntable and TILT turntable are independent components, which are easy to disassemble and can be controlled by linkage or individually.

8613371530291

8613371530291