servo rotary table factory

TMX160 Heavy Duty Rotary Table with increased rigidity for demanding applications. The internal air hydraulic booster gives extremely high clamping forces.

... rotating units of the DT series comprise of stainless steel and aluminium. They are available in many different designs. The rotary tables DT 80/100 or DT 100/140 are designed for motor-powered operation. ...

JVL introduces a highly effective, modern turntable that can be fully integrated in modern automation systems. TurnMaster Turntable is supplied with integrated electronic control and modern servo ...

Compact package and Superior design of the AccuRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

Compact package and Superior design of the AccuRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

These rotary tables provide superior angular positioning and are designed to eliminate backlash, friction and wear problems associated with worm, gear and belt drives. Low maintenance ...

The HRT-160 rotational table from the portfolio of the modular rotary table system is designed as a complete unit ready for connection. The rotational ...

... series compact gear drive servo-mechanical positioners deliver high torque for demanding payload applications with large inertia moments. The GTB units are orientation independent for flexible mounting ...

The Rotating rotary table DSH-S Series is manufactured by Isel Germany. The product has a compact and durable design; it is made of stainless steel that has protection class of IP 65. ...

... Tuenkers, and is a versatile rotary table that is equipped with a trunnion drive. The drive module has been specifically developed for the realization of versatile motion applications ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

... a heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary ...

... a heavy duty 310 mm servo rotary table designed for a myriad of machining applications. The HRT310 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive ...

This is a Servo driven rotary indexing table manufactured by Italplant which has been a study for automation of the whole unit. It comes with a wide ...

... the Hollow Rotary Actuator model number GSN130-18K-CS with table size 130mm gear ratio 1:18 and closed loop stepper motor. The CS type of GIGAGER Hollow Rotary Actuator is a line of ...

GOIZPER INDEXERS offers solutions to suit your applications. Servo rotary tables (or rotary indexing tables), flexible tables for welding cells, hemming, assembly and control. Ourrotary tables for automation systems can be used as rotating or positioning shafts or for a wide range of assembly applications. With a very high output rate and the shortest possible cycle times in addition to the highest standards of accuracy, they can increase the efficiency of your production processes for any application.

Our ZPGI range of servo rotary indexing tablewith heavy load positioning are ideal for dynamic, precise positioning of parts and large heavy equipment. Several versions of our cam operated servo driven rotary indexing table are available.

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

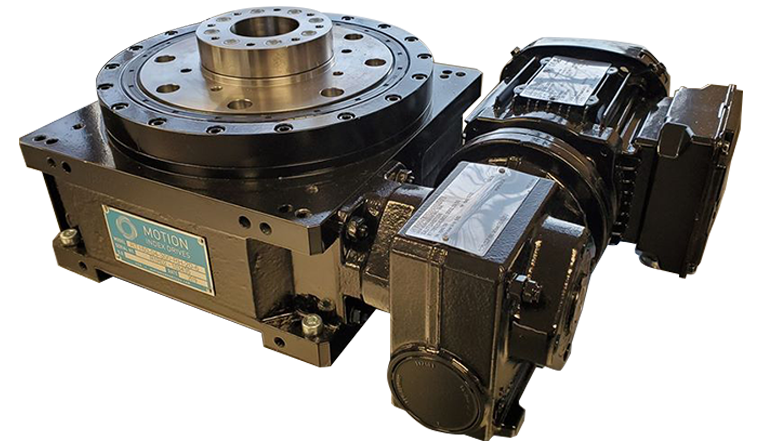

The Motion Index Drives RTX Series Servo Rotary Index Tables encompass a large range of sizes, ranging from our model RTX100 up to our RTX1250. In addition, special cam-driven devices can be custom made to order for your automation needs. Our servo rotary indexer is offered with a servo motor or standard AC brake motor with absolute hiperface or incremental encoder. The RTX Series Flexible Rotary Index Table is one of world’s most accurate barrel cam indexers. Motion Index Drives servo rotary indexer are constructed with strength and reliability in mind. Robust design and components ensure this device will maintain precision in intense factory settings.

M-036 high performance series of closed-loop servo motor driven precision rotation tables provide the highest resolution, excellent repeatability and minimum wobble. The stages are equipped with double rotational ball bearings for minimum backlash and high load capacity. Both the rotation platform and the scale ring (graduated in 2-degree increments) can be independently coarse positioned over 360 degrees and then be locked by screws.

The basic version, M-036.D0, is equipped with a DC servo motor drive providing a rotational range of ±10.5 degrees. A set of limit switches eliminates the possibility of overtravel.

M-035 series high precision rotary tables rotation stages feature high resolution, excellent repeatability and minimum wobble. These high performance rotational positioning stages are equipped with double ball bearings for minimum backlash and high load capacity. Both the rotation stage platform and the scale ring (graduated in 2-degree increments) can be independently coarse positioned over 360 degrees and then be locked by screws.

The basic rotary table version, M-035.D0, is equipped with a DC servo motor drive providing a positioning range of ± 6.3 degrees. A set of limit switches eliminates the possibility of overtravel. For the highest precision and highest performance, high speed air bearing rotary tables are recommended.

IntelLiDrives manufactures a large selection of rotary tables including direct-drive tables that use brushless torque rotary servo motors, as well as precision motorized worm-gear and belt-driven rotary actuators. These rotary stages are available with many different size apertures, table diameters, and mounting options to provide the ideal solution for your industrial automation application. IntelLiDrives rotary tables are used in industrial robots, fiberoptics and photonics, vision systems, machine tools, assembly, semiconductor equipment, medical component laser machining, electronic manufacturing, and other high-performance industrial automation applications.

Direct drive (DDR) rotary tables eliminate backlash and provide a stiff mechanical system for highly dynamic applications. Integrated with precision bearings and ring encoders, these rotary tables provide ultimate performance in rotary indexing applications

Motorized rotary tables incorporate an aluminum housing with bearing and precision ground worm or pinion gear drive. Multiple choices of gear reduction are available. Features no backdrive with minimum backlash.Supplied with stepper motors or brushless servo motor/encoder combination

High speed, large aperture and low profile motorized belt driven rotating actuators. Cost effective alternative to direct drive rotary servo tables. Supplied with NEMA23 stepper or brushless servo motors with encoders

Rotary tables incorporate ABSOLUTE RING ENCODERS with industry standard SSI, BISS-C and Fanuc interfaces. Absolute positioning information is maintained during power-down. No homing required upon power-up

Low profile rotation stages 22 to 42 mm. Light-weight and compact, these rotary actuators are best suited for integration with XY tables to minimize system stack-up height and errors

Direct drive air bearing rotation stages with axial and radial air bearings. Frictionless and maintenance-free rotary tables best suitable for cleanroom environments

Rotary tables with protection against ingress of water and particles. IP65,IP66and IP67 rated. Direct drive rotary servo tables and motorized actuators

Low profile and small footprint (40 mm to 115 mm) rotary stages. Designed for the confines of laboratory and production environment. Available in vaccum compatible versions

Servo rotary table HRTJ200 also called as freely programmable indexers, heavy duty hollow rotary table which has large central opening reach to 90mm, it is quite convenient for engineers to wiring and piping in automation rotary motion and provide more options for engineers.

Sango HRTJ200 servo rotary table is making better performance than HRT200, more output torque but keep same positioning accuracy, bigger designed loading than HRT200.

Sango Automation provide multiple options of servo rotary table, from small size HRT62, to big size HRT280. HRTJ series includes 130, 200 and 280 version, which are reinforced model on the same dimension.

Hollow Rotary Table is also called Hollow Rotary Actuator, Programmable Servo Rotary Table and Hollow Shaft Rotary Indexer, which can be equipped with any brand of stepper motor or servo motor in the market with support of Sango flange warehouse. With the most featured central hollow structure and its precision positioning control, Hollow Rotary Table becomes one of the popular rotary components in Automation Industry.

As a professional Hollow Rotary Actuator manufacturer in China, Sango Automation provides full range of Precision Rotary Table product which covers from frame size 60, 85, 130, 200 to 280, as well as reinforced, heavy-duty version to maximum meet the requirement for different industrial application.

These hollow rotary tables can meet the requirement on arc seconds level of positioning precision accuracy for automatic rotation motion for the well-known system integrators and reputable factories from China and worldwide.

BacklashNo backlash (adjustable structure)No backlash (adjustable structure)No backlash (adjustable structure)No backlash (adjustable structure)No backlash (adjustable structure)

Matched Motor200-400W Servo, 57/86 Stepper Motor, NEMA 23 NEMA 34 Stepper750-1000W Servo, 86/110 Stepper Motor, NEMA 34, NEMA 42 Stepper1000-2000W Servo, 110 Stepper Motor, NEMA 42 Stepper750-1000W Servo, 86/110 Stepper Motor, NEMA 34, NEMA 42 Stepper1000-3000W Servo, 110/130 Stepper Motor, NEMA 42 Stepper

57 Stepper Motor, NEMA 23 Stepper750W Servo, 86 Stepper Motor, NEMA 34 Stepper750-1500W Servo, 86/110 Stepper Motor, NEMA 34, NEMA 42 Stepper1000-3000W Servo, 110/130 Stepper Motor, NEMA 42 Stepper750-1500W Servo

As one type of industry precision reducers, the most advantage of hollow rotary platform is the large aperture hollow structure which allows easy wiring and piping when the rotary motion executed.

Sango Automation provides multiple options of rotary tables, from ouput surface size 62, 85, 130, 200 to 280, as well as reinforced, heavy duty version to maximum meet the requirement for different industrial application. On motor connection direction, we provide side connection and right angle type connection method, which gives more flexibility and space for automation engineers and designers.

Sankyo Automation is the worldwide leader in cam indexer technology; continuously working to develop new, innovative technologies in motion control. Our collection of high-speed, high-precision rotary indexing solutions are frequently utilized in manufacturing systems that require accurate, high speed actions.

Rotary indexing table use is widespread in automated assembly machinery and selecting the proper mechanism is essential for both maximizing performance and minimizing the cost of this critical component. This how-to-guide will explore two common devices that can be used for rotary indexing and give advice for proper selection. These two popular devices are cam indexing drives and servo rotary tables.

Cam indexers are a ubiquitous mechanism that have been used for rotary tables for many decades. They are a great fit for applications that will always index the same angle and that require high-precision positioning at a very reasonable cost. A cam indexer uses a mechanical cam to provide the motion control to position the load. A mathematical motion curve is machined onto the cam that provides extremely smooth and repeatable motion.

A cam indexer has two main modes of operation. One mode is referred to as “Cycle-on-Demand”. This indicates that the camshaft will be cycled one revolution at a time to advance the output one position at a time. This is typically achieved by using an inexpensive camshaft sensor package to detect camshaft position and a VFD to stop and start the motor. The camshaft dwell period offers a wide window for the camshaft to stop without affecting the position of the output. To cycle the indexer, a PLC gives a command to the VFD to accelerate the drive motor to a preset speed, the cam rotates one revolution indexing the output, a sensor sends an in-position signal to the PLC, and the PLC signals the VFD to stop the camshaft during the cam dwell position. The table will be in the dwell position for however long is necessary to complete the work at each station. The dwell time can range from a fraction of a second to several minutes or hours depending on the application. This combination allows very accurate positioning with an inexpensive drive system.

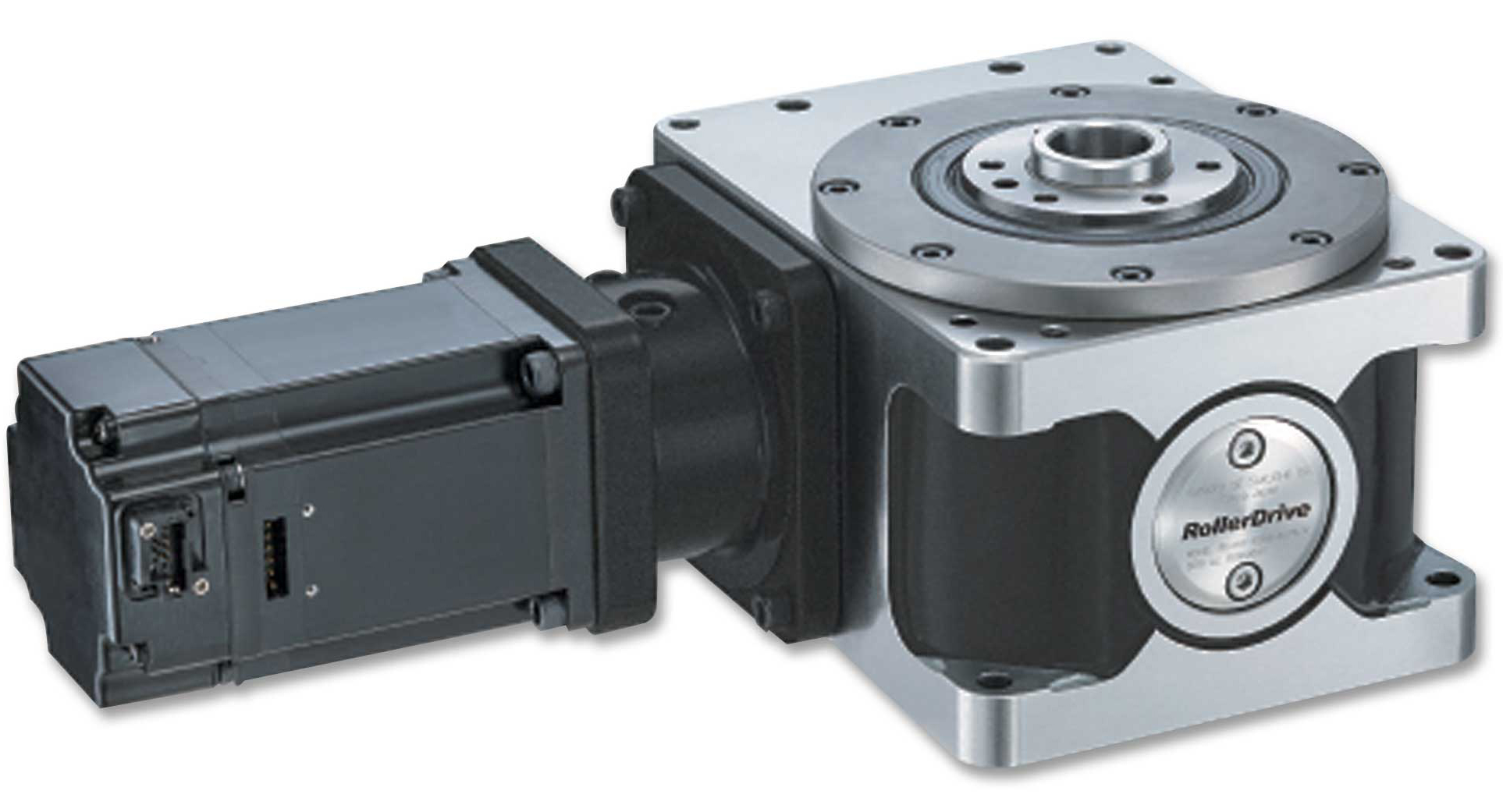

A fully programmable servo rotary table is another common option. There are two specific cases where a servo rotary table is advantageous. The first is when a flexible motion pattern is required. An example is two different products being run on one machine that each require different indexing patterns. The other situation that suits a servo indexer is when extremely fast positioning is required followed by a long dwell period. A cycle-on-demand cam indexer is limited by the need to accelerate the camshaft up to speed during the dwell period before output motion is started. There are practical limitations to how fast the camshaft can be accelerated so there will be a delay before motion is started. With a servo rotary table, the output rotates as soon as the servomotor starts moving. A practical example would be a load being indexed 90 degrees in 0.25 seconds. This is not difficult for a continuous cam indexer or a zero-backlash servo indexer, but a cycle-on-demand cam indexer may struggle with that motion. For quick servo indexing applications, a preloaded gear reducer with zero-backlash is critical to achieving smooth indexing motions with minimal settling time. A zero-backlash RollerDrive mechanism would be an optimal choice to achieve accurate positioning with great dynamic response.

For either style of indexer, application information including moment of inertia, indexing angle, indexing time, and dwell time is required. A reputable manufacture should then be able to properly size the rotary table for the application.

Designed specially for servo motor gearbox for motion control applications. It takes full advantage of the flexibility of the servo motor, giving designers greater freedom of mechanism design.

They are characterized by a whole new machine concept and design approach, allowing flexible use. All components are freely programmable and represent sound solutions for re-engineering. It could be added planetary gearbox to increase the gear ratio, available for matching with any brand servo motor and stepper motor based on our flexible flange system, thus make it easy for automation production line building and robot designing.

IP rated rotary tables provide more possibilities for humidity and dusty environment in actual working conditions, like CNC drilling work, CNC grinding work, laser marking and laser cutting work, etc.

High precision and excellent IP rated performance makes the high precision and accuracy work possible, such as diamond cutting rotary task, phone production and inspection rotary task, etc.

A CNC (Computer Numerical Control) rotary table is an automation tool used in a milling machine to perform complex machining operations. It consists of a circular disc, mounted on an axis so it can rotate around its circumference and provide multi-axis machining capabilities.

The rotary table enables users to produce workpieces with cylindrical surfaces, multiple faces, and holes located off-centerlines on any angle through indexing. This makes it possible to perform intricate machining operations such as face grooving, drilling and boring that would otherwise be impossible or require extensive setup time with the standard x-y axis milling machines.

Moreover, using CNC in combination with the rotary table provides even greater flexibility since commands are automatically sent from the computer software directly to the machine for precise movement without operator intervention or supervision during operation. In other words, this allows operators to program sequences of motions not normally done by hand which increases speed and accuracy significantly; thus increasing production efficiency overall.

CNC rotary tables are commonly used in industries like aerospace manufacturing where parts often require precision cutting for aerospace components that need fast completion times along with accuracy within tight tolerances. The versatile nature of this system also makes them suitable for use in all types of industries including automotive engineering where they are frequently used in creating molds or forming dies into specific shapes depending on part requirements while still maintaining a high level quality control. All these qualities make CNC rotary tables a great asset when striving for higher productivity levels while still achieving high quality results every time!

8613371530291

8613371530291