tjr rotary table manufacturer

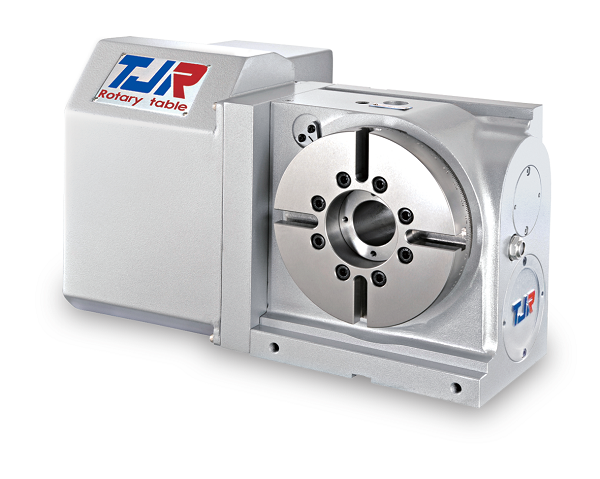

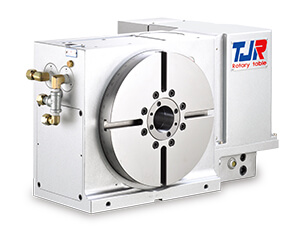

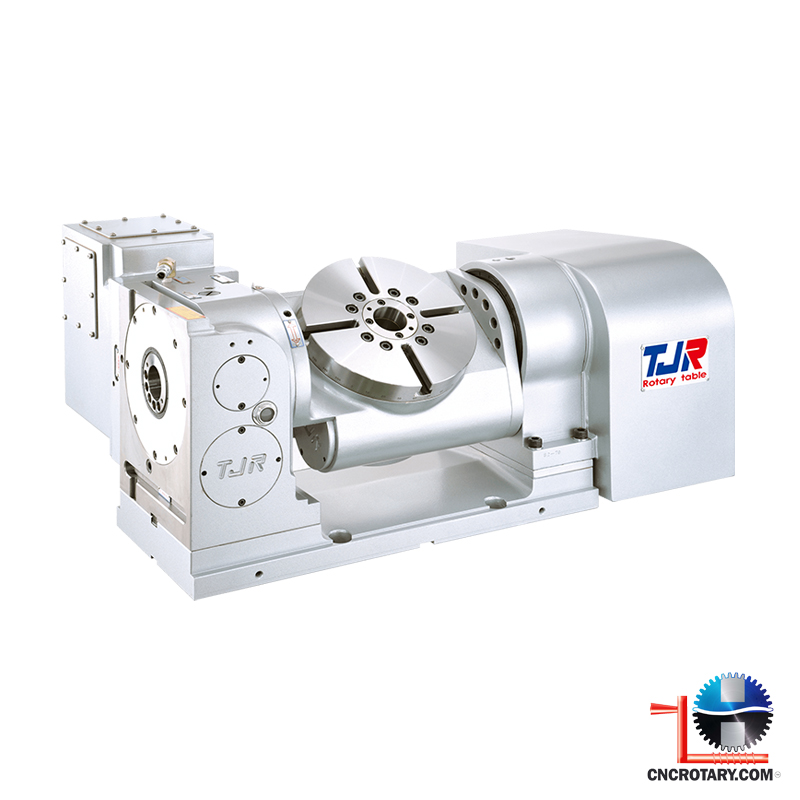

Benefiting from TJR’s proven knowledge and experience, TJR provides diverse transmission mechanisms such as 1. Driven by Worm & Worm Gear, 2. Driven by Roller Gear Cam, 3. Driven by Direct Drive Motor to meet various needs. If you are looking for the 4th axis rotary tables cooperation partner, please feel free to check out 4 axis rotary table here and get in touch with TJR.

TJR takes pride in producing high-quality parts for their rotary tables and indexers. Here are three main parts of a rotary table that demand high accuracy and high quality:

TJR rotary tables feature a dual-lead worm and worm gear made in Japan made from high tensile brass with abrasion resistance of 25.1 mg/cm2 per 10,000m. It has estimated wear life of 10 years, more than twice the wear life of components made from aluminum bronze.

The high performance braking and clamping mechanism is designed with full 360∘circumference hydraulic clamping that is synchronized for the entire table. Having the clamping area on the entire circumference of the table allows for improved rigidity, making it an ideal feature for heavy cutting application. With a higher clamping force than conventional disk braking systems, the mechanism’s proximity to the worktable reduces deviation during cutting.

TJR uses Radial-axial preloading bearings. The axial component of these bearings has an axial cylindrical roller and cage assembly, an outer ring, L-section ring and shaft locating washer and is axially preloaded after fitting. The radial component is a full complement preloaded cylindrical roller set. The outer ring, L-section ring and shaft locating washer have fixing holes. The unit is located by means of retaining screws for transport and safe handling. The Radial-axial preloading bearings offer static rigidity and high durability for heavy cutting both horizontally and vertically.

TJR Precision Technology co., Ltd. is a professional manufacturer of CNC rotary tables (the 4th and 5th axis). The main products are CNC rotary table, CNC index table, Auto Pallet Changer, and other accessories with high precision and stability.

TJR Precision Technology co., Ltd. is a professional manufacturer of CNC rotary tables (the 4th and 5th axis). The main products are CNC rotary table, CNC index table, and other accessories with high precision and stability.

We have the best research and development team that integrates the applications of machine centers and rotary tables, and have thestrictest quality control to ensure the highest quality. We also have the most active customer service to make the rotary table work in the optimal condition.

Established in the year2021, we,“Sv Cnc Technology”, are a prominent name engaged in Manufacturer and Distributor a wide and comprehensive range of CNC Lathe Machines and Table Machine.These machines are fabricated using high grade raw material, procured from reliable vendors of market. The offered range of CNC machines is appreciated for its robust engineering, optimum quality, longer functional life and superior performance. Turning machines offered by us, are ideally applicable in automobiles and industrial installations, owing to their sturdy construction, easier operations and quick results. Boring machines offered by us are developed using modern machinery and sophisticated technology in complete adherence with the highest quality norms. These boring machines are highly admired among the clients, owing to their operational fluency, higher efficiency and easy maintenance. In addition to this, our research and development experts ensure to conduct rigorous surveys and researches, so as to maintain and enhance the quality of machines.

In Booth S-9092, CNC Indexing & Feeding Technologies (Mason, OH) proudly announces their new partnership with TJR (or Tan Jia) Precision Technology Company, Ltd. (TJR; Taichung City, Taiwan), a well-established supplier of rotary tables to machine tool OEMs such as Okuma, Doosan, DMG Mori, Mazak, and Tongtai. “The new partnership allows us to supply the most technically advanced rotary tables in the industry, with special emphasis on direct drive and 5C collet 4th-axis series units,” explained Steve Smith, the president of CNC Indexing & Feeding Technologies.

The company originated as a rotary table sales and service agent prior to establishing TJR as an OEM in 2009. After much success, they grew to having the largest market share of machine tool accessories in China. Today, TJR is a top OEM with offices all around the world. Their rotary tables are built with high quality features, such as an anti-wearing worm gear and shaft made of high tensile brass for durability. Their encircling braking systems use a large clamping range to prevent displacement during heavy-duty cutting. For tilt rotary tables, TJR offers a 2+1 independent braking system and large diameter radial and axial preloaded bearings for rigid support during 4th- and 5th-axis cutting on both single and dual arm rotary tables. A three-year parts warranty is standard for all new TJR rotary tables.

TJR, the reliable precision rotary tables manufacturer in Taiwan, specializes in kinds of rotary tables to meet all machining requirements from customers. To learn more about rotary table suppliers, please feel free to contact TJR.

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

8613371530291

8613371530291