tjr rotary table brands

Benefiting from TJR’s proven knowledge and experience, TJR provides diverse transmission mechanisms such as 1. Driven by Worm & Worm Gear, 2. Driven by Roller Gear Cam, 3. Driven by Direct Drive Motor to meet various needs. If you are looking for the 4th axis rotary tables cooperation partner, please feel free to check out 4 axis rotary table here and get in touch with TJR.

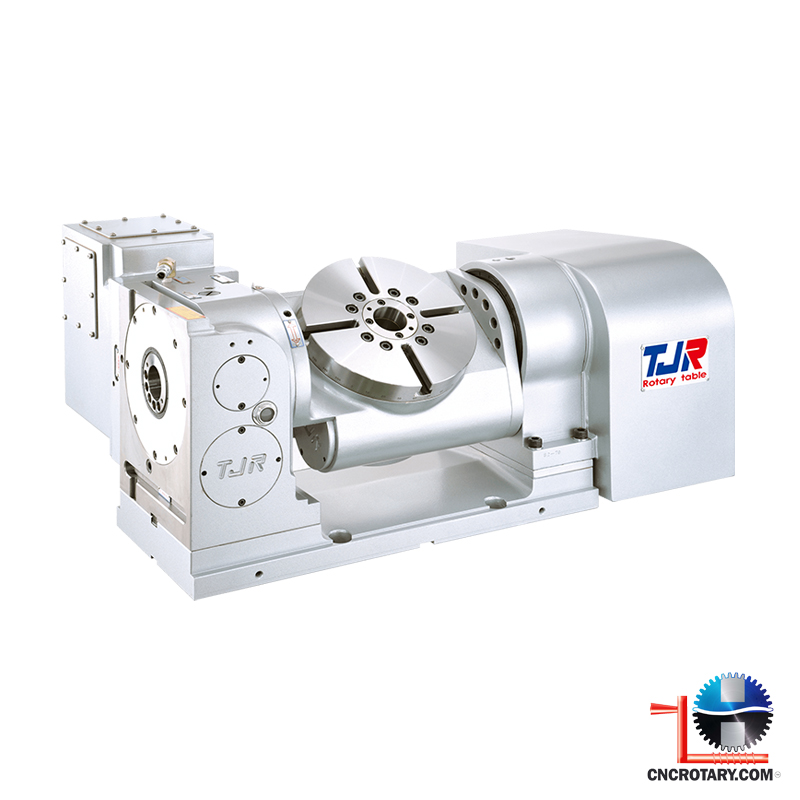

This is an ideal design of product for any VMC machine, particularly those with a good working envelope. The usual collision issues only generally appear with the older DC motorised machines where the motors are much longer than the digital counterpart, such as the Bridgeport VMC with SEM motor on the Heidenhain TNC370 controlled devices. This device is ideal for the smaller VMC machine up to and including around 800 to 1000 in X. Due the carrying capacity, however, if you have a larger VMC and are doing relatively light work you could mount this device on a raiser block and swing larger diameters than its standard design suggests. The TJR model type R can be used in vertical and horizontal applications, the motor is mounted to the right side of the device and therefore can be laid on its back. The TJR model type R is a full contouring 4th axis device. Can be controlled directly from the machine tool control or via a separate programmable box via M signal start.

CNC Indexing & Feeding Technologies is proud to represent the TJR line of rotary tables, indexers and accessories. TJR originated as a rotary table sales and service agent and established itself as an OEM in 2009.

TJR tables feature an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. All new TJR tables come standard with a 3-year parts warranty.

Standard Rotary Tables. The AR Series is TJR’s standard 4th axis pneumatic brake rotary table. It is offered in both a Right hand motor mounting and Left hand motor mounting option. The HR Series is TJR’s standard hydraulic brake 4th axis rotary table.

CNC Indexing & Feeding Technologies offers a wide range of TJR rotary tables. However, many are unclear about what rotary tables can do for their business, as well as how they work in CNC machining. First, let’s consider the basics about a rotary table and how it works in the machining and manufacturing processes.

A rotary table can tilt and rotate. The table makes use of the indexing head in order to cut according to a specific technique. This makes it possible for the machine to create a workpiece with complete flexibility in rotation and angling.

A rotary table can help to create arcs and circles, an important process in part or tool fabrication. Tools can be specially made, such as car parts, machine parts, and many other objects.

The CNC process lets companies make straight cuts even with multiple angles and to cut small objects into even smaller parts. CNC rotary tables can also help in the processes of cutting gears, drilling or cutting holes.

The table can also be used along with a dividing head and index plate, to further concentrate the shaping. Tables are also used to hold certain parts for superior milling techniques.

Adding rotary tables will improve your capacity to produce the parts you want and increase profits. This brings us to the primary advantage of CNC rotary tables: less time and greater accuracy in cutting.

The benefits of using cnc rotary tables include consistency, faster production and increased capacity. Products and work pieces assembled through CNC systems are more reliable than products created manually or through other methods. The process is identical each and every time, so consistency can be guaranteed. This is critical for a company trying to ensure safety protocol.

The capacity of complexity of product is another benefit. Complex motions are made simpler by CNC rotary tables, making them more affordable to produce.

Naturally, such an intricate process cannot be unsupervised, since efficiency depends on optimal performance. A supervisor must oversee a rotary table operating with CNC controls to ensure the machine and software are configured correctly.

We offer a wide variety of rotary tables to meet all of your needs. This includes standard rotary tables with full rotating axis capabilities, and vertical and horizontal mounting positions.

We also offer large rotary tables with hydraulic brake systems, which allow higher clamping torques. You can also find assistance with smaller rear mount rotary tables or tilt rotary tables.

Horizontal rotary tables are specially made for horizontal mounting and carrying a much heavier weight. Horizontal index tables are available, whether in manual or CNC index tables style. Finally, there are face gear rotary tables and rotary table accessories, ideal for projects that need higher degrees of accuracy.

CNC Indexing & Feeding Technologies can help you find the machine tool accessories you need to meet your production demands. This includes simple rotating feature, larger work pieces, vertical and horizontal applications, or even 4 or 5 axis work. With TJR rotary tables, you can improve your cycle and process time, reduce your down time and increase your profits.

When your workpieces require the use of 5C collets, the TJR AR-5C Pneumatic Collet Rotary Table from CNC Indexing & Feeding Technologies is an affordable alternative to 3- or 4-jaw chucks.

Offered in both Right Handed and Left Handed motor mount configurations, this unit employs a pneumatic brake and can be integrated into a CNC machine control either as a full 4th axis or can be operated as an indexer using TJR’s SAC (Single Axis Controller).

TJR’s one-piece dual lead wormshaft design is more accurate than split types used by other rotary table manufacturers. The oversize diameter pitch circle reduces pressure on the contact surface, and the worm gear’s full tooth depth engagement and larger gear module allow for a larger surface contact area and a much stronger worm gear system.

Weighing in at 34 kg (75lb), the AR-5C has a table diameter of 125 mm (4.92″), with a thru-hole diameter of 35 mm (1.37″), minimum indexing increment of 0.001˚, maximum table rotation speed of 83.3 rpm, and peak allowable workpiece load of 100 kg (220 lb.). Servo motor models are available for FANUC or Mitsubishi tapers.

CNC Indexing & Feeding Technologies is the exclusive U.S. importer for TJR Precision Technology rotary tables. We stock the TJR line at our Mason, Ohio, location, with full installation and repair services available. All TJR rotary tables come standard with a 3-year parts warranty.

TJR Precision Technology Co., Ltd. has been manufacturing rotary tables since 2009, providing highly advanced tables for top machine tools brands, including Doosan, Mazak, DMG Mori, Hardinge, YCM, Leadwell, Feeler, Bulova and Tongtai.

CNC Indexing offers a wide range of CNC accessories, including rotary tables, indexers, high pressure coolant systems, bar feeders, bar loaders and oil skimmers. Call 513-770-4200 today to learn more about how we can help you!

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

TJR Precision Technology co., Ltd. is a professional manufacturer of CNC rotary tables (the 4th and 5th axis). The main products are CNC rotary table, CNC index table, Auto Pallet Changer, and other accessories with high precision and stability.

TJR Precision Technology co., Ltd. is a professional manufacturer of CNC rotary tables (the 4th and 5th axis). The main products are CNC rotary table, CNC index table, and other accessories with high precision and stability.

We have the best research and development team that integrates the applications of machine centers and rotary tables, and have thestrictest quality control to ensure the highest quality. We also have the most active customer service to make the rotary table work in the optimal condition.

Our company is a prominent in the industry as a manufactures and supplies Rotary Table. We offer our product in diverse specifications to fulfill the differentread more...

We provide exclusive range of Goizper make Turn tables (CAM based), rotary tables (indexers), Clutch-Brake units, Spares, Couplings, customized Gear boxes. Goizperread more... Brochure

To meet the specific requirements of our clients, we are engaged in offering wide range of CNC Rotary Tables. Our products are available in accurate dimensions and used in various application areas. We offer CNC Rotary Tables to our clients for using in various industries and companies. Moreover, our CNC Rotary Tables areread more...

This CNC Rotary table is used for high accuracy indexing, high productivity. This is with radial axial bearings which provides excellent thrust force. Available in both Horizontal and Vertical application. This can be controlled by single controller. This 4th axis can be operated synchronously with the machine.

We provide optimum quality CNC tilting rotary tables which forms the 4th and 5th axis of the machining centers; however, when interpolated with the machines 3 axis, the face of the flat end mill can machine the curves which one can not think of with 3 axis or even 4 axes machining centers. Another possibility to the machiningread more...

cnc tilting rotary table forms the 4th & 5th axis of a machining center, it can be interpolated with other axis of machine to give a 5 axis machining center. Size available: 150 dia, 200 dia, 250 dia & 320 dia pneumatic / hydraulic clamping,

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available. A rotary fixture used in this fashion is more appropriately called a dividing head (indexing head).

The table shown is a manually operated type. Powered tables under the control of CNC machines are now available, and provide a fourth axis to CNC milling machines. Rotary tables are made with a solid base, which has provision for clamping onto another table or fixture. The actual table is a precision-machined disc to which the work piece is clamped (T slots are generally provided for this purpose). This disc can rotate freely, for indexing, or under the control of a worm (handwheel), with the worm wheel portion being made part of the actual table. High precision tables are driven by backlash compensating duplex worms.

The ratio between worm and table is generally 40:1, 72:1 or 90:1 but may be any ratio that can be easily divided exactly into 360°. This is for ease of use when indexing plates are available. A graduated dial and, often, a vernier scale enable the operator to position the table, and thus the work affixed to it with great accuracy.

Rotary tables are most commonly mounted "flat", with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternate setup is to mount the rotary table on its end (or mount it "flat" on a 90° angle plate), so that it rotates about a horizontal axis. In this configuration a tailstock can also be used, thus holding the workpiece "between centers."

With the table mounted on a secondary table, the workpiece is accurately centered on the rotary table"s axis, which in turn is centered on the cutting tool"s axis. All three axes are thus coaxial. From this point, the secondary table can be offset in either the X or Y direction to set the cutter the desired distance from the workpiece"s center. This allows concentric machining operations on the workpiece. Placing the workpiece eccentrically a set distance from the center permits more complex curves to be cut. As with other setups on a vertical mill, the milling operation can be either drilling a series of concentric, and possibly equidistant holes, or face or end milling either circular or semicircular shapes and contours.

* With the addition of a compound table on top of the rotary table, the user can move the center of rotation to anywhere on the part being cut. This enables an arc to be cut at any place on the part.

Additionally, if converted to stepper motor operation, with a CNC milling machine and a tailstock, a rotary table allows many parts to be made on a mill that otherwise would require a lathe.

8613371530291

8613371530291