3d printed rotary table manufacturer

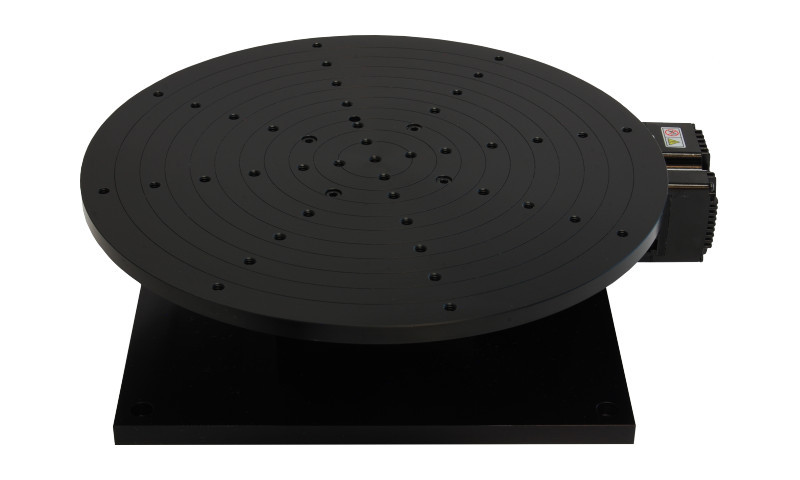

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

Der Dreh-Schwenktisch MAX Machining Table MMT-500-DD von MABI Robotic ist das perfekte Zubehör für Ihre Robotik Applikation im Bereich der Additiven Fertigung. Er ist ab Werk mit leistungsstarken, wassergekühlten Direktantrieben und einem hochauflösenden Encoder ausgestattet. Das garantiert hohe Leistung für eine effiziente Bearbeitung, kombiniert mit hoher Positioniergenauigkeit für eine hohe Bearbeitungsgenauigkeit. Der MMT-500-DD von MABI Robotic wurde speziell für Robotik Anwendungen im AM Bereich entwickelt.

Die massive Bauweise bietet eine extrem hohe Torsionssteifigkeit und eignet sich deshalb bestens für Anwendungen mit dynamischen Kräften, wie dem Fräsen. Die Tischplatte mit Endlosdrehung bietet mit optionaler Drehdurchführung, nebst elektrischen und pneumatischen Schnittstellen, auch eine Mediendurchführung. Die vielfältigsten Bearbeitungsszenarien lassen sich so realisieren – vom 3D-Druck bis hin zu mechanischer Bearbeitung. Die Ø600mm Tischplatte ist standardmässig mit M8 Gewinden versehen. Kundespezifische Tischplatten sind auf Anfrage erhältlich.

When needing to hold medium to large parts for multi-side machining or complex contouring, the HAAS HRT Series rotary tables are the perfect solution. The rugged, heavy-duty rotary tables can be mounted vertically or horizontally, and they feature precision T-slots and large through-holes for versatile fixturing.

pL ADDITIVE is a division of pL LEHMANN. With over 50 years" experience in machining production and as a manufacturer of CNC rotary tables for over 40 years, we are closely familiar with the demands placed on industrial production processes. The need for a zero-point clamping system was inspired by the fact that many workpieces made by LPBF technology need to be post-machined for mating surfaces, threads, surfaces or other precision contours. This synergy will allow the user not only to produce the 3D-printed workpieces, but also to post-machine and finish it in an efficient, precise and reliably manner. Here we focus mainly on the following post-processing methods:

Together with a well-known manufacturer, the development for a suitable zero point positioning clamping system AM-LOCK was started. It soon became clear that the installation space itself (construction shaft, construction platform) presents unresolved challenges for the manufacturers and the users. Also in this specific environment, pL ADDITIVE has acquired expertise in order to be able to advise you in the best possible way.

Vertical machining centers are the most commonly used type of machining center. In a vertical machining center, the spindle axis is in a vertical position. The axes of the machining table and workpiece can move in the X, Y, and Z directions. So the vertical spindle is in the most of vertical machining centers on the Z-axis. This type of machining center is best suited for machining relatively small workpieces.

The horizontal machining centers are another type of machining center. In horizontal machining centers, the spindle axis is horizontally oriented. This type of machining center is best suited for machining large workpieces. The spindle head of horizontal machining centers can move along the X-axis, while the work table moves along the Y-axis.

The 5 axis machining centers are the most advanced type of machine tool, as it is equipped with two rotational axes in addition to the three linear axes. Thanks to the additional rotational and tilting axes of the table, the 5 axis machine can perform highly complex machining operations that would otherwise be impossible with a 3 axis machining center.

8613371530291

8613371530291