3d printed rotary table supplier

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

We are the only Russian manufacturers of Delta printers with high accuracy and printing speed. We also provide a full range of 3D services and fulfill orders of any complexity!

The bearing used must guarantee smooth and clean operation of the rotary tables in their designated applications, and must also ensure high repeatability precision with simultaneous positioning accuracy.

The Franke LEZ bearing elements used are designed precisely to suit the various loads and hence guarantee smooth and clean movements of the rotary tables. Additionally, the 4-point system has no difficulty withstanding the prevailing loads.

The bearing used must guarantee smooth and clean operation of the rotary tables in their designated applications, and must also ensure high repeatability precision with simultaneous positioning accuracy.

The Franke LEZ bearing elements used are designed precisely to suit the various loads and hence guarantee smooth and clean movements of the rotary tables. Additionally, the 4-point system has no difficulty withstanding the prevailing loads.

Bearing for a high-performance placement head in printed circuit board production with a cycle frequency of 18 start/stop movements per second and up to 120 million revolutions over five years. The service life is defined as ten years. The bearing must be free from clearance in all directions at 70 °C so that the components can be fitted precisely.

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

pL ADDITIVE is a division of pL LEHMANN. With over 50 years" experience in machining production and as a manufacturer of CNC rotary tables for over 40 years, we are closely familiar with the demands placed on industrial production processes. The need for a zero-point clamping system was inspired by the fact that many workpieces made by LPBF technology need to be post-machined for mating surfaces, threads, surfaces or other precision contours. This synergy will allow the user not only to produce the 3D-printed workpieces, but also to post-machine and finish it in an efficient, precise and reliably manner. Here we focus mainly on the following post-processing methods:

Together with a well-known manufacturer, the development for a suitable zero point positioning clamping system AM-LOCK was started. It soon became clear that the installation space itself (construction shaft, construction platform) presents unresolved challenges for the manufacturers and the users. Also in this specific environment, pL ADDITIVE has acquired expertise in order to be able to advise you in the best possible way.

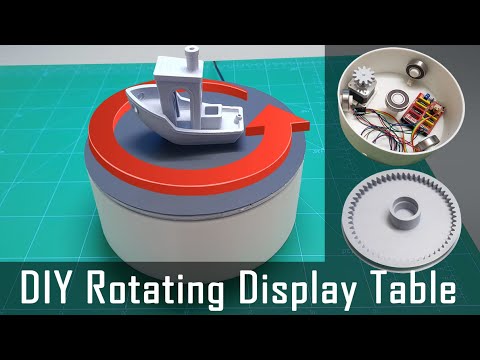

Go ahead at your own risk :) Assembly Video: https://www.youtube.com/watch?v=q4CSxE9dI0A More info: https://www.instructables.com/id/3d-Printed-DIY-Dremel-style-Rotary-Tool/ Note: Economically, this project is feasible if you have your own 3d...

There are plenty of DIY Dremel-style rotary tool ideas available on the internet but I couldn’t find anything that was powerful enough or usable in the long term, while looking good! So I decided to design and make my own 3d Printed Dremel-style...

These are ball joints for a DIY balcony table i made. The balls have an internal thread: M12, M10 and M8 are added. A counter nut is recommended.

I had this rotary meec tool laying around and I was building the diy dremel cnc by Nikodem Bartnik. I didnt want to buy a dremel because I had this one laying around and it was unused so I designed a mount for it.

**More information at:** https://daumemo.com/diy-3d-printed-desk-drill-press-for-a-rotary-tool-dremel-or-others/ As thingiverse wont"t show images at the top for some reason, I am adding some photos of this project here: [

The AM Flexbot is ideal for custom solutions to fit a specific application. Siemens Sinumerik is used to directly control the Comau robot arm, meaning no robot controller is needed. This enables very accurate operation of the robot, especially in terms of position accuracy while travelling along a path. The Siemens Sinumerik can control 31 axes. Therefore your AM Flexbot can be easily extended with additional functions such as a rotary table, additional robots or other production processes such as CNC milling but also other processes.

8613371530291

8613371530291