rotary table bearing free sample

Shandong Tefule Bearing Co., Ltd. is a company approved by the General Administration of Customs of China with import and export rights. Specializing in bearing trade at home and abroad, it is a large-scale industrial company integrating production and sales. Our bearing products have passed the ISO9001 quality system certification and ROHS lead-free certification. These products are widely used in the construction industry, railway industry, aerospace, agriculture, food industry, petroleum industry, cement industry, automobile industry, steel industry, mining, etc.

Rotation tables with air bearings are used when rotary motion with the highest accuracy, smoothness, and geometric performance is required. Due to the lack of friction, these high precision rotation bearings and direct-drive motorized rotary tables can achieve angular resolution in the sub-microradian range. PI’s air bearing design and manufacturing group provides hundreds of man years of design experience along with the manufacturing and test equipment to produce high quality rotary tables with the tightest tolerances.

Rotary air bearings (air bearing spindles) are friction free, and all of PI’s motorized air bearing rotation stages employ closed-loop, non-contact 3-phase direct-drive torque motors, and optical high-resolution rotary encoders for ultra-reliable maintenance-free operation with basically unlimited service life.

Absolute angle-measuring feedback sensors are available to provide closed-loop control with single digit microradian bi-directional repeatability. Direct-drive rotary air bearing tables also provide better eccentricity, flatness, and minimized wobble compared to rotary stages based on mechanical bearings. The friction-free design allows for high angular velocity without vibrations and noise.

Applications of rotary air bearing spindles / motorized direct-drive rotary tables include indexing, metrology, optical lens testing, bio-medical engineering, runout measurements of machined parts, and fiber optics.

PI’s high-performance closed loop servo motor controllers are available to precisely control position, acceleration and velocity, with advanced algorithms. Fully integrated multi-axis motion systems with linear air bearing stages and combinations with gantry systems are also available from PI’s air bearing division.

Air Bearing Rotary Tables, Table Top and Work Load are Supported on Air Bearings whose Freedom from Friction Contributes to Extremely High Positional Accuracy

An Interlocking Switch is used when Motors are Incorporated to Prevent the Table Top from Moving when the Air Supply is Turned Off. When the Air Supply is Turned Off, the Table Top Sits Firmly on our Cast Base with an Extremely High Accuracy of Parallelism Between the Base and Table Top

Rotary tables specifically developed for use in Metrology applications. CMM tables, inspection tables, assembly tables. Range of sizes 100mm thru 5,000mm. Larger on request.

Air bearing rotary tables, when rotating, the table top and work load are supported on air bearings whose freedom from friction contributes to the extremely high positional accuracy. High precision needle roller bearing maintains radial accuracy.

Supplied with each table. On/off Switch controls the compressed air supply to the table. Interlocking ensures that the motor drive can only operate if the air supply is on. When air supply is off, table sits firmly on the base casting with extremely high accuracy of parallelism between the top surface and the underside of the base.

BSPECT is an online B2B bearing treade platform. As a professional reseller, we collect China’s bearing supply information as well as the global bearing demand information in all directions.

For buyers, we have strict BSPECT Rules to guarantee best service and high quality products. For sellers, we will help you to find wider trade market and proper partner. With BSPECT, all your problems in bearing trade, such as quality problems, uncontrollable production, delayed delivery etc., can be prevented or solved perfectly.

—BSPECT brings authoritative bearing quality inspection engineers, who will offer you the services of both factory and product inspection in your demand.

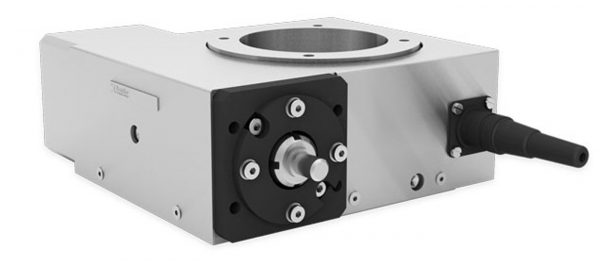

Lower your cost by using the rotary table bearing FMB. The compact designed FMB table bearing has been developed for high precision rotary motion. It reduces the cost compared to other rotary bearings since fewer components with less tolerance are used necessary for installation offering easy installation of the bearings and reducing the overall costs.

The turntable bearing can handle axial, radial, and a combination of loads. The main advantages of this bearing are the low height, easy mounting, and high precision run-out.

The super-precision balls move on highly accurate finished ways. The balls have 4 points of contact per ball offering very low, uniform, and smooth friction. As the bearings are preloaded by delivery they move with very high precision and repeatability. Values starting at 10 microns down to 1 micron can be achieved and wobble from 6 µrad down to 2 µrad.

The PTFE Teflon ball cages keep the precision balls separated, holds the bearing together, and offer smooth running performance. In case of light contaminants, the balls are self-cleaning due to the 4-point contact of balls the contaminant is pushed outside through the contact line of the balls on the raceway.

FMB turntable bearings include attachment holes to a standard configuration to attach the bearing fast and easy. The countersunk treaded holes can be used from attachment from the top and attachment from the bottom side.

Based on the groove geometry, specially designed raceways offer a greater contact surface for the bearing balls. This allows high rigidity, load ratings, and precise running. The smallest turn table bearing with an outside diameter of 140 mm offers a dynamic load rating of 6.070N and increased to 20kN for the largest bearing. The turntable bearings are preloaded before delivery by geometric matching and do not need readjustment.

The precision turntable bearing is available in sizes starting from an outside diameter of 120 to 350 mm. The inner bores start at 40 mm with a thickness of 8.5 mm and go up to 250 mm with a thickness of 12.5 mm.

Due that the turntable combines the advantages of low height, compact size, easy installation with a high running precision they are used in modern applications. Just to name a few:

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure is set automatically and independently of production tolerances. The freedom from friction at low speeds prevents slip stick and therefore allows maximum positioning accuracy.

Maintenance-free radial spherical plain bearings comprise inner rings, outer rings and maintenance-free sliding layers. The inner rings have a cylindrical bore with a curved outer slideway.

Radial spherical plain bearings are preferably used to support radial forces. GE..-UK-2RS(-2TS), GE..-FW-2RS(-2TS), GE..-DW and GE..-DW-2RS2 are also suitable for alternating loads up to a contact pressure of p = 150 N/mm2. The bearings are used where particular requirements for operating life apply in conjunction with maintenance-free operation or where, for reasons of lubrication, bearings with metallic sliding contact surfaces are not suitable, for example under unilateral load.

at the same time remaining smooth and with low breakaway torque and rotational resistance. Forces and torques occur from all directions. The bearings must not impede the camera"s imaging quality.

Bearing material, design and coating based on customer specifications. The 4-point contact bearing can accommodate forces from all directions and is insensitive to temperature fluctuation and vibrations. Smooth bearing with concomitant, high stiffness, at a favorable price.

Light, customised bearings are required for the articulation of the cardanic suspension; they must possess high stiffness while at the same time remaining smooth and with low breakaway torque and rotational resistance. Forces and torques occur from all directions. The bearings must not impede the camera"s imaging quality.

Bearing material, design and coating based on customer specifications. The 4-point contact bearing can accommodate forces from all directions and is insensitive to temperature fluctuation and vibrations. Smooth bearing with concomitant, high stiffness, at a favorable price.

at the same time remaining smooth and with low breakaway torque and rotational resistance. Forces and torques occur from all directions. The bearings must not impede the camera"s imaging quality.

Bearing material, design and coating based on customer specifications. The 4-point contact bearing can accommodate forces from all directions and is insensitive to temperature fluctuation and vibrations. Smooth bearing with concomitant, high stiffness, at a favorable price.

Light, customised bearings are required for the articulation of the cardanic suspension; they must possess high stiffness while at the same time remaining smooth and with

low breakaway torque and rotational resistance. Forces and torques occur from all directions. The bearings must not impede the camera"s imaging quality.

Bearing material, design and coating based on customer specifications. The 4-point contact bearing can accommodate forces from all directions and is insensitive to

The bearing requires high stiffness across its entire service life (shock stress due to waves and swell). The system must possess non-corrosive properties and provide constant rotational resistance across temperature ranges from –25°C to +60°C.

The bearing requires high stiffness across its entire service life (shock stress due to waves and swell). The system must possess non-corrosive properties and provide constant rotational resistance across temperature ranges from –25°C to +60°C.

A concept vehicle is to be motorized by one direct drive unit per wheel. This requires a bearing system with compact mounting space and sufficient load-bearing capacity. The maximum revolutions is 1000 rpm. The balls must be non-magnetic, as they are fitted adjoining the direct drive.

Customized bearings for direct integration in the customer-side design. Accommodation of forces from all sides, including tilting torque. Mounting space designed in cooperation with the customer. Joint assembly of the prototype at Franke.

A concept vehicle is to be motorized by one direct drive unit per wheel. This requires a bearing system with compact mounting space and sufficient load-bearing capacity. The maximum revolutions is 1000 rpm. The balls must be non-magnetic, as they are fitted adjoining the direct drive.

Customized bearings for direct integration in the customer-side design. Accommodation of forces from all sides, including tilting torque. Mounting space designed in cooperation with the customer. Joint assembly of the prototype at Franke.

Wire race bearings with high rigidity and highest accuracy are required for use in aircraft protection. The bearings must be able to compensate for thermal expansion.

Bearing assembly LDB80 / 295 as cylindrical roller bearing made of aluminium with a diameter of 295 mm.In addition, another bearing assembly is used in the form of a three-point bearing.

The bearing assemvly type LDZ has a running accuracy of 0.03 mm. Weight saving is achieved by the lightweight aluminum construction. The load ratings, the rigidity and the accuracy of the bearing are determined by the races. The second bearing has a support angle of 45 ° (three-point bearing). The outer ring is movable to optimally compensate for the thermal expansions that occur.

Wire race bearings with high rigidity and highest accuracy are required for use in aircraft protection. The bearings must be able to compensate for thermal expansion.

Bearing assembly LDB80 / 295 as cylindrical roller bearing made of aluminium with a diameter of 295 mm.In addition, another bearing assembly is used in the form of a three-point bearing.

The bearing assemvly type LDZ has a running accuracy of 0.03 mm. Weight saving is achieved by the lightweight aluminum construction. The load ratings, the rigidity and the accuracy of the bearing are determined by the races. The second bearing has a support angle of 45 ° (three-point bearing). The outer ring is movable to optimally compensate for the thermal expansions that occur.

The main bearing on the computer tomography machine is one of the elements responsible for ensuring that precise images are delivered. It must run quietly and with low vibrations, even at high speeds. It is necessary to guarantee exact radial and axial run-out.

Besides excellent running, the Franke CT bearings also come with ideal rotational resistance. The radial and axial run-out is just a few hundredth millimeters, depending on the engineering and diameter. All Franke CT bearings can be calibrated to suit customer specifications. The inner elasticity keeps the bearing outstandingly robust, even when exposed to the toughest conditions of use.

Extremely smooth running at up to 300 rpm. The elastomer suppresses the noise generation (60dBA). The bearing possesses a low rotational resistance (< 20Nm) and electrical insulation between the inner and outer ring. Loads in excess of 1000kg are possible.

The main bearing on the computer tomography machine is one of the elements responsible for ensuring that precise images are delivered. It must run quietly and with low vibrations, even at high speeds. It is necessary to guarantee exact radial and axial run-out.

Besides excellent running, the Franke CT bearings also come with ideal rotational resistance. The radial and axial run-out is just a few hundredth millimeters, depending on the engineering and diameter. All Franke CT bearings can be calibrated to suit customer specifications. The inner elasticity keeps the bearing outstandingly robust, even when exposed to the toughest conditions of use.

Extremely smooth running at up to 300 rpm. The elastomer suppresses the noise generation (60dBA). The bearing possesses a low rotational resistance (< 20Nm) and electrical insulation between the inner and outer ring. Loads in excess of 1000kg are possible.

The aluminium-carbon rim on an electric race car should be designed to accommodate the drive and braking systems in its center. The bearings used must require very little mounting space and possess a large open center. Plus they need to securely transfer substantial forces and torques.

Franke Wire Race Bearing, integrated directly in the housing components of the rim as double row angular contact ball bearings. The Wire Race Bearing handles the prevalent loads and works independent of the material used in the mating components. The wires and the rolling elements require minimal mounting space.

Space-saving bearing solution with large open center. Its arrangement as double row angular contact bearings permits extremely dynamic movement processes.

The aluminium-carbon rim on an electric race car should be designed to accommodate the drive and braking systems in its center. The bearings used must require very little mounting space and possess a large open center. Plus they need to securely transfer substantial forces and torques.

Franke Wire Race Bearing, integrated directly in the housing components of the rim as double row angular contact ball bearings. The Wire Race Bearing handles the prevalent loads and works independent of the material used in the mating components. The wires and the rolling elements require minimal mounting space.

Space-saving bearing solution with large open center. Its arrangement as double row angular contact bearings permits extremely dynamic movement processes.

The bearing used must guarantee smooth and clean operation of the rotary tables in their designated applications, and must also ensure high repeatability precision with simultaneous positioning accuracy.

The Franke LEZ bearing elements used are designed precisely to suit the various loads and hence guarantee smooth and clean movements of the rotary tables. Additionally, the 4-point system has no difficulty withstanding the prevailing loads.

The bearing used must guarantee smooth and clean operation of the rotary tables in their designated applications, and must also ensure high repeatability precision with simultaneous positioning accuracy.

The Franke LEZ bearing elements used are designed precisely to suit the various loads and hence guarantee smooth and clean movements of the rotary tables. Additionally, the 4-point system has no difficulty withstanding the prevailing loads.

The main bearing in the knitting machine plays a crucial role in the quality of the knitted goods. The highest standards are placed in the precision and operating performance of the bearing, despite the high mechanical and thermal load. The required speeds are up to 60 rpm.

A ground bearing element from the LEL series with a ball pitch diameter of 400 to 1500mm, made of chromium-silicon, ensures even, smooth running, even in the smallest mounting space. High precision of the bearing in axial and radial runout (<0.03mm) and the outstanding surface quality of the raceways ensure a constantly high quality of the machine.

The main bearing in the knitting machine plays a crucial role in the quality of the knitted goods. The highest standards are placed in the precision and operating performance of the bearing, despite the high mechanical and thermal load. The required speeds are up to 60 rpm.

A ground bearing element from the LEL series with a ball pitch diameter of 400 to 1500mm, made of chromium-silicon, ensures even, smooth running, even in the smallest mounting space. High precision of the bearing in axial and radial runout (<0.03mm) and the outstanding surface quality of the raceways ensure a constantly high quality of the machine.

Direct integration of the race segments in the housing components saves space and costs. The segment bearing is set free from clearance and can be moved by hand with a defined resistance.The movement is quiet and even. The 4-point contact bearing easily accommodates the high torque forces in any travel position.

Direct integration of the race segments in the housing components saves space and costs. The segment bearing is set free from clearance and can be moved by hand with a defined resistance.The movement is quiet and even. The 4-point contact bearing easily accommodates the high torque forces in any travel position.

Bearing for a high-performance placement head in printed circuit board production with a cycle frequency of 18 start/stop movements per second and up to 120 million revolutions over five years. The service life is defined as ten years. The bearing must be free from clearance in all directions at 70 °C so that the components can be fitted precisely.

Franke special bearing assembly LDB0110. Aluminium (Dispal) is used as the material for the inner and outer ring. It has almost the same thermal expansion coefficient as steel, facilitating constant unit set values across the entire temperature range.

Customer-specific design, which meets all requirements with regard to size, material and mounting dimensions. The integrated bearing element has a small cross section, giving the customer a compact, but nevertheless lightweight design. Franke is the only manufacturer worldwide that can satisfy these specifications.

RequirementsThe main bearing for a mobile satellite antenna must not weigh over 1kg. Smooth running with simultaneous tilting stiffness must be guaranteed.

Complete bearing assembly, ready for installation, made of aluminium and with tooth belt gear. Large open center and low mounting space thanks to the compact structure.

The bearing used must ensure a jerk-free and shock-free motion sequence of the rotary tables for the respective applications as well as high repeatability and high positioning accuracy in the end positions. High payloads are moved.

The Franke bearing elements LEZ used are precisely matched to the various loads and thus guarantee the required jerk-free and shock-free movement of the turntables. Due to the four-point system, the bearings easily absorb the occurring loads.

Rotary tables are positioning devices that are oftentimes used in precision manufacturing applications. More specifically, they are tools that hold parts on rotating axes, which increases productivity, accuracy, and repeatability. It seems simple enough, but there are various types of rotary tables. So how do you choose which one is best for you? Let’s go through three common kinds of rotary tables – air-bearing, oil hydrostatic, and mechanical-bearing – to assist you in answering that question.

In many cases, air-bearing rotary tables will be the answer. This is due to the fact that they have the capacity to run longer than other kinds. These are exactly what they sound like; with air-bearing rotary tables, parts float on air above the table. With this, there are no contacting parts to wear the machine down, resulting in decades of maintenance-free motion. That is a significant benefit to any piece of air-bearing equipment, but these rotary tables are specifically beneficial for certain applications.

Maximizing metrology productivity can be challenging, but utilizing air-bearings can assist in boosting turnover. Additional industries such as optics, assembly lines, and light machining and grinding, can use them to increase accuracy and productivity as well.

Similar to air-bearings, oil hydrostatic rotary tables do not have any contacting mechanical parts, as they float parts on oil. These rotary tables are most commonly used for grinding and machining when smooth and repeatable motion is a necessity. They provide high load capacity and can be useful when extreme stiffness is necessary.

Mechanical-bearing rotary tables are a bit different from the other two. Just as the name suggests, this type of rotary table does have moving, touching mechanical parts. And while this does sometimes result in a shorter life than the air-bearing or oil hydrostatic tables, many organizations will still pick these out of the others. Why? They still offer high performance.

These rotary tables can be used in most applications and provide superior performance in radial, axial, and angular error motions. In all, mechanical-bearing rotary tables do the job; however, it is possible that they will not last as long as other types.

The answer to the question, “Which one is best?” is the ever-hated, “It depends!” In general, air-bearing rotary tables will provide the highest accuracy for the longest amount of time. The lack of touching mechanical parts allows this type of rotary table to last decades. However, if you need a stiffer hold, oil hydrostatic could be the better choice. And in other cases, mechanical-bearing rotary tables could be best. All in all: It depends.

But if you want to know more about rotary tables and which would be the right choice for your application, contact the experts at ABTech. We will ensure you get exactly what you need.

Nanjing Younarui Bearing Co., Ltd. provides all kind of bearings, such as, Cylindrical roller bearing, Angular contact ball bearing, Deep groove ball bearing, Taper roller bearing, thrust roller bearing, thrust ball bearing, Self-aligning roller bearing, Needle roller bearing, Linear guide bearing, Slewing bearing, Bearing housing and accessories. Please enquriy us for above or special bearings according to your applications.

YNR large rotary table bearings are available for outstanding industrial performance in jaw and cone crushers, vibrating screens, feeders, wash plant equipment and conveyors in addition to other mining, excavation and mineral processing machinery.The bearings meet the most stringent tolerances ensuring equipment runs at maximum load for peak output.

Our factory was founded in 2004, We are a professional manufacturer of ball bearings and roller bearings, including deep groove ball bearing, self-aligning bearing, cylindrical roller bearing, tapered roller bearings, with our good team work and hard working of skillful staffs and our professional engineers, we got very good reputation in the world market, especially in American and European countries. Thanks for every customer"s support and trust, our company hope to establish mutual benefit and development business relations with you!

Available with inside diameters from 580 up to 1030mm, the YRTC and ZKXDF series rotary table bearings from Schaefflerare suitable for multi-axis simultaneous machining applications. They offer reduced friction, increased rigidity and operating speeds, as well as more compact designs.

Based on a combination of the company’s YRT and RTC series of rotary table bearings, the YRTC range provides the basis for highly dynamic rotary axes for rapid positioning and for form milling using multi-axis simultaneous machining. Operation at continuous speeds, for example, in intermittent turning, is also possible within the operating limits. Compared to traditional combination thrust and radial cylindrical roller bearings, power dissipation is also significantly reduced. As a result of this marked reduction in friction, a significantly increased proportion of the drive torque supplied by the machine tool drive is freed up for axis acceleration – which increases machine productivity. The amount of heat introduced to the machine tool also reduces with less friction, resulting in a reduction in temperature-induced changes in the geometry of the machine, which therefore increases machining accuracy. For cooled machining axes, this means the cooling capacity can be decreased in line with the bearing’s reduced power dissipation, which in turn reduces machine tool operating costs. Due to these larger-size bearings, the savings can quickly reach values in the low kilowatt range. By using YRTC bearings with reduced friction, the control properties of the rotary axis improve, resulting in more precise geometry transitions when machining shapes and contours.

The company has also developed a completely new design of rotary table bearing based on the its innovative Ball Roller design concept. This innovation is based on a double row angular contact, thrust ball roller bearing in an ‘O’ arrangement that uses new assembly methods and a unique rolling element. For the Ball Rollers, all parts of a conventional ball that are not under load are removed. This means that around 15% of the ball diameter is cut away from both sides. The result is a ball that is flattened on both sides and which is approximately 30% narrower (and therefore lighter) than a conventional fully spherical alternative. Ball roller elements offer all the axial load handling capabilities of fully spherical balls, but allow overall bearing width and mass to be decreased by 15 to 20%, as well as reducing friction. This not only saves valuable design space, but means that the ‘slim’ shape of the ball roller, in combination with new assembly methods, enables the number of rolling elements to be increased. This in turn enables the filling capacity of the bearing to be increased by up to 90%. Using more rolling elements in the same design space results in higher load ratings and longer service life, providing opportunities to downsize products and assemblies. Known as the ZKXDF series, the new bearings enable the design of more compact, higher performance rotary table supports in the high speed range. The benefits to machine tool manufacturers include increased rigidity and accuracy, simplified assembly processes and options for reducing system or machine build costs. Due to the single piece bearing rings, the running accuracy of the rolling bearings can be more easily transferred to the machine sub-assembly. The number of joints is also reduced, resulting in increased rigidity. Also, the new bearings do not require any holes to be incorporated in the raceways for inserting the rolling elements. This has a beneficial effect on the rating life and operational reliability of the bearings, particularly at high speeds. As a transport-securing mechanism for holding the split bearing rings together is no longer required, the rolling bearings are easier to install in the machine tool and assembly errors avoided. By using Ball Roller bearings, the ZKXDF bearings provide a larger grease reservoir, which increases operating life and allows longer relubrication intervals. Also, depending on the rigidity requirements of the application, the bearing rings do not have to be centered and supported by adjacent structures across the entire height of the bearing. Often centering on part of an adjacent component is sufficient or this process can be eliminated completely. The outer and inner rings are offset from each other to enable the bearings to be screw mounted onto flat surfaces.

For high speed precision rotary tables, the company’s product range also includes the YRTS and ZKLDF series. Typically, these are used in high performance machine tools for combined milling and turning in a single workpiece clamping operation. These bearings offer inside diameters up to 460mm.

With absolute enthusiasm and professional competence, we develop and manufacture trend-setting high-performance spherical plain bearings and high-performance rod ends for your demanding challenges. Our products convince through maximum load capacity at minimum weight.

Our standard assortment already covers a wide range: maintenance-free bearings, aluminum-titanium lightweight bearings, supporting and sliding ball joints, chassis components, radial and axial bearings. In addition, we design and produce individual high-end solutions.

8613371530291

8613371530291