tsudakoma rotary table manufacturer

Tsudakoma had been providing best-in-class rotary tables for over 100 years, offering multiple models and configurations to ensure seamless integration with your machining centers. Koma Precision has been distributing Tsudakoma’s tables for over 40 of those years and our North American sales team and in-house engineers will work with you to determine which model best suits your machining needs.

Tsudakoma"s relentless pursuit of ultimate performance, productivity and innovative technical advantages has made them the world’s largest and leading manufacturer of rotary tables. The rotary table specialists at CNC Engineering, Inc. can help you choose the right Tsudakoma rotary table and integration package for your application.

In May 1991, the department moved into the Nonoichi production facility in the city of Kanazawa, a port city on the Japan Sea and the administrative center of Ishikawa Prefecture, west of the main island of Japan. With 18,720 square meters, Nonoichi facility is the largest rotary table manufacturing facility in the world.

The precision parts, including the heart of the rotary indexing tables, worm screw and worm wheel, are manufactured and assembled in fully air-conditioned rooms. Equipped with the latest CNC technology and computer-aided production planning

Tsudakoma guarantees precision, quality and consequently customer benefits. Modern CAD programs, 3D measuring machines and special equipment are used.

The data pool, based on a wealth of experience in the development of many special models for machine tool manufacturers and automobile manufacturers, enables Tsudakoma to offer the customer a product that is optimal for his requirements.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

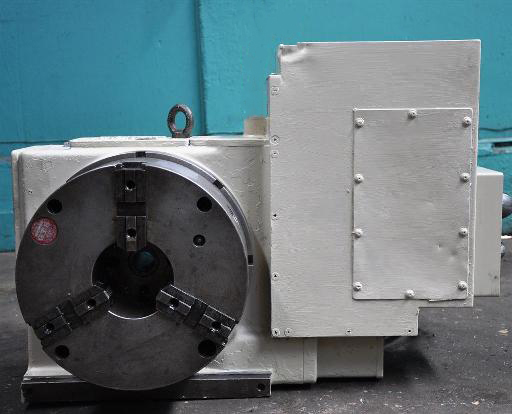

The latest TN tilting range from Tsudakoma, with major developments over earlier models with major increases in speed and power transmission, with high power pneumatic clamping system. The unit has a 55mm spindle nose location with a generous location depth of 15mm with 35mm directly through the table and a has a centre height of 150mm in the vertical position (90 degrees) and 210mm in the horizontal position (0 degrees) without faceplate, 235mm with faceplate. This device is around 524mm in overall width which would ideally suit a wide range of machine tool bed widths and an overall height of 235mm. The unit has a tilting range as standard of -17 to + 107 degrees. An excellent carrying capacity of 20kg through the whole tilting range and 35kg horizontally or between centres and speeds of up to 41. 6rpm in the rotary axis and 16. 6rpm in tilt dependent on motor selection. Net weight of this device is 80kg. The Tsudakoma TN-131 CNC rotary tilting table without motors, can be prepared to suit any interface at additional cost (see our interface listings for details and costs for “external interface” (motor, switch, cable and connector requirements if you already have a “4th / 5th ;axis interface” in the machine) and machine interface costs (if you do not have the additional axes fitted). Rotary axis motor is mounted to the right hand side on this device and may restrict the Y axis capability in certain circumstances, the tilt axis motor is mounted in a rear facing direction on the far side of the device and should not have any bearing on traverses. This range of Tsudakoma devices now come with dual lead full depth worm and wheel, which means that there is less load on individual teeth improving wear and torque performance over and above the conventional standard gear. Tsudakoma is one of the oldest and original manufacturers from Japan and in our experience build a very fine device with a very long service life, probably greater than those we have experienced from other Japanese makers. Tsudakoma products carry a standard one year parts and labour warranty and have a full working partnership with CNCROTARY. COM. This device may take from 2 to 3 weeks to configure as required.

The Tsudakoma dual leading gearing system features the largest tooth engagement of any rotary table manufacturer. This Generates up to 85% torque transfer efficiency.

Tsudakoma uses proprietary high tensile strength brass to build the gears. This enables exceptionally smooth cutting due to the inherent lubricating properties.

The Tsudakoma worm wheel uses an oversize diameter pitch circle resulting in reduced pressure on the contact surface compared to a conventional gearing system.

Tsudakoma utilizes full tooth depth engagement with a larger gear module resulting in a larger surface area yielding a substantially stronger worm gear system.

Koma Precision, Inc. provides comprehensive rotary table selection assistance. Torque calculations, interference drawings and 3D models are value added services offered by us.

Notes: 1. For RN-100, RNA-160 and 200 models, “Spindle end” replaces “Table top” 2. Indexing accuracy for tables with scales reflects Heidenhain encoder accuracies.

Methods & Equipment works with several manufacturers of rotary tables: Tsudakoma, Nikken, Yuasa and more. Give us a call or fill out the RFQ if you would like a quote on any of the high speed rotary tables, direct drive rotary table, or the new ball drive rotary table with zero backlash.

Officials at KOMA Precision Inc. introduce a new line of high performance fourth axis rotary tables from Tsudakoma, the world"s leading manufacturer of high-quality, precision rotary tables. The RNE Series fourth axis rotary tables are compact, high-performance tables offered at economy line pricing.

Four new models are available, ranging from the RNE-160 with 6.3" (160mm) face-plate capacity to the RNE-320 with 12.6" (320mm) face-plate capacity. The RNE Series tables’ feature speeds ranging from 25rpm to 44.4rpm and indexing accuracies ranging from 10 arc seconds to 12.5 arc seconds. These compact, high-speed, high-quality rotary tables offer economic line pricing, while retaining high clamp torque and increased production performance. Various options such as chucks, tailstocks, support spindles, and faceplates are available. Pneumatic and hydraulic rotary joints for automatic load and unload of the work piece are also available.

Like all Tsudakoma rotary tables, the RNE Series feature heavy-duty construction combining Tsudakoma casting material with Tsudakoma’s dual lead worm gearing system featuring the largest tooth engagement of any rotary table manufacturer. This proprietary gearing system generates up to 85% torque transfer efficiency. These tables also feature Tsudakoma’s ultra precision cross roller bearings that support radial, axial, and movement loads four times the level of stiffness as angular contact bearings. The combination of these innovative technologies gives Tsudakoma"s rotary tables the best reliability and productivity in the industry.

8613371530291

8613371530291