tsudakoma rotary table free sample

The latest RNA range from Tsudakoma, with major developments over earlier models with major increases in speed and power transmission, with new high power pneumatic clamping system. The Tsudakoma RNA-321 is an ideal device for larger VMC machines with a spindle nose diameter of 180mm with options to accept a 320mm (12. 59”) faceplate or can accept a standard or power chuck. The unit has a 115mm spindle nose location with a generous location depth of 45mm with 85mm directly through the table and a has a centre height of 210mm in the vertical position. This device in the first instance is a vertical and horizontal device with options for a backmount motor, which can be found under product code RNA-321R,B. An excellent carrying capacity of 175kg vertically and 350kg horizontally or between centres and speeds up to 25rpm dependent on motor selection. (example given is with a 3000rpm motor) – High speed versions are available with alternative gear ratio, please ask for further information. Net weight of this device is 150kgThe Tsudakoma RNA-321 CNC rotary table without motor, can be prepared to suit any interface at additional cost (see our interface listings for details and costs for “external interface” (motor, switch, cable and connector requirements if you already have a “4th axis interface” in the machine) and machine interface costs (if you do not have the additional axis fitted). Motor is mounted to the right hand side on this device and may restrict the Y axis capability in certain circumstances, the centre hole of 85mm is available should you want to machine long bar components that need to be mounted through the centre. This range of Tsudakoma devices now come with dual lead full depth worm and wheel, which means that there is less load on individual teeth improving wear and torque performance over and above the conventional standard gear. Tsudakoma is one of the oldest and original manufacturers from Japan and in our experience build a very fine device with a very long service life, probably greater than those we have experienced from other Japanese makers. Tsudakoma products carry a standard one year parts and labour warranty and have a full working partnership with CNCROTARY. COM. This device may take from 3 to 4 weeks to configure as required.

The latest RNA range from Tsudakoma, with major developments over earlier models with major increases in speed and power transmission, with new high power pneumatic clamping system. The Tsudakoma RNA-161 is the smallest device in the RNA range with a spindle nose diameter of 100mm with options to accept a 160mm (6. 6”) or 200mm (8”) faceplate or can accept a standard or power chuck. The unit has a 55mm spindle nose location with a generous location depth of 45mm with 40mm directly through the table and a has a centre height of 135mm in the vertical position. This device in the first instance is a vertical and horizontal device with options for a backmount motor, which can be found under product code RNA-161R,B. An excellent carrying capacity of 100kg vertically and 200kg horizontally or between centres and speeds up to 41. 6rpm dependent on motor selection. (example given is with a 3000rpm motor). Net weight of this device is 40 to 45kg dependent on motor selection. The Tsudakoma RNA-161 CNC rotary table without motor, can be prepared to suit any interface at additional cost (see our interface listings for details and costs for “external interface” (motor, switch, cable and connector requirements if you already have a “4th axis interface” in the machine) and machine interface costs (if you do not have the additional axis fitted). Motor is mounted to the right hand side on this device and may restrict the Y axis capability in certain circumstances, the centre hole of 40mm is available should you want to machine long bar components that need to be mounted through the centre. This range of Tsudakoma devices now come with dual lead full depth worm and wheel, which means that there is less load on individual teeth improving wear and torque performance over and above the conventional standard gear.

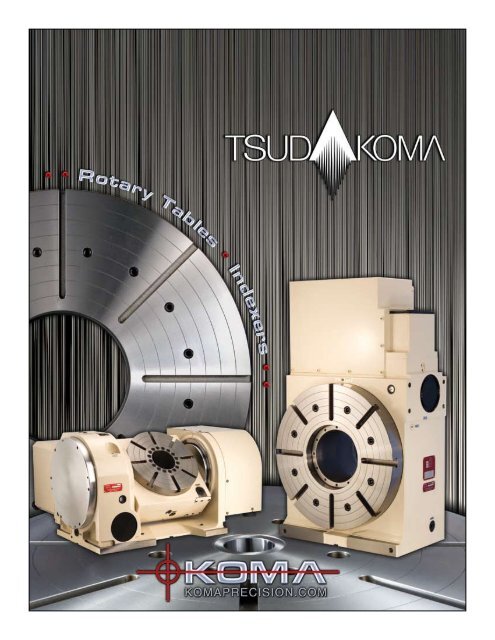

KOMA Precision Inc. introduces a new improved line of extra-large center bore, dual disc hydraulic clamping rotary tables from Tsudakoma. Like all Tsudakoma rotary tables, RCB Series has the proprietary dual lead worm gear system with ultra-precision cross roller bearings. The Tsudakoma dual lead gearing system delivers the optimal balance between power, durability and smooth cutting performance.

Three new models are available, with table diameter of RCB-350, R being 8.45", RCB-450, R with 10.4" and RCB-550, R with 12.4". The RCB Series rotary tables can be mounted either vertically or horizontally. Various options such as chucks, tailstocks, support spindles, and faceplates are available. Pneumatic and Hydraulic rotary joints for automatic load and unload of the work piece are also available.

"Koma Precision Inc. and Tsudakoma share a commitment to providing quality products that maximize the performance of machine centers," states Frank Cerrito, General Manager for KOMA Precision. "The features offered on the RCB Series are ideal for large-diameter work piece manufacturing that is mainly seen in the oil/energy industry."

The original Fadal rotary heads are still one of the best overall designed attachments for the Fadal machine. While there are many imported rotary heads that might "look good" on the outside, it"s the inside that really counts. The simple fact is the Fadal rotary tables were specifically designed to take a crash and keep on working.

Many different rotary heads were made throughout the years of production. A 4th or 5th rotary axis was one of the most popular machine options. In the early 90"s we started shipping all machines "4th axis ready" which means the machine has all the wiring necessary. You basically only needed an amplifier and a axis controller card with software. Contact us if you thinking of adding a 4th axis, we offer all the necessary components.

The very first rotary table sold that was sold on the VMC45 in 1981. It was designed and manufactured by Fadal for the VMC45, it never realized full production after production the VMC45 was stopped.

Troyke Mfg. Co. - Afterwards, with the introduction of the VMC40 in 1984, we began offering the TROYKE rotary products as a 4th axis option. The table had an interesting full contact bearing surface using Turcite between the faceplate and the casting with radial bearings support for the faceplate spindle. Few of these units still remain in the field today. If needed, we can provide complete service for these units.

Soon after 1987, we started adapting many of the popular Japanese rotary tables. Some customers would send us their tables and we adapt our motors and 4th axis interface to them. Eventually we started adding the Tsudakoma, Tecnara and Nikken rotary tables as a direct option to all machines.

VH65 - After years of installing and also repairing the many various manufactures rotary tables we sold, we learned what different designs worked and didn"t work in the machines. The second rotary head Fadal designed was the VH65. The VH65 stands for Vertical or Horizontal mount and 6.5" diameter faceplate.

TR65 - The TR65 (Tilt/Rotate, 6.5" dia. faceplate) had a unique clutch system build into the trunion for the B-axis. One of the biggest problems with 5-axis programming was that is was easier to crash than to program. And a B-axis crash usually resulted in the customer having to return the unit for repair. With this unique design, if the Z-axis crashed into the part, instead of damaging the gears it would simply slip the trunion clutch. The CNC knows the exact position of the B-axis because of the rotary scale feedback that is directly attached to the trunion and not the motor. The addition of the trunion clutch was so important because it virtually eliminated the disruption of operation for a service call.

You will receive an estimate of repair 5-10 days (depending on workload) after receiving rotary unit. Repairs take an average of 10 to 30 working days after receiving approval. Evaluation charge of $500.00 will apply if you do not get it done.

Your rotary unit is repaired, reassembled and run in for 10 hours. It is then re-inspected, all final adjustments and calibrations are performed to the original manufactures specification. We warranty our complete Rebuilds for 1 year.

As you can see we are the most qualified to tune-up or rebuild your rotary table. Having been there from the beginning, we know exactly what your table needs to bring it up to original specifications. Simply call Toll Free 1-800-342-3475 for any questions.

We bought an "externally controlled" table. We bought it with the TPC-Jr. Controller. The controller comes pre-wired to accept an M-code activated input signal to tell the box "rotate the Rotary". You use the control box to program the actual index angles.

The Tsudakoma rotary tables can be "direct wired" into your control as well, rather than the OEM unit, depending on your control model. If you have the option, I would recommend this route, rather than the separate control box, but both have their advantages...

Notes: 1. For RN-100, RNA-160 and 200 models, “Spindle end” replaces “Table top” 2. Indexing accuracy for tables with scales reflects Heidenhain encoder accuracies.

In Booth 5241, Koma Precision, Inc. (East Windsor, CT) will display NC rotary tables from Tsudakoma that feature a proprietary dual lead gearing system to deliver optimum balance between power, durability and smooth cutting performance. Also on display will be new Ball Drive System Rotary Tables that provide zero backlash, improved cycle times, energy conservation and a lifetime adjustment-free transmission system. Tsudakoma rotary tables are available in horizontal, vertical, tilting, multi-spindle, and high speed configurations with various options, such as chucks, tailstocks, support spindles, and faceplates. Pneumatic and Hydraulic rotary joints for automatic load and unload of the work piece are also available.

A follow-up. I decided that since my rotary table was originally a Centroid factory install...or so the PO believed...I went with the parameters right off the current Centroid schematics. I used 24vDC to the red and black wires, and connected the blue to the rotary input on the Allin1DC. Succcess! The rotary table now homes and 99% of the position error messages went away. The system test finally completed so the obnoxious warning about the set-up not being complete has disappeared from every start up.

On the other side...I still cannot figure out the nuances of the rotary table. It weighs at least 200lbs and has no markings at all. I have googled for days trying to find any similar tables, and there simply are no pictures of similar ones. I blew air into the 2 tube fittings. Absolutely nothing happens. No air escapes anywhere, and the table does not clamp. The air that comes out when I remove the pressure smells like heavy gear oil. I have to assume they are oil feed lines to the 2 ball bearings for the rotor.

Another option is the hoses may be for a hydraulic clamp, and I am not using enough air pressure to activate it. The pneumatics on the Bridgeport are all 3/8” lines, and the tubes into the rotary table are 1/4”. I am at a loss. I may have to tear down the entire unit to figure out how it works if nobody has any ideas?!? The table has no perceptible backlash at all...are there tables that do not require clamping features? What keeps going through my mind is that the X,Y and Z do not have clamps??

Koma Precision, Inc. introduces a new line of high performance, 4th axis rotary tables from Tsudakoma, a manufacturer of precision rotary tables. "The RNE Series 4th axis rotary tables are compact, high-performance tables offered at economy line pricing," said a Koma spokesperson.

Four new models are available, ranging from the RNE-160 with 6.3" (160 mm) face-plate capacity to the RNE-320 with 12.6" (320 mm) face-plate capacity. The RNE Series tables" feature speeds ranging from 25 to 44.4 RPM and indexing accuracies ranging from 10 to 12.5 arc seconds. Various options such as chucks, tailstocks, support spindles and faceplates are available. Pneumatic and hydraulic rotary joints for automatic load and unload of the work piece are also available.

"The RNE Series feature heavy-duty construction combining Tsudakoma casting material with Tsudakoma"s dual lead worm gearing system featuring the largest tooth engagement of any rotary table manufacturer. This proprietary gearing system generates up to 85% torque transfer efficiency. These tables also feature Tsudakoma"s ultra precision cross roller bearings that support radial, axial and movement loads four times the level of stiffness as angular contact bearings," said the spokesperson.

"Koma Precision, Inc. and Tsudakoma share a commitment to providing quality products that maximize the performance of machine centers," said Hiro Ichikawa, OEM Sales Manager for Koma Precision, Inc. "The features offered on the RNE Series are ideal for those looking for economical ways to improve the flexibility and productivity of their operation without compromising rigidity and accuracy."

In the market for a rotary table? The checklist of requirements starts with speed, accuracy and rigidity. Will it be used for contour machining? Do you need high-speed indexing for high-volume parts? What features and capabilities will help in the short and long term within the industries your company serves? CTE spoke with multiple rotary table manufacturers to discuss market trends, product innovations and add-ons that can improve overall machine tool performance.

In addition to a standard rotary table, many manufacturers require additional system features to meet the special machining requirements necessary in production facilities, according to Randy Conley, rotary table product manager at CNC Engineering Inc., Enfield, Conn. “Today’s rotary table customers typically look for a turnkey package that includes an additional axis interface, control options, rotary table hardware, installation, training and a complete documentation process. We also have to offer accessories like workholding fixtures, tailstocks, risers and hydraulic power units,” he said.

Off-the-shelf rotary tables are not always enough as customers seek equipment made specifically for their individual machining applications and the accessories. “For example, the application may require an outboard support spindle and a trunnion plate. A subplate or riser may be required. These parts would all be designed based on a particular manufacturing process for a particular machine,” Conley said.

CNC Engineering’s custom rotary table comes with a single PVC cable with a waterproof connector that can be connected or disconnected in a few seconds with a half turn. This cable has proven to be highly durable and remains flexible after years of use. Image courtesy CNC Engineering.

Conley said small improvements through the years have been the norm for rotary tables. “Most commonly, that has meant higher speeds and greater clamping torque. Many rotary table manufacturers offer worm wheel models that are able to run at 100 rpm or more, within a limited-duty cycle. Pneumatic clamping torque is often in the range now that could only be provided with a hydraulic clamping system just a couple of years ago,” he added.

Many manufacturers offer direct-drive rotary tables that eliminate the worm gear (see chart on page 66). “These tables can offer higher speeds than the traditional gear drive tables but, depending on the application, the drive torque may be lower. Furthermore, users may find it necessary to retune the servo drive for different applications to maintain optimal performance and stability,” Conley added.

“These direct-drive rotary tables specialize in eliminating backlash and can provide a stiff mechanical system for highly dynamic applications,” said Gregory Kane, marketing manager at IntelLiDrives Inc., Philadelphia. “Integrated with precision bearings and ring encoders, these tables provide high performance for indexing applications compared to other mechanical transmission rotary systems.”

Today’s rotary table users seek products that are accurate, efficient and easy to use, according to Frank Cerrito, general manager at Koma Precision Inc., East Windsor, Conn. “Our customers are looking for automatic fixturing to increase production and reduce errors, for example. They’re asking for higher speeds, higher accuracy and less backlash.”

These tables are being purchased for old and new machine tools, according to Conley. “Often our customers would like to be able to use an older rotary table on a new machine, as well as an older machine. Depending on the control vintages, we can often accommodate that need,” he added.

The Weiss rotary indexing ring has a large central opening to allow a customer to position all tooling and cables internally. Image courtesy Weiss North America.

Additional considerations play a part in choosing the right rotary table. This includes everything from number of axes, position requirements, faceplate size, motor location and energy requirements. “A customer may need a low-profile rotary table that reduces rotor inertia, improves start/stop behavior and enhances velocity control compared to conventional rotary systems,” Kane said. “This is due to the lightweight, direct-drive motor, resulting in precise bidirectional speed and position control, which is critical for high-speed motion contouring.”

Weiss North America Inc. says its index tables are sized properly so the use of an overload clutch is not needed in a jam-up situation. Overload clutches increase the maintenance cost of the table, according to John Treter, the Willoughby, Ohio, company’s product sales manager.

“Our tables are also filled with oil at the factory and will never need to be changed,” Treter said. “Because of these two differences, Weiss is a maintenance-free solution. We also manufacture risers, tool and stationary plates and machine bases. This saves our customers the hassle of purchasing multiple components from multiple vendors.”

The size of the through-hole is an additional factor. “A table with a large center hole allows [running] routing cables and pressure/vacuum lines through the aperture, placing test objects into the aperture, and inserting work tools and installing slip rings,” Kane said.

“Sometimes there may not be a pre-engineered solution for keeping a rotary table connected to the control throughout a pallet change,” Conley continued. “Designing and building a system for a particular machine model is often more work than a customer wants to take on. CNC Engineering has developed several types of cable management systems. If we’re dealing with a new model, we typically customize one of our existing systems to adapt it to a new machine configuration.”

Weiss North America introduced the first rotary indexing ring, which features a large central opening. “This allows the customer to internally position all tooling, cables, etc. and to work from the inside out, saving sought-after floor space,” Treter said. “From there, we moved to servo mechanical, offering another option utilizing the same design yet incorporating the flexibility of servo technology.”

Koma Precision, which distributes Tsudakoma rotary tables, offers a detailed comparison chart (www.komaprecision.com) for those interested in some of the advantages and disadvantages of a worm wheel vs. a direct-drive system. Here are some of the differences that distinguish the rotary tables from one another.

KOMA Precision is the foremost source for the finest the world has to offer in machine tool Productivity Innovation. For over 30 years KOMA has been providing superior service and support. KOMA precision is the largest distributor of NC rotary tables and indexers in the world with over 30,000 rotary table installations. KOMA is also the world’s largest supplier for Alberti (the originator and innovator of productivity tooling) with over 12,000 angle heads and live tools installations. Our 25,000 sq. ft. facility features a completely equipped machine shop, state of the art inspection equipment, a product demonstration showroom, and a multi-million dollar new product and spare parts inventory. All Koma products are covered by a one year warranty and backed by a service department with experience and expertise second to none. Koma application engineers - with AutoCAD® and SolidWorks® 3D CAD support – offer torque calculations and interference drawings at no-charge to ensure products purchased from Koma will be the best available for the required machining operations. Koma Precision distributes: • Tsudakoma Rotary Tables & Indexers • Alberti Angle Heads, Live Tooling, and Specialty Tooling • Koma Tool Presetters • Romai Angle Heads • Swiss Tools for CNC Type Machines • Koma Special Application Tools

8613371530291

8613371530291