nikken rotary table manufacturer

A special alloy steel worm screw with excellent shock resistance is adopted for small-size rotary tables to extend their service life and realize high cost effectiveness.

On the other hand, the extremely rigid and high-speed rotation-capable carbide worm screw is adopted for large-size rotary tables to withstand severe usage and maintain its accuracy almost permanently.

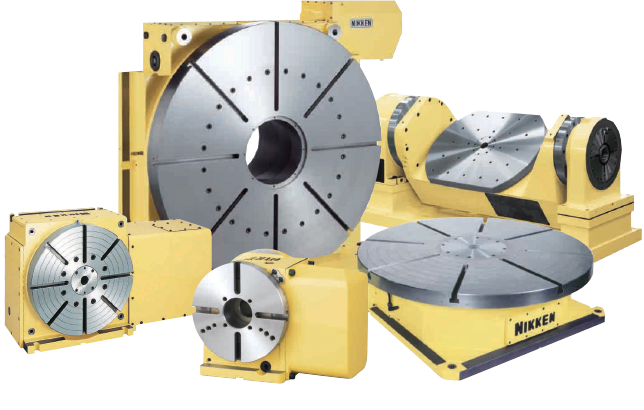

NIKKEN’s world-renowned CNC Rotary Table range provides proven performance, reliability and accuracy benefits for any application or requirement that others simply cannot hope to emulate.

With an extensive range of rotary table sizes, configurations and options available, all fully supported by our extensive global network, you can be sure to find the perfect product to meet any requirement or machine tool.

NIKKEN can also provide a complete and expansive range of accessories precisely engineered and customised to suit both the machine tool and the component. These options include a wide variety of chucking solutions, vices, bespoke trunnions & workpiece fixturing along with a wide range of NIKKEN manufactured rotary work supports and tailstocks to cater for all production expectations.

Martin Trunnion Tables and Lyndex Nikken are now offering complete 4th axis packages. Ready to be mounted into your machine tool, your Stallion Trunnion Table will already be attached to the Lyndex Nikken rotary table of your choice and assembled onto a baseplate. This allows for an easy transition from 3-axis machining to 4-axis machining. Our line of trunnion tables can be made to fit any Lyndex Nikken indexer. Multiple workholding options are also available including 5th axis, AME, Schunk, Triag, Orange Vise and more. If you have any questions, do not hesitate to reach out to one of our applications engineers! Scroll down to view package options.

NIKKEN Compact Rotary Tablesoffer a wide variety of solution to multiple applications, from drilling, to presses to CNC machine centers. The NIKKEN Tilting Compact Rotary tables are suitable for indexing the cutting of small workpieces, with several options for work chucking attachments ranging from 5C collet fixtures to pneumatic or hydraulic chucking jigs. Model 5AX-100 is the most compact table available with a length of only 466 mm and 84 kilos of weight, and a clamping capacity of 410 Nm, ideal for centers of compact machining.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

The largest B type model from Nikken with motor mounted to the rear, with higher gear ratio over earlier models increases speed over the vertically mounted motor version type CNC-400V. This unit also has a hydraulic clamping system. The unit has a 130mm spindle nose location with a location depth of 12mm with 105mm directly through the table and a has a centre height of 230mm in the vertical position. This device in the first instance is a vertical mount only device with options for a side mount motor, version which can be found under product code CNC-400V. An excellent carrying capacity of 250kg vertically unsupported and 500kg between centres with a standard tailstock with rotation speeds up to 22. 2rpm dependent on motor selection. (example given is with a 2000rpm motor)Net weight of this device is around 280kgThe Nikken CNC-401B rotary table is offered without motor and can be prepared to suit any interface at additional cost (see our interface listings for details and costs for “external interface”) (motor, switch, cable and connector requirements if you already have a “4th axis interface” in the machine) and machine interface costs (if you do not have the additional axis fitted). Motor is mounted to the rear via the right hand side on this device and is designed to avoid restriction to the Y axis capability and with a large bore available should you want to machine long bar components that need to be mounted through the centre. Please remember however, that being a back mount device the centre bore is restricted to passing through only the depth of the casting (240mm)This range of Nikken devices have Tungsten carbide worm shafts and hardened wheels which can mean less backlash adjustment required over a conventional brass/bronze standard gear.

320mm T-Slotted Table, 4" Hole Through, .001° Minimum Increment, 550lbs Max Vertical Load, 1100lbs Max Horizontal Load, 230mm Center Height, 22 Pin and 17 Pin Connectors.

By swapping its previous live toolholders for Mimatic models from Lyndex-Nikken, this manufacturer improved accuracy and rigidity in a critical drilling operation for a life-saving emergency rescue tool.

This shop refused to accept the notion that large, complex parts necessarily require multiple, time-consuming setups. Rotary tables from Lyndex-Nikken have saved time and expanded capabilities to the point where the shop can take on new work and bring previously outsourced jobs back in-house.

Integrating Lyndex-Nikken rotary tables into three-axis Mori Seiki VMCs provided this shop with five-axis capability at a fraction of the cost of a new five-axis machine.

A complete series of live tools for Nakamura Tome CNC lathes are now available from Lyndex-Nikken. Designed for precision and rigidity, these tools improve milling, drilling and tapping capabilities in turning operations, the company says.

Lyndex-Nikken’s shrink fit toolholders are designed for optimum accuracy, rigidity and balance. The solid construction minimizes unbalance variations when changing cutting tools, the company says.

The 5AX-200II CNC rotary table from Lyndex-Nikken is said to perform with high accuracy and fast rotating and tilting speeds. The company’s patented carbide worm system ensures wear resistance, rigidity and the rapid speeds of this rotary table. The carbide worm system uses a carbide worm screw and ion nitrided worm wheel rather than a conventional bronze or bronze-alloy actuation mechanism.

Mounted in a horizontal or vertical plane, rotary tables can be used to add fourth and fifth axis capability to conventional three-axis CNC machining centers. This rotary table manufacturer has developed an actuation mechanism that, according to the company, significantly increases the useful life of its rotary tables.

Pioneers in the industry, we offer Nikken NSVX400 Rotary Hirth Indexer, Nikken NSVX500 Rotary Hirth Indexer, Nikken NSVZ300 Rotary Hirth Indexer, Nikken NSVZ180 Rotary Hirth Indexer, Nikken Cncb630 Ultra Big Bore Rotary Table and Nikken DD400F-250 Direct Drive Rotary Table from India.

8613371530291

8613371530291