rotary table vise manufacturer

Mounts directly to a rotary table, Fixture Pro® Riser or any QLS Grid. Reduces distortion of parts like standard vises. Requires very little material (0.060” or less) to clamp. By cutting a 10º angle ...

Mounts directly to a rotary table, Fixture Pro® Riser or any QLS Grid. Reduces distortion of parts like standard vises. Requires very little material (0.060” ...

... gripping equipment. Detailed documentation is provided on request.These vises are exclusively intended for use as a static locking unit (mounting on CNC rotary tables, with rotating tools); ...

... gripping equipment. Detailed documentation is provided on request. These vises are exclusively intended for use as a static locking unit (mounting on CNC rotary tables, with rotating ...

High pressure ARNOLD TWIN vices are capable of clamping two pieces simultaneously.- Accuracy of 0.01 mm in clamping repeatability.- Suitable for working in horizontal and vertical machining centres.- Grinding of all ...

The original Kurt AngLock® vises were designed to provide precision part clamping for basic machining and milling applications. Our line of Kurt vises includes high precision CNC vises, 5-axis vises, rotary table workholding solutions for VMCs, and ToolBlox tombstones. Our precision workholding solutions provide increased versatility at your CNC machining stations. Precision measuring systems and accessories are also available to complement your Kurt workholding system.

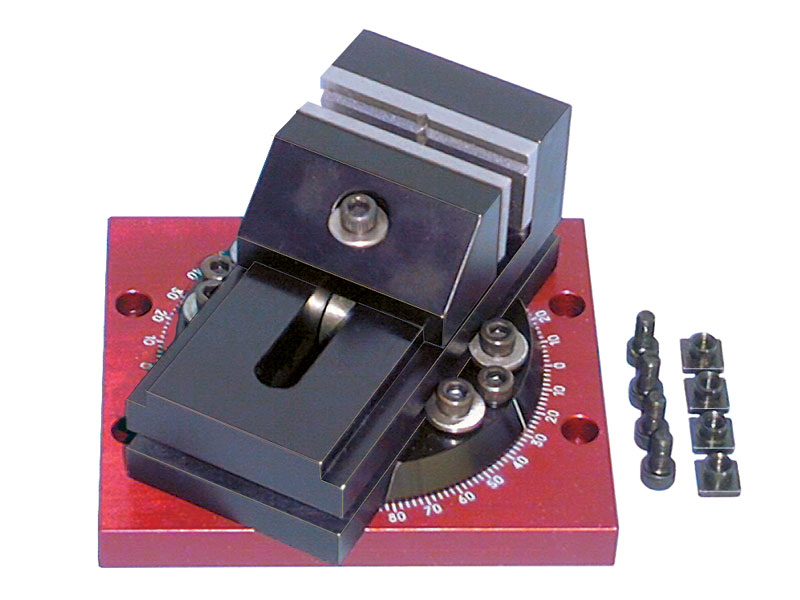

If you do not already have a vise and are considering purchasing both a vise and a rotating base, they can be purchased together at a price that is less than the two purchased individually.

A milling vise is a versatile way to hold parts securely. It is accurately made so it can be aligned to the mill table. It also has a jaw that pulls down as well as in to keep parts from being pulled up by the milling cutter.

The rotating vise base eliminates clamping and unclamping the vise to produce angles. Once mounted square to the table, the vise can be positioned using the laser engraved protractor scale as a guide for setting the angle. Properly positioned, the rotating base can even be used as a simple rotary table to drill or machine small, radial symmetric patterns.

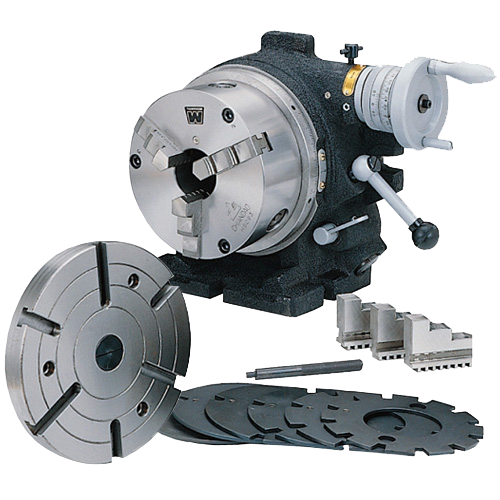

A rotary table vise is a combination of a rotary table and a working vise. A rotary table is a precision work positioning device used in metalworking, while a vise is a mechanical apparatus used to secure an object to allow work to be performed on it. The following description will be divided into two parts, the rotary table and the rotary table vise.

A vise is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever. Vises have a huge variety of kinds that can be categorized into different genres. But the main function of a rotary table vise comes from the rotary table.

A rotary table enables the operator to drill or cut work at exact intervals around a fixed axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available. For such construction, a rotary table vise is the best choice to work with a rotary table. Rotary tables are most commonly mounted flat, with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine.

An alternate setup is to mount the rotary table on its end, or mount it flat on a 90 degree angle plate, so that it rotates about a horizontal axis. In this configuration a tailstock can also be used, thus holding the workpiece between centers. With the table mounted on a secondary table, the workpiece is accurately centered on the rotary table"s axis, which in turn is centered on the cutting tool"s axis. All three axes are thus coaxial.

From this point, the secondary table can be offset in either the X or Y direction to set the cutter the desired distance from the workpiece"s center. This allows concentric machining operations on the workpiece. Placing the workpiece eccentrically a set distance from the center permits more complex curves to be cut. As with other setups on a vertical mill, the milling operation can be either drilling a series of concentric, and possibly equidistant holes, or face or end milling either circular or semicircular shapes and contours.

Before operating and mechanical device, safety always comes in first place. Wear safety glasses or goggles, or a face shield with safety glasses or goggles when using striking tools or power tools on a workpiece held by a rotary table vise. Attach a vise securely on a rotary table. Place bolts in all the holes in the base of the vise. Use lock washers under the nuts. Mount a vise so that the stationary jaw projects slightly beyond the edge of the rotary table. This allows long work to be clamped in the vise without interference from the edge of the rotary table. Ensure that the rotary table is firmly secured to its base.

There are some things to be aware when using a rotary table vise. Check the rotary table vise for cracks or other damage before clamping a workpiece in it. Attach a vise that is large enough to hold the work without strain. Place the workpiece in the vise so that the full clamping surface of the jaw supports the workpiece. Keep the workpiece in the vise close as possible to the jaws to prevent vibration when milling. Keep all threaded and moving parts clean, oiled and free of chips and dirt. Make sure to use jaw liners in a vise where there is any possibility of marking the work.

Do not weld the base of the rotary table vise to any metal. Repairing a vise by welding or brazing is also a big no. Do not try to bend a heavy rod in a light vise, nor try to apply heavy pressure at the corner of the vise jaws. Hammering on the handle to tighten beyond hand pressure. Do not use the jaws of the vise as an anvil. Never use any vise that has the slightest crack, nor unscrew or open the jaws of the vise wider than they were designed to be used. The smallest errors may cause huge danger to the machine and the user him or herself.

V E R T E X PRODUCES,MAKE ALL KIND OF ACCESSORIES FOR MACHINE TOOL - MILLING MACHINE ACCESSORIES - MACHINERY,MC-POWER-VISE-MC POWER VISE,INDUSTRIAL VISE,CLAMPING KIT,ROTARY TABLE,DIVIDING HEAD,HYDRAULIC VISE, PRECISION PNEUMATIC,MECHANICAL VISE, INDEXER,ANGLE,LOCK,FIXED POWER VICE,MODULAR MACHINE FREE VISE,M.C.P.O.W.E.R.,V.I.S.E.,POWER TABLE FEED,

GRINDING MACHINE ACCESSORIES - TOOL MAKER VISE, CHAMFERING & DEMURRING MACHINE, EDM WIRE, UNIVERSAL WHEEL DRESSER, MAGNETIC PLATE / CHUCK, DIAMOND WHEEL DRESSER, MAGNETIC ANGLE CHUCK / PLATE,PRECISION ANGLE BLOCK, PERMANENT MAGNETIC LIFETR, DEMANETIZER, COOLANT PAPER FILER, OIL SKIMMER, BLACK GRANITE SURFACE PLATES,COOLANT HOSE

GOOGLE search vertex vise - KEYWORD - TAIWAN VERTEX - IS THE BIGGEST PROFESSIONAL NC,CNC,MACHINE TOOL ACCESSORIES & HIGH PRECISION MACHINERY MANUFACTURER FOR MILLING,GRINDING MACHINE,MACHINING CENTER AND A COMPELETE TOTAL 1 SOLUTION.VERTEX - LEADING TOOLING MANUFACTURER,MAKER,EDM,WIRE CUT,CUTTING,DIE SINKER, SINKING,HOLE DRILLING,HIGH SPEED MILLING,FIXTURE MAKER,METAL,S O F T JAW H A R D J A W SAWING,MACHINE,PRODUCT,MANUFACTURER,R&D,RESEARCH,DEVELOP,SUPPLIER,CHAIN,MARKETING,OEM,ODM, CUSTOM DESIGN,VERTEX ,"BEST",TOOL,TAIWAN MILLING MACHINE ACCESSORIES - MACHINERY, MC POWER VISE,INDUSTRIAL,"VISE","CLAMPING KIT","ROTARY TABLE","DIVIDING HEAD","HYDRAULIC VISE",PRECISION," PNEUMATIC",MECHANICAL VISE,"INDEXER",ANGLE,LOCK/FIXED POWER VICE,MODULAR MACHINE FREE VISE,POWER TABLE FEED,GRINDING MACHINE ACCESSORIES - MAGNETIC CHUCK,"PUNCH FORMER",EDM WIRE,"EDM VISE",WHEEL DRESSER,DEMAGNETIZER,GRANITE SURFACE PLATE,TOOL MAKER VISE,EDM,VISE TAIWAN VERTEX,"GRINDING", VISE,VERTEX,BEST,"HYDRAULIC",TOOLING-SHANK-TOOLHOLDER, T.O.O.L.I.N.G.-TOOLING,T O O L I N G,TAIWAN VERTEX - TOOLING,COLLETS SET, COLLET CHUCK, BT,SK,VISE VERTEX,HSK,VISE,P O W E R,V I S E,HYDRAULIC/INDUSTRIAL VISE,C L A M P I N G,K I T,"WORK HOLDING",VISE,DIVIDING HEAD/SPACER,HYDRAULIC TOOL HOLDER,SPINDLE,SHANK,H Y D R A U L I C,VISE,PRECISION,DRILL,MILLING CHUCK,PROFESSIONAL MANUFACTURER OF MACHINE TOOL ACCESSORIES & MACHINERY - VISE TAIWAN VERTEX - MILLING MACHINE : MACHINERY, MC POWER VISE, MACHINE VISE, HYDRAULIC VISE, MECHANICAL VISE, PRECISION PNEUMATIC ANG-FIXED POWER VICE, MODULAR MACHINE FREE VISE, ROTARY TABLE, DIVIDING HEAD,INDEXER, CLAMPING KIT, GRINDING MACHINE ACCESSORIES: MAGNETIC CHUCK, PUNCH FORMER, EDM WIRE,EDM VISE,VISE TAIWAN VERTEX,"WHEEL DRESSER","DEMAGNETIZER","GRANITE SURFACE PLATE","TOOLING",SYSTEM:"ER COLLETS",SET,"COLLET CHUCK","BT","SK", "HSK","TOOL HOLDER","SPINDLE","SHANK",VERTEX TOOLING-BORING,T A I W A N ,B O R I N G,B.O.R.I.N.G.,"BORING HEAD",SET/TOOL,"ARM","AIR TAPPING",T.A.P.P.I.N.G.,T A P P I N G,TOOING-TAPPING,,AIR TAPPING ARM,MACHINING CENTER ACCESSORIES: NC ROTARY TABLE, TAIL STOCK, MACHINE VICE, BASE PLATE, ANGLE PLATE, OIL MIST CLEANER; LATHE ACCESSORIES: LIVE CENTER, 3/4 JAW CHUCK, SOFT JAW, HARD JAW, VDI HOLDER SMALL TYPE MACHINE: PRECISION END MILL GRINDER / DRILL GRINDER,TOOLING SYSTEM: ER COLLETS SET, COLLET CHUCK, BT,SK,HSK,TOOL HOLDER,SHANK, DRILL,OIL FEED,MILL

An essential workbench accessory, this versatile tool is so easy to use; you can even clamp it to a table if necessary. This helpful grip tool holds wood or other materials in place so you can work on it with both hands and with other tools, such as a saw. No workbench should be without a sturdy and robust bench vise manufacturers and the good news is you can find one for less when you shop wholesale prices. There are many reason shoppers come to Alibaba.com to buy wholesale tools, with buyers made up of construction companies, schools looking to kit out woodwork rooms and even those looking to make a saving on a single bench vise manufacturers for their own workshop. Many buyers are also woodworking stockists looking to obtain direct prices on large amounts of stock in order to sell on in their own store. Whatever your reason, search now and find a range of bench tools for every budget.

A clamping technique thought to have originated in the Middle Ages. Today the bench vise manufacturers is a versatile and essential facet of any workshop. Used extensively by wood-manufacturers, carpenters, on construction sites, in factories, in workshops, for woodwork classes, and even in backyard sheds, the simple but dependable bench vise manufacturers is an absolutely essential tool in any woodworking process.

Find the bench vise manufacturers you"ve been looking for at a price you weren"t expecting when you take a browse today through Alibaba.com"s wholesale bench vise manufacturers listings. The first port of call for low-cost tool purchases, you can also order multiple tools and enjoy even greater savings.

An essential workbench accessory, this versatile tool is so easy to use; you can even clamp it to a table if necessary. This helpful grip tool holds wood or other materials in place so you can work on it with both hands and with other tools, such as a saw. No workbench should be without a sturdy and robust rotary vise for milling machine and the good news is you can find one for less when you shop wholesale prices. There are many reason shoppers come to Alibaba.com to buy wholesale tools, with buyers made up of construction companies, schools looking to kit out woodwork rooms and even those looking to make a saving on a single rotary vise for milling machine for their own workshop. Many buyers are also woodworking stockists looking to obtain direct prices on large amounts of stock in order to sell on in their own store. Whatever your reason, search now and find a range of bench tools for every budget.

A clamping technique thought to have originated in the Middle Ages. Today the rotary vise for milling machine is a versatile and essential facet of any workshop. Used extensively by wood-manufacturers, carpenters, on construction sites, in factories, in workshops, for woodwork classes, and even in backyard sheds, the simple but dependable rotary vise for milling machine is an absolutely essential tool in any woodworking process.

Find the rotary vise for milling machine you"ve been looking for at a price you weren"t expecting when you take a browse today through Alibaba.com"s wholesale rotary vise for milling machine listings. The first port of call for low-cost tool purchases, you can also order multiple tools and enjoy even greater savings.

Simply put,a tailstock is NOT needed. Because of the compact length, rigid materials and parts held closely to the rotary table face, tailstocks have no effect on performance. We"ve rigorously tested the RotoVise for over four years and have cut aluminum, steel, stainless, cast iron and hardened alloys with excellent results and surface finishes at aggressive feed rates (250-600 ipm depending on material) without the need for a tailstock.

As previously mentioned, we"ve machined aluminum, steel, stainless, cast iron and hardened steels during the two year development of the RotoVise. In fact, most components of the RotoVise are made on the RotoVise! For comparison, we machine the ductile cast iron sliding jaw carriers at 300 ipm, .750" doc and .050" woc with a 4 flute 1/2 inch diameter carbide endmill with amazing results.

The RotoVise is designed to bolt to all brands of rotary tables that use 4 or 6 t-slots platters as well as all Haas Automation UMC models. For best results, only use rotary tables that have integrated pneumatic brakes that provide a minimum of 100 ft-lbs (136 Nm) of brake torque. Manual rotary tables also work well as long as they have a manual brake.

Each jaw station grips with up to 5,000 lbs of clamping force. Let"s think about this... a good conventional 6 inch vise clamps with about 8,000 lbs. With only 3 inch wide jaws, the RotoVise has an equivalent clamping force of 10,000 lbs on half the width compared to 6 inch vises. Furthermore, the RotoVise uses a fine pitch 16 tpi lead screw to exert more clamping force for the same torque input. We"ve designed this to minimize torque placed on the rotary unit without compromising clamping force.

45 foot lbs maximum.The RotoVise uses a finer pitch lead screw (16 tpi) than traditional vises (10 tpi). This means the same amount of handle torque applies 60% more clamping force than a standard vise. For this reason, only the 3-arm handle supplied with the RotoVise should be used because the shorter handles limit the amount of torque applied to the brake and gears of the rotary unit.

The HEGRA Machine Tools Pte Ltd. was established in Singapore in 2010. Our company provides its own brand of high-quality Driven (Rotary) and Static (fixed) Tool holders for CNC machinery centers such as lathes and milling machines.

SAFEWAY, starting with the manufacture of drill index head and lock- down jaw mechanical / hydraulic machine Vise, has become one of the most significant machine Tool providers. Our product portfolio includes metal cutting machine Tools,drilling machines, milling machines,cnc lathes with milling turret, and so on. "Innovation and Service Comes First" is our business philosophy. Hence, we conduct...

NC Rotary Table,Flexible Balance Gripper Jaw Machine Vise,Precision Machine Vise,Tooling Blocks,Super Index Table,Drill Grinding Machine, MC Tilt Table

The Company was established in 1995, specializes in manufacturing hydraulic Vise and accessories for machine Tools. The Vise is uniquely designed and specially constructed, minimum bending can be obtained when maximum clamping force applied. We employ highest quality FCD60 casting as material which can tolerate deforming and bending stress. Its slideway is hardened by heat treatment to reach hardn...

The Company was established in 1991, We specialize in manufacturing precision machine Vise, hydraulic Vise, Drill Re-Sharpening Machine and Machine Tool accessories.

Drill Re-Sharpening Machine,Precision Angle Lock Vise,Hydraulic Machine Vise,Rotary Table,Dividing Head,Cutting Machinery,Universal Cutter Grinder,Milling-Ground Parallels,Air Tapping Machine

MagVise Magnetic Workholding,Electro-Permanent Magnetic Chuck-Connection Type,Lifting Magnet,Drill Grinder & END Mill,Magnetic & Precision Tools (No14),Magnetic De-Burring

Golden State Machinery Co., Ltd., although not the largest manufacturer in this field, is the most energetic specialist with more than 30-year experience in steel clamping kit, drill press Vises and pipe threading hand Tools. In order to meet clientele"s critical specifications, we have teamed up with many skilled sub-contractors with more precision cnc machines and laboratory test equipment. We"v...

NKO Tool INC. is the high-performance solid carbide Tools reputable specialist. We have been engaged in this field for the past 10 years and get good feedback. Through a combination of modern technology and top quality materials we can offer machining Tools meeting all quality standards in major industries such as Die & Mold, Automotive, Aerospace, Medical, General Engineering., etc. ...

Hold Well is one of the leading manufacturers in Taiwan for Accessories of Machine Center, Turning Center, Milling Machine, Grinding Machine with high technical productivity and more than 25 years experience in world market. Our latest main products include: Angle Head (Angular Head, Angle Adjustable Angle Head, Aluninum Angle Head, Heavy Duty Angle Head), VDI / BMT Driven Tool Holder (Axial, Rad...

STANNY MACHINE ToolS CO., LTD. is a principal assembler of high quality and precision machine Tools in Taiwan. Our main products include precision Vise, precision sine bar, precision sine Vise, edm-electrode hold Vise, precise sine table, emery wheel angle dresser, cross travel table, boring head and whatnot. Having years" experience, efficient factory operations and the most sensible R&D team en...

Started from the production of hydraulic power machine Vise, Auto Well Enter. Co., Ltd is now a professional manufacturer of jigs,fixtures,Vises, univer sal Vises, standard Tools for milling machines, standard Tools for grinding machines, hydraulic type, synchronously bi-clamping, moulds & dies, etc. Within the guideline of "Do the right thing, do the thing right," we use cnc and surface grinding ...

AUTO SUPER CO.,LTD. was established in 1987 specializing in manufacturing hydraulic Vises and accessories for machine Tools. The Vises are uniquely designed and specially constructed, minimum bending can be obtained when maximum clamping force applied. We employ highest quality FCD55 casting as material which can tolerate deforming and bending stress. Its slideway is hardened by heat treatment to ...

MC Hydraulic & Angle Lock Vise,MC Mechanical Power Vise,Precision Hydraulic & Angle Lock Horizontal Vise,SELF CENTRING Vise,MULTIGRIP Vises,Max. Opening Hydraulic Vise

The machine is supported by multiple-point force and sturdy. It can overcome the downward twisting force when vertical working disc holds heavy thing(s). Ensure the precision and the life of rotary table.

8613371530291

8613371530291