direct drive rotary table pricelist

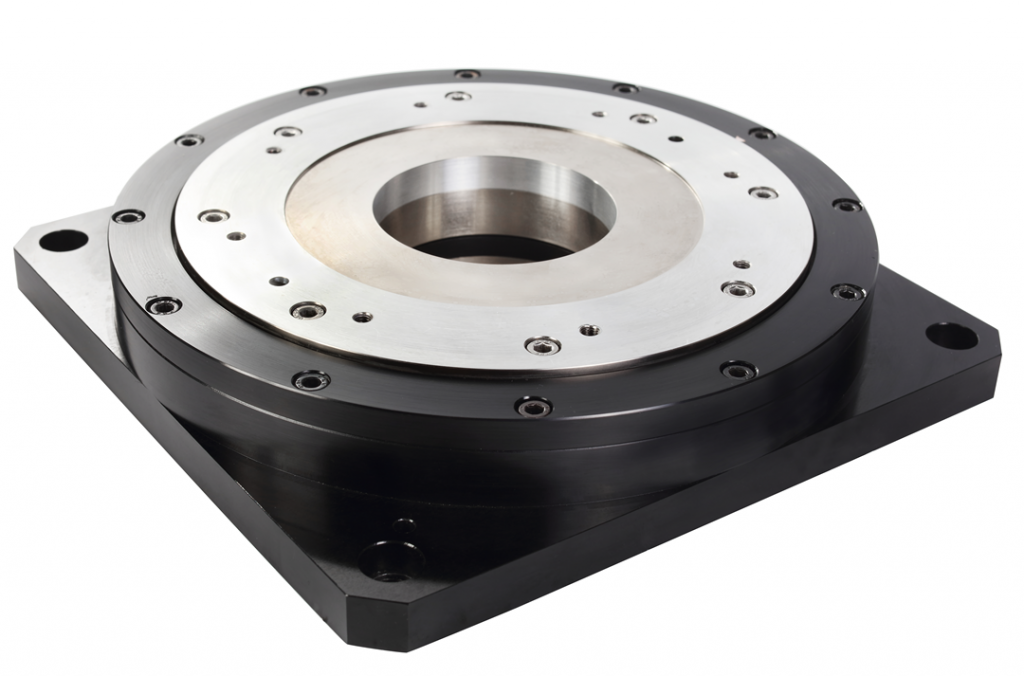

Direct Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion rotary tables.

Thanks to the use of specific bearings, Direct Drive Rotary Table has got to highly rigid and stable characteristics with a low runout of less than 0.015 mm in a very compact form factor.

A strong high torque motor used as the heart of the Direct Drive Rotary Table to make it rapid, stiff and powerful which is being monitored by a high-resolution encoder to reach the real flexibility with high accuracy.

From among other advantages of these Direct Drive Rotary Tables, we can refer to the short time of indexing, their repeatability, their free choice of indexing positions, and their tolerability of extremely high radial and axial torques during rotation and stopping.

Systems based on Direct Drive Rotary Table will surely be free of any defects for a long time, and will not require any repairs. Based on the application requirements, this product can be equipped with internal and/or external clamps.

Direct drive (DDR) rotary tables eliminate backlash and provide a stiff mechanical system for highly dynamic applications. Integrated with precision bearings and ring encoders, these rotary tables provide ultimate performance in rotary indexing applications

CNC Indexing has both pneumatic and hydraulic tables in stock for immediate delivery! Looking for a TJR rotary table price? We have a range of cost-effective options to suit your needs!

For TJR’s pneumatic series of rotary tables, prices start at $5,685. The AR Series is offered in both right hand and left hand motor mount options, with face plate diameter ranges of 125mm – 255mm.

Both the pneumatic and hydraulic brake series TJR rotary table price includes standard features such as an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. For new TJR tables, a standard 3-year parts warranty is included.

The versatile 900 series direct drive rotary tables are particularly suitable for HSC milling, mill-turn machining, modern hobbing (power skiving) or even demanding grinding operations. This transforms a simple and cost-effective 3-axis milling center into a fully automatable, multi-functional 5-axis machine. The housing of the 900 DD series is fully sealed to IP 67 and even rotations of well over 2,000 rpm are no problem. A specially developed Fail Safe system brakes the spindle to 0 within a very short time (e.g. With an emergency stop or power failure) without damaging the rotary table.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

The ACW series features a cogless construction and lean design, with high-precision coding and ultra-precision bearings. Together, this results in our highest performing motor in terms of repeatability and smooth motion.Direct drive brushless motor

The ADR-A series is available with both low and high speed windings and is fully equipped with an encoder and bearing. This series has a high slot fill factor and generates very high torque.Direct drive brushless permanent magnet motor

The ADR-B range performs at a similar slot fill factor and torque density to the ADR-A range, but has a larger center hole compared to its equivalent.Direct drive brushless permanent magnet motor

Similar to the ACD series, the AXM series also features an ironless design and zero noise characteristics. This motor has a compact design, making it ideal for applications with specialized size requirements.Direct drive brushless permanent magnet motor

Roller cam: Compared with worm gears type it is with higher wear resistance, high transmission efficiency , affordable prices and basically maintenance-free of table.

Table directly driven by a motor, high rotary speed , no backlash, no weariness and low inertia. But relatively technical requirement is high and difficulty, the price is the most expensive. Generally used for five-axis machine tools.

Our rotary table can be used in the aerospace industry, 3C high-tech industry semiconductor parts, auto parts and components automation manufacturing, or bathroom equipment and daily necessities manufacturing etc.

The backlash control of our rotary table is stable and reliable, it can be adjusted at the same time and is easy to operate to meet high-precision processing and production requirements, so that it can help customers reduce costs and create more profits.

With modular design concept and engineering, Rotary Production Systems have continued to support and succeed at applications which demand high volume productivity.

We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others

Rotary Tables allow machine shops to increase their production and meet their customer’s demand for quicker lead times while manufacturing increasingly complex components.

Production of a machine shop is restricted by the limited floor space the facility has. Due to this issue, Hyfore Workholding has seen an increase in customers looking to invest in 4th axis and 5th axis rotary tables.

A typical customer would be a CNC machinist who already has a 3-axis machine but is looking for greater flexibility, without having to spend a considerable amount of money on a 5-axis machine. For example, the software, motors, cables and rotary table could cost between £25k and £30k, compared to a new machine starting from £140K.

UCAM’s CNC Rotary Tables are renowned for their quality, reliability and performance. The tilting capability allows components to manoeuvre 360 degrees, so that the cutting tool can machine on all five sides, reducing secondary and third operations in the process.

CNC Rotary tables arean effectivecomponent for increasing production machine shops. Adding an extra dimension to your capabilities at a relatively low cost.

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

Technics SL-1200 is a series of direct-drive turntables originally manufactured from October 1972 until 2010, and resumed in 2016, by Matsushita Electric (now Panasonic Corporation) under the brand name of Technics. S means "Stereo", L means "Player". Originally released as a high fidelity consumer record player, it quickly became adopted among radio and disco club disc jockeys, thanks to the direct drive, high torque motor design, making it initially suitable for pushbutton cueing and starting of tracks on radio and in dance clubs. It is still extremely popular with audiophiles.

When the use of slip-mats for cueing and beat-mixing (and scratching) became popular in hip hop music, the quartz-controlled high torque motor system enabled records to be mixed with consistency and accuracy. A primary design goal was for hi-fidelity, but having good build quality, control over wow and flutter, and minimized resonance made the equipment particularly suitable for use in nightclubs and other public-address applications. Since its release in 1979, SL-1200MK2 and its successors were the most common turntable for DJing and scratching.DJs and MCs refer to the Technics turntable as "the 1s and 2s" and the "Wheels of Steel".

1200s are commonly used in recording studios and for non-electronic live music performance. More than 3 million units were sold. It is widely regarded as one of the most durable and reliable turntables ever produced.

The SL-1200 was the most influential turntable.New York City hip hop DJs in the 1970s. As they experimented with the SL-1200 decks, they developed scratching techniques when they found that the motor would continue to spin at the correct RPM even if the DJ wiggled the record back and forth on the platter.

The SL-1200 Mark 2 was introduced in 1979 as an update to the SL-1200. It represented a culmination of Technics Turntable Innovations. It was dubbed as "The Middle Class Quartz Direct Drive". It soon found its way into discos as well as radio stations for airplay because of its vibration damping ability and resistance to feedback, and eventually it became popular with pioneering hip-hop DJs. Following their established formula, Technics offered different model numbers in Europe: the 1200 (silver) and the 1210 (matte black), which were equipped with switchable dual voltage (110V or 220V) power supplies. Initially, there were only silver models (all named 1200 MK2) in official distribution in Japan and the US (Single voltage of 100V/120V accordingly). However, later the 1200 was available in both silver and matte black finishes (in Japan, the introduction of the MK3 in 1989 marked the first official introduction of a black version). Since 1997, the MK2 had the pitch slide potentiometer changed from 6 pin to 8 pin mounting and from 20k ohm to 22k ohm with part number SFDZ122N11-1, followed by SFDZ122N11-2 both made by ALPS.

The earlier MK2 models 1978-1980 or so also have a different construction in the rubber base of the turntable. Initially, these turntables were made with a base that was completely rubber whereas the newer version has 2 separate parts: rubber outside and a bakelite inlay that is considerably easier to take apart.

These were limited edition versions, with 24 karat gold plated metal parts including tonearm and buttons. Many "non-official" special models of the SL-1200 and SL-1210 appeared over the years, mainly given away as prizes for turntablism, most notably the DMC World Championship, who awarded the winner a pair of 24K gold plated Technics turntables. Due to the customisation trend that has grown in the DJ community, many local events or competitions gave away custom coloured or finished units.

Released in 2004, another limited edition model, with only 3,000 units manufactured. 500 released in Japan with the rest split between the US and International markets. It is based on the MK5G model, with blue (instead of the regular white) target lights, a piano black gloss finish, and gold-plated hardware. It was "created to commemorate the 3 Million turntables sold by technics in the last 30 years".

A Technics SL-1200G turntable with the platter removed reveals the top of the newly designed coreless direct drive motor assembly. In contrast to older models, the platter has no magnet ring on the backside, but is bolted directly onto the motor assembly instead, using three flathead bolts.

Development of a completely rebuilt SL-1200 from the ground up with the intent to create a new system for Hi-Fi use and to redefine the direct-drive turntable reference.

Announced in January 2016 CES in Las Vegas, released in October 2016, SL-1200 Grand Class, an aluminum bound turntable with a high–damping matte magnesium tonearm, a four–layer turntable cabinet, three-layer platter, complete with a microprocessor and the use of a newly developed coreless twin-rotor direct-drive motor with no iron core with rotary positing sensors to eliminate cogging, as well as providing 78 rpm speed compatibility.

Announced in January 2019 CES, the new model inherits the traditional design of the same series in all black and maintains the same operating ease, reliability and durability, while newly adding a coreless direct drive motor and other sound-enhancing technologies. It also features new DJ play functions and features, such as reverse playback, adjustable starting torque and brake speed, detachable terminals for power cable and phono cables (which was previously only available on the MK4 model), an option to select the strobe light indicator from red to blue (the 33/45 lights, 0-pitch reset light and the X2 pitch range light also change to match the color selected), and a new push-type structure for the white LED stylus illuminator.

Two SL-1200M3Ds set up for DJ battle, or scratching, mixing. An Allen & Heath 4-Channel with Effects Mixer sits between the two turntables, allowing shorter travel during battles, or competitions.

The SL-1200 series was developed as a special project by Technics parent company Matsushita in an attempt to solve problems related to turntable design. The task included minimizing acoustic feedback, unwanted resonances, wow and flutter and speed errors. This was achieved by designing a heavy plinth (base) made of a non-resonant composite sandwiched between a cast alloy top plate and a solid rubber base. In addition, the adjustable rubber-damped feet insulated against acoustic feedback, which can be a serious problem when operating a turntable in close proximity to loudspeakers (a common situation for DJs). The underside of the platter is coated with a 1.2mm layer of rubber to reduce ringing and the platter design is reliant on the use of the supplied 2mm rubber mat.

Most users remove the rubber turntable mat and replace it with a slip-mat for mixing. However, without the rubber mat, the platter is prone to resonance at 250 Hz when used near a large club sound system.

The drive system designed by Matsushita is direct-drive rather than the more commonly found belt-drive type, a less expensive design. The direct-drive design, which was developed to reduce wow and flutter, produces a very quiet turntable that, for a direct-drive turntable, has minimal motor and bearing noise, (although the bearing rumble does tend to become characteristic in well-used turntables). This was partially achieved through the fact that the SL1210/1200 made the platter a part of the motor mechanism.

On the underside of the platter a large magnet is placed over the spindle, surrounding the coils and forming the motor drive, thus eliminating loss through power transfer. The SL-1200 utilizes a Frequency Generator Servo Control Quartz Lock system that is claimed to produce the most accurate and consistent speed possible. The system is immune to static and dynamic stylus drag which otherwise cause unwanted speed variances that change the pitch and tempo of the music.

After more than 35 years as a leading manufacturer of analogue turntables, Panasonic has regretfully taken the decision to leave this market. However, Panasonic will continue to sell headphones under the Technics brand.

Panasonic employees who have been working on the analogue turntable range have been redeployed elsewhere within Panasonic - many of them continuing to work in Panasonic"s Audio Video Business Unit.

Due to the increasing popularity of vinyl by DJs, a petition has been underway (and a petition page on Facebook.Technics SL1200/SL1210 series turntables.Panasonic requested. On January 5, 2016 Technics agreed to relaunch both the SL-1200G and the SL-1200GAE

At the 2019 Consumer Electronics Show, Panasonic confirmed future production of a new turntable respectively the SL-1200 Mk7 in matte black, adding new features, fixing known issues with previous models, and all new lighter construction of aluminum and fiber glass.

Direct Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion rotary tables.

Thanks to the use of specific bearings, Direct Drive Rotary Table has got to highly rigid and stable characteristics with a low runout of less than 0.015 mm in a very compact form factor.

A strong high torque motor used as the heart of the Direct Drive Rotary Table to make it rapid, stiff and powerful which is being monitored by a high-resolution encoder to reach the real flexibility with high accuracy.

From among other advantages of these Direct Drive Rotary Tables, we can refer to the short time of indexing, their repeatability, their free choice of indexing positions, and their tolerability of extremely high radial and axial torques during rotation and stopping.

Systems based on Direct Drive Rotary Table will surely be free of any defects for a long time, and will not require any repairs. Based on the application requirements, this product can be equipped with internal and/or external clamps.

8613371530291

8613371530291