direct drive rotary table quotation

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

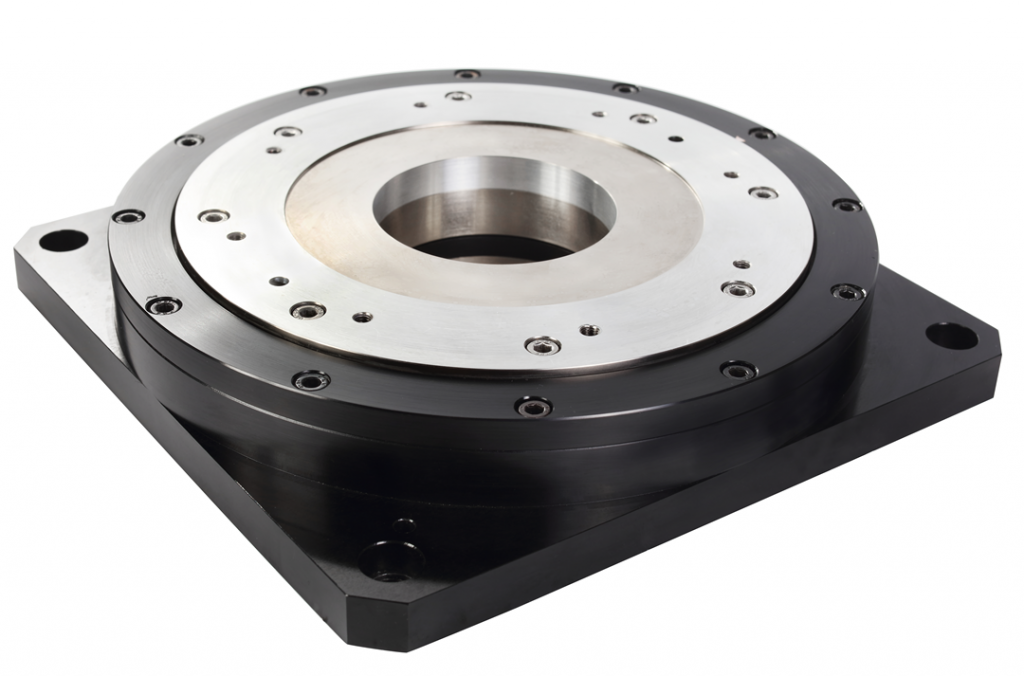

Direct drive (DDR) rotary tables eliminate backlash and provide a stiff mechanical system for highly dynamic applications. Integrated with precision bearings and ring encoders, these rotary tables provide ultimate performance in rotary indexing applications

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

The ACW series features a cogless construction and lean design, with high-precision coding and ultra-precision bearings. Together, this results in our highest performing motor in terms of repeatability and smooth motion.Direct drive brushless motor

The ADR-A series is available with both low and high speed windings and is fully equipped with an encoder and bearing. This series has a high slot fill factor and generates very high torque.Direct drive brushless permanent magnet motor

The ADR-B range performs at a similar slot fill factor and torque density to the ADR-A range, but has a larger center hole compared to its equivalent.Direct drive brushless permanent magnet motor

Similar to the ACD series, the AXM series also features an ironless design and zero noise characteristics. This motor has a compact design, making it ideal for applications with specialized size requirements.Direct drive brushless permanent magnet motor

PI’s direct-drive rotary tables with frictionless, brushless, closed-loop torque motors provide the best combination of high accuracy, high velocity, and maximum service life. PI provides closed-loop direct drive rotary tables with both mechanical bearings and air bearings. Stage models with large apertures and low profile are available. The stage design is optimized for high speed, stiffness, and high load capacity. If completely friction-free and maintenance free motion with virtually unlimited lifetime is required, air bearing rotation tables are recommended. These ultra-precision, high-speed rotary tables provide vibration-free motion with extremely high accuracy and negligible runout, wobble and eccentricity errors. The lack of lubricants makes these also clean room compatible and ideal for any high-performance metrology application in optics, photonics, and semiconductor manufacturing, test and metrology related projects.

In contrast to worm gear driven rotary stages or belt-drive rotation stages, torque-motor direct drive stages eliminate play in gears, couplings or flex in drive belts, providing motion with zero backlash and excellent constancy of velocity, while achieving higher speed than worm-gear drives.

PI’s precision direct-drive, positioning tables can be used in high performance factory automation, research, semiconductor, and laser processing applications. Due to the use of brushless high-torque, motors with direct metrology position feedback, backlash is completely eliminated, and reliability is greatly improved.

With modern direct-metrology rotary encoders, sensor resolution down to 1/100th of a microrad is available on select models with large rotary table platforms, using the high interpolation factors

Based on the high encoder resolution and powerful servo controllers, the direct-drive rotary tables also provide excellent velocity control, which is required in automation applications including high-speed laser processing, indexing, and semiconductor wafer inspection.

Most Direct Drive Rotation stages can be mounted horizontally and vertically, and with combinations all 3 rotary degrees of freedom (3DOF, pitch, yaw, and roll) can be addressed.

Direct Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion rotary tables.

Thanks to the use of specific bearings, Direct Drive Rotary Table has got to highly rigid and stable characteristics with a low runout of less than 0.015 mm in a very compact form factor.

A strong high torque motor used as the heart of the Direct Drive Rotary Table to make it rapid, stiff and powerful which is being monitored by a high-resolution encoder to reach the real flexibility with high accuracy.

From among other advantages of these Direct Drive Rotary Tables, we can refer to the short time of indexing, their repeatability, their free choice of indexing positions, and their tolerability of extremely high radial and axial torques during rotation and stopping.

Systems based on Direct Drive Rotary Table will surely be free of any defects for a long time, and will not require any repairs. Based on the application requirements, this product can be equipped with internal and/or external clamps.

Fitted with 4-point contact preloaded ball bearings, SRT-03 Rotary Table offers low and high speed windings up to 1,000 rpm, 0.2 arc-sec resolution, and 5 arc-sec accuracy. Encoder is mounted directly to rotor for positioning accuracy and to eliminate backlash, positioning delays, and maintenance requirements. Providing peak torque of 10 Nm, table can be used as flexible indexer or to replace mechanical transmissions such as gearboxes and timing belts.

IntelLiDrives, Inc. (www.intellidrives.com) released compact SRT Rotary Table with direct drive servo motor technology (DDR) to eliminate backlash, reduce the number of mechanical components and to provides stiff mechanical system for highly dynamic applications. Pre-tapped mounting holes and a hollow-through shaft permit a variety of machine designs.

SRT-03 rotary tables fitted with precision four point contact preloaded ball bearings. Low and high speed (1000 RPM) windings and resolution to 0.2 arc-sec available.

SRT-03 DDR Rotary Table equipped with a high-accuracy encoder mounted directly to the rotor to provide improved positioning accuracy and to eliminate backlash, positioning delays and maintenance requirements.

SRT-03 DDR (direct drive rotary) can be used as a flexible indexer, providing programmable, rapid indexing far exceeding the throughput of conventional mechanical or variable reluctance technology indexers. It can also be used for replacing mechanical transmissions such as gearboxes, timing belts, and rack and pinion reducers.

The versatile 900 series direct drive rotary tables are particularly suitable for HSC milling, mill-turn machining, modern hobbing (power skiving) or even demanding grinding operations. This transforms a simple and cost-effective 3-axis milling center into a fully automatable, multi-functional 5-axis machine. The housing of the 900 DD series is fully sealed to IP 67 and even rotations of well over 2,000 rpm are no problem. A specially developed Fail Safe system brakes the spindle to 0 within a very short time (e.g. With an emergency stop or power failure) without damaging the rotary table.

The particularly flat and lightweight DMN rotary tables are suitable for all applications in which high rigidity and accuracy are needed along with ...

... assemblies with integrated direct drive (torque motor) are characterized by high dynamics, maximum energy efficiency and a compact installation space combined with center-free design.

Compact package and Superior design of the AccuRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

... Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system working ...

... Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system working ...

While the conventional drives are dependent on an external controller unit, for the compact drives no additional controller is needed. The complete electrical parts, including the drive ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

A Direct Drive Rotary Table is the revolving plate on the rig"s drill floor that turns the drill string in a clockwise path. The Direct Drive Rotary Table surrounds the 4 or six-sided kelly bushing and kelly drive to which the drill string is attached, transferring the power from the rig"s drive machine to the drill string and bit.

The Direct Drive Rotary Table hyperlinks the rig"s electricity supply to the drill string, it may be defined as a seize. maximum rigs have a rotary table because the top mover for the drill string, however, pinnacle power systems that permit continuous rotation of the drill string have changed the rotary table, the kelly bushing and the kelly pressure in some rigs, because of adjustments in trenchless construction requirements.

Direct Drive Rotary Table Production System machines 3 or all the 4 sides of the component in a single set up.Thus gives better productivity. Acts like an integrated system With Faceplate tailstock, base plate, fixture mounting brackets, and fixture plate . Further it gives advantages like Quick in change set-up, flexibility, higher clamping torque due to break on both Rotary table and Faceplate tailstock side. HMC jobs can be done on VMC at competitive machine hour rate. In fact, rotary production system has got modular concept design and drop in rotary union for power clamp.

Methods & Equipment works with several manufacturers of rotary tables: Tsudakoma, Nikken, Yuasa and more. Give us a call or fill out the RFQ if you would like a quote on any of the high speed rotary tables, direct drive rotary table, or the new ball drive rotary table with zero backlash.

The global Direct Drive Rotary Tables market size is projected to reach multi million by 2028, in comparision to 2021, at unexpected CAGR during 2022-2028 (Ask for Sample Report).

The Direct Drive Rotary Tables has several applications, including: Machine Tool,Cnc Rotary Conveyor,Milling Machine,Machine Center,Others. Based on types these are segmented in External Rotation Direct Drive Turntable,Internal Rotation Direct Drive Turntable. The market for Direct Drive Rotary Tables is highly competitive. There are a number of major market players in the market, including Hiwin Technologies Corp.,Rototrans,NIKKEN KOSAKUSHO WORKS, LTD,IntelLiDrives,PI USA,MASTED ASSEMBLY,SOLPOWER Machine Electronics Corp,Yukiwa Seiko Inc.,MMK Matsumoto Corporation. The report provides an expansive market geographical regions analysis by covering areas like North America: United States, Canada, Europe: GermanyFrance, U.K., Italy, Russia,Asia-Pacific: China, Japan, South, India, Australia, China, Indonesia, Thailand, Malaysia, Latin America:Mexico, Brazil, Argentina, Colombia, Middle East & Africa:Turkey, Saudi, Arabia, UAE, Korea.

Key Benefits for Industry Participants & StakeholdersThis Direct Drive Rotary Tables research report gathers the current position and the future prospects of the global market along with various market segments and analytical components.

Through a broad and profound analysis of the global and territorial markets, the Direct Drive Rotary Tables market report has generated different aspects to resolve obstacles and combat the competitive environment.

This Direct Drive Rotary Tables research report provides an expansive market analysis of the desired sector by wrapping areas like growth drivers, trends persisting in the endeavor, regulatory framework prevalent in the sector as well as a comprehensive SWOT analysis.

Sections in Direct Drive Rotary Tables Market Report:Section 1 mainly consists of an overview and an introduction of the Direct Drive Rotary Tables company focusing on the important figures and statistics of the market.

Section 2 comprises numerous marketing methodologies, sales generation, consistency key factors, and the overall growth of the Direct Drive Rotary Tables company.

Section 3 chiefly covers the analysis of the effect of the impact of the Direct Drive Rotary Tables industry on the development and growth factors of the market across the globe.

Section 4 primarily gives pointers on the current and future prospects of the Direct Drive Rotary Tables company along with their culture and regional growth.

Section 7 enlists the benefits of the Direct Drive Rotary Tables company, by providing a full overview of the feasible company verdicts which include SWOT analysis, product profiles, and corporate growth.

Section 10 is the final section of the Direct Drive Rotary Tables market report that summarizes and gives a full stop to all arguments and wrong interpretations by providing the right outcomes to the reader end.

The Direct Drive Rotary Tables research report covers all topics of the company including marketing methodologies, analysis of the growth and performance, and interaction with real-time consumers.

It contains all the components of numerous market ideas, prototypes, product profiles, trends, and figures a user needs to evaluate the growth of the Direct Drive Rotary Tables company.

Another significant subject of this market report is the necessity to grade and evaluate the effectiveness of the Direct Drive Rotary Tables company in the global development of the firm.

In addition to this Direct Drive Rotary Tables research study, it aids in business marketing, business analysis, and overall performance with respect to the competitive field.

The Covid-19 Pandemic has hyped up the reality and has drastically affected the financial and developmental criteria of the Direct Drive Rotary Tables market. These features have shattered the core sustaining pillars of modern world economies. Even to the current date, the economic shock and impact arising from the Covid-19 pandemic are still being weighed. Data information and statistics of the Direct Drive Rotary Tables report remained in flux, and government policies fluctuate to extremes, as the killer virus swept through nations, affecting production, disrupting supply chains, and unsettling the financial markets. The report produced by the Direct Drive Rotary Tables company mainly focuses on and comprises several actions and plans devised by the company to make up for the loss and upskill their profits.

This Direct Drive Rotary Tables study highlights that there is a paradigm shift in the market regarding regional competitive advantages and the competitive environment of comparatively larger companies. The Direct Drive Rotary Tables research report is an extensive study that focuses on overall consumption patterns, development trends, sales figures, and economical crises in key countries of the Direct Drive Rotary Tables market. This report focuses on the well-recognized suppliers of the industry, market components, competition, and macro environment. A complete market investigation is carried out taking into account various factors, from the viability and business cycle of a particular country to the specific microeconomic impact of the market.

Reasons to Purchase the Direct Drive Rotary Tables Market ReportThe market research includes historical and forecasts market data, demand, application details, pricing history, and company shares of the Direct Drive Rotary Tables market by geography.

The research report also mentions the new innovations, profound inventions, latest developments, marketing strategies, and branding techniques, present in the Direct Drive Rotary Tables market.

The opportunities and threats that are ought to arise in the future for the key market players have also been emphasized in the Direct Drive Rotary Tables research report publication.

This Direct Drive Rotary Tables report additionally states import/export consumption, supply and demand figures, demographics, revenue, and gross margins alongside the features of different methodologies to upskill the company’s development.

Rotary stages from Griffin Motion are direct-drive, precision positioning tables designed for laboratory, factory automation, and semiconductor processing equipment. The high-torque, brushless direct-drive technology eliminates backlash and improves reliability by minimizing sliding friction throughout the stage. The large bore allows convenient routing of tubing and cabling for application requirements. Positioning resolution can be selected, with most controls, to meet the needs of the final application.

Aerotech’s ADRT series of mechanical-bearing, direct-drive rotary stages is an excellent choice for applications that require fine precision, smooth motion, rapid accelerations, high speeds, large payloads, or any combination of these.

Dual, large-diameter bearings provide considerable payload capacity and moment stiffness. Combined with a slotless, brushless torque motor, ultra-smooth, high-speed motion is easily achieved. A selection of high-resolution position feedback devices allows for highly accurate and repeatable positioning performance.

ADRT stages are ideal for applications that require very precise rotary motion, combined with high torque, speed, and payload-carrying capacity, including:

Further enhancing stability, the motor and rotary encoder are directly coupled to a common shaft. There are no position errors triggered by hysteresis, windup or backlash because ADRT does not have any gear trains or mechanical couplings.

All ADRT configurations deliver outstanding accuracy, smoothness and runout performance. Additionally, slip rings and rotary unions can be added upon request to ease integration of custom tooling. An optional holding brake is available to limit movement of the stage during large impulse loads or when power is removed from the motor.

8613371530291

8613371530291