hirschmann rotary table for sale

Our product range includes single and multiple axes, tilt/rotating tables, and indexing and high-speed spindles. Additionally, we offer customized solution tables for customer requests or OEM projects.

Even for EDM machines that have been in use for decades, we will work with you to determine the ideal rotary indexing table and/or rotating/indexing spindle solution.

Our state-of-the-art rotary indexing tables and customizable reference and clamping systems provide endless application possibilities and highly efficient solutions.

Our state-of-the-art rotary indexing tables and customizable reference and clamping systems provide endless application possibilities and highly efficient solutions. They are used on wire and sinking EDM machines, HSC machines, and laser equipment for precise angle positioning (index and burn). Our rotary indexing tables can also move simultaneously with one or more machine axes while operating (turn while burn).

All rotary indexing tables can be equipped with a precise clamping system for quick manual or pneumatic change of workpieces. Our sales staff will be pleased to give you any advice you may need, on site if requested.

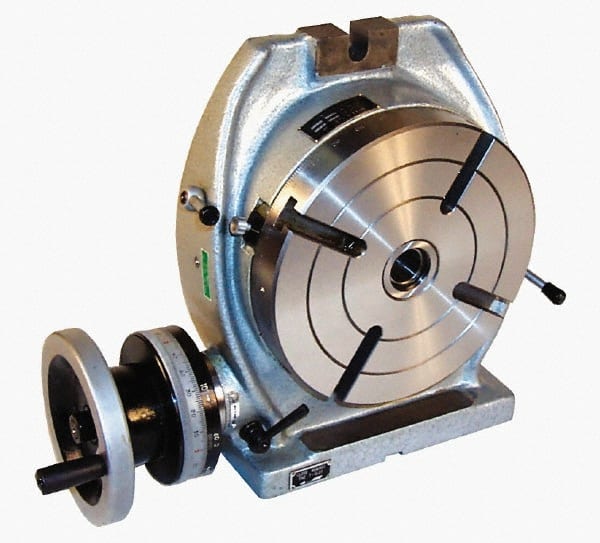

Single-axis rotary index/turn while burn table with a 100 mm diameter faceplate. For vertical use only, with a maximum workpiece weight of 15 kg. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with a 100 mm diameter faceplate. In horizontal use, a workpiece with a maximum weight of 15 kg can be machined. In vertical use, a workpiece with a maximum weight of 25 kg can be machined. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with a 120 mm diameter faceplate. In horizontal use, a workpiece with a maximum weight of 60 kg can be machined. In vertical use, a workpiece with a maximum weight of 40 kg can be machined. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with a 140 mm diameter faceplate. In horizontal use, a workpiece with a maximum weight of 80 kg can be machined. In vertical use, a workpiece with a maximum weight of 120 kg can be machined. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with a 226 mm diameter faceplate. In horizontal use, a workpiece with a maximum weight of 100 kg can be machined. In vertical use, a workpiece with a maximum weight of 300 kg can be machined. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with a 340 mm diameter faceplate. In horizontal use, a workpiece with a maximum weight of 300 kg can be machined. In vertical use, a workpiece with a maximum weight of 1000 kg can be machined. Available in bronzed or stainless steel. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with a 500 mm diameter faceplate. In horizontal use, a workpiece with a maximum weight of 500 kg can be machined. In vertical use, a workpiece with a maximum weight of 2000 kg can be machined. Available in bronzed or stainless steel. Operated via external control or integrated to the machine control.

Single-axis rotary indexing table with either HSK A63 or HSK F63 tapers. In horizontal use, a workpiece with a maximum weight of 30 kg can be machined. In vertical use, a workpiece with a maximum weight of 50 kg can be machined.

Single-axis rotary indexing table with either SK50 or CAT tapers. In horizontal use, a workpiece with a maximum weight of 30 kg can be machined. In vertical use, a workpiece with a maximum weight of 50 kg can be machined.

... RIGIDIAL" rotary tables by COLOMBO FILIPPETTI spa have a globoidal cam which transforms the uniform rotary input motion into an intermittent rotary output motion.

The indexing rotary tables of the "IR" Minindex series by COLOMBO FILIPPETTI spa are cylindrical cam mechanical units that transform the uniform rotary motion of the ...

... heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive to deliver a true 4th-axis ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary control box for ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

The ITP Series are the package version of the IT Rotary Tables. They are equipped with a gearbox and three-phase induction motor for a shorter lead time and fast delivery ...

The TRP Series are the package version of TR Rotary Tables. They are equipped with gearbox and three-phase induction motor for a shorter lead time and fast ...

The FTP Series are the package version of FT Ring Tables. They are equipped withgearbox and three-phase induction motor for a shorter lead time and fast reaction to the market ...

The “HOMGE” PRECISION INDEXING TABLES are constructed with an AIR CYLINDER between the mating surfaces. This system ensures reduces friction when heavy loads are applied to ...

... can shift across the board on the rotary podium due to the pneumostatic air bearing. Additionally, the motorization can change as per the desired angular resolution from 5.120 up to 655.360 ppr.

This is a Servo driven rotary indexing table manufactured by Italplant which has been a study for automation of the whole unit. It comes with a wide range of product such as robot guided ...

G.P.A. Italiana pneumatic rotary indexing tables are available in two versions: TAR 270 and TAR 160. TAR 270 can handle bigger loads, aided by the hydraulic control and double cylinder ...

The NC combines robustness and durability with the advantages of a user-programmable rotary table that offers a high level of torque. This is made possible by the latest generation of servo motor drives ...

The RDH-XS is a rotary indexing table. This industrial component is capable of accommodating high load capacity. A transfer accuracy of <2 minutes of arcRepeatability. The device is manufactured ...

Rotary indexing tables provide an indexing axis for mounting workpieces on machine tools. They are designed to position workpieces at precise angles for different machining operations.

These devices are used on CNC machining centers, lathes, presses and other types of production or manufacturing machines. A CNC milling machine uses a rotary indexing table to provide a fourth or even a fifth axis for certain machining operations.

Such tables can be mounted either vertically or horizontally. The rotary drive can be manual, electric, pneumatic or hydraulic. It uses either a rack and pinion, or a servomotor and gearbox. Some models have multiple rotating tables, providing multi-axis workpiece mounting.

When selecting a rotary indexing table, be sure to determine the mounting orientation: horizontal, vertical, multi-axis and tilting. Other factors are table diameter, maximum load capacity and indexing accuracy.

ISO 9001:2008 certified custom manufacturer of rod ends & spherical bearings, axial shafts, seals, submersible rotary axes & tables for EDM, workholding fixtures, robotic integration, dielectric fluids & grinding fluids. Rod ends & bearings are available in relubricatable or maintenance free versions & in metric sizes ranging from 2mm to 50mm & from 5/16 in. to 3/4 in, & in free-cutting steel, tempered steel, galvanized steel, chromalized steel & stainless steel. Other products include threaded bolts, metalworking fluids, work holding pallet systems for CNC machining, pallet systems for EDM, robotic loading devices, CNC rotary submersible axes, C axes & tool-changers for the machine tool industry. Serves various industries including aerospace, agricultural machinery, bakery machines, driving machinery, engine building, filling machine, hydraulic cylinders, machine tools, pneumatic cylinders, printing machines & welding machines. Meets DIN ISO 122404 & Cetop standards.

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation.

Quad-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard.

:quality(90)/images.vogel.de/vogelonline/bdb/1072500/1072570/original.jpg)

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

From spherical rod end bearings, rotary tables, clamping systems, axial shaft seals, oelheld UK can supply the full Hirschmann range which offers excellent workholding systems at competitive prices for EDM processes. Read on for system details or get in touch with our technical team on 01745 814 777 to discuss your requirements.

System 5000 - Workholding solution for conventional EDM and milling / electrode manufacture applications. Ease of manufacture and precision are the key to successful, profitable use of EDM machines and the Hirschmann System 5000 offers both with a repeatability of 0.002mm across its whole range. Electrodes are transferred from milling to grinding then used in EDM without the need for continuous checking of datums.

Submersible Rotary Spindles - For EDM Turn & Burn / indexing and EDM Turning applications. Carl Hirschmann have been producing rotary spindles for EDM for more than 40 years. A variety of specifications are available depending on workpiece size and application.

Rotary Spindles for Special Applications - The use of Polycrystalline diamond (PCD) as a material for the production of cutting tools in constantly increasing. The complex geometries required for this type of cutting tool can present great difficulties for standard production techniques which wire erosion processes can overcome. The addition of a high specification systems such as the Carl Hirschmann servo controlled A Axis which is suitable for use in submerged environments can quickly and effectively give a standard wire EDM machine PCD capabilities.

Lyndex Nikken – Hydraulic Chucks & Toolholders, 3 Jaw Chucks and Angle Heads, Rotary Tables, Live Tools for Turning Cneters, Shrink Fit Machines & Holders, Precision Collets

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis

The report focuses on the Rotary Tables market size, segment size (mainly covering product type, application, and geography), competitor landscape, recent status, and development trends. Furthermore, the report provides detailed cost analysis, supply chain. Technological innovation and advancement will further optimize the performance of the product, making it more widely used in downstream applications. Moreover, Consumer behavior analysis and market dynamics (drivers, restraints, opportunities) provides crucial information for knowing the Rotary Tables market.

The report can help to understand the market and strategize for business expansion accordingly. In the strategy analysis, it gives insights from marketing channel and market positioning to potential growth strategies, providing in-depth analysis for new entrants or exists competitors in the Rotary Tables industry.

Based on the Rotary Tables market development status, competitive landscape and development model in different regions of the world, this report is dedicated to providing niche markets, potential risks and comprehensive competitive strategy analysis in different fields. From the competitive advantages of different types of products and services, the development opportunities and consumption characteristics and structure analysis of the downstream application fields are all analyzed in detail. To Boost Growth during the epidemic era, this report analyzes in detail for the potential risks and opportunities which can be focused on.

Chapter 1 provides an overview of Rotary Tables market, containing global revenue and CAGR. The forecast and analysis of Rotary Tables market by type, application, and region are also presented in this chapter.

Chapter 3 introduces the industrial chain of Rotary Tables. Industrial chain analysis, raw material (suppliers, price, supply and demand, market concentration rate) and downstream buyers are analyzed in this chapter.

Chapter 6 provides a full-scale analysis of major players in Rotary Tables industry. The basic information, as well as the profiles, applications and specifications of products market performance along with Business Overview are offered.

Chapter 7 pays attention to the sales, revenue, price and gross margin of Rotary Tables in markets of different regions. The analysis on sales, revenue, price and gross margin of the global market is covered in this part.

Chapter 10 prospects the whole Rotary Tables market, including the global sales and revenue forecast, regional forecast. It also foresees the Rotary Tables market by type and application.

Their innovative rotary indexing tables with coordinated reference and clamping systems optimize machine runtime and increase profitability. As a complete supplier, they develop specific solutions exactly according to your ideas. In addition, you can choose from a comprehensive standard range of suitable components.

They supply everything out of one source: from design, development and production to assembly in the metal-cutting machine. With decades of experience and sophisticated engineering, Carl Hirschmann is the leading manufacturer of rotary indexing tables, A-axes as well as rotating and indexing spindles including clamping systems for EDM technology or for EDM machines.

Anyway, to answer your questions, I looked up the Hirschmann table you referenced and it looks to me like it"s a spinner and indexer, not a turn while burn table.

Hirschmann must have a similar provision to integrate their turn while burn capable tables to whatever machines they are going to be run on...I don"t think you can just buy one and bolt it to a machine without the interface kit to mate it to the control.

Turn while burn requires that the controller governs the rotary motion; this is because the rate of rotation has to be driven by the spark gap conditions in conjunction with the axis motion of the rest of the machine whether it"s X or Y or U or V.

It was faked by tilting the wire to an angle other than the thread helix angle with the U axis, then driving a fine pitch helix with B and X (B is the rotary axis on my machine).

You can imagine just how many passes that would take (a LOT), and you will always have a 0.005" radius at the junction of each flank and the root, which may or may not be acceptable depending on the application.

8613371530291

8613371530291