rotary table tailstock manufacturer

The answer depends on the length of the piece. For short-length pieces, you can get by without a tailstock. However, a tailstock for long, slender pieces — such as a rifle barrel — a tailstock is vital to ensure accurate machining without distortion or chatter. Read more

The center of the tailstock is aligned with the center of the spindle if it comes from the factory. If the tailstock is added to a rotary table, the center height of the tailstock is matched to the center height of the rotary table. If you want to check the alignment, you would use an indicator sweep of the tailstock quill. Indicators can be mounted to either the lathe spindle or the rotary table faceplate. Tailstocks can be adjusted side to side, but if the center height is off you will either need to add shims if it is low or remove material if it is high.

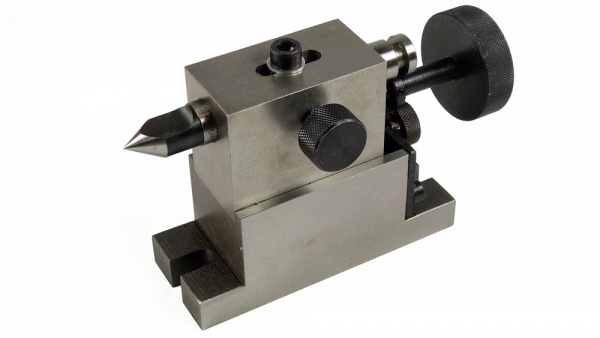

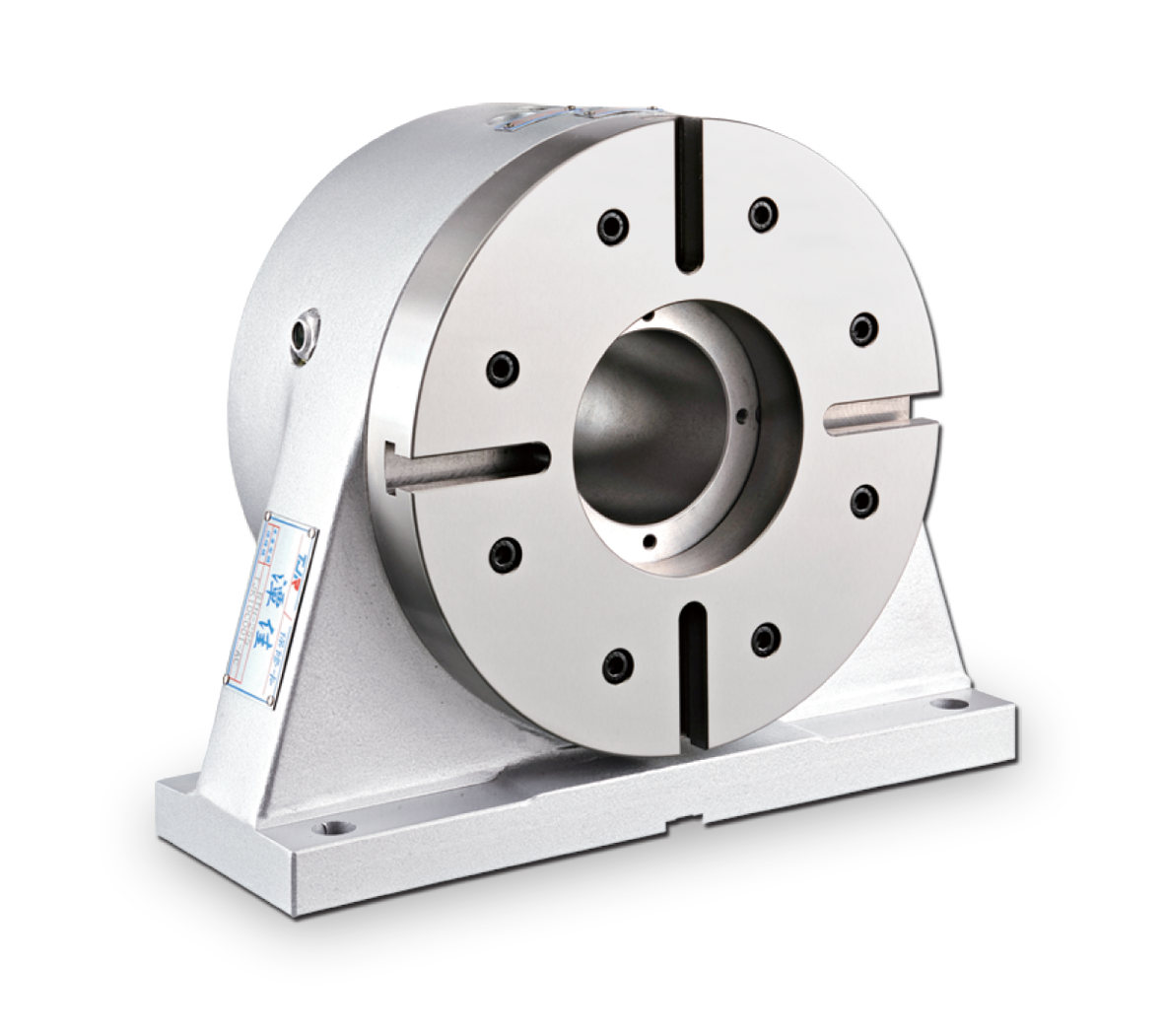

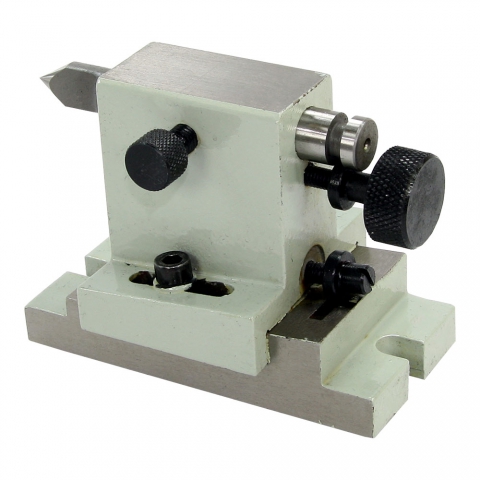

There are manual, hydraulic, pneumatic tailstocks, and there are tailstocks with built in live centers. In the case of rotary tables, you can also get a heavy duty tailstock which looks more like a another rotary table to support heavy parts.

There are dead centers and live centers. Dead centers that do not turn are almost always used on manual machine tools or rotary table tailstocks. Live centers, with built in bearings, are commonly used on CNC machines and where higher RPMs are required.

A support table (on one side) of the rotary tailstock is usually used together with a connection plate and the 4th axis rotary table (on the other side). The rotary tailstock support can be equipped with Pneumatically Brake, Hydraulically Brake, or No Brake.

1. The selection of manual tailstock or rotary tailstock shall be determined according to the characteristics of the workpiece, which is not difficult to select. Please note that it must be consistent with the center height of the four axis rotary table.

2. The rotary tailstock is generally used with L block, connecting plate, chuck, hydraulic station and other accessories. Please check the details of other accessories.

The adjustable right angle tailstock supports the end of long stock held in the rotary table when it is in the vertical position. This allows you to accurately rotate a part between centers for milling or drilling operations.

Because of “tolerance buildup” in the various parts used to place the rotary table in the 90° position, it is not possible to build a tailstock that would come out exactly on center each time. By using a split base design with slightly oversize holes, the height of the tailstock center is adjustable slightly. Once set to exactly match your rotary table/right angle attachment combination, it should not need to be readjusted. It will work with both the Right-Angle Attachment and the Tilting Angle Table in the 90° position.

☆ A tailstock, is a device often used in conjunction with a rotary table on a milling machine and to give support to round job on conventional machines. It used to apply support to the longitudinal rotary axis of a work piece being machined. A Tailstock is particularly useful when the work piece is relatively long and slender.

We are Designer, Manufacturer, Supplier of superior quality Faceplate Tailstocks. It is used to support long work piece or fixture on a rotary table during the machining process

The exit of the MT4 TAPER is operated hydraulically by means of buttons (or pedal) that activate the exit and withdrawal of the mt4 taper. The tailstocks can also be operated by CNC with relative “M” codes.

8613371530291

8613371530291