lehmann rotary table price

The Lehmann EA-520 is an ideal mid to large size VMC, drilling or tapping centre device with a centre height of 180mm and a spindle nose of around 130mm which can accept a whole host of accessories directly. There are options of increased gear precision versions, raised centre height to 220mm, chucking options and rotary couplings to meet any demand, so please contact our sales department to discuss your exact requirement. This device in the first instance is a vertical and horizontal device with the motor mounted to the left (right hand mount motor version is available) options for a raised backmount motor, which can be found under product code EA-520. OL. An excellent carrying capacity of 400kg vertically and 800kg between centres and speeds up to 50rpm dependent on motor selection. The Lehmann EA-520 CNC rotary table without motor, can be prepared to suit any interface at additional cost (see our interface listings for details and costs for “external interface” – motor, switch, cable and connector requirements if you already have a “4th axis interface” in the machine) and machine interface costs (if you do not have the additional axis fitted). Motor is mounted to the left hand side on this device and may restrict the Y axis capability in certain circumstances, the standard centre hole of 46. 55mm is available should you want to machine long bar components that need to be mounted through the centre. Alternatively the unit can be supplied with an HSK-A63 / KK5 spindle with a 64mm bore. The Lehmann products now come fitted with their own “Lehmann blackBOX” which allows for instant user monitoring of the device, showing the status of all switches, valves, the 24V supply condition, a service light to indicate when the device requires a service. In addition, remote monitoring is possible via a USB connection. The Lehmann devices are modular and can therefore be constructed as multi-spindle devices or built into 5 axis assemblies in various configurations.

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

2 Lehmann NC dividing heads with sliding slides. Both dividing heads were mounted on a manual milling machine. Have worked perfectly until the end. Complete with control, operating instructions.

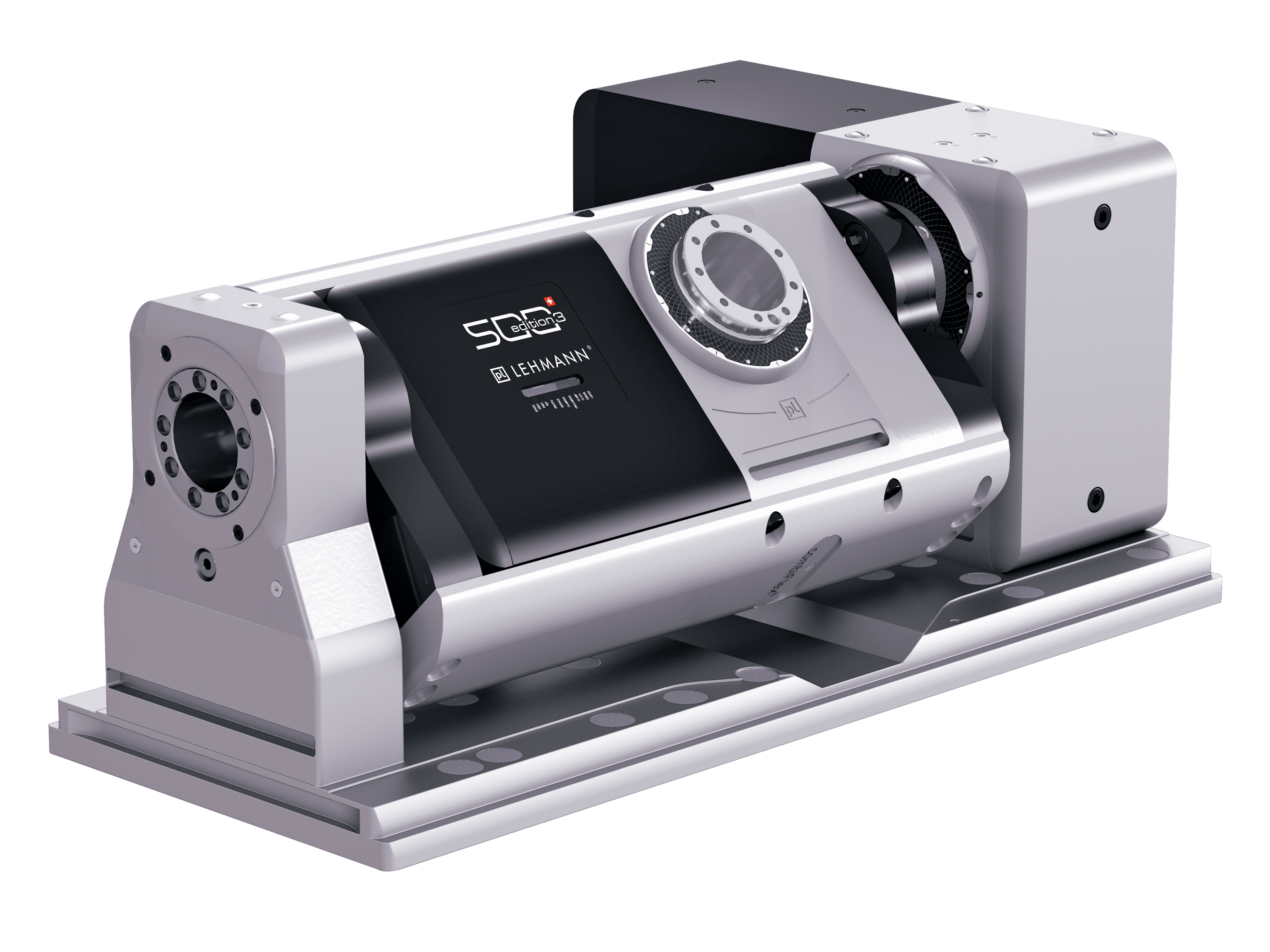

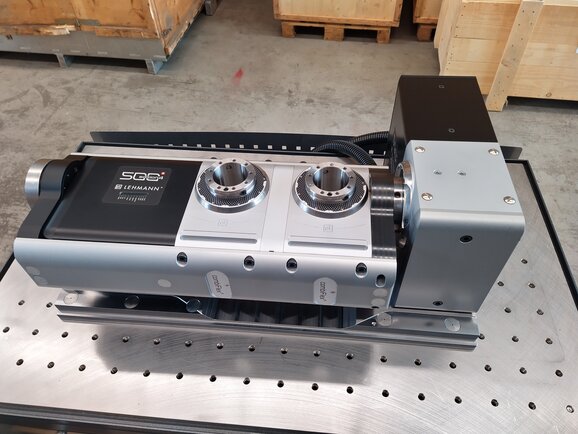

Complete With DMG MORI 19" SLIMline Multi Touch 45 Degree Control Panel with Siemens Package & Pendant; Max "X" Axis = 800mm; Max "Y" Axis = 560mm; Max "Z" Axis = 510mm; 4th Axis Lehmann 500 Series, Edition 3 Rotary Table; Max Workpiece Length 1100mm; Max Workpiece Length 560mm; Max Workpiece Height 630mm; Max Weight 800kg; Field Force 5KN; (30) Tool Storage/Pockets, 80/125 Double Gripper; Single Spindle, BT 40 Taper.

Extremely dynamic short circuit protection, therefore excellently suited for rugged industrial use with high Schalthaeufigkeiten, electrical loads and harmonic components. Stable boiler. Reduced losses (Po / Pk between BA "and A-C"). Available with outer-cone Elastimold Steckdurchfuehrungen, of course, also with HV / LV-sided porcelain execution.

These devices can be called up via our online database with individually printable data sheet. The database has an internal search function and is maintained on a daily basis.

Our large range of 4th and 5th axis rotary tables manufactured in Switzerland by pL Lehmann are both innovative and of the highest quality. The modular system lets you build up axis with standard products to cater for the growing needs of your business. Designed to work with almost any machine tool or control, we can offer a full installation and service package to our customers.

The innovative design of Lehmann rotary tables offer a high speed, backlash free indexing motion with higher clamping torque than any of its competitors. This is also achieved with one of the smallest footprints on the market give customers more room for second operation Workholding on the machine bed.

Word soon spread within the F1 community regarding CNC Techniques range of capabilities and Mr Eden’s fledgling business quickly established a loyal customer base. The mainstays of CNC Techniques machining capabilities are its high-performance Hurco 3-axis and 5-axis machine tools. To provide an additional 2-axes to the company’s 3-axis machines and to add greater machining flexibility, CNC Techniques recently invested in a rotary table solution from Lehmann.

“Although we are kept busy throughout the year, our workload more than doubles in the traditionally busy F1 months of December through to February. Therefore, at this time of year, apart from working around the clock, we need to work smarter and employ equipment that provides greater flexibility. The need for machining flexibility and the requirement for an additional 2-axes on our Hurco VMX 30, 3-axis machining centre, were the major motivations behind the recent rotary table purchase.

“Even though I was aware of the excellent reputation of Lehmann products, I was open to the idea of purchasing alternative brands of rotary tables. Although, when compared to the indifferent response I received when I contacted some other manufacturers, the reaction I had from Lehmann was first-class. All of my questions were answered quickly and several constructive suggestions were made by the company’s technical staff.

“In addition to giving us the ability to achieve five-sided machining in a single setup, I was assured that a Lehmann rotary table would withstand the high forces involved in machining exotics and also deliver the standards of precision we need.

“The installation of the rotary table was carried-out by a couple of knowledgeable technicians who made all of the connections to our Hurco VMX 30 3-axis machine tool’s control system,” he adds.

“Then, whilst observing the rotary table’s try out I realised how easy it was to operate. We now use the rotary table along with our Lang Technik workholding. In addition to standing up to the machining forces used to machine exotics, the rotary table is simple and fast to operate and is making a significant contribution to our 3+2 axis machining capabilities.”

Increasingly, users of 3-axis VMCs are fitting Lehmann CNC rotary tables to their machines as they represent a cost-effective means of entry into 5-axis machining. When mounted in a VMC, the tables are able to deliver a tilting A-axis and/or a rotational C-axis.

Given the compact nature of Lehmann CNC rotary tables, they allow workholding devices to be located alongside them inside VMCs. If required they are able to remain in the machine, or they can be quickly removed and later replaced according to the machining jobs being carried-out.

By locating workholding beside the a compact Lehmann rotary table, a virtual 6-axis condition can be achieved. For example, following the five-sided machining of a workpiece held on the rotary table, without a break, machining can be undertaken on the next workpiece in a batch that is held in the neighbouring workholding.

As floor space is at a premium in most machining environments, mounting a CNC rotary table inside an existing 3-axis VMCs provides a major advantage over purchasing a large 5-axis machine tool. In addition, the cost of the table is a mere fraction that of an expensive new machine tool

Lehmann has been designing and manufacturing high-quality rotary tables for more than 40 years. The experience and expertise gained over this time is reflected in the quality of the company’s advanced products and in its exemplary levels of service.

To minimise parts and to enable the delivery of Swiss quality at a cost-effective price, Lehmann rotary tables are based on an innovative, standard modular system. This highly efficient approach allows a wide range of CNC rotary table options to be made available to meet all customers’ diverse needs.

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Europe and America: the best selling brands in the Chinese market are Haas and Lehmann. Haas is mainly configured on its machine tools, other brands of machine tools are rarely installed. Lehmann is positioned at the high end and mainly cooperates with some high-end machine tools. In addition, it is also used in some occasions with high accuracy requirements, but the demand is small

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

This is an accurate designed table for milling, boring and other machine tools. This table allows indexing, facing and other work to be carried out rapidly with extreme precision. Tiliting range 0-90 degrees fromread more...

8613371530291

8613371530291