lehmann rotary table pricelist

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

The robust geared rotary tables of the 500 series are extremely flexible to use and, thanks to the combiFLEX® modular system, can be converted or extended at any time to meet new machining tasks. The rotary tables are not only suitable for positioning operation, but can also be used for short simultaneous machining operations. The preloaded gear and the powerful bearings allow high long-term accuracies as well as large spindle loads. The maximum clamping force of up to 7,000 Nm leaves hardly anything to be desired.

A recently installed pL LEHMANN CNC rotary table is enabling a Bostomatic high speed milling machine belonging to Thomas Keating Toolmaking Ltd to perform highly efficient 5-axis machining.

Due the demanding nature of the machining undertaken when manufacturing scientific instruments, rather than invest in a 5-axis machine tool, the company recently took a more ‘bespoke’ route. Having decided that a pre-owned, 3-axis Bostomatic milling machine had the ideal, stable machine structure to support the company’s challenging 5-axis work, the machine was comprehensively re-built and fitted with a Heidenhain TNC640 5-axis controller by ACC Systems Ltd. To complete the Bostomatic’s conversion to 5-axis work, company Managing Director, Dr Richard Wylde searched for a suitably accurate and flexible CNC rotary table. The answer was found in an advanced pL LEHMANN T1-507510.LL TAP1 model.

«We are constantly searching for ways to improve our capabilities, hence the recent Bostomatic machine tool, Heidenhain control and Lehmann rotary table purchase. When judged against the alternatives that I considered, the pL LEHMANN T1-507510.LL TAP1 rotary table best met our exacting technical criteria and also represented excellent value for money. Now installed in our re-built Bostomatic machine, it is in daily use and is helping us to perform exceptionally accurate and highly efficient 5-axis machining.»

«In addition to the advantages the rotary table has provided to our tool making activities, it has proven extremely useful when we manufacture our high-precision scientific instruments. For example, we are currently involved in the production of the next generation of satellite-based weather prediction instruments. The precision 3+2 axes capabilities provided by our Lehmann rotary table have been invaluable when undertaking this challenging work.»

«Equally, when recently manufacturing thin, metal film coated dielectric mirrors for use in Dynamic Nuclear Polarization instruments, the use of our new rotary table enabled our complex 5-axis machining tasks to be performed with ease. In addition to delivering 5-axis capabilities our new Lehmann rotary table has considerably increased our manufacturing speeds.»

«So successful has our use of a Lehmann rotary table been when used in our Bostomatic machine tool, we are currently in the process of purchasing another Bostomatic machine that will be fitted with a second Lehmann rotary table.»

t is estimated that 90% of machining procedures carried out by 5-axis machining centres are basic five-sided processes. Therefore, the fitting of a CNC rotary table, that costs a fraction of the price of a 5-axis machining centre, to an existing 3-axis VMC, represents an excellent alternative way of achieving 5-axis capabilities. It also results in a rapid ROI.

pL LEHMANN’s advanced CNC rotary tables are based on an ingenious modular design concept that enables a range of high-quality standard components to be used to produce a comprehensive series of product variants. Each of the company’s rotary tables can be further refined according to customers’ specific needs. This innovative approach provides pL LEHMANN’s customers with several major advantages. For example, rather than accept a ‘nearest-fit’ rotary table solution, pL LEHMANN’s customers are able to receive a CNC rotary table that exactly matches its intended use. In addition, efficiencies gained by pL LEHMANN’s modular approach allows the delivery of Swiss quality products at affordable prices.

The advanced designs and relatively small footprints of pL LEHMANN’s rotary tables ensures that, when installed in VMCs, such as Thomas Keating Toolmaking’s Bostomatic machine, they occupy minimum bed areas. As well as freeing-up room for the fitting of additional vices and other workholding devices, the space-efficient nature of the rotary tables means that, when a VMC is not undertaking 3+2 axis work, they are able to remain inside the machine when 3-axis machining is being performed. Furthermore, the compact size of pL LEHMANN’s CNC rotary tables helps to take full advantage of the available working volumes of the machine tools that they are fitted to.

pL LEHMANN’s heavy-duty rotary tables have earned a global reputation for their outstanding quality and longevity. The company’s robust products benefit from excellent clamping torque, load weight and accuracy specifications. In addition, pL LEHMANN CNC rotary tables are able to interface with the vast majority control systems.

On website of FAMAGA you can buy , and many other spare parts from the Lehmann Rotary Tables with delivery all over the United States United Arab Emirates, India, Iran, Saudi Arabia, Pakistan, Turkey, Uruguay, Myanmar, Antigua and Barbuda, Madagascar, Indonesia, Togo, Belgium, Gambia, Cote d\"Ivoire, Guinea-Bissau, South Korea, Nepal, South Africa, Brunei, Namibia, El Salvador, Netherlands, Japan, China, Panama, Spain, Slovenia, Venezuela, Bulgaria, Moldova, Azerbaijan, Belarus, Bahamas, Liberia, Kuwait, Lithuania, Lebanon, Germany, Jordan, Guyana, Malaysia, Sri Lanka, Senegal, Vietnam, Dominican Republic, Russia, Chad, Malawi, Papua New Guinea, San Marino, Cambodia, Czech Republic, Macedonia, Australia, Grenada, Tanzania, Belize, Zambia, Cyprus, Luxembourg, Tunisia, The Gambia, Lesotho, Turkmenistan, Andorra, Qatar, Sierra Leone, Uganda, Benin, Argentina, Israel, Liechtenstein, Mongolia, including: Los Angeles.For price list, delivery timings and other product features of the Lehmann Rotary Tables, please, fill in the feedback form or send a description of goods you need to our e-mail [email protected]

If you want to get Lehmann Rotary Tables EA-510.L, additionally require other industrial equipment and replacement parts for its fix, please connect FAMAGA United Kingdom, United States, Netherlands, Germany, France, Ireland, Bosnia and Herzegovina, Côte d\"Ivoire, Lebanon, Philippines, Paraguay, Iraq, Thailand, Brunei, Laos, Swaziland, Dominica, Indonesia, Antigua and Barbuda, Italy, Malta, Luxembourg, Vietnam, Angola, Kenya, Mali, Eswatini, Sudan, Grenada, Hungary, Suriname, Spain, Switzerland, Jamaica, Cameroon, The Gambia, Japan, Mauritania, Egypt, Denmark, Equatorial Guinea, Belarus, Cape Verde, Madagascar, Turkmenistan, Bahrain, Uzbekistan, Yemen, Armenia, Niger.

We have been distributing Lehmann Rotary Tables units all around Great Britain and anywhere in the planet for over 10 years. All machinery and components are provided with appropriate quality certificates, as well as a guarantee from the official producer of products Lehmann Rotary Tables.

To clear up the value of Lehmann Rotary Tables EA-510.L and delivery times, you can fill out a special filling form on our website, send a list of necessary instruments by E-mail or call to the indicated phone numbers. We will be able to create the best commercial offer for you and prepare prompt supply times to any city in Great Britain and any country in the planet.

Customers fundamentally expect high precision and quality from Swiss machining service providers. To be able to meet these expectations at marketable prices, service providers need not only machining know-how but high-performance machinery as well. Appenzell-based AITech AG reveals how, together with suppliers pL LEHMANN and Schunk, it has turned a three-axis DMG standard machining center into a «marvel» of flexibility that reduces tooling times to the absolute minimum too.

To that end, AITech employs two horizontal 4-axis machining centers automated with pallet systems. When, in 2020, two vertical milling machines had reached the end of their useful life and had to be replaced, Bösch wanted to see multi-point clamping and complete machining implemented here as well. He envisioned a three-axis vertical milling machine equipped with an additional rotary axis: «Because the four axes allow us to machine workpieces on five sides, and even clamp round parts and machine their lateral surface at the same time where necessary.»

So Bösch and his milling technology team decided to invest in a DMG MORI CMX 1100V. The three-axis drilling-milling center offers high stability and good accessibility thanks to its C-frame concept. The high degree of precision required is guaranteed, among other things, by a direct displacement measurement system; the positioning accuracy is 6 µm on all axes. «The large machining range is also important for us, especially the X travel of 1100 mm,» emphasizes Thomas Bösch. «Although we very rarely have workpieces that long, this allows us to set up an additional rotary table in the work area and install even more vises or special fixtures for multi-point clamping next to it,» he says, explaining his basic idea.

First and foremost, the precision machinists wanted their new milling center to be completely flexibility in terms of component diversity. The idea was to reach this goal by means of an integrated CNC rotary table and flexible clamping technology. When it came to the rotary table supplier, there was only one choice for AITech – pL LEHMANN from the Swiss town of Bärau. Thomas Bösch had worked with products from this rotary table specialist in the past, experiencing only the best in terms of quality and precision. The preferred supplier for the clamping systems was Schunk. The background: AITech has always purchased its vises from Gressel AG, which has been part of Schunk GmbH & Co. KG from Lauffen, Neckar since 2014. In Switzerland, the two clamping technology specialists work closely together at the Aadorf site.

pL LEHMANN and Schunk gathered at AITech to collect and evaluate ideas and ultimately develop a concept to guarantee the shortest possible tooling times and maximum flexibility.

The details were discussed there and then. The pL sales manager for Switzerland suggested the EA-520.L-M1 rotary table version, a model that perfectly matches the machine and the intended machining spectrum in terms of drive power, clamping forces and precision. The pL rotary table needed to operate as a separate axis when required, but also together with a bridge plate or a tailstock. Not a problem for pL LEHMANN. The product range includes standard additions such as rotoFIX bridge plates and the longFLEX tailstock. However, the company is also open to special requests: pL LEHMANN offered to make the tailstock movable, and did in fact do so.

Point 1: The EA-520 pL rotary table is attached to the machine table by two Gressel gredoc zero-point clamps. If needs be, it can be completely removed in less than 15 minutes and reinstalled without lengthy calibration procedures. «This doesn’t happen too often,» admits Ettemeyer, «because we positioned it at the very edge of the table, beyond the traversing range of the X-axis. As a result, it leaves enough space for several vises or fixtures for multi-point clamping and can remain on the machine most of the time, even when it is not needed.» That said, the rotary table did have to be removed several times last year. According to Ettemeyer, this made the relatively small additional financial outlay for the zero-point clamps worthwhile.

omationPoint 2: The vises, multi-point clamping devices, counter bearings and tailstock are also fixed to the machine table with a zero-point clamping system. The choice fell on a VERO-S eight-point clamping station from Schunk. The pneumatic system proposed by the regional sales manager of the Swiss sales office SCHUNK Intec AG appeared to be the best solution for all parties involved.

This is a spring-loaded system, opened pneumatically at an actuating pressure of 6 bar. The clamping station is suitable for holding all common clamping pallets as well as clamping devices with the associated gage. Because AITech also wanted to keep the automation facilities flexible, Schunk met the special request of controlling the chucks in pairs, as opposed to the standard version of using a single cable to control the overall system.

The fact that a total of two different zero-point clamping systems were selected is down to the diverse requirements to be met. The clamping of the pL LEHMANN axis on the machine table mentioned above can easily be handled by the gredoc mechanical zero-point clamping system, a system set apart by low overall dimensions, high precision and a very good price-performance ratio. Besides the gredoc double clamp for mounting on the machine table, AITech uses a single clamp of the same model for the spindle of the pL LEHMANN rotary table. With its 20 kN of pull-in force, this zero-point clamp is the perfect solutions for such applications. It allows machine operators to interchange a three-jaw chuck with the adapter flange for the rotoFIX bridge plate and vice versa in no time at all.

This QR code can be used to call up an animated graphic showing the flexible use of the EA-520 pL rotary table in combination with zero-point clamping systems.

… the Swiss manufacturer of CNC rotary tables and other components for metal machining, is an experienced machine construction company, whose rotary and swivel axes have proven their worth in production for over 40 years. In addition to these products, which often make three-axis drilling and milling machines into more productive four- or five-axis machining centers, you can also find a variety of workpiece clamping systems in the product line.

Founded in 1960 strictly as a contract manufacturer, pL LEHMANN has been developing and producing CNC rotary tables for over 40 years. With innovations and Swiss quality, the family-owned company in the Swiss town of Bärau (Emmental) succeeded in opening up new opportunities for its customers and developing lean machining solutions characterized by high productivity through use of additional NC axes. One of the highlights of the company’s history is the powerful and flexible Series 500 – developed in 2009 – which is ideal for the most demanding tasks thanks to its modular design. With the backlash-free, preloaded PGD gear unit – developed in 2014 – pL LEHMANN reached another milestone. In 2017, the company introduced, among other things, the new pL-iBox generation, making their rotary tables ready for Industry 4.0 and digital production. This was followed in 2019 by the introduction of the Series 900 DD (Direct Drive) rotary tables with speeds of up to 5,450 rpm. As an additional new product, the AM-LOCK system, a special zero-point clamping system for 3-D printing, including preprocessing and postprocessing, was presented for the first time in 2019.

The key to high flexibility and shorter tooling times: the pL LEHMANN EA-520 CNC rotary table mounted on the far right edge of the machine table (shown here with rotoFIX bridge plate), combined with zero-point clamping systems from Schunk and Gressel.

New at AITech: the DMG MORI CMX 1100V three-axis drilling-milling center, upgraded by the pL LEHMANN EA-520 CNC rotary table and a broad range of accessories (in the foreground, the movable tailstock, the adapter flange for the bridge plate, its counter bearings and the three-jaw chuck that can be mounted via the gredoc zero-point clamping system).

Thanks to the large machining range (X-travel of 1100 mm), the pneumatically releasable eight-point clamping system VERO-S from Schunk can be mounted next to the pL rotary table. This prepares the machine for robot loading.

With its 20 kN of pull-in force, the gredoc zero point clamp is perfectly suited to the rotary table spindle – shown here with clamped adapter flange for the rotoFIX bridge plate. A quick changeover to the three-jaw chuck is guaranteed.

The pL rotary table EA-520.L-M1 is a perfect match for the machine in terms of drive power, clamping forces and precision. It also allows heavier machining operations.

The longFLEX tailstock supplied by pL LEHMANN is placed on the VERO-S zero-point clamping system. In order to adjust the position to the length of the component to be supported, it was designed to be movable.

The spindle of the pL rotary table EA-520 is equipped with a gredoc zero-point clamping system, into which the three-jaw chuck shown can be inserted in the shortest possible time.

“To further develop our capabilities in the important area of tooling trials we recently searched for a large, heavy-duty CNC rotary table that would provide the high-precision five-axis machining that we need, and that could be retrofitted to our DMG Mori DMC 1450 machine tool. After carefully assessing the alternative products from several major manufacturers, we came to the conclusion that an advanced rotary table from Lehmann best matched our demanding needs.

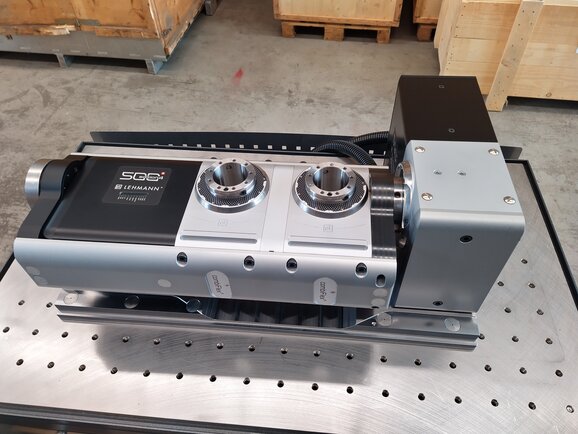

“Lehmann’s knowledgeable technical staff quickly understood our needs and suggested a T1-520530 TOP3 model, the largest 5th axis rotary table in the company’s range. As we were aware Lehmann’s excellent reputation, and as the T1-520530 TOP3 ticked all of our boxes, we were happy to place an order.

“Following the trouble-free fitting into our DMG Mori DMC and integration into the machine’s Siemens controller, our new rotary table soon began to deliver the levels of performance we were promised. The fifth axis provided by our Lehmann rotary table, and its impressive speed and precision, are now making significant contributions to our tooling machining trials.”

Lehmann has been at the forefront of the design and manufacture of high-quality, durable rotary tables for over four decades. The Swiss company’s expertise is reflected in the premium quality of the company’s products.

The CNC rotary tables are divided into geared and direct drive rotary versions and offer great flexibility. The company’s powerful designs offer many useful features, such as a built-in booster for spindle clamping, an internal monitoring system of all important functions and Bluetooth access for remote service.

Lehmann’s product line also offers a wide range of workpiece clamping possibilities, including options for fully automatic loading, and unloading by robots.

The T1-520530 TOP3 model, as installed in Exactaform’s DMG Mori DMC 1450 machine, is Lehmann’s largest available CNC, fifth axis rotary table and is able to accommodate workpieces of up to 600mm diameter and weighing up to 200kg.

Despite its generous capacity, the rotary table’s clever design means that it occupies a relatively small space within the machine tool. Given the demanding machining applications it is designed to undertake, the robust rotary table boasts high clamping forces of 2,000Nm rotating/7,000Nm tilting.

Aiding machining efficiency, the T1-520530 TOP3 provides 50rev/min rotating and 25rev/min tilting speeds. The advanced Lehmann rotary table is lifetime pre-loaded (adjustable) and backlash-free and delivers impressive accuracy and repeatability figures of 12a rc/sec and 2 arc/sec respectively.

The machining of complex workpiece geometries requires robust, flexible workpiece clamping and rapid, precise compound movements within the machine tool compartment. Throughout the world, and across multiple machine tools and challenging applications, Lehmann CNC rotary tables deliver all of these needs.

Lehmann’s products can be fitted to new machine tools or retrofitted to existing machines. In addition, the flexible rotary tables allow trouble free Integration into all known CNC control systems, including Fanuc, Siemens, Heidenhain, Haas, Winmax, Mitsubishi, Brother and Mazatrol.

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Europe and America: the best selling brands in the Chinese market are Haas and Lehmann. Haas is mainly configured on its machine tools, other brands of machine tools are rarely installed. Lehmann is positioned at the high end and mainly cooperates with some high-end machine tools. In addition, it is also used in some occasions with high accuracy requirements, but the demand is small

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

8613371530291

8613371530291