hydraulic rotary table supplier

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

Hosea hydraulic rotary table including right hand, left hand, back or top type, etc. Our hydraulic rotary tables are manufactured in a quality production process. Different item model has its own characteristic, some of them can be used vertically or horizontally, others can complete machining in a single setup. We can Provide pneumatic or hydraulic clamping brakes according to industry requirements. If you are looking for high-quality hydraulic rotary tables, just feel free to contact the Hosea at your time, we are your best option!

Hosea provides a diversity of Hypoid gear rotary tables for customers to choose from, our Hypoid gear rotary tables with stable index accuracy and high transmission efficiency. Moreover, they are easy to adjust. Please feel free to contact us as you are interested in our products detail!

Air-Hydraulics is committed to delivering quality products on time to achieve customer satisfaction. Air-Hydraulics uses a process approach to achieve this policy in accordance with ISO 9001:2015 and is committed to continually improve at this process.

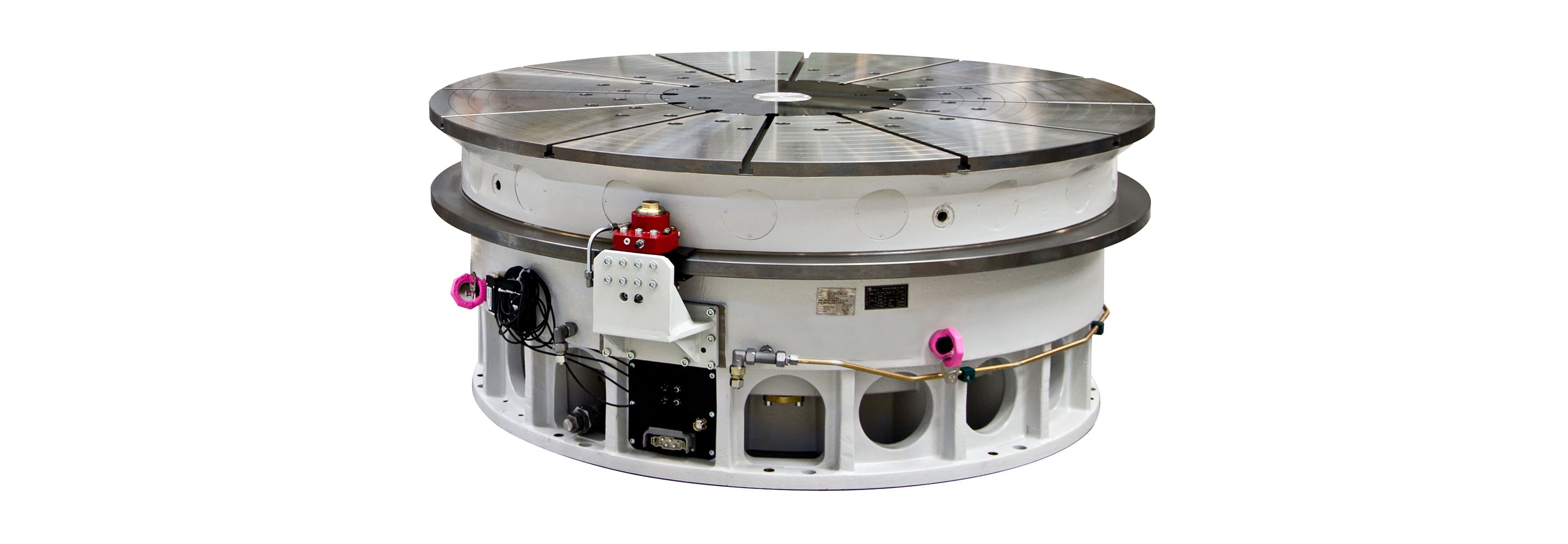

RDE"s 22K Hydraulic Rotary Table is designed to add high speed, high torque rotational capacity to snubbing units. This unit is mounted above the snubbing unit’s hydraulic cylinders. A pneumatic or hydraulically actuated slip assembly (supplied by others) can be bolted to the rotary’s top mounting flange to accommodate both pipe pulling (tension) and pipe snubbing (compression) operations.

The Rotary Table’s large bore design 11.06 inch ID will readily allow the passage of large downhole tools. This feature significantly reduces tripping times when compared to other systems which must be removed when large diameter tools such as mills, packers, or side pocket mandrels are encountered.

Four single speed hydraulic motors with Three piece shafts directly drive the Rotary Table to provide high torque capacity in a compact package. High efficiency Rineer MO-15 vane type motors are powered by the snubbing unit’s hydraulic power supply to eliminate the need for additional power units. Precise speed, direction, and torque control are achieved by means of pilot operated control valves (supplied separately). Note: A two speed motor option is available. Motors are interconnected by welded supply and return manifolds with split flange O-ring connections to provide optimum reliability in service.

Among the many indexer manufacturers, what sets Pascal’s indexing table apart is undoubtedly its brakeless design, compact size, and durability. It has an ample amount of ports lending itself well to automation.

Pascal’s MDF index table operates with a 90° index 0.5 sec. Its unique rolling gear transmission is maintenance free and can operate with high index speed and accuracy for a long time unlike traditional worm gear. Traditional worm gear undergoes abrasive wear that can lead to backlash causing machining failure and degrading index accuracy.

Pascal’s high-performance rotary unions are integrated to enable clamp sensing and actuation but also provides a footprint 20% smaller than its competitors. Ideal for indexing large workpieces in compact machining centers, you will also achieve increased production capacity. As one example, our rotary indexing table can allow a machining center to increase their production capacity from 16 robodrill units to 24 units in the same amount of space.

The MDF index table has a total of 20 ports, lending itself well to automation. 18 of those ports can be used for hydraulic and air, while 2 are for coolant. A double acting cylinder with sensing can be used instead of a single cylinder, and its rotary joint accommodates a 7MPa pressure circuit.

Pascal is confident in the quality and reliability of our rotary indexers so much so that we use them in our own factories. That is also why these indexers are utilized in the factories of major automakers around the world.

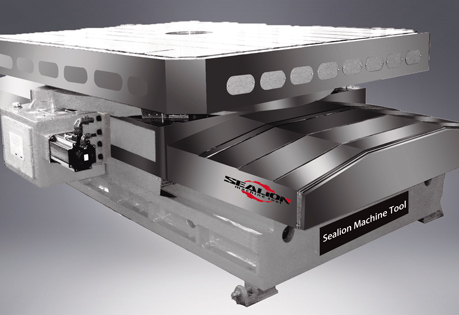

Ganro Industrial Corporation offers large rotary tables in their standard DR series configuration. The large rotary tables are available in a range of 1000mm (40”) to 2500mm (98”) in faceplate diameter. They can be utilized as a full rotating axis incorporated into a machine’s control or as indexers with Ganro’s M-Mate AC servo controller. These rotary tables and indexers are all capable of being mounted in both the vertical and horizontal positions to give manufacturers maximum flexibility. These large rotary tables and indexers utilize a hydraulic brake system to reach high clamping torques. All Ganro DR Series rotary tables and indexers use Ganro’s core technology of a double lead worm shaft and worm wheel system for high precision and reduced backlash. Ganro rotary tables are assembled using cross cylindrical roller bearings with high rotation accuracy capable of bearing heavy loads in every direction.

As the exclusive importer and dealer of Ganro products in the United States, CNC Indexing & Feeding Technologies stocks the most popular Ganro rotary table models, accessories and spare parts. We have certified service technicians for installation and repair of all Ganro and Golden Sun rotary table and indexer models. Please contact us today to learn how adding a Ganro rotary table or indexer can help improve your manufacturing process.

Among the many indexer manufacturers, what sets Pascal’s indexing table apart is undoubtedly its brakeless design, compact size, and durability. It has an ample amount of ports lending itself well to automation.

Pascal’s MDF index table operates with a 90° index 0.5 sec. Its unique rolling gear transmission is maintenance free and can operate with high index speed and accuracy for a long time unlike traditional worm gear. Traditional worm gear undergoes abrasive wear that can lead to backlash causing machining failure and degrading index accuracy.

Pascal’s high-performance rotary unions are integrated to enable clamp sensing and actuation but also provides a footprint 20% smaller than its competitors. Ideal for indexing large workpieces in compact machining centers, you will also achieve increased production capacity. As one example, our rotary indexing table can allow a machining center to increase their production capacity from 16 robodrill units to 24 units in the same amount of space.

The MDF index table has a total of 20 ports, lending itself well to automation. 18 of those ports can be used for hydraulic and air, while 2 are for coolant. A double acting cylinder with sensing can be used instead of a single cylinder, and its rotary joint accommodates a 7MPa pressure circuit.

Pascal is confident in the quality and reliability of our rotary indexers so much so that we use them in our own factories. That is also why these indexers are utilized in the factories of major automakers around the world.

INPROS rotary tables are available both in hydraulic or electric drive version; basing on Client requirement, the proper solution for the specific application will be offered.

The actuator of the electric version consists of a servomotor controlled by absolute encoder and driven by inverter, while in the hydraulic one the actuator is a hydromotor controlled by proportional valve. An hydraulic power unit is provided in case of hydraulic supply outlet unavailability on the press. Distribution inlets and outlets are placed on table side, instead of the classic solution at the center and behind the moving platen towards the ejection plate. In standard version the tables are foreseen for 2 positions moulding, but 3 or 4 positions are available on demand.

Tables are supplied in standard version complete with 2 outlets and 2 inlets for oil, plus 2 outlets and 2 inlets for cooling water. Additional lines for compressed air or gas are available on demand.

Additional holes for mould centering are available on request; sustaining pads of the table on tie-bars can be supplied in case of high tolerance between bushings and tie-bars of the machine, or clamping unit basement flexion due to high mass of the table-mold assembly.

Tables height does not exceed 190 mm. in standard configuration; average cycle time is 1,5″ for tables up to 900 mm. diameter, and 4″ maximum for bigger sizes

8613371530291

8613371530291