nikken rotary table maintenance manual brands

Nikken offers a wide lineup of high-rigidity and high-accuracy products that can handle all kinds of machining applications, including a milling chuck series, a collet chuck series, a tool holder series with dampening mechanisms, and boring systems.

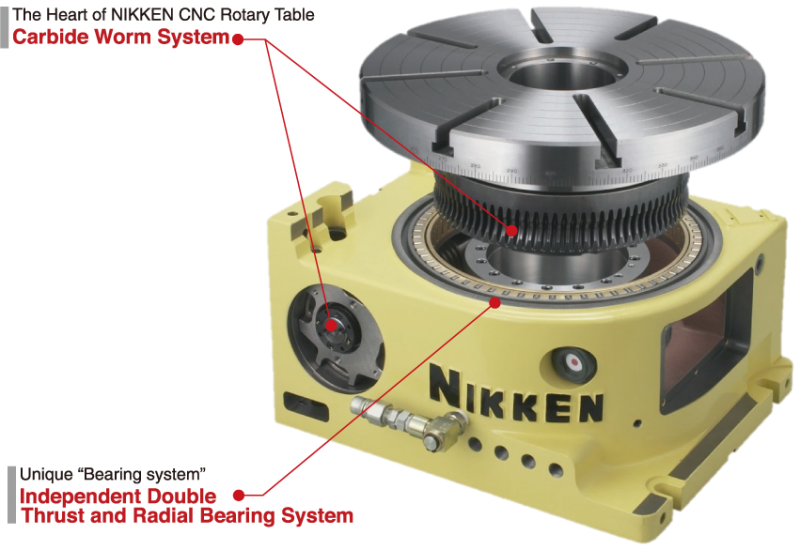

A special alloy steel worm screw with excellent shock resistance is adopted for small-size rotary tables to extend their service life and realize high cost effectiveness.

On the other hand, the extremely rigid and high-speed rotation-capable carbide worm screw is adopted for large-size rotary tables to withstand severe usage and maintain its accuracy almost permanently.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

On Machine Enhancements Work Holding Our range of modular work holding integrates seamlessly with our multi axis platform approach. Zero point location and modular base rail technology are available to suit NIKKEN standard table interfaces. This allows rapid change over of component fixtures and work holding set ups. Standard clamping modules, centring vices and chucks are all interchangeable with machine bed and additional axes, in addition a wide range of standard and bespoke trunnion set ups are available as options. Productivity Options Featuring a complete range of Tool Presetting,...

Rotary Tables Section NIKKEN provide a wide range of on Machine enhancements to create a flexible multi-axis machine platform essential for todays highly competitive market. Machine Enhancements, NIKKEN Rotary Tables 4 Axis Solutions Our range of 4th and 5th axis tables open up the possibilities of part manufacture in a single cycle, improving process flow and productivity! NIKKEN’s extensive product range combined with technical expertise, training and after sales service come together with the Okuma range of machine tools to offer a superior end-to-end experience that allows our customers...

Rotary Tables NIKKEN Kosakusho Works Limited, located in Japan, annually produces over 3,500 rotary tables, employs a global workforce in excess of 550 and has earned a reputation for producing quality products and demonstrating total commitment to its clients. Our unique table construction delivers unrivalled performance and reliability, which are fully supported by our team of factory trained Service Engineers and Advanced Manufacturing Specialists. NIKKEN Tables are the perfect fit for the Okuma range which offer the opportunity to combine operations and multi part load to...

Rotary Tables Unique Table Construction Casting NIKKEN Rotary Tables utilise fine grain, high-density, Grey Cast Iron castings, which are stabilised prior to finishing operations offering long term stability, low distortion, high strength and rigidity. Industry 4.0 NIKKEN are leading the way by utilising the latest, cloud-based technology to access big data during the lifetime of our products. Providing you with full Industry 4.0 compliance. Being able to sense and predict failure is a major aspiration for optimising machine uptime, with this goal in mind NIKKEN have created our new NIKKEN...

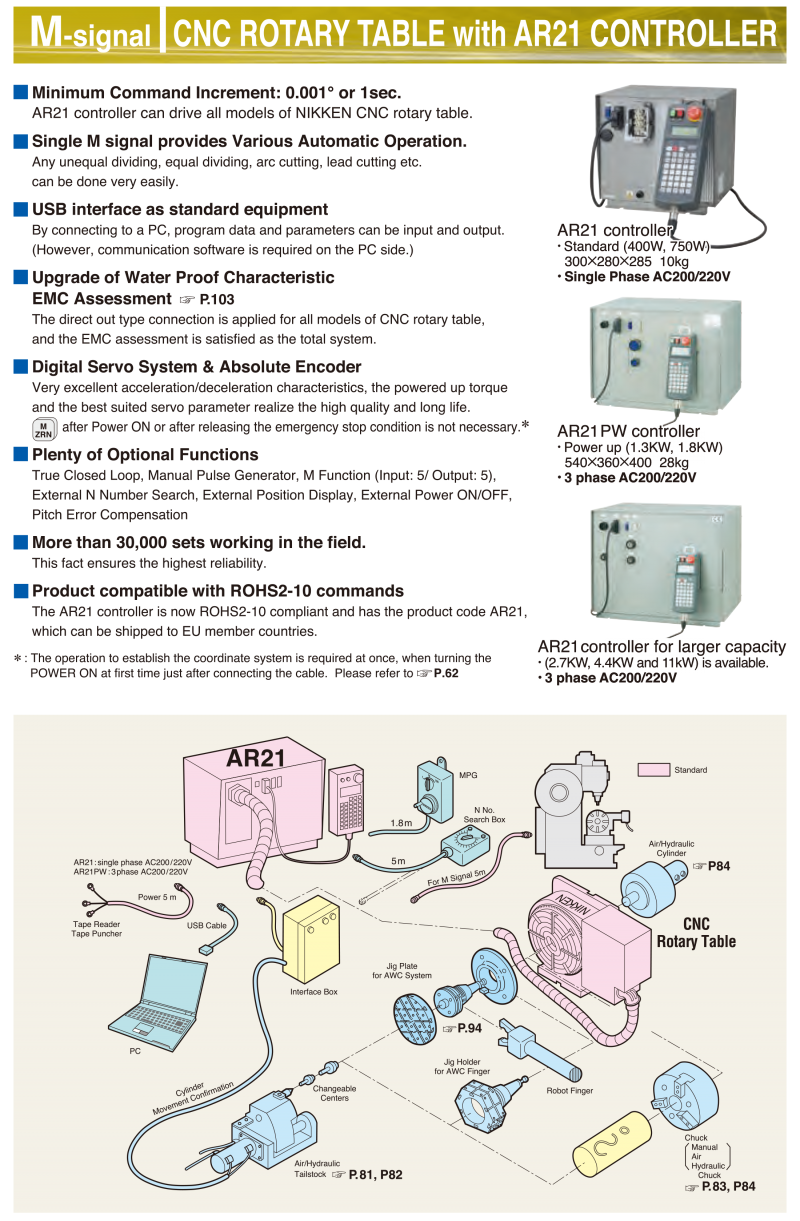

On Machine Enhancements Rotary Tables NIKKEN NC Tables offer unrivalled quality and performance by optimising production and can be configured for all types of Machining centres. NIKKEN offer a wide range of 4th and 5th Axis Tables that can be easily configured to a variety of work holding solutions such as Trunnion fixtures, built in rotary joints for facilitating hydraulic clamping, chucking and vice systems. The range consists of gear driven and direct drive units which can be controlled by the machine tool directly or via our own Alpha21 control system.

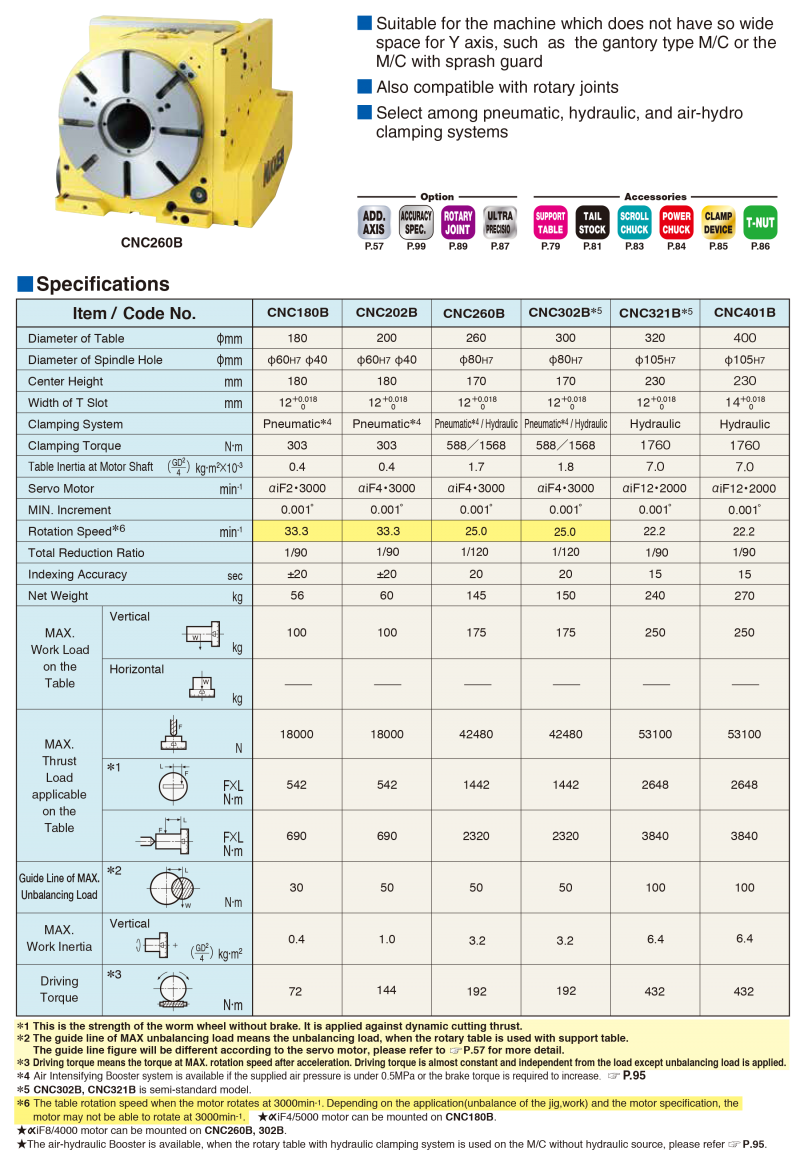

Rotary Tables Standard Rotary Tables NIKKEN offer a comprehensive range of tables for Vertical machines. Face plate diameters range from 105mm to 1600mm and Motor positions can be left hand, right hand or back mounted to ensure units are able to be mounted in the most efficient position. Options Include: ■■ Built in Rotary Joints ■■ Direct encoders ■■ Zero Point Quick change solutions ■■ Machine Vices ■■ Trunnion systems ■■ Modular Work Holding and clamping ■■ Manual and Power Chuck systems ■■ Manual, Pneumatic and Hydraulic ■■ Tailstocks ■■ TAT end Support Units NIKKEN Tables are suitable...

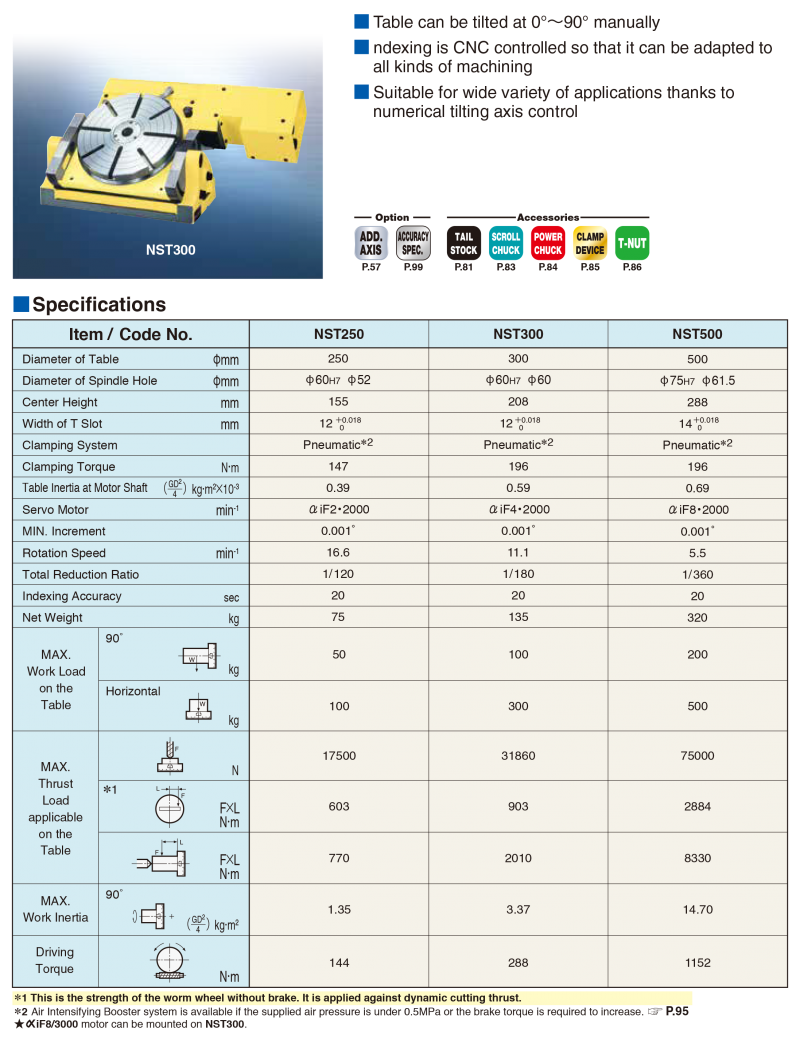

On Machine Enhancements 5 Axis Solutions NIKKEN are at the forefront in the field of 5 axis tables, we feature a comprehensive range to suit Okuma machining centres. Okuma offers the opportunity to maximise productivity by combining multiple operations, and are ideally suited for complex multi-faceted parts or components with compound detail to be machined.

A comprehensive range of modular vices and chucking systems are available to compliment NIKKEN 5 Axis solutions. 5 Axis Solutions are an ideal addition to any Okuma machining centre. They are perfectly suited to hold complex parts, by reducing set ups they optimise quality and productivity. In many instances a part can be manufactured and inspected in a single operation. “Sputnik” multi part clamping system Compact 5 Axis units can be mounted along the Y Axis of a vertical Machine to facilitate part manufacture in a single set up. Tables can be mounted along the X axis of the machine to...

Spindle Optimisation Advanced Tooling System For many years NIKKEN have been at the forefront in the field of precision spindle tooling, we offer a full range of systems to meet all the essential requirements when Milling, Drilling, Reaming, Boring and Threading. Our standard tapers offer a better than AT3 interface to the machine spindle. This optimises performance whilst helping to protect the machine spindle from the effects of vibration and cutting forces. This can be further enhanced with the NBT connection that offers simultaneous taper and face contact with the spindle for 30, 40 and...

NC Tooling System Pro End Mill - A unique tool from NIKKEN and the ultimate solution for Indexable Milling up to 32mm, Taper and Face contact as Standard for maximum rigidity, Unique “MD” anti- vibration technology. Multi-Lock Milling Chuck - The market leading solution for cylindrical tools shanks up to 42mm. Available in a wide range of lengths and diameters. Our unique design and manufacturing processes ensure long lasting performance. Multi-Lock Milling Chuck Mini-Mini Advanced Alpha - Our ultimate solution for small diameter end mills (up to 12mm). Tools are gripped up to the front...

Spindle Optimisation Angle Heads With 35 years of experience and over 50,000 products installed, NIKKEN-ALBERTI are delighted to be able to offer a wide range of Angle Heads and attachments to enhance the functionality of any Vertical Machining Centre. Whether that be increasing the output RPM of the spindle or machining internal features otherwise impossible to achieve by other means, NIKKEN have a solution. All our attachment bodies are manufactured from GS600 stabilised spheroidal Cast Iron to better absorb vibration and deliver higher levels of thermal stability, further enhanced by a...

Martin Trunnion Tables and Lyndex Nikken are now offering complete 4th axis packages. Ready to be mounted into your machine tool, your Stallion Trunnion Table will already be attached to the Lyndex Nikken rotary table of your choice and assembled onto a baseplate. This allows for an easy transition from 3-axis machining to 4-axis machining. Our line of trunnion tables can be made to fit any Lyndex Nikken indexer. Multiple workholding options are also available including 5th axis, AME, Schunk, Triag, Orange Vise and more. If you have any questions, do not hesitate to reach out to one of our applications engineers! Scroll down to view package options.

Are you looking for an accessory to boost the precision of your modern machining centers? CNC rotary tables provide a versatile tool in expanding the capabilities of your machines. They allow for precision positioning during 4 and even 5 axis cutting operations, thereby transforming 3-axis machinery into CNC machines with heightened accuracy. CNC rotary tables are a cost-effective solution to perform complicated machining tasks, with additional benefits such as increased productivity, efficient use of labor and materials, and better quality control.

Additionally, CNC rotary tables can be used independently to mount other components on a table, including trim attachments and chucks for drilling applications. CNC rotary tables offer considerable advantages that promote their usefulness in a variety of industrial settings.

Looking to sell your CNC Rotary Table? Simply fill out the sell your machine form and we will get back to you with a quote. Interested in one of our used machines for sale? Simply click the “Get Quote” button and a sales representative will contact you shortly.

Eagle Machine, Inc. is a distributor for Eurotech Multi Tasking Lathes, Hermle Precision 5 Axis Machines, Fermat Horizontal Boring Mills, YCM Precision Machines, Cosen Saws, NIKKEN Tooling & Rotary Units, Golden Sun rotary tables, Sharp Manual Machines

A large number of specially selected, high-quality second user products are available through our webshop or directly from our technical sales department, providing rotary table products that have been fully rebuilt exclusively by us, to a very high...https://facebook.com/cncrotaryshop/videos/475171379666589/…

All axis movements on the 66B/68B are servo controlled with absolutely no operator contact with the column. This drastically increases machine accuracy and repeatability over similar machines which incorporate the movement via a manual handle mounted on the column.

NIKKEN Kosakusho Europe is a world-class manufacturer of CNC Rotary Tables, High accuracy NC Tooling Solutions, and Tool Presetters. Operating in 3 continents and 70 countries, Nikken has a global reputation for exceptional service, professionalism, and the design and production of the highest quality machinery.

8613371530291

8613371530291