rotary table injection molding machine manufacturer

Serving as an industrial leader and a technical pioneer in the field of plastic injection molding machines, Haitian started to research and develop multi-component injection ...

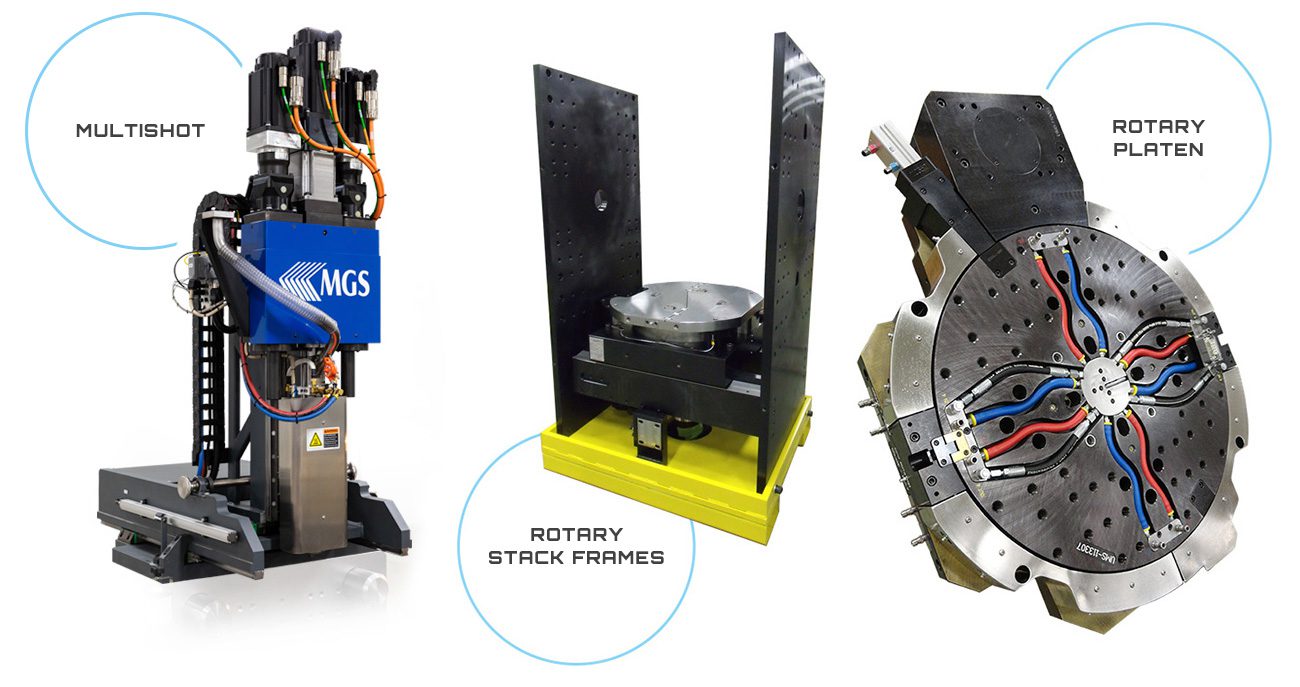

... and operation of core pulls and servo electric operation of injection unit and drive of the rotary plate. As an alternative, the hydraulic version can also be operated by a speed-controlled servo motor. ...

... with a servo-powered, electric injection unit and featuring the innovative hydraulic ENGEL ecodrive as a standard, it will achieve even more precision.

... efficiency for our customers, and with our wide range of machine models, we can handle any specific production requirement. ARBURG is our exclusive distributor for rotary table injection ...

... services for specific product and Sector, Such as Two Color Machine、 C Type Machine、Glass Fiber、Bakelite Machine、Zipper Machine、Horizontal clamping & vertical injection ...

Inserts can be ergonomically encapsulated with our vertical ALLROUNDER injection molding machines. You can choose from the most extensive range of machines available in the industry, from the comprehensive spectrum of different ALLROUNDERs through to automated machine concepts and customer-specific special solutions.

The technology of our vertical ALLROUNDERs can be matched precisely to your specific injection molding tasks, while still maintaining maximum ergonomic efficiency. A wide range of clamping forces, flexible vertical and horizontal injection units, as well as task-specific equipment packages are available, for example for thermoset or silicone processing.

TAYU Machinery Co.,Ltd. is a professional injection molding machine manufacturer in China. It possesses two core manufacture bases in Zhejiang Hangzhou and Guangdong Dongguan respectively. It specializes in research, develop and manufacture high precision plastic injection equipment such as vertical injection molding machine,rubber injection molding machine,bakelite injection molding machine, BMC injection molding machine,Insert injection molding machine. TAYU positioning its products in middle and high-end market, with t…

Multiplas is the professional injection molding machine manufacturer in Taiwan. Through years of efforts, Multiplas has established an excellent reputation in the worldwide markets for the dependability of its

PRM-TAIWAN The number one Plastic and Rubber Machinery B2B platform in Taiwan. With our interactive website, you will be able to find the machines for your business needs. If you don"t know exactly what machine you are looking for, but know the type, just fill in the inquiry form with the type of machine you need and we will do the hard work for you! On our site you will find all sorts of different types of machinery such as different types of pelletizing machine, plastic recycling machine, blown film extruder, filament extrusion line, injection molding machine, blow molding machine, injection blow molding machine, bag making machine, flexo printing machine, laminating machine, molds and dies, screw and barrel, and more machines in this field.

Vertical clamp machines bring you every advantage for insert molding, making it easy to combine two materials and reduce assembly costs. From encapsulation of delicate electronic parts to over molding of plastic on metal for diverse automotive applications, ABS-VV-R also offers a reduction in post-molding operations, saving time and money.

All Plast ABS-VV-R machines can be configured for every possible insert molding application by combining a wide range of clamp, table and injection unit configurations. Vertical clamps with horizontal tables let gravity gently and easily do the work of holding single or multiple inserts. Open clamp designs with rotary and shuttle tables give the advantage of working with multiple molds and simultaneous operations including pre-molding, injection and post-molding operation. Simultaneous operations are easily automated for consistent quality, high productivity and high profitability.

"description": "Machinery Center has an Extensive array of used Injection Molders Rotary Type for sale from all the major manufacturers such as Milacron, Engel, Van Dorn, Newbury and Nissei. We are Americas largest stocking dealer of machinery including Injection Molders.",

"twitter:description": "Machinery Center has an Extensive array of used Injection Molders Rotary Type for sale from all the major manufacturers such as Milacron, Engel, Van Dorn, Newbury and Nissei. We are Americas largest stocking dealer of machinery including Injection Molders.",

"og:description": "Machinery Center has an Extensive array of used Injection Molders Rotary Type for sale from all the major manufacturers such as Milacron, Engel, Van Dorn, Newbury and Nissei. We are Americas largest stocking dealer of machinery including Injection Molders.",

Machinery Center has an Extensive array of used Injection Molders Rotary Type for sale from all the major manufacturers such as Milacron, Engel, Van Dorn, Newbury and Nissei. Rotary table vertical injection molding machines rotates the mold first to a load station, then a molding station, and finally an unloading station. Rotary tables allow for complex parts to be formed and maximize production. We are Americas largest stocking dealer of machinery including Injection Molders.

Make your cap production more time and labor-saving with top-rated rotary injection molding machine available at Alibaba.com. These rotary injection molding machine are loaded with astonishing attributes that foster efficiency and performances that align with users’ expectations. They simplify the steps of making caps for you to produce more within a short timeframe. These rotary injection molding machine present to you a sure way to increase the capacity and profitability of your facility.

Our huge network of mold shops on Alibaba.com are ready to help you find the right wholesale rotary injection molding machine for your products. Use the information available on the platform to decide on the perfect rotary onjection mould machine that meet your requirements of quality and price. When starting a molded products manufacturing project, it starts with a dfm or design for manufacturing which is created by the mold making shop after analyzing your product design and is there to tell you how the mold is going to be made. After your approval, the mold will be made according to the mold shape.

Each wholesale rotary injection molding machine from Alibaba takes plastic granules and shapes them into your required dimensions. Here’s where you’ll get improved accuracy on your applications. The steel bush in the clamping unit adopts a new structure. This construction minimizes wear resistance and reduces the effect of steel bush lubrication. That means you can now save the costs used on lubrication oil. Invest in plastic injection moulders today. Simply browse the wholesale rotary injection molding machine listing from leading global wholesalers and get one for use in your plastic processing business.

The plastic injection molders at Alibaba are durable and designed for long service life. Each table injection molding machine undergoes constant design improvement for high-speed work. With versatility at heart, some molding tools allow for multi-select high-end applications. From consumer electronics to pharmaceuticals to food & beverage, and also the automotive industry. Limit your concern of experiencing considerable defective rates. Get ready for a fast and industry-standard response rate thanks to the single-cylinder system with servo-valve. You’ll also be investing in a table injection molding machine of precise industry-standard. Long-lasting service and durability will be your rewards.

The plastic table injection molding machine products from wholesalers on Alibaba are specialized for different sizes of preforms. The special screw in the equipment highly increases plasticizing shot weight and speed. And with a clamping force ranging between 2,000 kN to 13,000 kN, molding machines boast the capacity to resist external machining forces. This plastic injection moulding machine is suitable for the packaging industry: thin wall containers, caps, pails, buckets, etc. Your go-for equipment for designing a wide range of PVC pipe fittings. The special design of the plastic molder means you’re investing in the exact clamping force you actually require.

Each wholesale table injection molding machine from Alibaba takes plastic granules and shapes them into your required dimensions. Here’s where you’ll get improved accuracy on your applications. The steel bush in the clamping unit adopts a new structure. This construction minimizes wear resistance and reduces the effect of steel bush lubrication. That means you can now save the costs used on lubrication oil. Invest in plastic injection moulders today. Simply browse the wholesale table injection molding machine listing from leading Chinese wholesalers and get one for use in your plastic processing business.

The machine can be equipped with automatic inserting and removing devices to achieve fully automatic operation. It is more convenient to operate and connect with automation to increase production capacity.

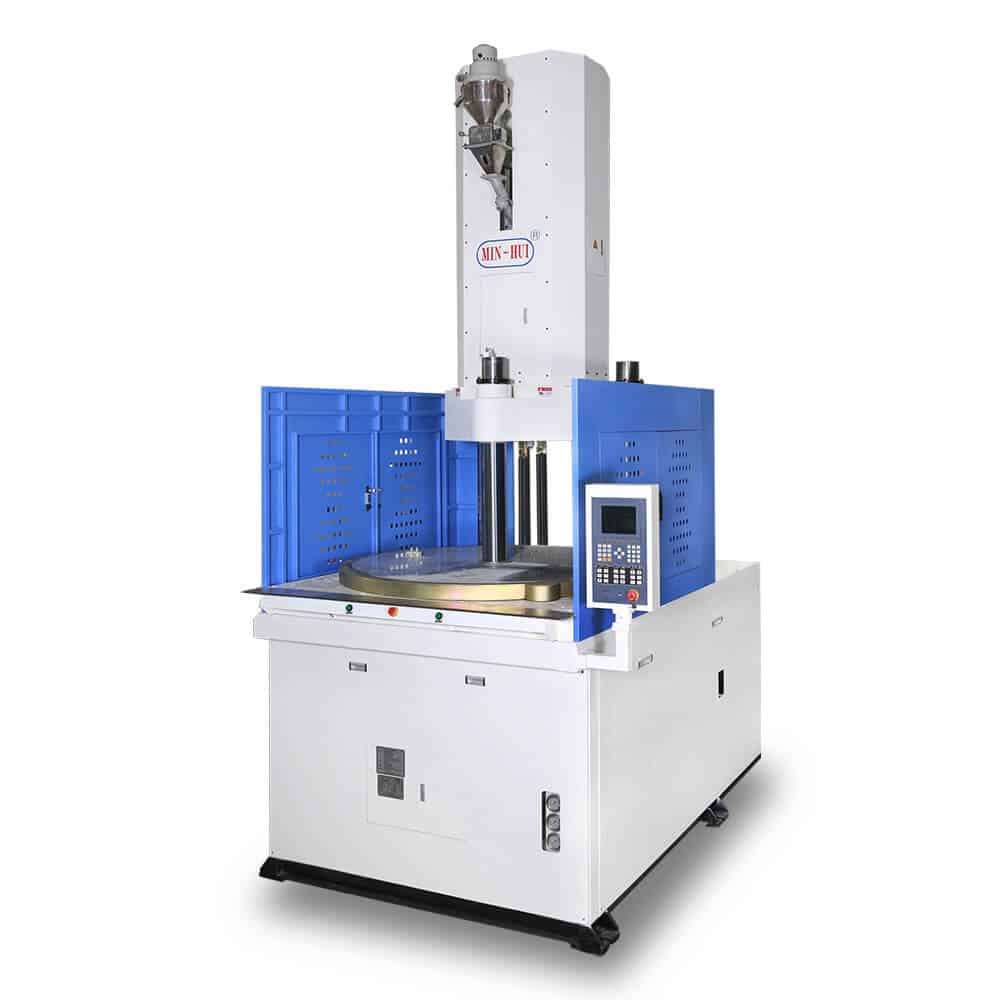

Vertical rotary plastic injection molding machine, also known as rotaryinjection molding machine, multi-station injection molding machine, its function is more than twice of the vertical injection molding machine, through a machine to improve production efficiency (one set of upper mold, three sets of lower mold, can do more) vertical mold closing, vertical injection, easy to put the product.

Vertical rotary plastic injection molding machine is suitable for producing automotive parts, energy-saving lamp heads. Golf balls, eyeglass holder nosepiece, LED brackets, and other metal bodies and plastic products forming work of appliance of direct contact with the public, can do fully automatic workflow operation, high efficiency, and low cost.

The machine surface is chrome plated to prevent rust, beautiful and durable. The power section is available with hydraulic motor and servo motor, or higher configuration according to the customer’s product and requirements.

www.plasticsmachinerymanufacturing.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

With double slide table or rotary design, put-in, take-out products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production.

High precision mold platen ( Parallelism/ flatness : 0.02/100 mm), heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life.

8613371530291

8613371530291