weiss rotary table factory

In 1996, Precision Detroit Company established a relationship with WEISS GmbH. WEISS has been manufacturing high quality index tables for decades and is the leading automation component manufacturer in Europe today.

In August, 2007, WEISS GmbH established WEISS North America, Inc. as a wholly-owned subsidiary. On September 30, 2007, WEISS North America, Inc. acquired the assets of Precision Detroit Company, Inc. relative to its PDC Geneva Motion index tables and its network of sales representatives throughout the U.S. and Canada.

Today, WEISS North America is not only a rotary table manufacturer but your complete automation manufacturer and solutions partner. WEISS has decades of expertise in providing automation, drive and control solutions to industrial markets. WEISS offers industry-specific, cost-effective and efficient technology solutions to help you maximize your efficiency, increase your productivity and achieve optimal system performance. We understand that your application has unique processes and specific requirements and we work closely with you to develop the perfect automation solution for your particular needs.

Successfully competing in our increasingly competitive global environment requires strategy, innovation and proven reliability from a partner that you can trust. Give us a call at 888-WEISSNA, fill out the form above, schedule a call below or simply send us an email to discuss your automation needs.

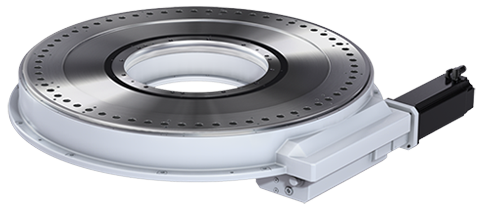

Boasting a 1300 mm footprint, the TO1300 suddenly makes larger scale applications possible that previously seemed out of reach− as current direct-drive tables are relatively small and limited to a diameter of 750 mm. Additionally the TO1300’s high-tech drive operates predominantly without mechanics or gearboxes.

With over ten years of expertise in the field of direct drive torque motors, WEISS often designs and develops out of the logical response to changing market requirements and customer demand. This was the case with the TO1300 as a client’s concrete custom requirements stipulated a high mass inertia of 160 kgm2 and a large index increment of 45° with fast cycles−namely an index time of 0.21 seconds with a dwell time of 0.29 seconds.

For challenging tasks of this nature, a mechanical heavy duty table is typically the logical choice. Due to their gearing ratio, however, these tables don’t fare well in service life calculations for use at such high speeds as the needle bearings simply suffer from too much wear.

The correct alternative is a direct drive; which inspired the development of the TO1300. With a direct drive, only one bearing is under load which is virtually free of backlash. The table is low-wear and easily capable of delivering the desired dynamic performance requirements.

Unique to the TO1300 is that customers can customize it to their individual requirements. For example; they can make a modular selection between bearings, encoder and motor, and thereby alter the following table characteristics:

A specialist in automation, WEISS also offers many sizes for the TO series direct-drive rotary indexing tables; ranging from small to very large. Optimal solutions for specific application challenges can be achieved from the series wide range of options. Each TO model is also available in a version with a cleanroom certificate.

Corporate Profile: An integral part of the Weiss global network, Weiss North America (ISO-9001 Certified) leverages over 45 years of reliable world-wide expertise to comprise an integrative, customer-specific approach to its vast array of electromechanical products. Our 100% vertical range of manufacturing ranges from rotary indexing tables, handling systems, and linear assembly systems−providing flexible technology for turnkey solutions that incorporate electronics, mechanical systems, software, and comprehensive engineering support. This enables us to provide pre-installed, intelligent, and highly convenient solutions for the entire field of kinematics.

Weiss Automation Solutions India Pvt Ltd, a world leader in the development of advanced industrial automation solutions, announced the launch of its next-generation CR-700 indexing ring which is the newest addition to its CR series of rotary Indexing table.

As a part of the growth plan & strategy for Asia Pacific & India Market, Weiss Group has been beefing up its operations & resources in the region. The first step in that direction, it has added customer-facing & technical resources, competence & infrastructure along with a brand “New Campus” in Chakan, Pune; that will house under one roof, Weiss APAC regional HQ, India Sales Office, The Engineering Knowledge Centre, Weiss Solution Factory, Global Sourcing & Global Technical Development Centre.

WEISS GmbHbased in Buchen, Germany is one of the world’s leading suppliers of modern and efficient industrial rotary and linear movements in automation. Weiss was founded over fifty years ago and is now the world leader in rotary indexing tables for assembly, welding, packaging, medical devices, and many other industries.

Weiss Group is serving its customers worldwide through more than 550 employees, across 17 countries with its own subsidiaries having over 125 million Euro sales worldwide.Weiss Automation Solutions India Pvt Ltdisthe fully owned Indian subsidiary of the Weiss GmbH.

TECHNOLOGY THAT INSPIRES WEISS PRODUCT RANGE INSPIRING PEOPLE GREAT SOLUTIONS WEISS GMBH Siemensstraße 17 74722 Buchen Phone 06281 5208-0 Fax 06281 5208-99 info@ weiss-international.com www.weiss-international.com PRODUCT RANGE ROTARY TABLES LINEAR SYSTEM HANDLING SOFTWARE

FIXED-STATION ROTARY INDEXING TABLES TC Rotary indexing table 14 TR Rotary indexing ring table 36 EF2 Rotary table control system 48 FREELY PROGRAMMABLE ROTARY TABLES NC Rotary table 54 NR Rotary ring table 64 CR/TH Heavy duty rotary table 76 TO Torque rotary table 96 ST Torque Rotating Unit 110 TW Rotary table with hybrid drive 118 CUSTOMER-SPECIFIC SOLUTIONS SR/SK Indexing machine bases 130 LINEAR ASSEMBLY SYSTEM LS 280 Linear Assembly System 142 HANDLING MODULES HP Pick & Place 164 HG/HN Linear axis 176 Pick-o-Mat automated assembly system 194 WEISS...

FOUR STEPS TO PERFECT AUTOMATION Experience a product portfolio with unparalleled scope: from basic machines, through handling units, right up to plates, attachments and custom solutions. All components can be controlled using the WEISS Application Software (W.A.S. 2) for fast and easy commissioning. I would like to commission my installation quickly and efficiently WEISS Application Software 2 SOFTWARE I require machine frames, mounting bases or customised equipment Bases, mountings, modifications Customer-specific systems CUSTOMER-SPECIFIC SOLUTIONS I require handling components Linear...

PRODUCTION / MANUFACTURING AREA DEVELOPMENT DESIGN MILLING TURNING DRILLING MESHING GRINDING PAINTING FITTING MEASURING For us, quality comes first. Our rotary indexing tables and automation components have earned a legendary reputation in terms of reliability, robustness and precision. Our comprehensive manufacturing expertise plays a key part in this regard. Working in interdisciplinary teams, we develop precise solutions for our customers – with the right technical and economic attributes. Our new measuring centre at the production location in Buchen also supports this high quality...

MANUFACTURING EXPERTISE WEISS QUALITY FROM CLEVELAND TO SHANGHAI: YEARS OF PRODUCING LINEAR ASSEMBLY SYSTEMS MACHINING OF PLATES WITH DIAMETERS OF UP TO

WE COMBINE EXPERTISE WITH SOLUTIONS – AND SOLUTIONS WITH MARKETS NO MATTER WHERE We are represented worldwide, wherever our customers need us. We can be on site quickly thanks to our network of subsidiaries and offices, as well as our own service and support teams. Regional inventories at dedicated logistics hubs allow us to cater to local requirements quickly and effectively. Our subsidiaries also offer maximum mobility so that we can react to specific market requirements flexibly. Yet even with maximum flexibility and adaptability, one thing always remains the same: at its heart, WEISS is...

FIXED-STATION ROTARY INDEXING TABLES | TC ROTARY INDEXING TABLE TC ROTARY INDEXING TABLE: RELIABILITY FOR A LIFETIME EXTENDED WARRANTY Using our rotary table control system minimises brake wear. This makes the rotary indexing table virtually maintenance-free throughout its entire service life. And using this control system also extends the warranty to four years.

Custom machine for an automotive supplier. The assembly of sealing rings for injection pumps requires maximum precision. The TC 150 rotary indexing table with matched rotating plate delivers this. One of the most reliable and robust rotary indexing tables available worldwide. Your most popular partner in the field of automation technology. Extremely long service life combined with impressively fast switching. Now in its third generation. Robust rotary indexing table with smooth, jerk and impact-free running and extremely long service life. When using a WEISS rotary table control system, we...

The TC is one of the most reliable and robust rotary indexing tables available worldwide. Our roller cam drives are dimensioned as large as possible. And the full length of the cams is used here. The fastest switching times and an extremely long service life – we achieve this with high-precision drive cams made by our in-house manufacturing department.

FIXED-STATION ROTARY INDEXING TABLES | TC ROTARY INDEXING TABLE DELIVERS WHAT IT PROMISES – THAT’S A PROMISE. GENERAL INFORMATION ON THE MODEL RANGE ·· TC rotary indexing tables can be operated clockwise, anti-clockwise and also in reversing mode. ·· The drive can be swung downward. You can do the conversion work yourself. ·· The TC rotary indexing tables are “lubricated for life”! ·· The maximum switching frequency is up to 220 cycles per minute, depending on the size, the system’s mass moment of inertia and the angle of rotation. ·· All TC rotary indexing tables are equipped with...

FIXED-STATION ROTARY INDEXING TABLES | TC ROTARY INDEXING TABLE VERSIONS: MOUNTING POSITION VERTICAL, DRIVE ON RIGHT / MP 3 VERTICAL, DRIVE AT BASE / MP 4 OPTIONS ·· If necessary, the stationary central section can be raised 5 mm or 10 mm. ·· All sizes in the TC model range can optionally be equipped with a DRIVE-CLiQ absolute encoder. ·· In connection with the new 2.1 version of the EF2 control system software, the rotary encoder offers the following options: » Cam switching mechanism: 16 user-programmable electronic cams allow early triggering of process actuators or help reduce the cycle...

... RIGIDIAL" rotary tables by COLOMBO FILIPPETTI spa have a globoidal cam which transforms the uniform rotary input motion into an intermittent rotary output motion.

The indexing rotary tables of the "IR" Minindex series by COLOMBO FILIPPETTI spa are cylindrical cam mechanical units that transform the uniform rotary motion of the ...

... heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive to deliver a true 4th-axis ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary control box for ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

The ITP Series are the package version of the IT Rotary Tables. They are equipped with a gearbox and three-phase induction motor for a shorter lead time and fast delivery ...

The TRP Series are the package version of TR Rotary Tables. They are equipped with gearbox and three-phase induction motor for a shorter lead time and fast ...

The FTP Series are the package version of FT Ring Tables. They are equipped withgearbox and three-phase induction motor for a shorter lead time and fast reaction to the market ...

The “HOMGE” PRECISION INDEXING TABLES are constructed with an AIR CYLINDER between the mating surfaces. This system ensures reduces friction when heavy loads are applied to ...

... can shift across the board on the rotary podium due to the pneumostatic air bearing. Additionally, the motorization can change as per the desired angular resolution from 5.120 up to 655.360 ppr.

This is a Servo driven rotary indexing table manufactured by Italplant which has been a study for automation of the whole unit. It comes with a wide range of product such as robot guided ...

G.P.A. Italiana pneumatic rotary indexing tables are available in two versions: TAR 270 and TAR 160. TAR 270 can handle bigger loads, aided by the hydraulic control and double cylinder ...

The NC combines robustness and durability with the advantages of a user-programmable rotary table that offers a high level of torque. This is made possible by the latest generation of servo motor drives ...

The RDH-XS is a rotary indexing table. This industrial component is capable of accommodating high load capacity. A transfer accuracy of <2 minutes of arcRepeatability. The device is manufactured ...

Rotary indexing tables provide an indexing axis for mounting workpieces on machine tools. They are designed to position workpieces at precise angles for different machining operations.

These devices are used on CNC machining centers, lathes, presses and other types of production or manufacturing machines. A CNC milling machine uses a rotary indexing table to provide a fourth or even a fifth axis for certain machining operations.

Such tables can be mounted either vertically or horizontally. The rotary drive can be manual, electric, pneumatic or hydraulic. It uses either a rack and pinion, or a servomotor and gearbox. Some models have multiple rotating tables, providing multi-axis workpiece mounting.

When selecting a rotary indexing table, be sure to determine the mounting orientation: horizontal, vertical, multi-axis and tilting. Other factors are table diameter, maximum load capacity and indexing accuracy.

We combine rotary index tables with industrial automation systems so each task of your manufacturing process blends seamlessly into the next. For example, in the past we’ve created industrial automation systems that join rotary indexing machines with pick-and-place units for some of our clients. Contact us to see what we can do for you.

Rotary indexers are just one part of the equation when building a custom assembly cell. It’s important to remember the entire scope of the project and be cognizant that the rotary table should be able to move precise distances before stopping cleanly, with no backlash or wobbling. It needs to be balanced and capable of handling the tasks at hand.

Our automation experts have years of experience in consulting with our customers to create machines that suit their needs. We incorporate rotary tables from industry leaders like WEISS, Fibro, and Camco into our machines to create the perfect fusion of form and function. Our dedication to quality is unmatched in the world of custom machinery.

We seamlessly integrate rotary indexing tables into our automated machinery to provide you with custom solutions that work for your business. If you’re looking to take your manufacturing process to the next level, give the custom machine builders at Paramount Tool a call at (616) 582-5300 today. We’re always happy to answer any questions you may have about our rotary indexing machines or the machine building process as a whole. For a free quote, fill out our contact form and we’ll get back to you as soon as we can.

WEISS North America, Inc. is an integral part of the Weiss global network and leaders in rotary and linear motion automation solutions. As your worldwide partner for factory automation, WEISS manufactures and delivers high-quality cam-, servo-, and linear motor-driven solutions to key industries such as automotive, mechanical and plant engineering, life science, electronics and more. WEISS manufactures robust and reliable rotary indexing tables, ring indexers, palletized conveyors, linear motor-driven pick-and-place units, cam- and servo-driven assembly chassis, machine bases and tool plates.

WEISS leverages over 50 years of reliable global expertise to deliver solutions that enable our customers to be more efficient, effective, and competitive. WEISS specializes in the highest quality craftsmanship and offers an industry leading four-year warranty.

Beyond inventing a new, innovative ring binding system made of paper, Kugler-Womako was also the first in its sector to switch over to the accompanying binding production process from a traditional linear transfer unit to a rotary indexing ring. According to Anton Jost, Project Manager at Kugler-Womako, “Since our paper binding system is fundamentally new, we also wanted to rethink the processes employed. All previous binding machines worked with a linear system, but we wondered whether we could improve on this with a different approach.”

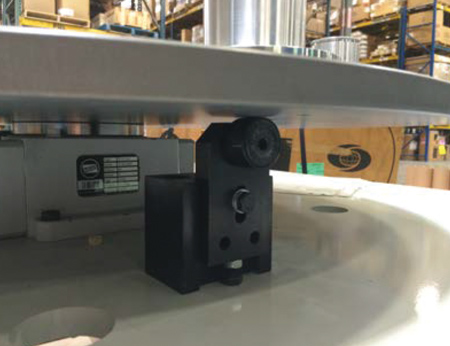

Ultimately, the concept for the first EcoBinder binding machine was a semi-automatic unit with four processing stations − based on a highly dynamic, fixed-position WEISS TR750 rotary indexing ring with 90 degree divisions.

Given their successful collaboration in establishing a rotary indexing table solution, the company further enlisted WEISS to manufacture and deliver the complete table including: subframe, a fixed and rotating aluminium ring with milled recesses and drilled mounting holes, as well as connection elements for the mountings of the processing stations. This allowed the engineers at Kugler-Womako to focus all of their attention on designing their new binding process.

Even with up to 12 stations, this machine wouldn’t prove to be a problem for the WEISS TR series which offers ring diameters of up to 2,200 mm – providing more than enough scope for coupling with processing stations.

Jost noted the mechanical integration capabilities of the rotary indexing rings from WEISS, “We were able to connect the frequency inverter control on the TR750 to our higher level machine control system with no issues. In fact, the binding machine was already up and running just a few hours after installation.”

When compared to a linear design, the WEISS TR750 rotary indexing table broke new ground for Kugler-Womako by saving space and moving the infeed and output areas of the blocks closer together − offering a particular advantage for manual operations. Essentially, because a rotary indexing table is made up of significantly fewer parts than a transfer line, it was also possible to lower the cost for the binding machine while increasing production quality.

An integral part of the Weiss global network, Weiss North America (ISO-9001 Certified) leverages over 45 years of reliable world-wide expertise to comprise an integrative, customer-specific approach to its vast array of electromechanical products. Our 100% vertical range of manufacturing ranges from rotary indexing tables, handling systems, and linear assembly systems−providing flexible technology for turnkey solutions that incorporate electronics, mechanical systems, software, and comprehensive engineering support. This enables us to provide pre-installed, intelligent, and highly convenient solutions for the entire field of kinematics.

8613371530291

8613371530291