weiss rotary table in stock

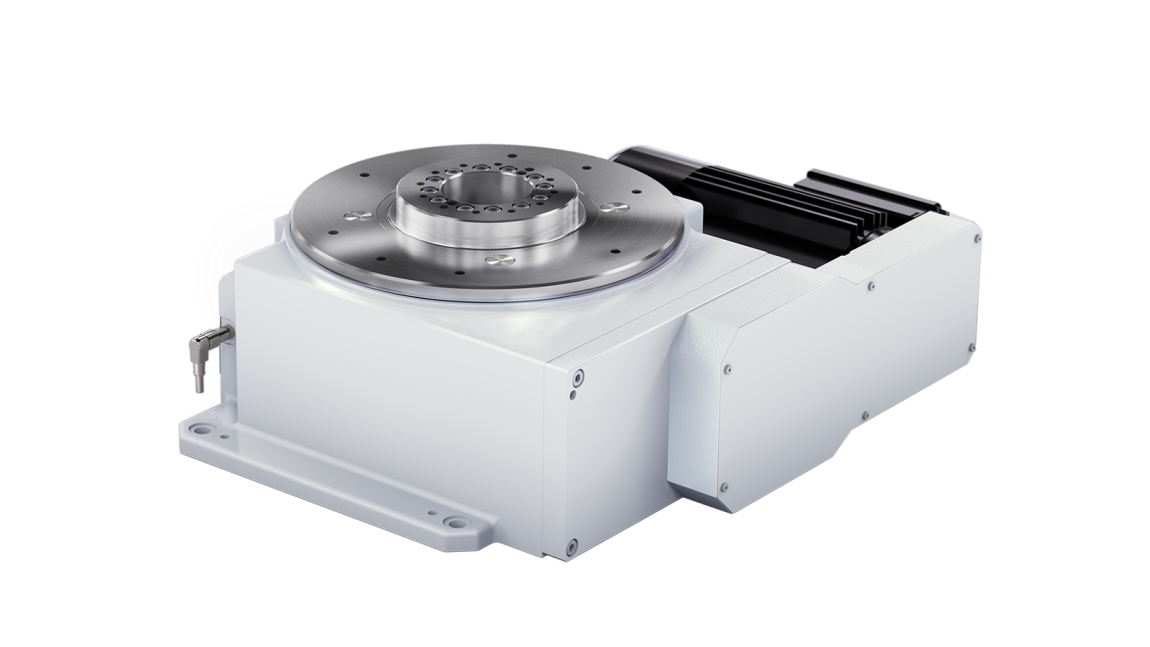

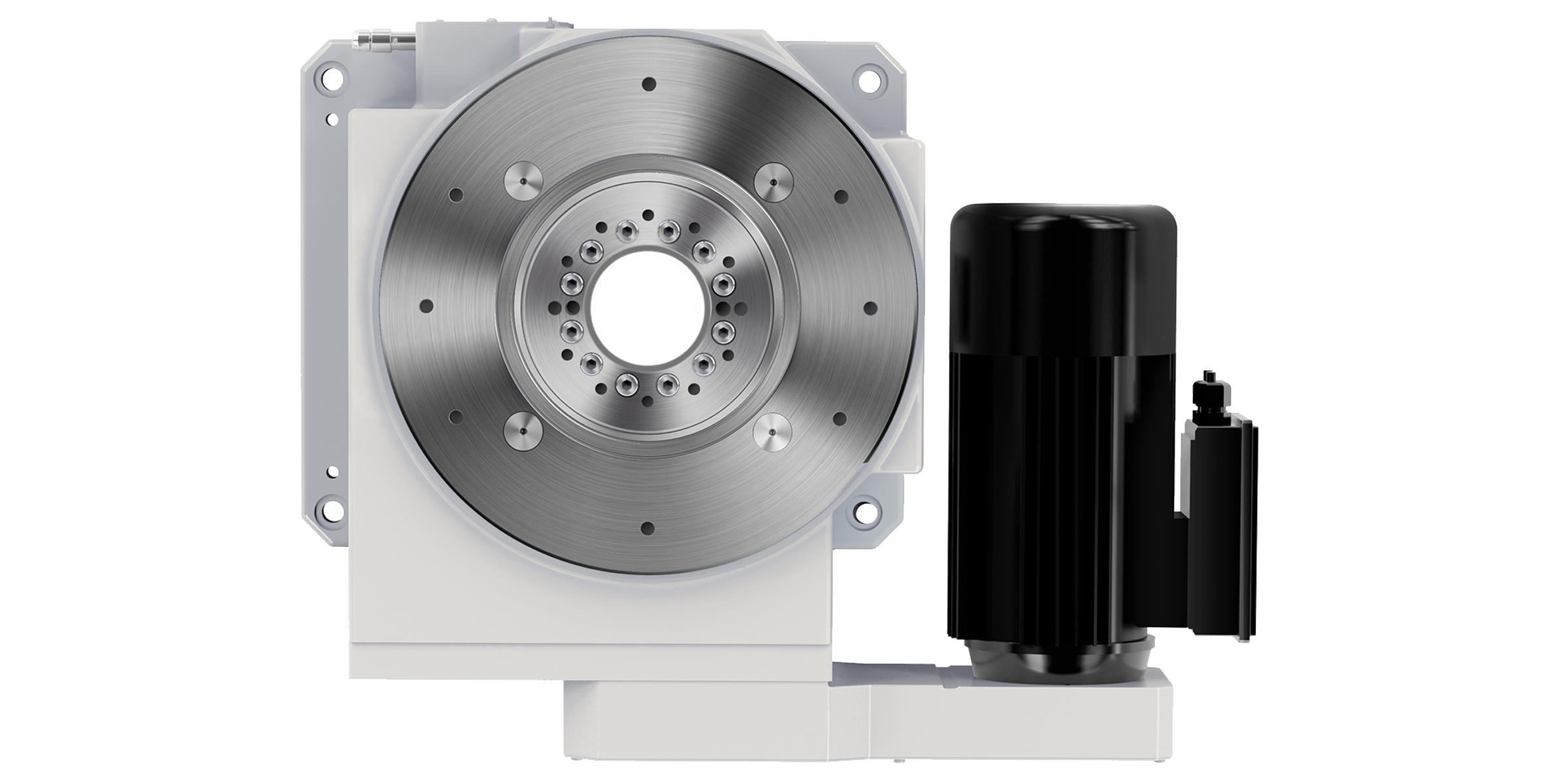

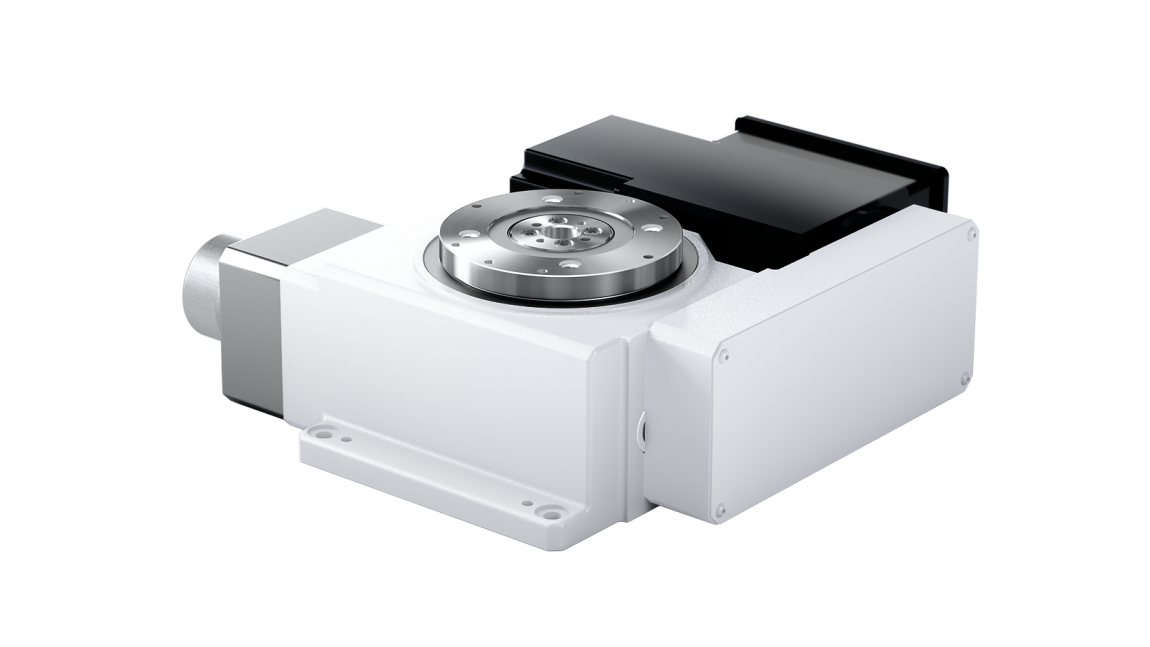

WEISS is a high quality manufacturer of cam, servo, and linear motor driven automation components. We supply the world with rotary index tables, palletized conveyors, linear motor driven pick and place units, cam and servo driven assembly chassis, ring index tables, and machine bases and tool plates. WEISS was founded over 40 years ago and is now the world leader in rotary indexing tables for assembly, welding, packaging, medical devices and many other industries. We specialize in the highest quality craftsmanship and offer an industry leading four year warranty. No matter if you need to rotate 100 tons or pick and place a 1 oz. part very accurately, WEISS has the solution. As the world leader in indexing/positioning tables we still have the most innovative designs and newest products. We also offer many other additional handling and positioning devices for your automation needs.

In 1996, Precision Detroit Company established a relationship with WEISS GmbH. WEISS has been manufacturing high quality index tables for decades and is the leading automation component manufacturer in Europe today.

In August, 2007, WEISS GmbH established WEISS North America, Inc. as a wholly-owned subsidiary. On September 30, 2007, WEISS North America, Inc. acquired the assets of Precision Detroit Company, Inc. relative to its PDC Geneva Motion index tables and its network of sales representatives throughout the U.S. and Canada.

Today, WEISS North America is not only a rotary table manufacturer but your complete automation manufacturer and solutions partner. WEISS has decades of expertise in providing automation, drive and control solutions to industrial markets. WEISS offers industry-specific, cost-effective and efficient technology solutions to help you maximize your efficiency, increase your productivity and achieve optimal system performance. We understand that your application has unique processes and specific requirements and we work closely with you to develop the perfect automation solution for your particular needs.

Successfully competing in our increasingly competitive global environment requires strategy, innovation and proven reliability from a partner that you can trust. Give us a call at 888-WEISSNA, fill out the form above, schedule a call below or simply send us an email to discuss your automation needs.

Rotary indexing table use is widespread in automated assembly machinery and selecting the proper mechanism is essential for both maximizing performance and minimizing the cost of this critical component. This how-to-guide will explore two common devices that can be used for rotary indexing and give advice for proper selection. These two popular devices are cam indexing drives and servo rotary tables.

Cam indexers are a ubiquitous mechanism that have been used for rotary tables for many decades. They are a great fit for applications that will always index the same angle and that require high-precision positioning at a very reasonable cost. A cam indexer uses a mechanical cam to provide the motion control to position the load. A mathematical motion curve is machined onto the cam that provides extremely smooth and repeatable motion.

A cam indexer has two main modes of operation. One mode is referred to as “Cycle-on-Demand”. This indicates that the camshaft will be cycled one revolution at a time to advance the output one position at a time. This is typically achieved by using an inexpensive camshaft sensor package to detect camshaft position and a VFD to stop and start the motor. The camshaft dwell period offers a wide window for the camshaft to stop without affecting the position of the output. To cycle the indexer, a PLC gives a command to the VFD to accelerate the drive motor to a preset speed, the cam rotates one revolution indexing the output, a sensor sends an in-position signal to the PLC, and the PLC signals the VFD to stop the camshaft during the cam dwell position. The table will be in the dwell position for however long is necessary to complete the work at each station. The dwell time can range from a fraction of a second to several minutes or hours depending on the application. This combination allows very accurate positioning with an inexpensive drive system.

A fully programmable servo rotary table is another common option. There are two specific cases where a servo rotary table is advantageous. The first is when a flexible motion pattern is required. An example is two different products being run on one machine that each require different indexing patterns. The other situation that suits a servo indexer is when extremely fast positioning is required followed by a long dwell period. A cycle-on-demand cam indexer is limited by the need to accelerate the camshaft up to speed during the dwell period before output motion is started. There are practical limitations to how fast the camshaft can be accelerated so there will be a delay before motion is started. With a servo rotary table, the output rotates as soon as the servomotor starts moving. A practical example would be a load being indexed 90 degrees in 0.25 seconds. This is not difficult for a continuous cam indexer or a zero-backlash servo indexer, but a cycle-on-demand cam indexer may struggle with that motion. For quick servo indexing applications, a preloaded gear reducer with zero-backlash is critical to achieving smooth indexing motions with minimal settling time. A zero-backlash RollerDrive mechanism would be an optimal choice to achieve accurate positioning with great dynamic response.

For either style of indexer, application information including moment of inertia, indexing angle, indexing time, and dwell time is required. A reputable manufacture should then be able to properly size the rotary table for the application.

Camco 1305RDM4H48-330 Rotary Indexer 4 Stop, 2 Hp, 180V DC Motor-Index Period: 330-Motion: msc.25-B10 Capacity at 50 RPM (in-lb): 21640-Internal Inertia (lb-in2): 4415CAMCO MSHV48880C-Y7A:-20:1 Ratio-Input RPM: 1750-Rating: 5.85-Service Factor: 1.2MADE...

Welding Rotary Tables - You find here 11 suppliers from Germany ✓ Netherlands and ✓ Switzerland. Please obtain more information on spare parts, servicing, maintenance, Repair, repair or accessories directly from the registered companies.

Are you looking for Welding Rotary Tables. IndustryStock"s product and service search engine will not only help you find relevant results for Welding Rotary Tables but also related products and services. All contact information of listed Welding Rotary Tables manufacturers, traders, suppliers and dealers are freely available to all users.

8613371530291

8613371530291