weiss rotary table pricelist

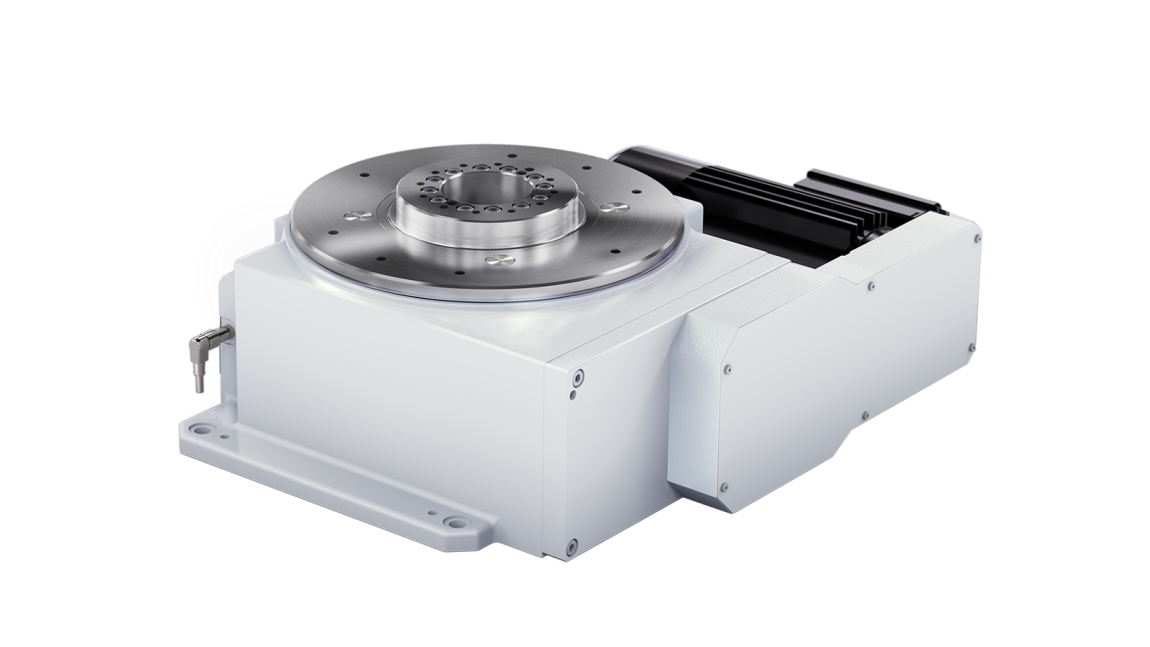

The NC combines robustness and durability with the advantages of a user-programmable rotary table that offers a high level of torque. This is made possible by the latest generation of servo motor drives with integrated absolute value encoder and a drive cam with constant pitch. For applications requiring extreme precision, we offer the additional encoder option, which is connected directly to the drive cam.The further refined NC range has been given a significantly larger central opening. The cables and hoses can now be guided downwards directly through the table or through the practical side channel. We have achieved this while maintaining the same external dimensions as its predecessors – which have now been replaced by the new range.

Beyond inventing a new, innovative ring binding system made of paper, Kugler-Womako was also the first in its sector to switch over to the accompanying binding production process from a traditional linear transfer unit to a rotary indexing ring. According to Anton Jost, Project Manager at Kugler-Womako, “Since our paper binding system is fundamentally new, we also wanted to rethink the processes employed. All previous binding machines worked with a linear system, but we wondered whether we could improve on this with a different approach.”

Ultimately, the concept for the first EcoBinder binding machine was a semi-automatic unit with four processing stations − based on a highly dynamic, fixed-position WEISS TR750 rotary indexing ring with 90 degree divisions.

Given their successful collaboration in establishing a rotary indexing table solution, the company further enlisted WEISS to manufacture and deliver the complete table including: subframe, a fixed and rotating aluminium ring with milled recesses and drilled mounting holes, as well as connection elements for the mountings of the processing stations. This allowed the engineers at Kugler-Womako to focus all of their attention on designing their new binding process.

Even with up to 12 stations, this machine wouldn’t prove to be a problem for the WEISS TR series which offers ring diameters of up to 2,200 mm – providing more than enough scope for coupling with processing stations.

Jost noted the mechanical integration capabilities of the rotary indexing rings from WEISS, “We were able to connect the frequency inverter control on the TR750 to our higher level machine control system with no issues. In fact, the binding machine was already up and running just a few hours after installation.”

When compared to a linear design, the WEISS TR750 rotary indexing table broke new ground for Kugler-Womako by saving space and moving the infeed and output areas of the blocks closer together − offering a particular advantage for manual operations. Essentially, because a rotary indexing table is made up of significantly fewer parts than a transfer line, it was also possible to lower the cost for the binding machine while increasing production quality.

An integral part of the Weiss global network, Weiss North America (ISO-9001 Certified) leverages over 45 years of reliable world-wide expertise to comprise an integrative, customer-specific approach to its vast array of electromechanical products. Our 100% vertical range of manufacturing ranges from rotary indexing tables, handling systems, and linear assembly systems−providing flexible technology for turnkey solutions that incorporate electronics, mechanical systems, software, and comprehensive engineering support. This enables us to provide pre-installed, intelligent, and highly convenient solutions for the entire field of kinematics.

Please Contact Us to Order to offer competitive prices and delivery time forWeiss - EF2150B-0000-0000-01 Web-based rotary table control number, also you may ask some other model number is well. We can offer competitive price, and delivery time with wide products distribution network in United States Industrial products Market.

FEATURES: The TSL series horizontal and vertical rotary tables are for indexing,circular cutting,angle setting,boring,spot facing operations and similar work in conjunction with a milling machine. This type rotary table is so designed as to permit...

Given these distinct design advancements, the customer’s end-use advantages are clear and simple. The same machining processes are handled in a smaller area and the floor space savings are immense−as twice the number of work stations can be set up on the exact same rotary indexing table or linear assembly system.

Additionally, the new unit is even more user-friendly, as the manual teaching of positions has been further simplified. The module can be moved freely and have its respective position saved by the WEISS Application Software (WAS) at the push of a button. Utilized for fast, convenient, and secure commissioning of all freely programmable WEISS components, WAS features a highly intuitive and uniform graphic user interface.

According to WEISS’ Product Sales Manager-Direct Drives, Josh Treter, “During its development, great emphasis was placed on ensuring the module"s compact dimensions. The result of these efforts is that the HP70 takes up less space than any other Pick-and-Place unit. At just 60mm wide, the slimline configuration eliminates the size advantage previously enjoyed by a pneumatic modules’ design. Also, conventional direct-drive modules cannot compete in this respect either – since they are significantly wider.”

Treter also noted, “The original inspiration for this new development came from practical applications in the field, with WEISS customers being responsible for improvement proposals to a certain degree. With the new system, you can now set up twice the number of workstations on the identical rotary indexing table or linear assembly system.”

Finally, in all phases of the manufacturing process, particular emphasis was placed on consistent cost optimization. The result is a cost savings of over 10%, which WEISS passes on directly to its customers. Combined with the significantly lower operating costs in comparison with pneumatic units (particularly when processing large quantities) and the lack of any maintenance costs−the compact HP70 powerhouse quickly pays for itself.

Please Contact Us to Order to offer competitive prices and delivery time forWeiss - TC0220T-0000-0000-10 Ротари маса number, also you may ask some other model number is well. We can offer competitive price, and delivery time with wide products distribution network in Bulgaria Industrial products Market.

Please Contact Us to Order to offer competitive prices and delivery time forWeiss - 507-634141102 motor number, also you may ask some other model number is well. We can offer competitive price, and delivery time with wide products distribution network in Lithuania Industrial products Market.

Nanjing Weiss Mechanical & Electrical Co., Ltd. Subsidiary of Weiss Machinery Co., Ltd. Established in 2008 Located in Nanjing Riverside Economic Development Zone Covers area of 22620 square meters Has 17000 square meters of modern workshop and office facilities Specialized in R&D and manufacture of various lines of metal cutting machine tools, including Lathe, Drilling and Milling Machines, CNC machines etc. WE SUPPLY MACHINE TOOLS OF THE BEST QUALITY ONLY We have built up our international sales network scattering all around the world. At present we have long lasting business partners in more than 60 countries, such as USA, UK, Germany, France, Russia, Australia, South Africa,...

8613371530291

8613371530291