weiss rotary table quotation

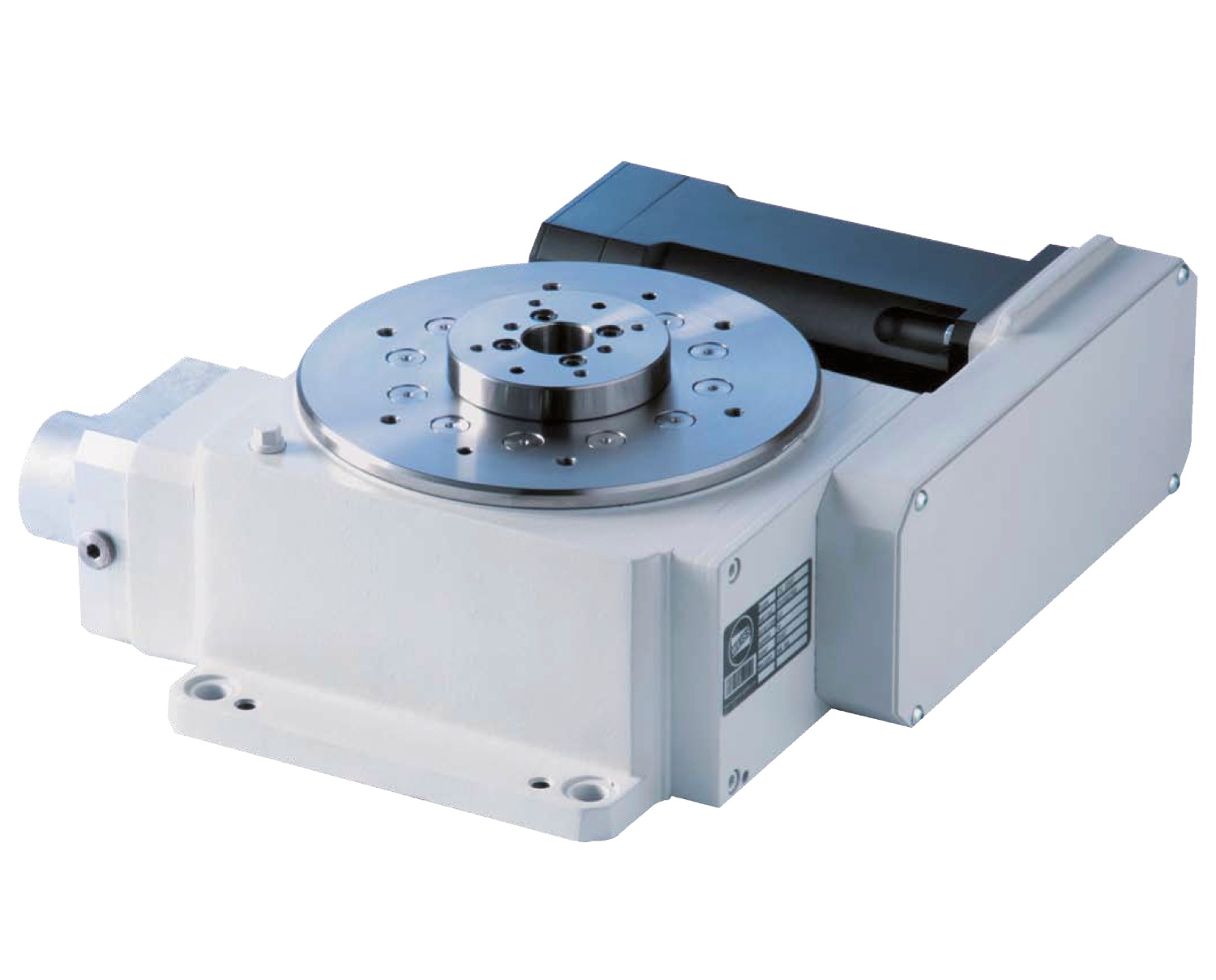

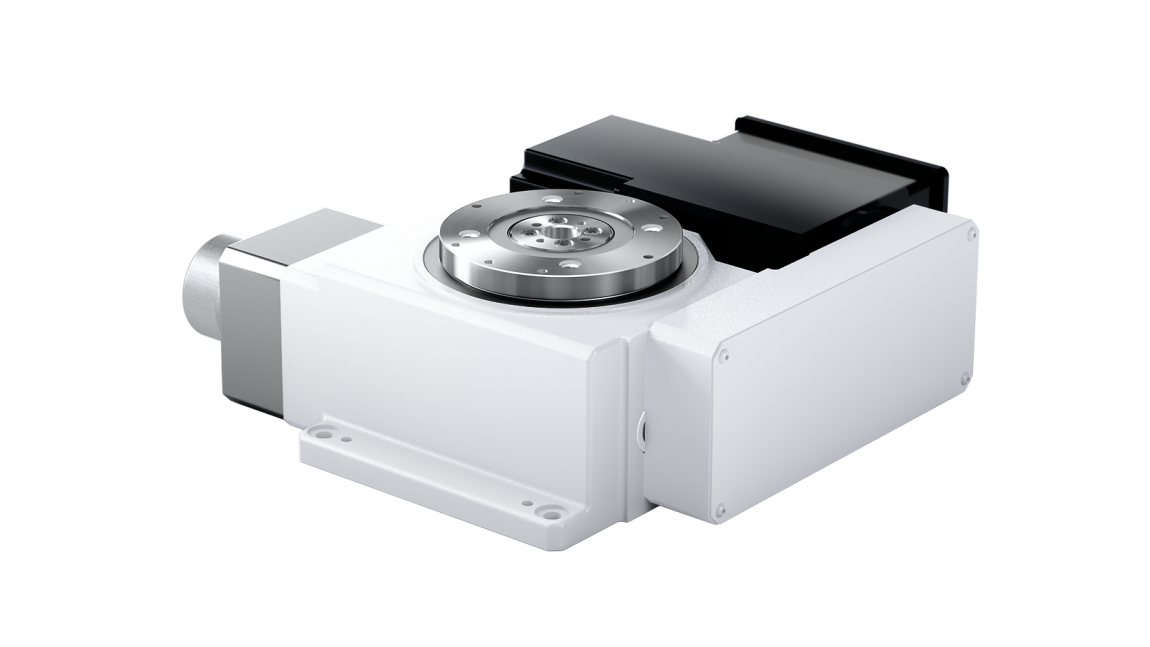

... with the advantages of a user-programmable rotary table that offers a high level of torque. This is made possible by the latest generation of servo motor drives with integrated absolute value encoder ...

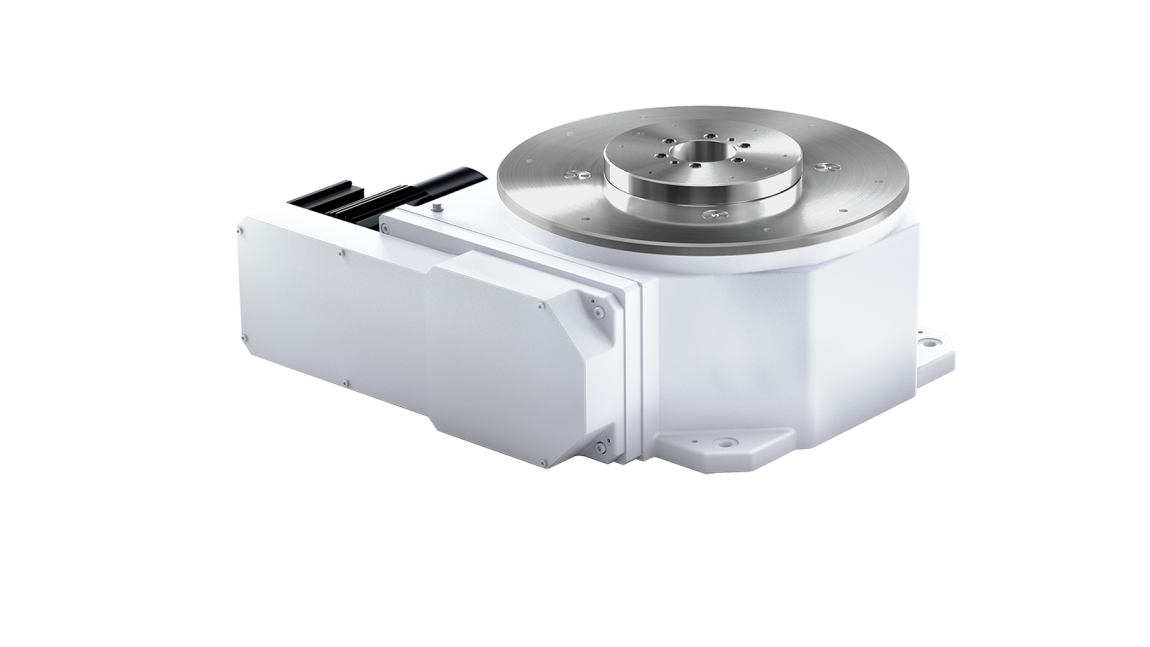

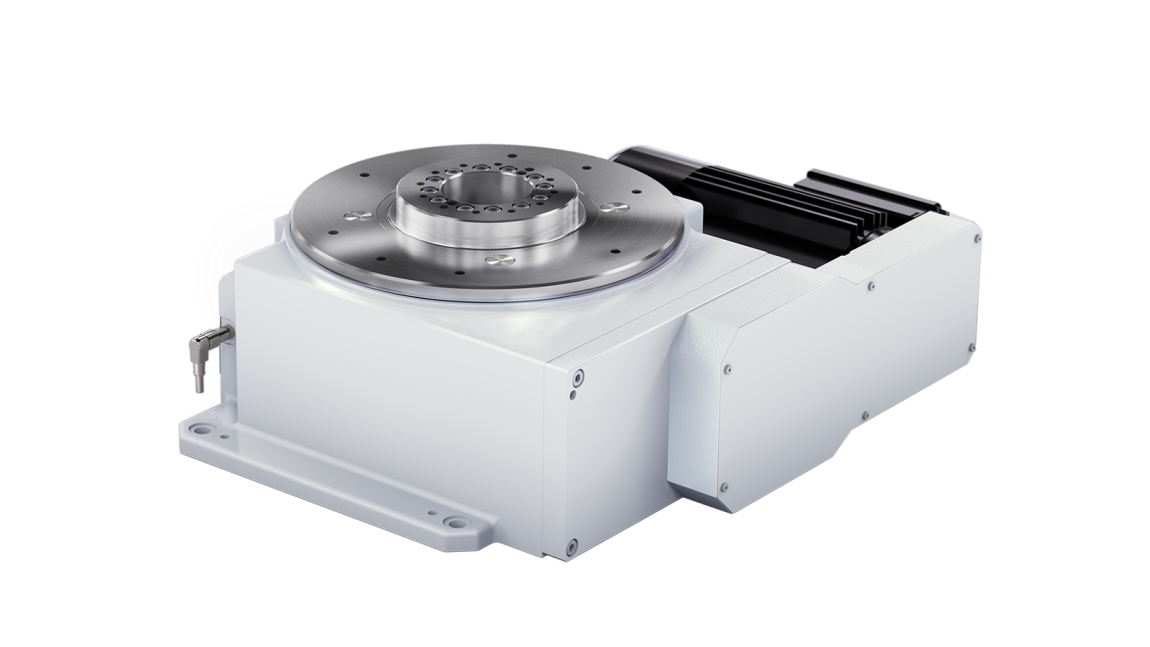

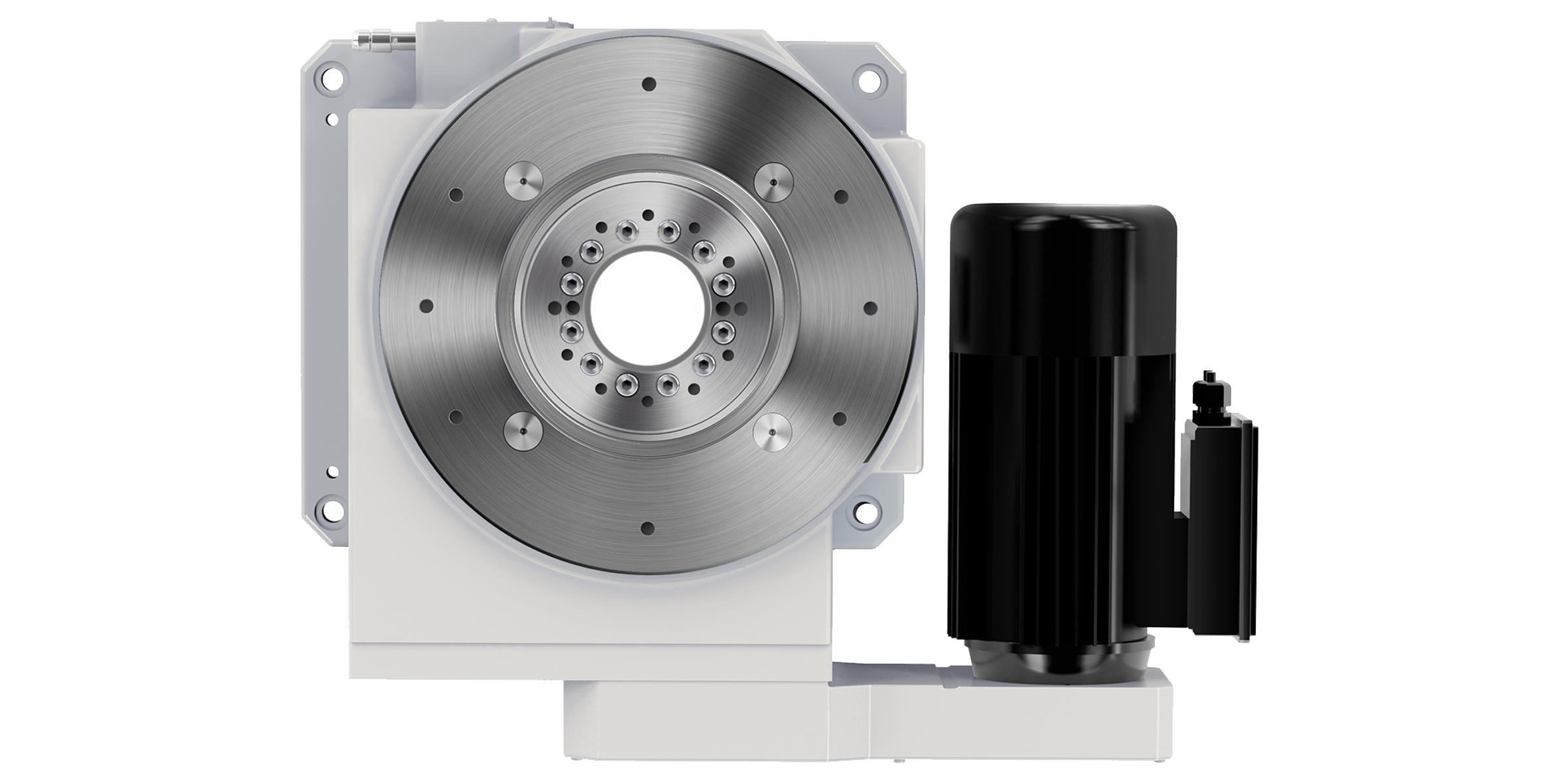

The TO750 is a direct drive rotary table. The device consists of an impressive dynamics and high degree of repeat accuracy. The device can be programmed freely and is suited on clean rooms.

In 1996, Precision Detroit Company established a relationship with WEISS GmbH. WEISS has been manufacturing high quality index tables for decades and is the leading automation component manufacturer in Europe today.

In August, 2007, WEISS GmbH established WEISS North America, Inc. as a wholly-owned subsidiary. On September 30, 2007, WEISS North America, Inc. acquired the assets of Precision Detroit Company, Inc. relative to its PDC Geneva Motion index tables and its network of sales representatives throughout the U.S. and Canada.

Today, WEISS North America is not only a rotary table manufacturer but your complete automation manufacturer and solutions partner. WEISS has decades of expertise in providing automation, drive and control solutions to industrial markets. WEISS offers industry-specific, cost-effective and efficient technology solutions to help you maximize your efficiency, increase your productivity and achieve optimal system performance. We understand that your application has unique processes and specific requirements and we work closely with you to develop the perfect automation solution for your particular needs.

Successfully competing in our increasingly competitive global environment requires strategy, innovation and proven reliability from a partner that you can trust. Give us a call at 888-WEISSNA, fill out the form above, schedule a call below or simply send us an email to discuss your automation needs.

We combine rotary index tables with industrial automation systems so each task of your manufacturing process blends seamlessly into the next. For example, in the past we’ve created industrial automation systems that join rotary indexing machines with pick-and-place units for some of our clients. Contact us to see what we can do for you.

Rotary indexers are just one part of the equation when building a custom assembly cell. It’s important to remember the entire scope of the project and be cognizant that the rotary table should be able to move precise distances before stopping cleanly, with no backlash or wobbling. It needs to be balanced and capable of handling the tasks at hand.

Our automation experts have years of experience in consulting with our customers to create machines that suit their needs. We incorporate rotary tables from industry leaders like WEISS, Fibro, and Camco into our machines to create the perfect fusion of form and function. Our dedication to quality is unmatched in the world of custom machinery.

We seamlessly integrate rotary indexing tables into our automated machinery to provide you with custom solutions that work for your business. If you’re looking to take your manufacturing process to the next level, give the custom machine builders at Paramount Tool a call at (616) 582-5300 today. We’re always happy to answer any questions you may have about our rotary indexing machines or the machine building process as a whole. For a free quote, fill out our contact form and we’ll get back to you as soon as we can.

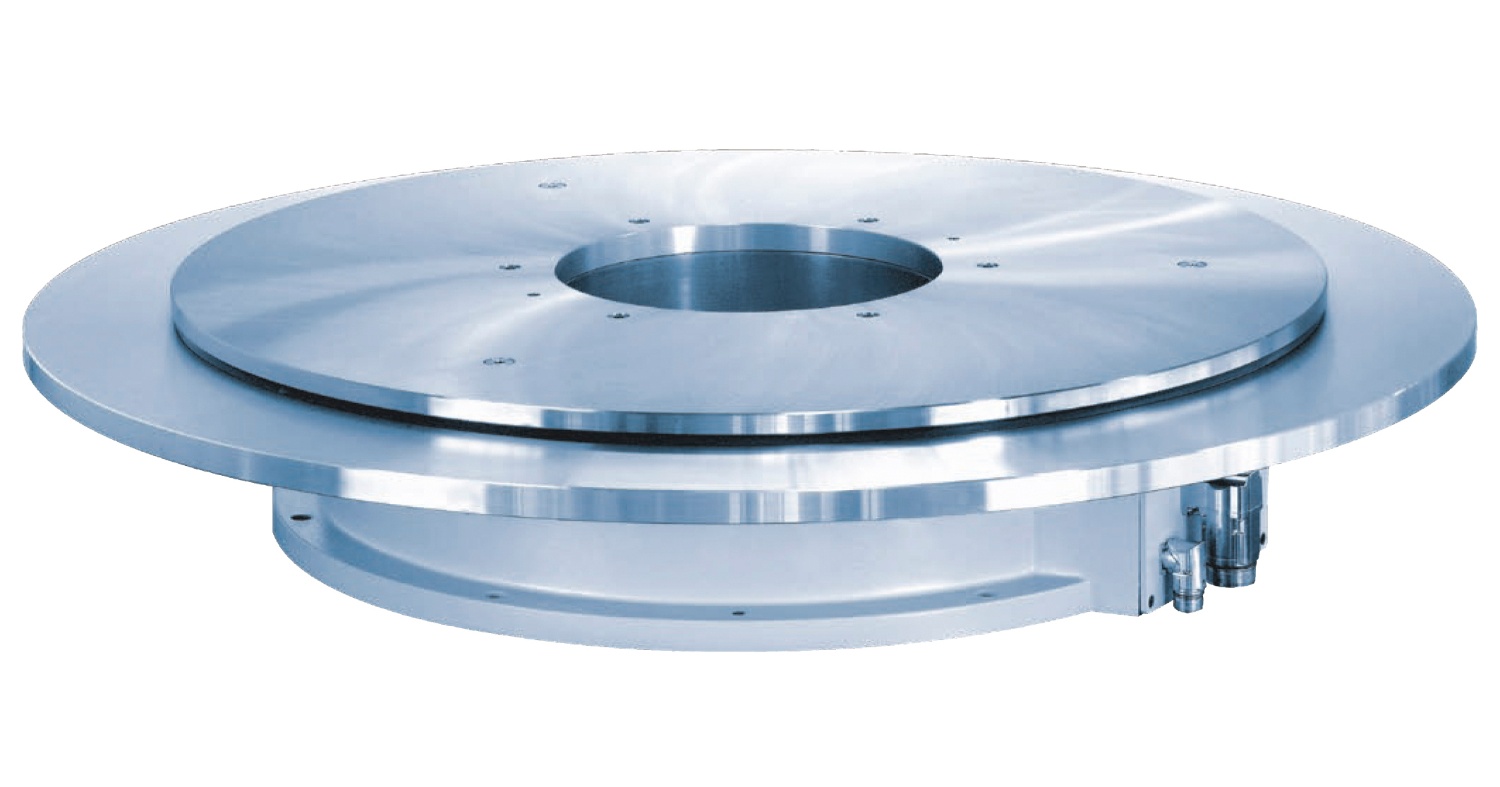

We have given the new TC range a significantly larger central opening for the 120 – 320 sizes. The cables and hoses can now be guided downwards directly through the table or through the practical side channel. We have achieved this while maintaining the same external dimensions as its predecessors – which have now been replaced by the new range.

Alongside automatic nest detection, with the new DriveCliq encoder option in connection with the EF2 rotary table control system we now also offer cam switching mechanism functionality, which permits a significant increase in the effectiveness of the overall system.

By the way: we also offer automation options for cleanroom environments. If you would like to receive information and offers relating to the Cleanline versions of our rotary tables

Rotary indexers for automation applications offer a high degree of flexibility and performance. As you’ll discover, if applied correctly, WEISS rotary indexers can operate at peak performance and output for many years with minimal maintenance and virtually no adjustments.

Weiss has been designing and building rotary and linear motion products for over 50 years. During that time, we have developed simple sizing tools that enable us to precisely calculate your requirements and ensure that you receive a product that meets or exceeds the specific demands of your application.

Our free Sizing Guide Forms greatly simplify the process of designing and specifying a rotary indexer but there are a few key concepts that must be understood before moving ahead with your rotary indexing project. The following guide will reveal these simple concepts and provide you with a deeper understanding of how to more easily specify your next rotary indexer.

Armed with this information, you can determine your Dwell Time (the time spent at each station) and Index Time (the time required for the dial or plate to index from one station to the next). Dwell Time is determined by “the longest” individual station processing time. You may specify a particular Index Time or WEISS can optimize the Index Time by reviewing the load and output requirements, potentially offering multiple possible solutions for your application.

Now that you have a brief understanding of these fundamentals, you can simply download and fill out a WEISS Sizing Guide Form that is freely available for download at https://smart.myweissna.com/sizing.

WEISS offers a broad selection of rotary indexing solutions that satisfies the needs of our customers from both a performance and price perspective. Our goal is to deliver solutions that yield the optimal level of cost vs. performance.

Manufacturer of modules for assembly plants types of products include rotary barrel cam indexers, tooling plates & machine bases, control software & linear motor driven handling systems. Capabilities include welding, assembly, material joining, testing/inspection, marking.

We supply the world with rotary index tables, palletized conveyors, linear motor driven pick and place units, cam and servo driven assembly chassis, ring index tables, and machine bases and tool plates. WEISS was founded over 40 years ago and is now the world leader in rotary indexing tables for assembly, welding, packaging, medical devices and many other industries.

We specialize in the highest quality craftsmanship and offer an industry leading four year warranty. No matter if you need to rotate 100 tons or pick and place a 1 oz. part very accurately, WEISS has the solution.

For holding medium to large parts or fixtures, the HRT210 rotary table is the answer. This rugged, heavy-duty table can be mounted vertically or horizontally for added versatility. Chucks and fixtu...

Our HRT210SS Super Speed rotary table uses a heavy-duty cycloidal drive system to provide a maximum indexing speed of 490° per second – nearly five times the speed of our standard HRT210. The unit’...

8613371530291

8613371530291