2 axis trunnion rotary table price

"twitter:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

"og:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

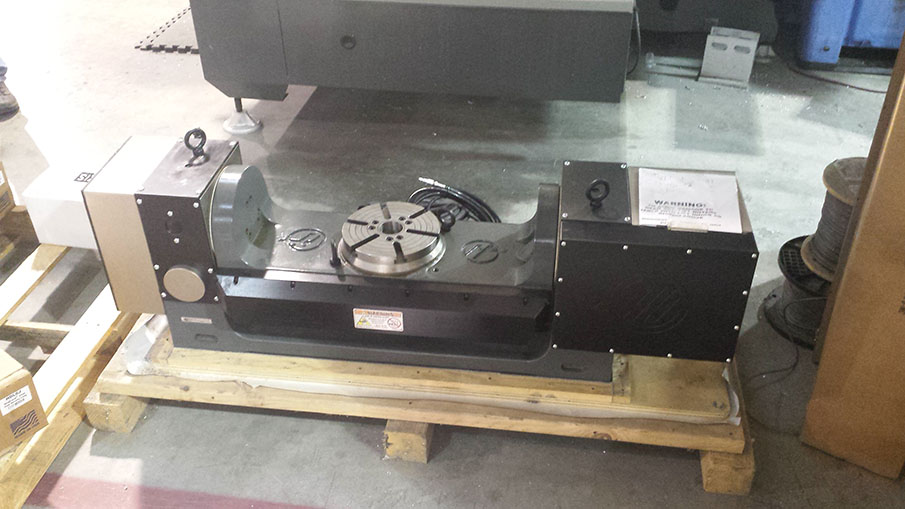

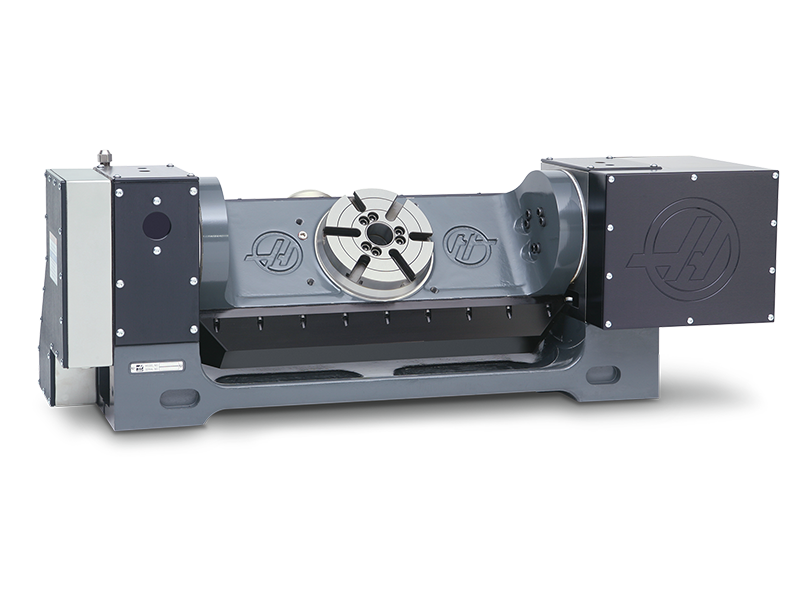

The TR160-2 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. The dual-spindle design allows two workpieces to be loaded and machined in a single setup. Scale feedback on the A (tilting) axis increases positioning accuracy and repeatability. The unit fits into VF-2 and larger VF Series machines (extended Z-axis clearance option highly recommended).

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

The TN4 Trunnion Table is a very compact yet rigid device offering rapid, zero backlash rotary motion using maintenance free Harmonic Reducers and Crossroller bearings. It is engineered and built here in California with all aluminum and stainless steel construction. This 2-Axis Trunnion is primary designed for machining applications and can be purchased as part of a complete 5 axis mill or as a retrofit to one of our existing 3 axis cnc mills. Both rotary axes are sealed to allow for operation with liquid coolant. Homing Switches are integrated into each axis to provide a repeatable reference point.

This trunnion table can also be used for non-machining applications such as dispensing and 2-Axis rotary positioning for sensor calibration. Call use today to discuss your custom application!

If you would like to discuss your 5-Axis CNC Mill application with us please give us a call and we will be happy to help you determine which of our Small 5-axis CNC Mill is best for you.

Turn Your Vertical Machining Center into a 5-Axis Production Machine. Designed specifically for Vertical Machining Centers, KME CNC’s 5-axis platters are built right into a precision rigid meehanite cast iron trunnion frame and table.

Standard models come with 1, 2, or 3 independent 5-axis platters on the trunnion table, giving your VMC full-range production capability. Just like the 5-axis tombstones, KME CNC’s trunnions are able to completely integrate with control systems, so you do not need to program the control box.

Increase productivity and reduce setup time with the TR-8, 4th- and 5th-axis rotary table by eliminating second and third operations. In a single set-up, achieve multi-sided machining capability as well as the ability to tackle tough complex shapes and difficult to reach angles. Both housings were based on our VH8 and still come packed with the same quality. Both spindles and worms have dual bearings. Each worm wheel is helically cut and throated for greater surface contact between the wheel and worm. The B axis housing uses a stronger motor to make up for the extra weight of tilting the A axis housing and maintain accuracy.

Our control box is a cost-efficient solution for machining parts not needing true 5-axis, simultaneous motion. Add a single-axis controller with our 5th axis head turning your 4th axis machine into 4+1. Or add our dual-axis controller with our 5th axis head turning your 3 axis machine into 3+2.Either way, this allows you tomachine 5 sides of a part, thus reducing the number of machining operations and dramatically increasing efficiency and accuracy.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th and 5th axis drive needed.

The Double Sided Stallion Trunnion Table takes efficiency to the next level by holding double the amount of parts as the Stallion 6/18. This fixture has a 6" x 18" working surface, making it ideal for self centering vises and other workholding products. Every time a part is handled or indicated, there is an increased risk of scrapping it. The Stallion Trunnion Table minimizes this risk through 4th axis milling. With full 360-degree rotation, machining multiple sides of a part becomes possible, allowing your operators to handle a part as little as necessary.

The same Stallion Trunnion Table, up to eight times the productivity. Built for the highest production jobs. Available in 3 to 8 sided configurations. Complete solutions available to maximize your VMCs throughput. Also made for any rotary table and machine tool on the market.

Payment must be made via WIRE TRANSFER or ACH only.Final payment information will be provided in a separate invoice within 24 hours following the auction. Payment must be received in full within 48 hours of receipt of invoice.

The fastest way to increase the productivity of your Haas mill is to add a Haas single or dual-axis rotary product. You can reduce or totally eliminate multiple setups, and easily handle machining multi-sided parts.

With a full line of Haas rotary products, including many specialised units designed for maximum productivity, Haas continues to lead the way to higher productivity through automation.

All Haas rotary products are designed to integrate seamlessly with the control on your Haas mill. This means true simultaneous 4-axis or 5-axis motion, synchronized with the axes of your mill. Rotary setup is a simple plug-and-play process through the Haas Control, with on-screen instructions, and diagrams that are intuitive and easy to use. It’s possible to install a Haas rotary on other makes of mill as we also offer the Haas Servo Control. Activated by a single M-code, the Servo Control is easy to set up, and fully programmable.

Adding a rotary axis to your CNC mill is the fastest way to boost throughput and increase accuracy. Because Haas began as a rotary table manufacturer in the 1980s, we are able to provide the simplest and most cost-effective entry into 4-axis and 5-axis machining available.

Going from 3-axis machining to 4-axis and 5-axis machining can be intimidating. This short video shows how easy it is to transition from basic 3-axis milling to full 5-axis design and production.

Haas offers a wide selection workholding solutions for your 4-axis and 5-axis clamping needs, from compact air-collet closers to quick-change fixture plates to manual scroll chucks.

Constructed of heavy-duty materials and designed for dependable day-in, day-out operation, Haas rotary products are the benchmark by which all others are measured. We manufacture all critical components in-house at our state-of-the-art California facility. At the core of every Haas rotary table is a large-diameter, aluminium-bronze worm gear meshing with a ground alloy steel worm (hardened to 60 Rc) submerged in a synthetic oil bath.

To ensure indexing accuracy, we cut the worm gear while it’s attached to the spindle, rather than assembling the finished worm gear to the spindle, as other manufacturers do. Each assembled spindle is trammed-in on a CNC gear hobber to a maximum 2-micron runout, and then the worm gear is precision cut. This guarantees the utmost concentricity between the large-diameter ball bearings and the worm gear, ensuring many years of smooth, extremely accurate, and bind-free operation.

8613371530291

8613371530291