2 axis trunnion rotary table pricelist

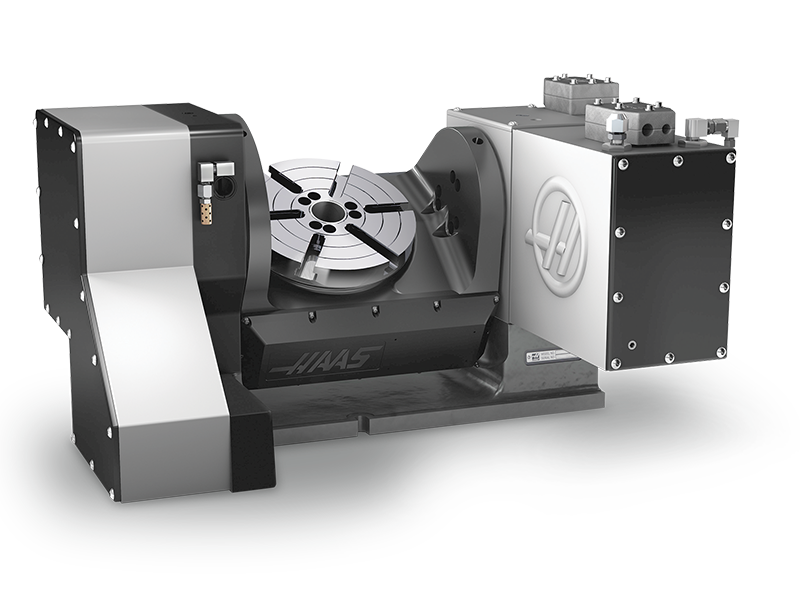

The TR160-2 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. The dual-spindle design allows two workpieces to be loaded and machined in a single setup. Scale feedback on the A (tilting) axis increases positioning accuracy and repeatability. The unit fits into VF-2 and larger VF Series machines (extended Z-axis clearance option highly recommended).

Increase productivity and reduce setup time with the TR-8, 4th- and 5th-axis rotary table by eliminating second and third operations. In a single set-up, achieve multi-sided machining capability as well as the ability to tackle tough complex shapes and difficult to reach angles. Both housings were based on our VH8 and still come packed with the same quality. Both spindles and worms have dual bearings. Each worm wheel is helically cut and throated for greater surface contact between the wheel and worm. The B axis housing uses a stronger motor to make up for the extra weight of tilting the A axis housing and maintain accuracy.

Our control box is a cost-efficient solution for machining parts not needing true 5-axis, simultaneous motion. Add a single-axis controller with our 5th axis head turning your 4th axis machine into 4+1. Or add our dual-axis controller with our 5th axis head turning your 3 axis machine into 3+2.Either way, this allows you tomachine 5 sides of a part, thus reducing the number of machining operations and dramatically increasing efficiency and accuracy.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th and 5th axis drive needed.

The Double Sided Stallion Trunnion Table takes efficiency to the next level by holding double the amount of parts as the Stallion 9/23. Every time a part is handled or indicated, there is an increased risk of scrapping it. The Stallion Trunnion Table minimizes this risk through 4th axis milling. With full 360-degree rotation, machining multiple sides of a part becomes possible, allowing your operators to handle a part as little as necessary.

The 9/35 Stallion Trunnion Table allows for even larger parts than the 9/23. At this size, we recommend adding our hydraulic clamping outboard braking system to decrease the possibility of tool forces moving the rotary table by overpowering the rotary table brake system. Every time a part is handled or indicated, there is an increased risk of scrapping it. The Stallion Trunnion Table minimizes this risk through 4th axis milling. With full 360-degree rotation, machining multiple sides of a part becomes possible, allowing your operators to handle a part as little as necessary.

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits into the CM-1 or larger machines. It is ideal for smaller ...

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version ...

Our redesigned TRT160 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater mounting flexibility than its predecessor. ...

Our redesigned TRT210 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater mounting flexibility than its predecessor. ...

... TRT310 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its compact size also provides greater mounting flexibility in mid-size mills. The unit easily ...

The TR160 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. Scale feedback on the A (tilting) axis ...

The TR160-2 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. The dual-spindle design allows two workpieces ...

The TR200Y is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. Scale feedback on the A (tilting) axis ...

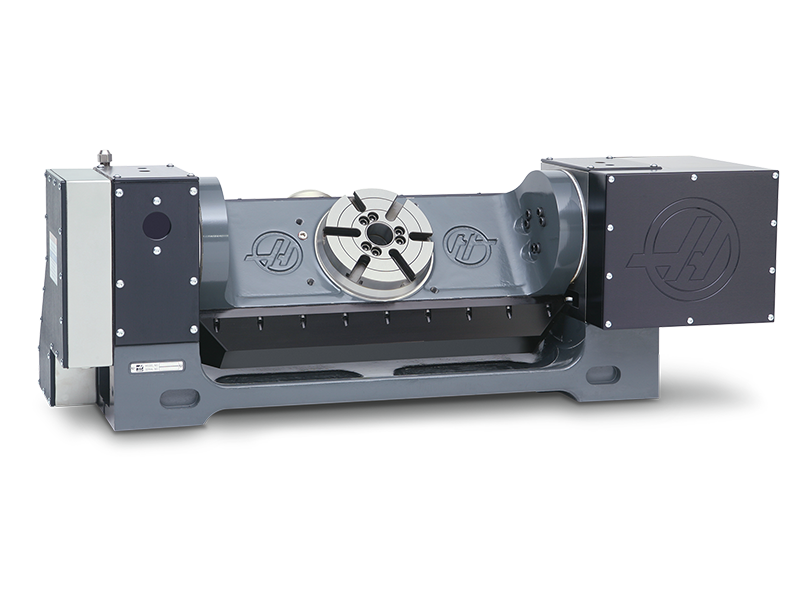

The TR210 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of medium to large parts. Scale feedback on the A (tilting) axis ...

The TR310 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of medium to large parts. Scale feedback on the A (tilting) axis ...

The TN4 Trunnion Table is a very compact yet rigid device offering rapid, zero backlash rotary motion using maintenance free Harmonic Reducers and Crossroller bearings. It is engineered and built here in California with all aluminum and stainless steel construction. This 2-Axis Trunnion is primary designed for machining applications and can be purchased as part of a complete 5 axis mill or as a retrofit to one of our existing 3 axis cnc mills. Both rotary axes are sealed to allow for operation with liquid coolant. Homing Switches are integrated into each axis to provide a repeatable reference point.

This trunnion table can also be used for non-machining applications such as dispensing and 2-Axis rotary positioning for sensor calibration. Call use today to discuss your custom application!

If you would like to discuss your 5-Axis CNC Mill application with us please give us a call and we will be happy to help you determine which of our Small 5-axis CNC Mill is best for you.

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version M18.24B or later. Not available for stand-alone operation.

5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Dual-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Triple-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Quad-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Dual-Spindle Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

200 mm (7.9") Compact Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Mounts along Y axis of VF- 3 and larger machines. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box.

210 mm (8.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

210 mm (8.27") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

310 mm (12.2") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

Dual-Spindle Servo 5C System mounted on plate with pneumatic tailstocks. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation. This ...

5C Collet Servo Rotary Head with Manual Collet Closer. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation.

Dual-Spindle Servo 5C System. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation. This unit has no collet closing capability as st...

Triple-Spindle Servo 5C Heads with heavy-duty motor. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation. This unit has no collet c...

Quad-Spindle Servo 5C Heads. Requires Haas mill with 4th axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation. This unit has no collet closing capability as sta...

5C Collet Super-High-Speed 725 deg/sec indexing with manual collet closer. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation.

160 mm (6.3") Roller Cam Rotary Table with 830 deg/sec indexing. Requires Haas mill with 4th-axis drive for full 4th-axis operation. Requires a Haas mill wi...

210 mm (8.3") Roller Cam Rotary Table with 830 deg/sec indexing. Includes the necessary 4th-axis drive and wiring. Requires a Haas mill with software version 18.13 or later. Not available for stand...

160 mm (6.3") Servo Rotary Table. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation.

160 mm (6.3") Dual-Spindle Rotary Table, 10" (254 mm) center distance. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation.

160 mm (6.3") Servo Rotary Table with wraparound motor. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation.

160 mm (6.3") Super-Speed Servo Rotary Table with 570 deg/sec indexing. Requires Haas mill with 4th-axis drive. Mills built before 1/1/2011 require software version 17.06C or later; mills built aft...

210 mm (8.3") Servo Rotary Table. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation.

210 mm (8.3") Dual-Spindle Servo Rotary Table, 12" (305 mm) center distance. Cannot be operated laying on its back. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary c...

210 mm (8.3") Servo Rotary Table with special cable assembly, modified to stand upright. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone ...

210 mm (8.3") Servo Rotary Table with wraparound motor. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation.

310 mm (12.2") Servo Rotary Table. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation.

310 mm (12.2") Servo Rotary Table with wraparound motor. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation.

450 mm (17.7") Servo Rotary Table. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation.

600 mm (23.6") Servo Rotary Table. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation.

Rotary Table with A1-5 Spindle Nose (draw tube not available). Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation.

Rotary Table with A1-6 Spindle Nose (draw tube not included). Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation.

5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard.

Dual-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard.

Triple-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard.

Quad-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard.

160 mm (6.3") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedbac...

160 mm (6.3") Dual-Spindle Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. ...

210 mm (8.27") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedba...

310 mm (12.2") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedbac...

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation.

It may be a moot point due to iffy support and prices, but it seems to me the trunnion of the (German) Spinner U5 620 and U5 1520 would be the most versatile and yet rigid at the same time. The main table support is at the column but unlike some of that design that just hang out, the Spinner also has an outboard support for the table. And the tables are pretty large, about 25 inch diameter, so big enough for much standard 3 axis work as well. And yet the machines are not huge....around 13,000 lb for the U5 620 I think.

Having said that, I have a Hurco VM10U 5 axis...which has only an 8 inch table, with obstructions from the trunion supports left and right....but it seems like every video I see of 5 axis work they are doing something that would easily be within the capabilites of the Hurco regardless....so maybe it"s really rare a 25 inch table would be needed anyway. Best use of the larger round tables might be multivise fixtures where you can set up for 3 to 6 parts in one run.

The advantages of 5-axis machining are many. A particularly significant advantage is that a workpiece can be mounted on the table only once, meaning that up to five surfaces can be machined with a single chucking operation.

In addition, repeated setup changes cause errors in workpiece mounting accuracy. 5-axis machining minimizes the number of setup changes, minimizes mounting errors, and improves machining accuracy.

When using a 3-axis MC to cut areas with large height differences and deep depths, the cutting tool must be long enough to avoid collision with the spindle and toolholder. However, the longer the cutting tool extends, the more likely it is to deflect. This causes vibration during machining, which deteriorates the surface and dimensional accuracy of the workpiece.

On the other hand, 5-axis MCs can tilt the spindle and table, allowing machining of deep areas even with shorter tools and maintaining machining accuracy.

Firstly, as 5-axes are controlled, it requires more advanced control technology than 3-axis machining. In addition, as the number of axes handled increases, it becomes more difficult to program tool paths, so CAM software to create highly functional NC programs for machining is also essential. Another issue is that the “accumulated error”, which is the accumulation of small errors in each axis, can become large.

In response to these issues, machine tool builders that develop 5-axis MCs are focusing on improving machining accuracy and control technology. They are also pursuing improvements in usability, such as more efficient program creation.

8613371530291

8613371530291