ag davis rotary table factory

The ULTRARON is a precision-engineered rotary table, produced entirely at A.G. Davis - AA Gage, with applications for inspection, tool room and/or production machining. The ULTRARON"s accuracy is made possible by the use of precision lapped balls and integral ground races. The ULTRARON has a standard concentricity accuracy of 30 millionths T.I.R. (0.000030) and a wobble or rotating parallelism is held within 100 millionths (0.0001) on sizes to 24" in diameter.

The A.G. Davis - AA Gage Precision Broach Rotary Tables are high precision rotary systems manufactured for precision broaching applications. The Broach Rotary Tables can be supplied with stand-alone or rack-mounted controller, or can be interfaced to your operational Rotary Axis Control.

The Precision Rotary Tables are designed for use in Metrology, Inspection, and other precision applications. The Rotary Tables can be supplied with stand-alone or rack-mounted controllers, or can be interfaced to your operational Rotary Axis Control. The control is a solid-state, closed-loop system incorporating the latest State-of-the-Art concepts and can include IEEE or RS232 interface for remote program control.

The Air Float Rotary Table consists of hardened steel faceplate, which is floated on air in the thrust plane and centered by preload ball bearings radially during rotation. After an index move is completed the Air float is shut off allowing the faceplate to rest on the base of the rotary table producing excellent wobble characteristics. This action also friction locks the Air Float Rotary Table. A high-grade meehanite base casting is used to support the faceplate. Standard faceplate mounting pattern is by threaded hole patterns with other configurations available. The Air Float Type Precision Rotary Table can only be used with the faceplate in the horizontal plane.

The Ball Bearing Rotary Table consists of hardened steel faceplate supported by a maximum diameter preloaded angular contact ball bearing. The large diameter ball bearing produces excellent wobble characteristics. The preloaded ball bearing along with the closed loop servo system provides for continuous as well as point-to-point measuring. A high-grade meehanite base casting is used to support the ball bearing. Standard faceplate mounting pattern is by threaded hole patterns with other configurations available.

The Air Bearing Rotary Table consists of hardened and stabilized stainless steels and/or high-grade steels with corrosion resistant coatings. The base is made from high-grade meehanite castings. The Rotary Table employs a fully trapped gas bearing for both radial and thrust planes. The gas bearing jets are manufactured of precision machined gemstones. The air bearing along with the closed loop servo system provides for continuous as well as point to point measuring. Standard faceplate piece part hold down consists of threaded hole patterns, or special configurations are optionally available.

Air bearings require small clearances between rotating members. The possibility of these surfaces contacting each other during rotation is a major concern of air bearing users. Typically when this touch down does occur conventional air bearings will seize up and require major repairs. A.G. Davis-AA Gage has eliminated this possibility. The air orifice manifold detail is constructed from hardened stainless steel. The opposing surfaces are constructed from high-grade hardened steel and coated with a proprietary material. This construction permits the air bearing to lose air pressure while rotating even under maximum rated load and not damage the air bearing thrust and radial precision surfaces. After the air pressure is reinstated the bearing will freely operate as before.

The servo drive utilizes a capstan type friction wheel drive system. This drive system eliminates backlash (lost motion) between the servo motor and the Rotary Table it must position. The zero backlash condition provides an excellent foundation for a servo system which positions accurately without instability over a wide range of payload conditions.

The drive is constructed to eliminate any side loading of the rotary table bearings. Tangential loading only. This is accomplished by mounting the entire capstan drive package on a pivot which is tangent to the table drive rim. The main capstan drives on the O.D. of the drive rim while an opposing wheel bearing runs on the I.D. of the drive rim. The drive force required to engage the main capstan is provided by the opposing wheel bearing which creates a pinching action on the drive rim. This pinching action along with the pivot allow the drive to follow the drive rim"s motion without imparting any force to the rotary tables precision bearings. Note -unwanted side loading of the rotary table bearing will cause an increase

The base of the rotary table can be provided with air jet pads. These pads when actuated allow the rotary table to float on a level continuous flat surface. This feature is particularly convenient to CMM users who often move the rotary table to other locations on the CMM for various applications. The Air Ride is actuated by a dead man switch (automatically turns off when released). The switch is located adjacent to the drive cover.

A micro switch can be provided to close approximately 10° to 15° before the encoder"s marker pulse. The approach direction can be either clockwise or counterclockwise. Specify the desired approach direction when ordering. The encoder marker pulse will be located within 5° of the rotary tables zero position (the RT outline drawing shows the rotary table at it"s zero position).

A switch (DISENGAGE/ENGAGE DRIVE) can be provided adjacent to the drive cover. This toggle switch actuates a cylinder that alternately disengages and/or engages the drive. This switch also turns the Air Float Bearing on and off. This permits freewheel rotation of the face plate for faster centering and complete manual operation.

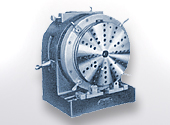

The ULTRADEX MK II & III Indexing Table is designed for precision machining, inspection, calibration, test gear and other applications where absolute rotary positioning accuracies of 1/2 arc second band tolerance not accumulative (+/- 1/8 arc second) or better are required, with a repeatability accuracies to +/- 1/20 arc second.

The tables are manufactured for manual indexing applications; automatic tables are available (consult factory). They are supplied with a wide range of indexing positions varying from 180 to 1440. Accessories are supplied for sub-dividing the positioning increments, by both mechanical and electronic means, to give an almost infinite number or rotary positions.

Custom manufacturer of gaging systems & components including automatic gaging systems. Gages, indexing tables & workholding devices are available. Design & build capabilities include PC-based programmable statistical process control & control programs with customized software. Other capabilities include surface grinding & jig boring.

Afghanistan, Algeria, Angola, Azerbaijan Republic, Bahrain, Bangladesh, Belarus, Benin, Bhutan, Botswana, Brunei Darussalam, Burkina Faso, Burundi, Cambodia, Cameroon, Cape Verde Islands, Central African Republic, Chad, Comoros, Côte d"Ivoire (Ivory Coast), Democratic Republic of the Congo, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon Republic, Gambia, Georgia, Ghana, Guinea, Guinea-Bissau, Iraq, Jordan, Kazakhstan, Kenya, Kuwait, Kyrgyzstan, Lebanon, Lesotho, Liberia, Libya, Macedonia, Madagascar, Malawi, Mali, Mauritania, Mauritius, Mayotte, Mongolia, Morocco, Mozambique, Namibia, Niger, Nigeria, Oman, Qatar, Republic of Croatia, Republic of the Congo, Reunion, Russian Federation, Rwanda, Saint Helena, Saudi Arabia, Senegal, Seychelles, Sierra Leone, Slovakia, Somalia, South Africa, Sri Lanka, Swaziland, Tajikistan, Tanzania, Togo, Tunisia, Turkey, Turkmenistan, Uganda, Ukraine, United Arab Emirates, Uzbekistan, Western Sahara, Yemen, Zambia, Zimbabwe

Design & mfg of ultra-precision rotary motion systems to test & calibrate exacting applications. Design & mfg of precision gaging systems manual & fully automatic. Also a line of Hydra-Grip workholders - arbors and chucks. Ultradex, Ultraron, SPC Software

accelerometers, absolute, acceptance, accuracy, air,bearings, alignment, analog, angle,measurements, angularity, apply, arbors, artifact, attribute, audit, autodex, automaticm, axis, bar, bearing, best-fit, bizillionths, bore, broaching, calibrate, calibration, chamfer. checkmate, , chucks, circularity, column, comparison, compensation, con-ax, concentricity, contouring, controls, couplings, custom , cylindricity, dedicated, depth, depth, gage, diagnostic, dial, diameter, digital, circle divider, roto-con, dimensional, disc, display, digasine, eccentricity, electronic,encoder,inspection, fail, feeler, final-inspection, fit, fixture, flatness, flexible, flush,pin, form, function,functional, gage-maker, gases, geometric, go, g-no,go, grip, groove, guidance, gyroscope, hand,height, hirth, hole, hydra-grip, i.d., indicating, indicator, inertial,navigation, index, indexer, indicator, in-line, in-process, inside, inspection, lay-on, layout, length, limit, linear, machining, master, manudex, measurement, measurement devices, metric, metrology, micron, milling, minimum-maximum, miss-alignment, multiple, multi-axis systems, no-go, o.d., off-line, omni, on-line, outside, parallelism, pass, perpendicularity, plug polygons, position, precision, production, profile, program, quality, rate,tables, readout, reject, relation, resolver,testing, ring, roil-chek, rotary, roundness, runout, servo,systems, sight, size, snap, software, spc, special,delivery, squareness, station, straightness, star-tracker, sweep, tables, teeth, template, test, test,stands, thread, tolerance, true position, ultrachucks,ultradex, ultraron, ultra-ro-dex, variable, width, workholding,

precision rotary index tables, gages, gage components, fixture gaging, work holding and automatic gaging systems - a. g. davis / aa gage in michigan.

AG Davis / Aagage Precision Rotary Table (36 inch). Jack"s Rigging & Machinery L.L.C. 36" diameter Model No: R17398-2 Serial No: 2405 Year: 6/20/03 1000 lb capacity Needs Servo Motor Very Little use

A.G.Davis-AA Gage Company is a world class producer of a complete line of standard gages and custom gaging equipment as well as semi-auto and fully automatic inspection machines for over 53 years. The precision required in the manufacturing of gaging equipment lead the company into the manufacture of high precision Rotary Table products, and Rotary Indexers that gives customers rotary accuracies into the sub-arc second categories.

A.G.Davis-AA Gage also designs and manufactures Work Holding fixtures, featuring it"s "Hydra-Grip" Arbors and Chucks. All these products have served the aerospace, aircraft, automotive, bearing, consumer products, defense, off road and many other industries where integrity and accuracy is essential.

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

A. G. Davis - AA Gage has been the industry leader in providing the design and manufacture for precision gages of all types, from small attribute (go/no go) gages, variable (data) gages, standard gages and components, to transfer line, gantry loaded semi-automatic and fully automatic inspection machines.

B23Q39/04—Metal-working machines incorporating a plurality of sub-assemblies, each capable of performing a metal-working operation the sub-assemblies being arranged to operate simultaneously at different stations, e.g. with an annular work-table moved in steps

B23Q39/04—Metal-working machines incorporating a plurality of sub-assemblies, each capable of performing a metal-working operation the sub-assemblies being arranged to operate simultaneously at different stations, e.g. with an annular work-table moved in steps

B23Q39/042—Metal-working machines incorporating a plurality of sub-assemblies, each capable of performing a metal-working operation the sub-assemblies being arranged to operate simultaneously at different stations, e.g. with an annular work-table moved in steps with circular arrangement of the sub-assemblies

Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

8613371530291

8613371530291