autocam rotary table brands

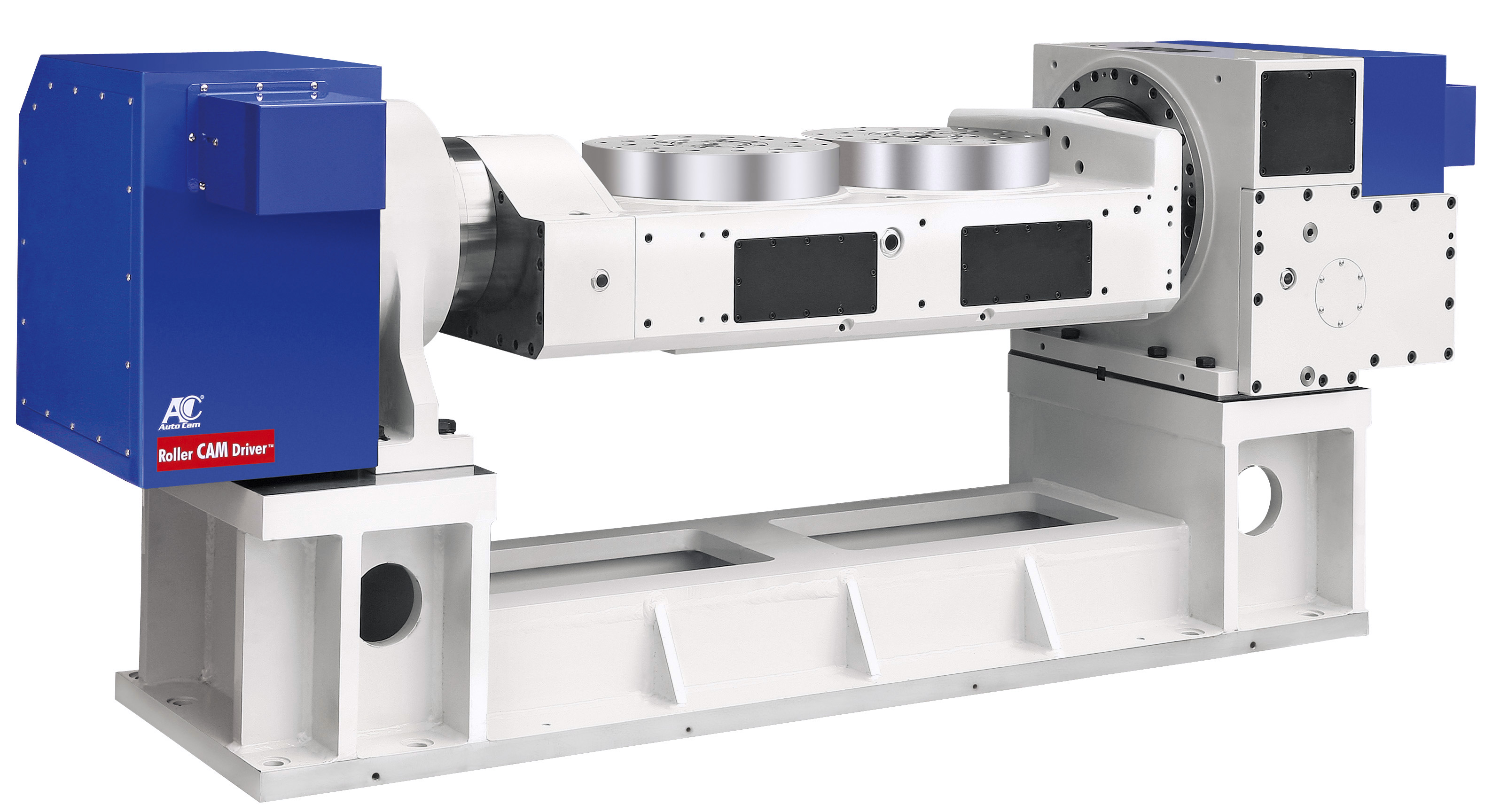

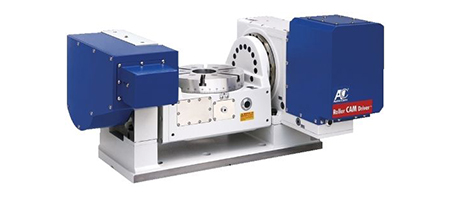

Double the machining speed! AutoCam presents the new Multi-spindle Roller Cam Driver tilting rotary table. The rotations are driven by only one servo unit, furthermore the accuracy and working ability as good as tradition one rotation models. It can carry the production volume and precision at the same time.

AutoCam adhere to three ideas of " Insistence, Innovation, Growing ". It’s our duty to carry technology first of the world, and improve our competition advantage to create with customer"s cooperative opportunity.

Our customers rely mainly on machine tools manufacturers in initial stage. We researched and developed and produced " the automatic tool changer unit " at first. Beginning to sell 60 growth to sell 600 per month per month, and we cultivate the achievement that have today in this field. We have invested " Rotary Table" in 2006.

We exhibit the practical “Tilting rotary table”(B/C ATS160B) products on TIMTOS (Taipei International Machine Tools Show) for the first time in 2007, and exhibited the “Rotary table” and “Tilting rotary table” of the whole series on TIMTOS in 2009. We extend for the future with the development orbit of history, and management idea and industry future is it go down to writing of us.

Year by years, metal-cutting technology steps forward to an higher level. The application of machine tool becomes more diversity. We want it faster, cheaper, and better! AutoCam, provides key accessories for machining tool as 4/5 axis NC Rotary table and Automatic Tool Changer. To meet the marketing demand, we spend years of time, to improve our product every day. To satisfy todays’ production capacity, multi-axis metal working, we focus on the target market such as automobile industry, aerospace technology, medical application and also energy solution. AutoCam is established in 1995. Auto is for “automated production”; Cam for “Roller Cam”. All products made by AutoCam are designed by different kind of cam. In 1998, we announced the first one cam-type sync-unclamping ATC. By 2004, Roller Cam Driver series launched; It becomes an AutoCam flagship product for years till today. “What we want is when engineers push the Cycle-Start button, they feel the difference.”

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

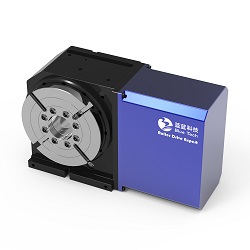

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

The Cam can extend the development and application limitlessly , Our customer relies mainly on machine tools manufacturers in initial stage. We research and develop and produce " the automatic tool changer unit " in the first. Begin to sell 60 growth to sell 600 per month per month, and we cultivate the achievement that have today in this field. But we are not complacent , because the world is flat. Our challenge of accepting all the time, and it is the competition rule even more that not to advance is to go back. We must be inevitable to more high-tech level development. The industry of Taiwan should move ahead simultaneously and can just face the challenge in the world. We will have already invested the cam will be developed " Rotary Table" in 2006.

This is a brand-new application technology, and NO.1 of Taiwan, develop with the world in step. We offer a large amount of manpower and materials to make perfectly during the course of testing. and exhibit the practical “Tilting rotary table”(B/C ATS160B) products on TIMTOS (Taipei International Machine Tools Show) for the first time in 2007, and exhibited the “Rotary table” and “Tilting rotary table” of the whole series on TIMTOS in 2009. Because the “Tilting rotary table” B/C axle actual achievement experience that has 2007~2009 two years, let the perfect product line be extended and practical.

CALCIUM MAGNESIUM PHYTATB CNC ROTARY TABLE AN CALCIUM MAGNESIUM PHYTATB CNC ROTARY TABLE AN CALCIUM MAGNESIUM PHYTATB CNC ROTARY TABLE AN CALCIUM MAGNESIUM PHYTATB CNC...

CNC TILTING ROTARY TABLE ROTARY TABLE WITH AC CODE 8466. 30, 8466. 93 8CTNS RECEIVED IN 8 P LTS SCAC CODE CNSV AMS NO.…CESSORIES ROTARY TAILSTOCK WITH ACCESSORY HTS

...CM -GENERIC DESCRIPTION- CNC VERTICAL TURNING CENTER...MACHINING CENTER (DUEL TABLE ) MODEL F500D WITH...ACC. (INCLUDING NC ROTARY TABLE) HS CODE...

CALCIUM MAGNESIUM PHYTATE TOOL HOLDER, CNC ROTARY TABLE AND ACCESSORY BEZEL RH. BEZEL LH. OTHER CULTURED CRYSTALS, CHEMICAL MIXTURES, H YDROCARBONS MOLD TEMP CONTROLLER ALUMINUM...

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

We believe that our wealth of experience and our passion for quality makes Midland Engineering the best choice when it comes to the repair of your rotary table. We understand the need for a quality assured repair service with a focus on keeping downtime to a minimum.

KME CNC has introduced the NDX135-RF, a completely wireless CNC rotary table. Users can operate up to four of these units with a single standard KME control system. The indexer is easily set in place and the battery is easy to change.

Engineered to meet complex machining needs, KME"s rotary tables can easily integrate with a vertical machining center (VMC). They can turn VMCs from 3rd axis into 4th, or 4th into a 5th by simply mounting the rotary table onto any pallet. The compact units feature a rigid build, a solid Meehanite cast body frame and a high torque capacity of 250 ft-lbs. Featuring a compact size, these rotary tables may be used in numerous applications and are designed to be simple plug & play.

Eppinger, manufacturer of tool systems and toolholders, has introduced a range of rotary tables for machine tools. The rotary tables are available with rotary plate sizes from 160 mm to 320 mm and are suitable for both initial installation and retrofitting of vertical and horizontal milling machines.

"We have used more than 30 rotary tables of different brands at our production sites for many years," said Managing Director Uwe Eppinger. "That is why we are well aware of the pros and cons of installation, flexible application, maintenance costs and decreasing accuracy."

The increasing degree of automation in Eppinger"s own production also requires a more compact design of the rotary tables, which allows the use of suitable clamping devices without restricting the required travel distance of the machining axes too much.

"Although the existing market is already highly competitive, Eppinger is venturing into this segment. Our rotary tables differ significantly from existing solutions. They have been used for some time in our own manufacturing, where they gradually replace third-party products," explained Mr. Eppinger. "The reason is that for our own production of tools, wheel gears and gear units, we need rotary tables that can be quickly and precisely positioned, that are extremely compact and suitable for fine grinding as well as for rough milling operations. In addition, they should be easily integrated into existing vertical and horizontal machining centers and used there in a flexible way. Since we could not find suitable rotary tables on the market for our specific requirements in this specific combination, we developed them ourselves."

The company was able to rely on its many years of experience in the design and manufacture of high-precision components for machine tools as well as in drive technology. "The high requirements for positioning accuracy and compactness could only be achieved with a preloaded drive system and integrated angle measuring system. When developing the rotary tables, we thought very hard to come up with an innovation for the market," said Eppinger.

"An essential distinguishing feature of the Eppinger rotary table is the preloaded, backlash-free twin-engine drive that allows quick indexing even without clamping. Furthermore, an integrated angle sensor on the rotary plate ensures the highest positioning accuracy even with changing loads," said a company spokesperson. Although this principle is already used for larger rotary tables, Eppinger found a practical solution to implement this also for rotary tables with rotary plate sizes from 160 mm to 320 mm. Although the angle measuring system integrated into the housing measures the angle directly on the rotary plate and compensates for mechanical interferences, the preloaded drive makes it possible to set up a high control loop gain. "Only in this way is it possible to make the bidirectional positioning extremely precise in the angular seconds range," said the spokesperson.

To integrate into already existing machines, the company relies on a plug & play concept. This applies both to the connection of the rotary tables within the processing area of the machine (via splash-proof plug connector) as well as to the electrical connection to the machine control system via a specially developed machine interface unit. Thus, the rotary tables are suitable both for the initial installation as well as for the retrofitting of vertical and horizontal milling machines. When placing the rotary spindle, precision classes from 3 µm down to 1.5 µm in lapped or ground execution are available, both for radial and axial run-out.

"An obvious benefit is the multi-disc clamp that is installed as standard," said Eppinger. "It ensures strong clamping at high machining forces since it clamps the rotary plate directly. Apart from a high clamping torque, a high torsional rigidity is achieved, which in turn ensures high surface qualities with changing cutting forces. Based on our experience, this aspect is often disregarded since high clamping torque does not mean high clamping rigidity at the same time."

The rotary plate can be exchanged precisely using a taper planar support with radial and axial change accuracies of 3 µm and more. As a result, workpieces from manufacturers such as Hainbuch, Lang or Erowa can be precisely clamped over T-slots, short taper clamps or workpiece clamping systems. "In this case, we rely on a system similar to that of our toolholders with Prexi-Flex spindle interface," said the spokesperson. "However, when using the rotary tables-in contrast to the Prexi-Flex interface-it is the planar support that is rigid and not the cone, which stays flexible due to a machined groove. This guarantees a stable taper planar support where a very high change accuracy is achieved at the same time."

Eppinger has also integrated an exchangeable plate system into the rotary tables. Thus, the customer has the option when placing an order or even later to choose whether he or she wants to have the rotary table equipped with rotary plate, plate with T-slots or with a spindle nose. The buyer can also decide whether a left-sided, right-sided or elevated rotary table is preferred: the rotary table can be easily turned due to its symmetrical housing shape.

"And finally, problem-free installation of the rotary tables is ensured due to the specially developed plug & play connection concept," said the spokesperson. Since the rotary tables are supplied with their own preconfigured axis controller, no additional axis controller or axis controller configuration by a service technician is required on the machine side during installation.

"The Eppinger rotary tables are also particularly easy to maintain," said the spokesperson. "In contrast to known solutions, clearance and wear are automatically compensated over the lifetime, which considerably increases availability and service life of the product." Optionally one or more rotary axes can be connected to one machine with the innovative machine interface unit. If the rotary table is to be used on another machine, no reconfiguration of the machine control system is needed, which reduces machine downtime and involvement of service technicians. Workpiece clamping systems and material feeding systems can be controlled via the machine interface unit without having to additionally activate M functions.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

Kehren RIW9 CNC rotary table surface grinding machine Max workpiece diameter 900mm x 500mm height complete with internal grinding spindle it can be inspected in our warehouse in Gussago BS Italy Mimu Machine Tools

8613371530291

8613371530291