autocam rotary table made in china

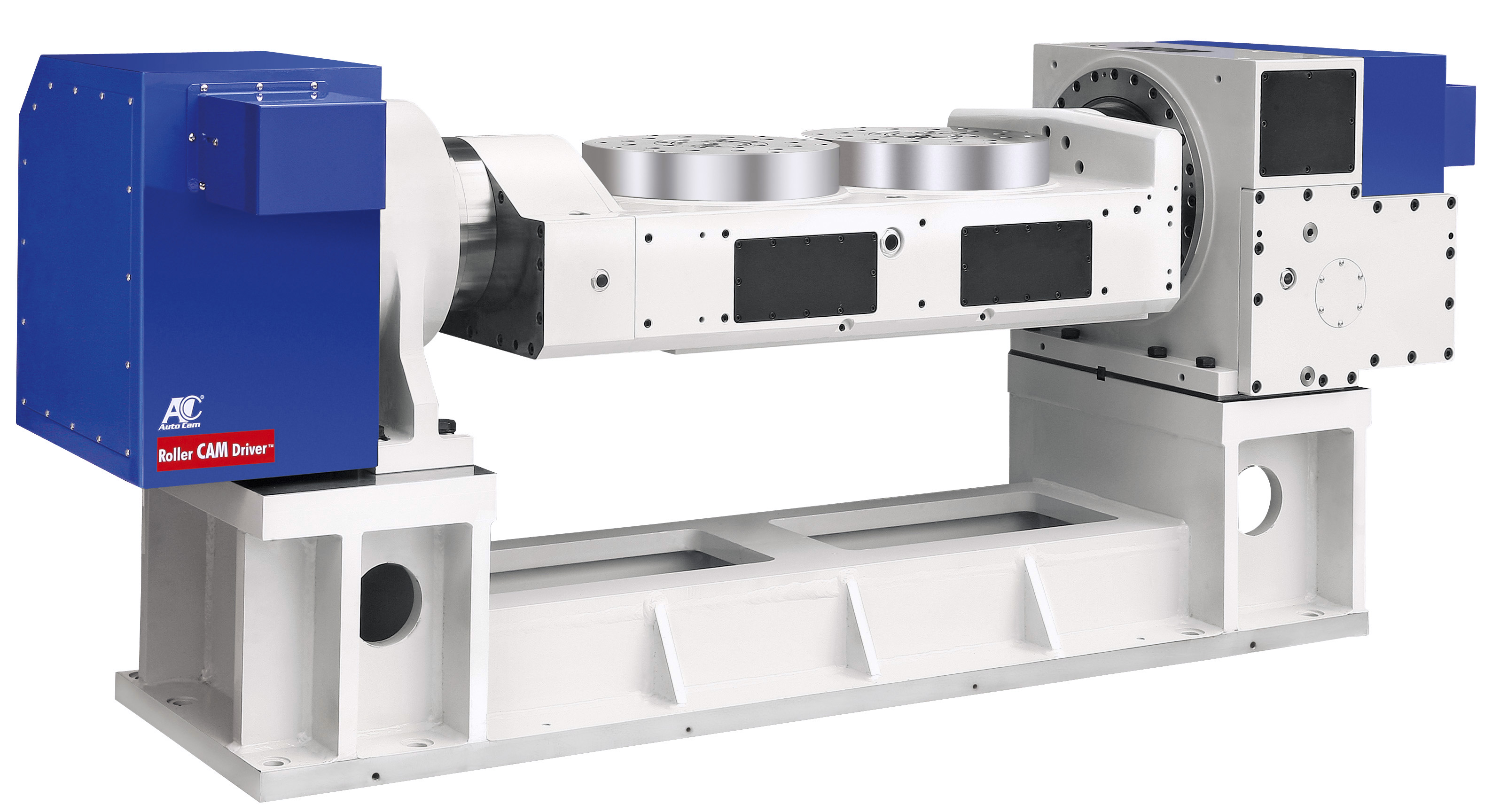

Double the machining speed! AutoCam presents the new Multi-spindle Roller Cam Driver tilting rotary table. The rotations are driven by only one servo unit, furthermore the accuracy and working ability as good as tradition one rotation models. It can carry the production volume and precision at the same time.

AutoCam adhere to three ideas of " Insistence, Innovation, Growing ". It’s our duty to carry technology first of the world, and improve our competition advantage to create with customer"s cooperative opportunity.

Our customers rely mainly on machine tools manufacturers in initial stage. We researched and developed and produced " the automatic tool changer unit " at first. Beginning to sell 60 growth to sell 600 per month per month, and we cultivate the achievement that have today in this field. We have invested " Rotary Table" in 2006.

We exhibit the practical “Tilting rotary table”(B/C ATS160B) products on TIMTOS (Taipei International Machine Tools Show) for the first time in 2007, and exhibited the “Rotary table” and “Tilting rotary table” of the whole series on TIMTOS in 2009. We extend for the future with the development orbit of history, and management idea and industry future is it go down to writing of us.

Year by years, metal-cutting technology steps forward to an higher level. The application of machine tool becomes more diversity. We want it faster, cheaper, and better! AutoCam, provides key accessories for machining tool as 4/5 axis NC Rotary table and Automatic Tool Changer. To meet the marketing demand, we spend years of time, to improve our product every day. To satisfy todays’ production capacity, multi-axis metal working, we focus on the target market such as automobile industry, aerospace technology, medical application and also energy solution. AutoCam is established in 1995. Auto is for “automated production”; Cam for “Roller Cam”. All products made by AutoCam are designed by different kind of cam. In 1998, we announced the first one cam-type sync-unclamping ATC. By 2004, Roller Cam Driver series launched; It becomes an AutoCam flagship product for years till today. “What we want is when engineers push the Cycle-Start button, they feel the difference.”

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

This is a brand-new application technology, and NO.1 of Taiwan, develop with the world in step. We offer a large amount of manpower and materials to make perfectly during the course of testing. and exhibit the practical “Tilting rotary table”(B/C ATS160B) products on TIMTOS (Taipei International Machine Tools Show) for the first time in 2007, and exhibited the “Rotary table” and “Tilting rotary table” of the whole series on TIMTOS in 2009. Because the “Tilting rotary table” B/C axle actual achievement experience that has 2007~2009 two years, let the perfect product line be extended and practical.

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

US Customs records for Kauffman Racing Equipment in Glenmont. See their past imports and exports, including shipments from Autocam Technology Co., Ltd., a supplier based in China Taiwan.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

Kehren RIW9 CNC rotary table surface grinding machine Max workpiece diameter 900mm x 500mm height complete with internal grinding spindle it can be inspected in our warehouse in Gussago BS Italy Mimu Machine Tools

Autocam Medical, a contract manufacturer of precision surgical and medical components and devices, has announced that three new pieces of its manufacturing equipment were installed in Western Michigan University"s (WMU) regional Advanced Manufacturing Partnership Laboratory (AMP Lab).

"Autocam is a key partner in the AMP program, which is focused on encouraging and facilitating the development of students pursuing careers in engineering and manufacturing. In addition, Autocam participates in a CNC Machinist Apprentice program in which it sends workers to college to receive training in CNC machining. Students that complete 728 hours of classroom instruction while maintaining a full work schedule receive their journeyman"s card in CNC machining and 27 college credits towards an associate"s degree.

Now students in the program will have access to some specialized equipment. The AMP lab equipment, a CNC 5-axis mill, a Swiss lathe and a 3D metal printer will provide engineering students and current engineers and designers with an opportunity to experience the high-tech devices needed to develop and test new products and prototypes. "We are primarily focused on the medical industry, so the machines are designed to make smaller parts," said John Kennedy IV, General Manager at Autocam Medical.

In addition to the opportunity to use the specialized equipment, students will also be able to receive valuable input from industry experts at the lab. "Engineering students that have a concept that is a little bit more technical than what they have the ability to do on the Web, can come down here and say, `I have this great idea can you guys help me figure out how to make this?," while they learn more about advanced machining," said John Kennedy IV, General Manager at Autocam Medical.

The facility is located on the bottom two floors of WMU"s building at 200 Ionia Avenue SW in Grand Rapids. Students begin their learning in the apprentice lab and classroom and then move down to the lower level, where the new equipment from Autocam Medical is located, for hands-on experience. In addition to providing students with the tools they need to bring their concepts to fruition, the location of the Autocam Medical equipment in the lab"s lower level allows passersby to have a birds-eye view of the machines from the sidewalk above.

Autocam Medical is a global contract manufacturer of precision-machined drill bits, drivers, screws, plates, cutting tools and other complex, highly engineered surgical implants, instruments and handpieces, as well as other device components. It has facilities in the U.S., China and Brazil.

Mecof, part of the EMCO Group, has released the Powermill travelling-gantry, 5-axis machining centre. The machine permits loading of large, heavy workpieces on the stationary work table from overhead or from either end of the machine, making it suitable for large aerospace components. According to...

Creform Corp. has introduced a drawbridge cart designed to be towed by an NSI AGV. It is built so the AGV can tunnel underneath, and it features an A-HPL hitch that accepts the tow pin of the AGV unit. Four of the five shelves tilt up. This is suitable for a sequential operation that requires...

“Taiwan Excellence Smart Machine Tools and Precision Components Webinar” had been released through YouTube on March 17 by Taiwan Excellence, a campaign to bring the best Taiwan-made products to the world. The webinar had shown manufacturers in Americas the latest industry upgrading solutions and precision parts from five of the most well-known Taiwanese machine tools suppliers and four leading precision components makers: CHMER, Takisawa Taiwan, APEC, Campro, Buffalo Machinery (AXILE), Gifu, AutoCam, Taiwan Chelic, and GMT Global. This showcase was held in order to assist American manufacturing industries on their mission to build up advanced and accurate metal processing procedures to improve production performance.

AutoCam presented the company’s latest roller cam technology and its potential applications on CNC rotary tables, and explained how these tables help to improve manufacturers’ overall production efficiency.

8613371530291

8613371530291