autocam rotary table pricelist

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

AUTO CAM TECHNOLOGY is a world distinguished machine tool supplier and exporter with a reliable reputation on quality assurance and groundbreaking designs for many years. Our main products include high rotary table, high speed indexing unit, and machine tool changer unit. In-house design, production and assembly make us the right manufacturer for you, providing high quality products at competitive prices and prompt delivery. Our group is writing history for the products, and our products are being written with history for the world, which represents a new era that better, faster and more perfect products are coming out. AUTO CAM TECHNOLOGY is the leader in this field. No matter what your requests are, we have the capability to cater for and even exceed them.

2. To drain the A axis unscrew the drain port [4] at the bottom of the rotary. The rotary likely will be to be suspended in the air to do this. Rotary units are heavy so take appropriate safety measures while draining the oil. Clean off the oil remaining on the rotary and replace the screw. Both rotaries have two screws on the bottom.

4. To drain the B axis tilt axis to 90° and unscrew the drain port [3]. Only one side has a drain port check for it before tilting the rotary. Once the rotary is empty screw the port plug back in.

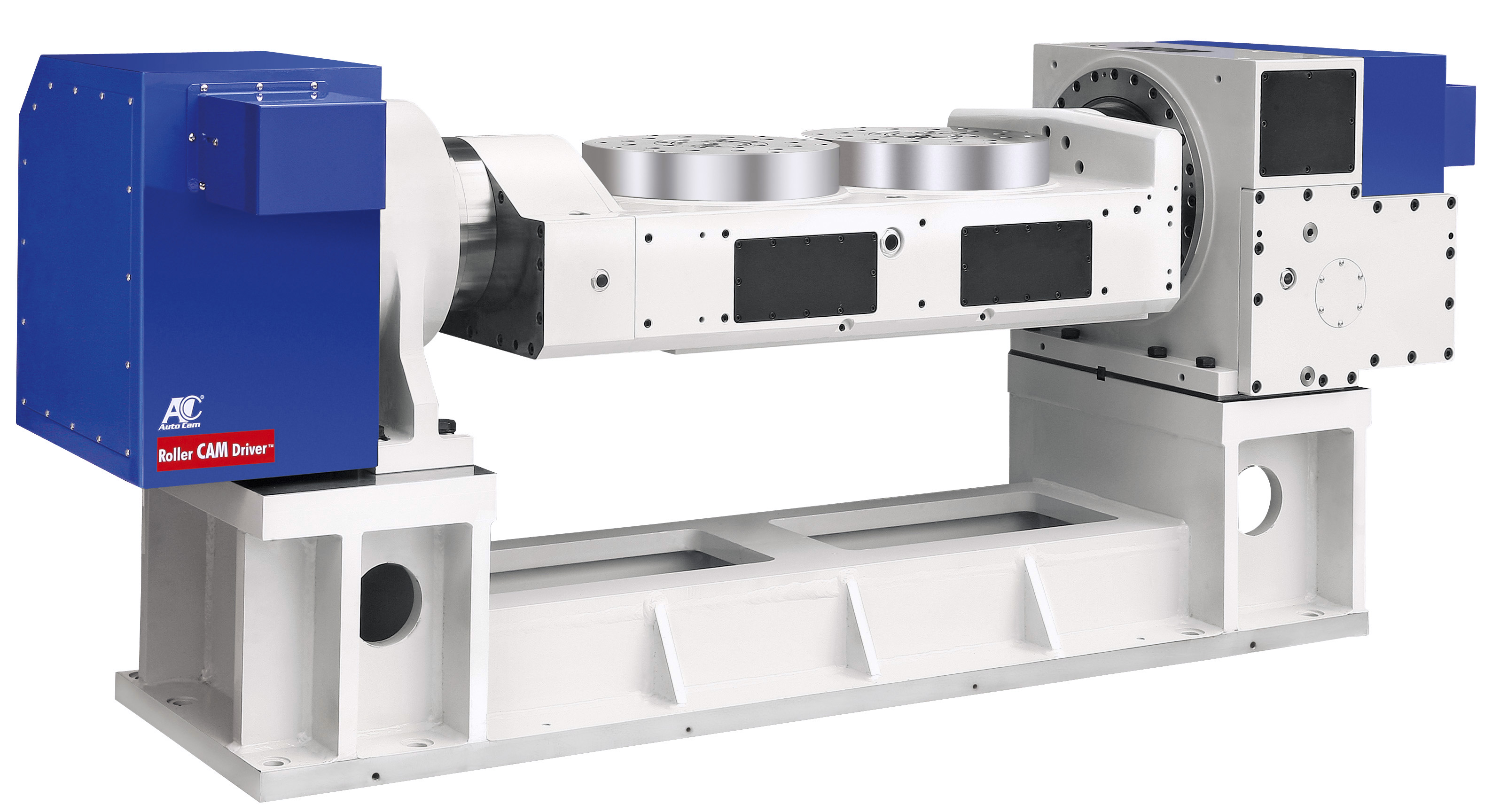

Double the machining speed! AutoCam presents the new Multi-spindle Roller Cam Driver tilting rotary table. The rotations are driven by only one servo unit, furthermore the accuracy and working ability as good as tradition one rotation models. It can carry the production volume and precision at the same time.

AutoCam adhere to three ideas of " Insistence, Innovation, Growing ". It’s our duty to carry technology first of the world, and improve our competition advantage to create with customer"s cooperative opportunity.

Our customers rely mainly on machine tools manufacturers in initial stage. We researched and developed and produced " the automatic tool changer unit " at first. Beginning to sell 60 growth to sell 600 per month per month, and we cultivate the achievement that have today in this field. We have invested " Rotary Table" in 2006.

We exhibit the practical “Tilting rotary table”(B/C ATS160B) products on TIMTOS (Taipei International Machine Tools Show) for the first time in 2007, and exhibited the “Rotary table” and “Tilting rotary table” of the whole series on TIMTOS in 2009. We extend for the future with the development orbit of history, and management idea and industry future is it go down to writing of us.

Year by years, metal-cutting technology steps forward to an higher level. The application of machine tool becomes more diversity. We want it faster, cheaper, and better! AutoCam, provides key accessories for machining tool as 4/5 axis NC Rotary table and Automatic Tool Changer. To meet the marketing demand, we spend years of time, to improve our product every day. To satisfy todays’ production capacity, multi-axis metal working, we focus on the target market such as automobile industry, aerospace technology, medical application and also energy solution. AutoCam is established in 1995. Auto is for “automated production”; Cam for “Roller Cam”. All products made by AutoCam are designed by different kind of cam. In 1998, we announced the first one cam-type sync-unclamping ATC. By 2004, Roller Cam Driver series launched; It becomes an AutoCam flagship product for years till today. “What we want is when engineers push the Cycle-Start button, they feel the difference.”

Analyzed by the machine type, the first place in the import of metal cutting machine tool is electric, laser and ultrasonic tools, with an import value of nearly US$425 million, accounting for 43.8% of the total import value, and a significant increase of 51% compared with 2020. The second largest import is lathe, with US$148 million, accounting for 15.2% of total imports, and 78.2% growth compared to 2020. The main importing countries are Japan, China (including Hong Kong) and Thailand, please refer to Table 11 for detailed statistics.

Analyzed by the importing country (region), the top ten countries (regions) for Taiwan"s machine tool imports in 2021 are: Japan, China (including Hong Kong), Germany, Singapore, Switzerland, Thailand, Korea, Italy, the United States, and Israel, in order. Taiwan"s imports of machine tool from Japan accounted for 52% of the total imports, amounting to US$505 million, up 54.7% compared to 2020. Japan and China (including Hong Kong) mainly imported electric discharge, laser, and ultrasonic tools, while Germany mainly imported planing, inserting, drawing, sawing, and gear cutting tools. For detailed statistics, please refer to Table 12.

In the face of the normalization of the pandemic, due to several issues, such as material shortage, manpower shortage, port congestion, and soaring sea freight, , which used to be cost and efficiency oriented, the global supply chain structure has changed to a safe and stable regional supply chain, and the industry"s long chain has become a short chain in response to the rapidly recovering market demand. This wave of supply chain shift and restructuring is driving the global economy and trade, and driving a new wave of demand for machine tools. Mizuho Bank of Japan predicts that the global machine tool market will grow by 17.5% in 2021 compared to 2020, and that capital outflows from industries in North America and Europe will continue to grow, resulting in a steady recovery of machine tool orders in the global market.

In 2021, the major export type of metal cutting machine tool was Machining Centers, with an export value of US$941 million, up 34% from 2020; Lathes ranked second, with an export value of US$590 million, up 32.4% from 2020. As to the exports of metal forming machine tool, Forging and stamping machines was about US$378 million, an increase of 28.6% compared to 2020, please refer to Table 1 for detailed statistics.

Analyzed by export countries (regions), the top ten countries (regions) for Taiwan"s machine tool exports in 2021 are: China (including Hong Kong), USA, Turkey, Russia, Vietnam, Thailand, India, the Netherlands, Italy, and Malaysia. Among them, Taiwan"s exports to China (including Hong Kong) amounted to nearly US$911 million, an increase of 20.4% over 2020, accounting for 32.7% of the total exports; the U.S. market ranked second, with exports of nearly US$323 million, an increase of 18.3% over 2020, accounting for 11.6% of the total exports; Turkey ranked third, with exports of 241 million. Turkey ranked third, with exports of US$241 million, a significant increase of 46.2% compared to 2020, accounting for 8.7% of the total exports. For detailed statistics, please refer to Figures 1 to 2 and Table 2.

There are two types of gantry milling machine, CNC computer type and non-NC computer type (traditional manual type). It is a milling machine with a portal frame and a horizontal long bed. Gantry milling machines are suitable for machining flat and inclined surfaces of large workpieces in batch and mass production. CNC gantry milling machines can also process space curved surfaces and some special parts.

*Suitable for various materials from coarse to fine: the finer the sand, the better the polishing effect; the coarser the sand, the better the polishing effect.

1. Lower clamping force: While machining, the lower clamping force will lead to an unstable reference point due to high-speed rotation, and the pressure from turning tools.

With the changes in machining, the application and mode of the chuck are getting more and more complex and various. The choices of chucks are included not only diverse jaws and collets but also different quantities of the jaw so finding a suitable chuck is also a big issue for CNC lathe users.

The unprocessed area: The unprocessed area of the workpiece is the clamped positions of CNC lathe while machining. Generally speaking, the more clamping points, the more stable is the processings. In the other words, the collet chuck is more stable than the jaw chuck but the clamping shape has more restrictions!

The shape of the workpiece: If the shape is rods, our team recommends our partners machine the parts with a collet chuck. On the other side, jaw chuck is suitable for other kinds of shapes. However, the machining industry changes day and night. The jaw chuck is not enough of all kinds of machining based on the changes in the machining industry. Usually, we will recommend our partners the chucks in accordance with the total number of quantities and shapes. If the shape of workpiece is special with big quantities, customized chucks will be the only answer for such kind of issue. However, the special shapes with small-scale machining will be more suitable for soft jaw chuck.

Hard jaw: The hard jaw was heated before finishing. The hardness allows the jaw surface kept after several times machining. However, the shapes can not be adjusted because of the hardness. It is suitable for a single shape with heavy quantities.

Soft jaws: Without the heat process, the soft jaw can be fit whatever you want. Most applications, the soft jaws use with constantly changeable shapes in lower quantities. Normally, the mass-production is not suitable for such jaws. The surface of the jaw will be changed after machining.

About the jaw, whatever the number of jaws, the interference of the jaw is the biggest issue while selection. Some special workpieces are not suitable neither jaw nor collet. As a result, we recommend MYLAS machine users customized chuck. Moreover, our partners also combine an automatic loading system to achieve the one-stop solution.

HARDY spindle model FMDC155W built-in drilling and tapping head with automatic tool changer received the Taiwan Excellence Award 2022. The spindle configuration is optimized to match the design with the built-in motor, and the pulleys and belt drive are no longer required. After reducing the space of the motor box, space interference is improved, and the weight and volume are reduced as well. The improvement of the spindle to the direct mounting type not only improve the precision of the spindle nose, but also shorten the processing time and reduce the production cost of the equipment. The flange mount structure can be applied to the special machine for trunnion rotary machines. The flange spindle head supports both vertical and horizontal configuration, which subverts the space waste caused by the traditional spindle head with horizontal configuration. The design of the FMDM155 flange type built-in spindle increases the flexibility of the workstation configuration, also reduces the setup space occupied by the spindle head. Machining performance is better than ordinary spindles, while each spindle is up to 35% lighter than the ordinary style. In the past, when customers purchased a spindle head, the first choice to consider is whether there will be interference problems and machine space issues. FMDC155W built-in drilling and tapping spindle is the one of best choices for customers.

Shuzhou Tong-Yu Machine & Tool Co., Ltd, a Tongtai subsidiary, is located in China. For providing real-time services to the clients in China, Tong-Yu built distribution channels, 5 branches and 17 offices, which are able to provide services to the customers nearby. Now the epidemic limits the transportation, but our services to the clients are never postponed. Completed service channels, good relationships with customers, and stable incomes are driving Tongtai to keep optimistic towards the China market. Not only in the conventional automobile and aerospace industries, Tong-Yu has stepped into the electric vehicle industry in 2022. In recent years, Tong-Yu has self-developed machines including: Vertical machining centers, Horizontal machining centers, and CNC lathes. These machines have much better performance/cost ratio and also high production efficiency. To achieve the goal of carbon neutrality, Tong-Yu is also working on processing a green transformation and has been awarded relative certificate. Aims at lowering carbon emissions, Tong-Yu not only redesigns machines with optimized energy management mechanisms, but also adopts energy saving and carbon reduction concepts in the existing and new factories.

This is the most common milling machine, which has 5 basic components that are the work table, saddle, head, knee, and over arm. Considered as the simplest machine type, its cutting device is vertically suspended to allow drilling of metals. This is typically used when creating car parts because it is small and handy.

This machine runs parallel to the ground. The table from which the object to be worked on is placed moves sideways while the cutting device goes up and down.

The worktable cannot be raised ad lowered, but can be moved longitudinally and laterally along the guide rail of the bed base, and the milling head or column can be moved vertically.

In an age when multi-axis machining has become standard, we have teamed up with ITRI on the development of distinct training machine suitable for vocational centers and schools at all levels. Through hands-on practice, students gain familiarity with multi-axis machining, tools, controllers, and G-codes.

According to the data provided by Taiwan Customs Administration, Ministry of Finance, the total export value of machine tool accessory, including Work Holders, Dividing Heads and Other Special Attachments for Machine Tools, Parts and Accessories for Metal Cutting Machine Tools, Parts and Accessories for Metal Forming Machine Tools, Ball Screws, and Ball or Roller Linear Side Guides, was US$2.138 billion in 2021, up 58.6% compared to 2020’s export value of US$1,405 million. In terms of quarterly export value, the total export value for the fourth quarter of 2021 was US$581 million, an increase of 3.4% compared to the third quarter of 2021. Please refer to Table 1 for detailed statistics.

In terms of major exporting country of Taiwan machine tool accessory in 2021, China (including Hong Kong) is the largest market with a total export value of US$1.35 billion, up 49.9% from 2020; followed by Japan, with total exports of US$121 million, up 65.4% from 2020, followed by the United States, the Netherlands, Korea, India, Italy, Germany, Thailand, and Turkey. Please refer to Table 2 for detailed statistics.

Total import value of Taiwan machine tool accessory in 2021 was US$275 million, up 44.5% from 2020. In terms of quarterly imports, total imports in Q4 2021 was US$73.81 million, a 6% increase compared to Q3 2021. Please refer to Table 9 for detailed statistics.

In terms of major import countries of Taiwan machine tool accessory, Japan is the most important import country, accounting for 35.2% of the total imports. Second is China (including Hong Kong) with imports of US$85.55 million, up 64.1% from 2020. Germany is in third place, with imports of nearly US$27.62 million, up 31.3% from 2020, followed by Italy, Switzerland, the United States, the United Kingdom, Korea, Romania and Vietnam. Please refer to Table 10 for detailed statistics.

Among the award-winning manufacturers this year, Tokugawa Machinery, which is famous for its high-precision rotary table, is not only the best backing for domestic machine tool factories, but also provides a series of high-precision components and successfully develops the global market. The quality is well received by foreign customers. It has been highly affirmed by the designated suppliers of major international first-class brand machine tool factories. This year, it stood out from the selection of many Golden Hand Award manufacturers. This year"s Taichung City Golden Hand Award is well deserved.

detron Dechuan Machinery was established in 2006, dedicated to the production of CNC turntables, the whole process is made in Taiwan. Not only uses ERP standard operating procedures to control large-scale production, but also strictly implements high-standard quality inspection, the product has become the CNC turntable designated by the world"s first-class brand machine tool factory

This time, Jiang Lihua, deputy general manager of Dechuan Machinery, took the stage to accept the award. He said that the Tokugawa spirit is "virtuous in the world, the sea is inclusive of all rivers". Since its establishment, our business philosophy has always been based on the principle of "integrity". .We believe that as long as we uphold integrity and enterprising spirit, we will definitely become the largest CNC turntable manufacturer in Taiwan with the best products.

This is the most common milling machine, which has 5 basic components that are the work table, saddle, head, knee, and over arm. Considered as the simplest machine type, its cutting device is vertically suspended to allow drilling of metals. This is typically used when creating car parts because it is small and handy.

This machine runs parallel to the ground. The table from which the object to be worked on is placed moves sideways while the cutting device goes up and down.

The worktable cannot be raised ad lowered, but can be moved longitudinally and laterally along the guide rail of the bed base, and the milling head or column can be moved vertically.

OCD5-200PH is a two-axis rotary table for machining centers (tilting axis: cam / rotary axis: DD). The product features a preloaded barrel cam structure for the tilting axis, and the backlash is close to zero. Rolling friction transmission to extend service life. The transmission element is made of steel, which is more rigid than copper and has strong eccentric load bearing capacity. The rotating shaft is driven by a direct-drive motor, which is fast, space-saving, and has no backlash. Suitable for multi-angles machining and simultaneous workpieces

HIWIN is the global leader for motion control and system technology. HIWIN’s headquarters is located in Taichung, Taiwan. HIWIN is the No.2 global manufacturer for ballscrews and linear guideways. HIWIN offers precision module products- Datorker Robot Gear Reducers, Torque Motor Rotary Tables, industrial robots and medical robots. HIWIN has 14 subsidiaries and more than 200 distributors globally, serving our customers in the 5G, semiconductor, medical, machine tool, automation, Electrical vehicles, and precision equipment industries.

HIWIN Mikrosystem’s LMSSA linear motor is a direct drive, plug and play solution. A linear motor is capable of fast acceleration and high speed, while providing unmatched precision and accuracy. HIWIN offers standardized linear motor design, but customizable options are available. LMSSA linear motor is a cost-saving variant of this product group. The cost advantage is achieved through consistent reduction to the essentials and limitation of the options and variants available as standard. This significantly reduces manufacturing costs, while at the same time, the LMSSA stage offers all advantages of a conventional linear motor axis. These compact and lightweight units are customizable and can be easily transformed into a multi-axis system, making them suitable for a wide range of industrial applications, depending on the application needs.

Brand meaning: The rising sun is a reflection of our enthusiasm, dedication, professionalism, solidarity, and readiness to take action. It expresses the image of a high-quality milling machine brand. Our marketing promotion is like the red dots on the LOGO. We hope the “Made in Taiwan” Sunmill brand will be sold all over the world and shine on the international stage. Extending our market worldwide, we strive to create profitable business relations, share glory, and grow together with our customers and manufacturing partners.

The UH-500 is primarily suitable for fine processing, as the UH-500 can perform diversified manufacturing processes on a complex workpiece without the need to reposition the workpiece. As the UH-500 enhances processing efficiency for complex workpieces, it will shorten production time, reduce manufacturing costs, and increase your market competitiveness.

Our multiple size, 3-axis machining centers are continually top sellers. Models such as the JHV-800 work well with the Fanuc M-10iA robot to achieve factory automation, thus reducing the manual operations required for production process. The high-precision and highly stable qualities of the robotic arm solve the problem of labor shortage and reduce production costs. They not only improve work efficiency and reduce the risk of human negligence, but also improve the competitiveness of enterprises.

The VL-160C-2R is equipped with HONOR SEIKI’s patented clamping system, Solid Lock that can provide a clamping force of up to 10 tons, allowing for heavy cutting, with reduced tool vibration and increased tool life. Dual-ram, simultaneous machining, effectively shortens processing times by 50%. A special chuck supports flexible production of over 50 types of wheelsets which is a significant savings in the frequency of changing fixtures, and makes clamping extremely stable.

NFX400A, with a 6-slide blocks on the X-axis, and high-horsepower, IDD PLUS direct-drive spindle, gives increased speed and extreme machine stability. Various options of tool magazine capacities are available to achieve fast and reliable tool change efficiency, allowing the NFX400A to meet the varying processing needs often encountered in the aerospace, automotive, medical and other industries, where complex and precision parts are often produced. Its 5-axis rotary table, which adopts a trunnion-type support, can process workpieces with a maximum size of ø400 x 310 mm and a load of 200 kg.

The UV650 high-performance, 5-axis, vertical machining center, combines advanced technology with high-precision, simultaneous 5-axis processing. This not only shortens the installation and overall lead time, but also effectively improves the processing accuracy and quality. The UV650’s self-made IDD direct-drive spindle, and 17 kW high-power motor, with a maximum speed of 15,000 rpm, enables perfect surface smoothness when machining hard materials. In addition, the UV650 is equipped with a ø650mm B/C-type tilting, large-plate, rotating table, with a spacious processing area that can load up to 300 kg (0°~45°)/200 kg (45°~90°) workpieces. For workpieces with complex contour features, a reliable and diversified tool magazine selection is provided. The standard configuration is 40T, 48T, or 60T which can be selected for different processing requirements.

Over the past 70 years, upholding the concept of "Stable, Practical, and Sustainable Operations," and positioning itself as the "Leading Brand in Machine Tools", YCM has always adapted “Supreme Quality”, “Cutting-edge Technology,” and “Total Solution Service" as its core values. YCM is "Always Progressing" and constantly developing innovative technology to create maximum value for our customers.

The high-precision CNC 5-Axis indexing table of HOSEA meets the most stringent standards in the European market. The products are widely used and favored in Europe, and are well-known by global machine tool manufacturers.

For machining conditions involving high load, high rigidity, and high speed, or requiring high precision, fine tolerances or hydrostatic rotary tables, HOSEA provides customized products for complete solutions.

We currently supply milling heads used in 5-axis CNC machines used for aerospace and aviation applications, precision molding, or for wind turbine blades. We offer an alternative to the 2-axis spindle heads currently imported mostly from Europe, by providing suitable products and services designed for the Asia market, eliminating the long repair cycle and high maintenance cost of other manufacturers.

The built-in electric spindle + direct drive DD motor is suitable for surface processing and high-precision processing required for finely finished surfaces.

Equipped with variable tape sizes: 5mm, 7mm, 10mm, 13mm. Suitable for gas valves, oil pressure gauges, fire sprinklers, oil pressure joints etc. Metal or plastic materials are all suitable for winding.

For example, if the connection is not properly tightened, it will cause an unstable joint. Oil leakage, air leakage, and water leakage can all cause environmental problems. Attention should be paid to the tape winding process.

Now, we are continuous designing and focusing on shaft cooling system, vibration reducing during high speed, and intelligent spindle system; moreover, the user can easily know the spindle operation status, reach stable machining, and high efficiency production.

The T-slot table is a nice touch, and from what I can tell from the few marketing photos, the new Bantam Tools CNC machine is sturdily built, or at least as sturdy as a machine this size could be. I saw a 70 lb machine weight spec, although I couldn’t locate it again during fact-checking. 70 pounds sounds about right, and it looks like there’s bulk where you need strength and weight-savings and lighter materials where you don’t.

8613371530291

8613371530291