bridgeport rotary table parts manufacturer

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Hardinge and Bridgeport make it easy to select and connect a rotary device to the vertical machining center for precision fourth-axis parts positioning. Hardinge fourth-axis rotary tables will increase the machine capability with rapid positioning speeds and fast job changeover. The rigid design characteristics of the machine and the quick-change spindle nose design of the rotary device offer a rugged and flexible fourth-axis machining option.

The Bridgeport GX 1000 OSP high-performance machining center is unique to the Bridgeport family of mills as it incorporates the Okuma OSP P200 CNC control, encoders, motors, and drives. The GX 1000"s popularity has risen over the years as a true workhorse in the industry, and with the addition of the OSP P200 control, this machine offers even more performance capabilities. The advanced architecture of the OSP-P200 NC control enables access to almost any application and peripheral, including factory management systems, and will interface with bar coders, feeders, robots, probes and tool setters to help streamline production.

The stiff and thermally stable spindle, rigid C-frame fixed column design, and fixed pre-tensioned double nut ball screws on all axes of the machining center, provide superior rigidity, accuracy and repeatability. Hardinge provides a smooth integration of their precision rotary tables into the GX 1000 OSP, to operate in a fully interpolated fashion with the other axes of the machine.

Hardinge rotary packages include the Okuma motor and cables to connect via fourth-axis to the new, pre-wired Bridgeport GX 1000 vertical machining center with an OSP control. The new Bridgeport VMC must be prewired to accept the rotary package. Rotary systems can also be operated using just the Hardinge servo control if true fourth-axis is not required.

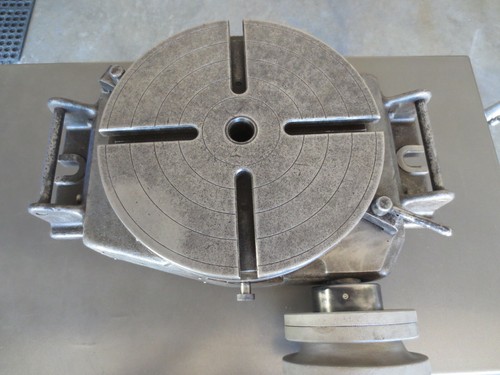

Hardinge has a large selection of rotary products that are compatible with the Bridgeport GX 1000 OSP machining center including single and multi-spindle units. Hardinge rotary products incorporate an A2-4, A2-5 or 5C threaded-nose collet-ready spindle that will accept collets, expanding collets, step chucks and chucks (as well as the traditional faceplate) to expand part gripping capabilities and improve part accuracies. The generous 44.09 x 21.25" machine table provides plenty of room for a rotary table and a vise to allow maximum job flexibility.

Together Hardinge and Bridgeport provide a reliable, versatile and flexible package to take on multiple machining applications. For more information, request document #2383-OSP by calling our Workholding group at 800-843-8801.

Hardinge is a global designer, manufacturer and distributor of machine tools, specializing in SUPER- PRECISION(TM) and precision CNC Lathes, high performance Machining Centers, high-end cylindrical and jig Grinding Machines, and technologically advanced Workholding & Rotary Products. The Company"s products are distributed to most of the industrialized markets around the world with approximately 74% of the 2011 sales outside of North America. Hardinge has a very diverse international customer base and serves a wide variety of end-user markets. This customer base includes metalworking manufacturers which make parts for a variety of industries, as well as a wide range of end users in the aerospace, agricultural, transportation, basic consumer goods, communications and electronics, construction, defense, energy, pharmaceutical and medical equipment, and recreation industries, among others.. The Company has manufacturing operations in the United States, Switzerland, Taiwan, and China. Hardinge"s common stock trades on NASDAQ Global Select Market under the symbol, "HDNG." For more information, please visit www.hardinge.com

Hardinge Rotary Products More Accuracy, Speed and Flexibility! The Most Flexible Quick-Change Workholding Concept on the Market… Hardinge’s A2-4 (5C) and A2-5 (16C) spindle nose designs allow quick change between collets, expanding collets, step chucks, 3-jaw chucks and face plates. Common spindle tooling can be shared between the Hardinge Rotary System(s) and a lathe. The gripping is in the spindle, closest to the spindle bearings, unlike surface-mounted adapters used on traditional rotary tables. Multiple workholding options provide alternate gripping solutions for increased precision and...

Table of Contents Hardinge has a large selection of rotary products for all ranges of production. Choose from precision and super-precision systems – single-spindle, multi-spindle and dual-axis configurations… 5C2 Gear-Driven Rotary Indexers GD5C2 single GD5C2-02 dual GD5C2-03 triple GD5C2-04 quad pages 8 - 9 • Accuracy to ±3 Arc-Sec • Repeatability to ±2 Arc-Sec • Rapid positioning speeds • Reliability • Zero backlash systems • Flexibility of workholding tooling 16C2 and 3J2 Gear-Driven Rotary Indexers GD16C2 and GD3J2 single GD16C2-02 and GD3J2-02 dual GD16C2-03 and GD3J2-03 triple pages...

Quality Manufacturing Processes Hardinge"s GD5C2 has more accuracy, more spindle clearance and more thrust & radial load. All rotary products are manufactured in Elmira, New York to strict specifications. Curved front casting and removable handle for increased spindle clearance and better tool access. ±5 arc-sec Repeatability ±25 arc-sec Accuracy .0002" Max. Runout (.005mm TIR) Robust, dual-bearing spindle for heavier radial and axial loads. 50-lb (23kg) part weight and 1000-lb (4448N) tailstock thrust per spindle is not a problem – even on a quad unit with tailstocks! 1 4 6 2 4 5 3 Small...

Productivity Features Hardinge Collet-Ready Spindles provide the most Flexible Rotary Products in the industry! Hardinge rotary systems accept many styles of standard tooling without an adapter, which is unique in the industry. You can purchase a complete system all tooled up and ready to run your parts. Rely on the spindle tooling experts for the accuracy and repeatability to get the job done. Zero-Backlash Direct-Drive Technology Hardinge offers direct-drive technology for flexible, high-speed, SUPER-PRECISION® parts positioning. Features include rapid bidirectional response, zero...

Fourth-Axis Integration GD160LP Rotary Indexer mounted in a Bridgeport® vertical machining center machining six sides of the part. Direct-Drive DD300 Rotary Table Indexer mounted in a Bridgeport® vertical machining center machining an out-of-round, elliptical part. Trunnion tailstock application for the DD100 High-Speed Direct-Drive Rotary Positioner. Spiral milling application on a Bridgeport knee mill using a 5C2 indexer and manual tailstock. 6

Interfacing to a Host Machine True 4th-Axis* via the host machine (gear-driven) Hardinge gear-driven rotary systems may be connected directly to the host machine and its CNC control. Connecting to the machine"s CNC control requires replacing the standard servo motor and cable with a servo motor and cable that is compatible with the host CNC. If the machine is not 4th-axis ready, the machine will need a 4th-axis option and servo amplifier installed. Hardinge has integrated its rotary products with Fanuc, Siemens, Heidenhain, Okuma and Milltronics. Other systems can be supported with the...

5C2 Rotary Indexers The 5C2 Rotary System is based on a long history of Hardinge 5C spindle and manual indexer designs. Over 60 years of GD5C2 GD5C2-02 GD5C2-03 GD5C2-04 Hardinge-engineered and proven mechanical elements guarantee an accurate, repeatable, reliable and flexible product. SERVO CONTROL / PROGRAMMING Servo Model Standard Servo Storage - Number of programs/steps up to 50/1000 RS-232 Interface YES Text Display multiple lines Infrared Upload/Download Baud Rate Capacity YES up to 56K SPINDLE Runout Maximum (TIR) Standard Features • Curved front casting and removable handle for...

16C2 and 3J2 Rotary Indexers 16C2 and 3J2 Rotary Table Indexers Hardinge"s world-renowned collet-ready A2-5 spindle is the heart of the system. The same accuracy, precision and reliability built into the Hardinge lathe extends to a large capacity rotary indexer. A variety of standard 16C or 3J spindle tooling will mount directly in or on the spindle without the use of an adapter. Common spindle tooling can now be shared between a rotary unit and a lathe. SERVO CONTROL / PROGRAMMING Servo Model Enhanced Servo Storage - Number of programs/steps RS-232 Interface YES Text Display multiple lines...

Question 2. Oil for these appears to be critical. Am I correct that the rotating table and cast base make a "way" surface? If so how is this lubricated?

Bridgeport 5-Face (4+1) Machining Centers feature an integrated 5-axis robust rotary table supported by large bearings to allow heavy horizontal and vertical cutting loads with smooth and accurate rotation at all times. Bridgeport incorporates heavy-duty linear guideways and oversized double-nut ballscrews that are pre-tensioned to provide superior accuracy and repeatability. The linear way modules consist of slide members (guide trucks) and linear rails to provide a large load rating, stable accuracy, high rigidity and low friction. The wide spacing between all axes rails provides optimum stiffness for the overall machine structure. Oversized 45mm (1.77”) ballscrews are featured in the GXR 320 5F, while 32mm (1.26”) ballscrews are incorporated in the GX 250 5F. All of these robust features are designed into a small cost-effective footprint.

Bridgeport 5-Face (4+1) Machining Centers are designed with an optimum work envelope to machine small to medium parts. Machines with larger work envelopes use a larger rotary table, increasing the size of the machine, increasing the overall cost. Bridgeport offers a smaller footprint machine for 5-face machining that is ideal for the medical and dental market and that complements the automotive, aerospace and other industries as well.

Both machines come packed with standard features including a BIG-PLUS spindle, oil chiller, chip conveyor, coolant flush system, preparation for through spindle coolant (with rotary union), coolant wash down gun, tri-color stack light and many standard control features.

"These new Bridgeport 5-Face (4+1) Machining Centers offer a high degree of sophistication and functionality in a small footprint at an attractive price," states Andy McNamara, Director of Sales and Marketing, North America. "Like all Bridgeport machining centers, these machines reflect Hardinge"s commitment to quality and performance without compromise." Hardinge also offers a full 5-axis VMC for machining complex contoured parts such as impellers and turbines where fivesimultaneous axis movements are required.

A-Team Machine provides specialized manufacturing services to our customers that need fabricated and machined parts. We use a team approach in order to satisfy our customers" manufacturing needs with quality products that are delivered in a timely fashion.

8613371530291

8613371530291