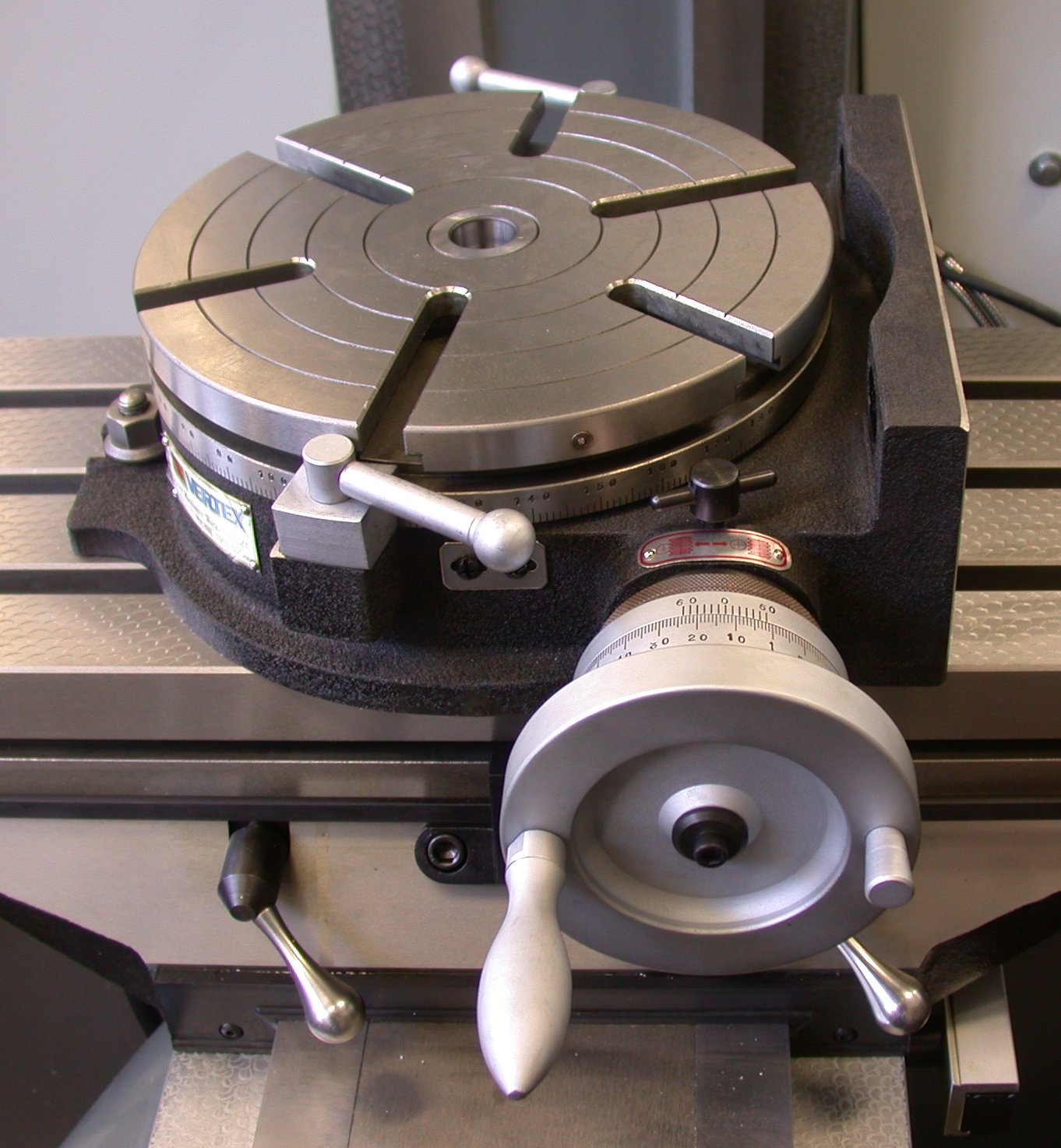

building a rotary table factory

For a corner fillet weld such as those, it may help if you grind off half of each corner on the slotted plates giving a 45 deg V. This will help to ensure the weld gets good penetration and strength at the same time as allowing you to retain the original edges for alignment.

Looks to me like you are using a 240V single phase welder. In Oz I would use a Satin craft 13 electrode as these have a slower flux than a Satin craft 12. This helps stop the flux from running into the weld pool and stopping the arc. My welder has only 2 settings 2.5 and 3.2 mm so I try and use the shortest possible cable between the power point and the welder. If I have to go longer a heavier duty cable helps keep up the volts and amps.

I was once thinking 2 standard transmission flywheels would make a fixture that you are needing. the bottom fly wheel would be surface side down with no ring gear for a bolt down flange. The top flywheel would be face up with a seriese of tapped hole for hold down capabilitys. Im still pondering on the bearing between the 2. The ring gear on the upper flywheel can be mated with a crank handle to provide rotation.

When autocomplete results are available use up and down arrows to review and enter to select. Touch device users, explore by touch or with swipe gestures.

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

rotary filing—that is, running a circular cutter withfile-like teeth in the headstock of alathe.Rotary filling and later,true milling were developed to reduce time and effort

One major challenge to rotary index table manufacturers that supply to system integrators building lines for automated food processes is how to protect exposed steel to the cleaning agents that are used on a daily basis to sanitize the equipment. Another challenge is how to completely seal these units from preventing water or other chemicals from getting inside the rotary index tables.

With over 50 years of experience in providing rotary index table solutions to various industries we have learned over the years what works best for these harsh automated environments. In the past we would have relied on nickel plating the exposed steel surfaces. The nickel plating can quickly breakdown from specific chemical washdowns and once this happens rust will quickly take over. Our solution is to add a custom stainless-steel dial plate that has labyrinth sealing to cover the standard rotary table output dial. The input shafts are also made of stainless steel and the input shaft seals are viton to prevent premature breakdown from cleaning agents.

The RT100 unit featured here is a fixed sixteen station cam indexer that will be used in a facility that manufactures hot peppers. These units are exposed to the high acidity from the product itself and the daily barrage of harsh chemicals used during the washdown process to clean the machines to prevent bacteria buildup. To combat these challenges the housing has a special powder coating and custom stainless steel dials.The gear motor is a IP66 rated SEW DAS series and are suited for the food production and caustic washdown chemicals

At Rusach International,rotary table design, engineering and manufacturing & pallet system design, engineering and manufacturing is our specialty. We can supply rotary tables from 100mm up to 8 Meters in diameter. See our rotary table pages. We specialize in high accuracy, up to +/- 1 arc second, heavy load capacity, large work pieces, production style, heavy duty rotary tables and pallet shuttle/storage/transfer systems. We also have a line of standard small production tables that are very cost effective, yet can be customized per application.

Rusach International systems are not proprietary and therefore can be integrated into any machine, control system or application. We do not believe in “locking” a customer down with proprietary parts! We work with all the major industry control, motor and encoder manufacturers.

They are characterized by a whole new machine concept and design approach, allowing flexible use. All components are freely programmable and represent sound solutions for re-engineering. It could be added planetary gearbox to increase the gear ratio, available for matching with any brand servo motor and stepper motor based on our flexible flange system, thus make it easy for automation production line building and robot designing.

IP rated rotary tables provide more possibilities for humidity and dusty environment in actual working conditions, like CNC drilling work, CNC grinding work, laser marking and laser cutting work, etc.

High precision and excellent IP rated performance makes the high precision and accuracy work possible, such as diamond cutting rotary task, phone production and inspection rotary task, etc.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A cookie is a small text file that a website saves on your computer or mobile device when you visit the site. It enables the website to remember your actions and preferences (such as login, language, font size and other display preferences) over a period of time, so you don’t have to keep re-entering them whenever you come back to the site or browse from one page to another.

8613371530291

8613371530291