cnc indexing rotary table manufacturer

CNC Indexing & Feeding Technologies is proud to represent the TJR line of rotary tables, indexers and accessories. TJR originated as a rotary table sales and service agent and established itself as an OEM in 2009.

TJR tables feature an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. All new TJR tables come standard with a 3-year parts warranty.

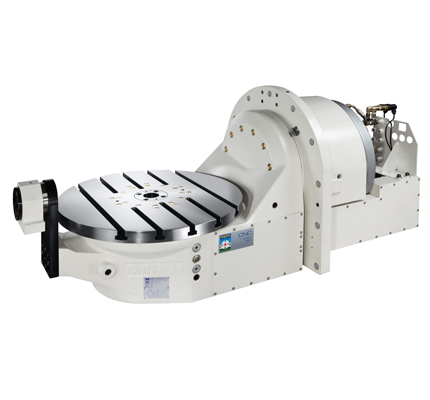

Standard Rotary Tables. The AR Series is TJR’s standard 4th axis pneumatic brake rotary table. It is offered in both a Right hand motor mounting and Left hand motor mounting option. The HR Series is TJR’s standard hydraulic brake 4th axis rotary table.

CNC Indexing & Feeding Technologies offers a wide range of TJR rotary tables. However, many are unclear about what rotary tables can do for their business, as well as how they work in CNC machining. First, let’s consider the basics about a rotary table and how it works in the machining and manufacturing processes.

In many cases, the work pieces created through CNC machining would be impossible without computer assistance. The code used to communicate between the CNC machine and computer software is specialized. Older machines, or manual machines, used hard wired controllers. However, new CNC machines rely on modern devices like CDs, USB drives, networks and so on.

A lathe or milling machine requires its own set of parts to work sufficiently. For example, an indexing head is needed to allow circular shaping. The indexing element allows the piece to be rotated at an angle or even divided into sections.

A rotary table can tilt and rotate. The table makes use of the indexing head in order to cut according to a specific technique. This makes it possible for the machine to create a workpiece with complete flexibility in rotation and angling.

A rotary table can help to create arcs and circles, an important process in part or tool fabrication. Tools can be specially made, such as car parts, machine parts, and many other objects.

The CNC process lets companies make straight cuts even with multiple angles and to cut small objects into even smaller parts. CNC rotary tables can also help in the processes of cutting gears, drilling or cutting holes.

The table can also be used along with a dividing head and index plate, to further concentrate the shaping. Tables are also used to hold certain parts for superior milling techniques.

Adding rotary tables will improve your capacity to produce the parts you want and increase profits. This brings us to the primary advantage of CNC rotary tables: less time and greater accuracy in cutting.

The benefits of using cnc rotary tables include consistency, faster production and increased capacity. Products and work pieces assembled through CNC systems are more reliable than products created manually or through other methods. The process is identical each and every time, so consistency can be guaranteed. This is critical for a company trying to ensure safety protocol.

The capacity of complexity of product is another benefit. Complex motions are made simpler by CNC rotary tables, making them more affordable to produce.

Naturally, such an intricate process cannot be unsupervised, since efficiency depends on optimal performance. A supervisor must oversee a rotary table operating with CNC controls to ensure the machine and software are configured correctly.

We offer a wide variety of rotary tables to meet all of your needs. This includes standard rotary tables with full rotating axis capabilities, and vertical and horizontal mounting positions.

We also offer large rotary tables with hydraulic brake systems, which allow higher clamping torques. You can also find assistance with smaller rear mount rotary tables or tilt rotary tables.

Horizontal rotary tables are specially made for horizontal mounting and carrying a much heavier weight. Horizontal index tables are available, whether in manual or CNC index tables style. Finally, there are face gear rotary tables and rotary table accessories, ideal for projects that need higher degrees of accuracy.

CNC Indexing & Feeding Technologies can help you find the machine tool accessories you need to meet your production demands. This includes simple rotating feature, larger work pieces, vertical and horizontal applications, or even 4 or 5 axis work. With TJR rotary tables, you can improve your cycle and process time, reduce your down time and increase your profits.

Let us be your one-stop supplier for all your rotary table, bar feeder, bar loader and high pressure coolant needs. Check out CNC Indexing & Feeding Technologies and you’ll see – no other supplier of CNC machine tool accessories can compare!

The HHI-Series is TJR’s horizontal CNC index rotary table design. The HHI-series is available with table tops ranging from 320mm (12.59”) to 800mm (31.49”) square. TJR’s HHI-series can be used in various areas of manufacturing but are ideal for horizontal boring mill applications.

The HHI series is available in 1 degree or 5 degree indexing increments and employ a hydraulic braking system. HHI-series does not lift the working table during indexing to ensure positioning accuracy and they are designed for horizontal mounting only which offers high weight capacities for large workpieces. They are capable of being used as a full 4th axis that is integrated into the CNC machine control or as an indexer with the use of TJR’s SAC (Single Axis Controller).

Sherline has taken their accurate and reliable 4″ rotary table into the 21st century with the addition of Computer Numeric Control. Clock-makers or anyone with a need to cut gears or other complicated radially symmetrical patterns will find this accessory takes all the headaches out of repetitive indexing operations.

The rotary table comes with clamps and T-nuts for attaching it to the T-slots of a Sherline mill table. In addition, there are two options available for mounting the table in the vertical position or at other angles:

Right-Angle Attachment—This plate holds the table in the vertical position with a center height of 2.7″. A right-angle tailstock is also available to support long stock held on center in the rotary table.

Tilting-Angle Table—This table holds the rotary table and can be fixed at any angle from 0° to 90°. In the 90° position, the rotary table center is also at the 2.7″ height, which allows the right-angle tailstock to be used with it.

After entering the number of steps per revolution (or the number of degrees per step) on a simple numeric keypad, the table advances quickly and precisely to the next position at the touch of a single advance key. If an error is made, previous positions can be accurately recalled by hitting another button. Basic resolution is 28,800 steps per revolution, ±0.006° per step. This allows the accurate machining of items like gears with odd numbers of teeth. Computations are made internally to a high degree of accuracy to avoid cumulative errors.

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

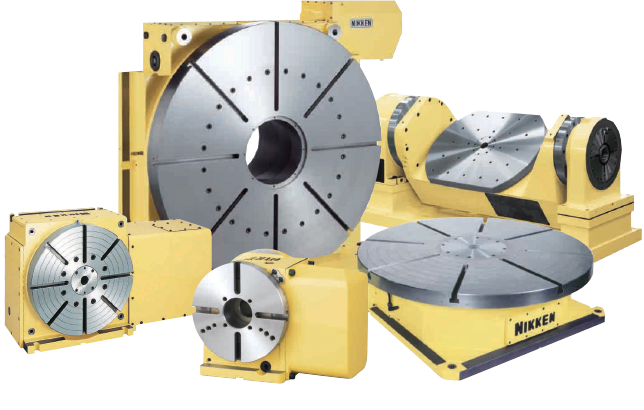

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

GSA TECHNOLOGY CO., LTD. established in 1978, from time to time, our growing of devotion work stable, keeping in mind of honesty, faith, profession and innovation, nonstop communication and promotion of critical quality procedure, ensure every products could meet high quality of duration and precision.

TANSHING products can be selected depending on different machining conditions. A wide range of models, such as the type of high load, high rigidity, high speed, high precision, long life span, zero backlashes, ultra-high load 10-60 tons large precision rotary table, and hydrostatic table can be customized. In addition, there is a variety of new 5 axis rotary tables, swing head rotary, etc. The complete series is available in our product line.

TANSHING’s R&D team is capable of dealing with a variety of machining requirements, such as speed and load capacity improvement. Any customized accessories can be planned and designed quickly. The same type of rotary table with a direct drive motor has been widely installed at domestic and foreign machine tool manufacturers. Our techniques for the function application of product, assembly, and testing are well-developed. We welcome machine tool manufacturers and machining shops to contact us for any kind of inquiry.

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

Many rotary table manufacturers outsource gear fabrication to lower costs. While that strategy may offer short term cost savings, Index Design’s American made rotary tables are built with gears cut in house. This is the only way to closely monitor and control tolerances, consistency and performance.

Our rotary tables incorporate large diameter high tensile bronze worm gears mated against hardened steel drive shafts. The combination of metal gives superior wear properties for long lasting operation. As the rotary table is run, the properties of a tin bronze gear develops a low friction deposit on the mating steel drive shaft. These deposits fill in microscopic pores of the mating surface. Over time, as these deposits are embedded on the surface, wear decreases followed by a reduction in frictional forces within the gear assembly.

In addition, the data gathered from our automated calibration procedure allow our engineers to assess, monitor and improve the static and dynamic performance of prototype rotary tables during the design phase.

Our engineers have a long and rich history in the machine tool business, they combine decades of both CNC machine tool and rotary table manufacturing experience with the latest design tools to produce rotary tables with superior performance and dependability.

Our CAD/CAM software is used to analyze displacement and stress for each component, sub-assembly and total assembly. However, the best software and technology is worth next to nothing if no one understands the craftsmanship. This is particularly true when manufacturing precision rotary tables which involves many steps. Despite all the modernization and automation available, a large part of the manufacturing process is still completed by hand. At Index Designs, we understand and appreciate craftsmanship, It is designed and built into our products.

Whether your CNC control has AC or DC drives, uses Fanuc, Mitsubishi, Yaskawa, Glentek, Siemens, Baldor, etc. we can build your rotary table with a compatible motor for just about any 4th axis-ready machine on the market! If you need help getting a machine 4th axis ready, we also supply the parts you need; such as amplifiers, drives, cables and connectors. If your application does not require simultaneous 4th axis cutting, we offer an easy-to-program, single-axis control box that can be M-function interfaced to your CNC machine. The control box can either be programmed directly or fed data via RS-232 for fast, accurate indexing to any angle.

Yukiwa CNC Rotary Tables and Index Tables are installed on the machining centers, tapping centers and special purpose machines and are used in various workings and operations, such as the machining of automobile parts, IT parts and etc., and also auto-transfer line. They have variety of features, such as light weight, compact, high precision, strong rigidity, patented water protection structure, which contribute to rationalization of production and the cost reduction in your company.

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Sankyo Automation is the worldwide leader in cam indexer technology; continuously working to develop new, innovative technologies in motion control. Our collection of high-speed, high-precision cnc rotary tables are frequently utilized in manufacturing systems that require accurate, high speed actions.

TJR Precision Technology co., Ltd. is a professional manufacturer of CNC rotary tables (the 4th and 5th axis). The main products are CNC rotary table, CNC index table, and other accessories with high precision and stability.

We have the best research and development team that integrates the applications of machine centers and rotary tables, and have the strictest quality control to ensure the highest quality. We also have the most active customer service to make the rotary table work in the optimal condition.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Manufacturers worldwide are always looking for the most reliable workholding devices on the market to accommodate their indexing and rotating needs. For more than 30 years, Ganro (Golden Sun) has been providing the world with a wide range of products to meet any manufacturing needs. To meet those needs, a manufacturer must know which table is the right choice and understand the proper use and capabilities of the different styles of equipment.

With sizes ranging from 120mm (4.72”) to 2500mm (98”), these rotary tables and indexers are capable of both vertical and horizontal mounting and have large thru-holes to offer maximum flexibility.

At CNC Indexing, you have the choice of three different types of Ganro standard tilting rotary tables that can accommodate most 4th/5th axis manufacturing needs. These include :

This manual rotary table is designed with full 4th axis and manual tilting axis that is perfect when tilting capabilities are just occasionally required.

With table tops ranging from 400mm (15.74”) to 300mm (118”) square, Ganro’s horizontal CNC rotary tables are useful in a wide range of manufacturing needs. The tables are designed for horizontal mounting only, and have the added benefit of withstanding extremely heavy workpieces. They are particularly suited to horizontal boring mill applications. These horizontal rotary tables can be used as a full rotating axis integrated into the machine’s CNC controller, or utilized as an indexer with Ganro’s M-Mate AC servo controller.

Our line of precision horizontal index rotary tables come in two different types, both of which use a two-piece Hirth coupling design that offers superior indexing accuracy while still maintaining a high level of rigidity during heavy cutting.

CNC Index Rotary Table: These index rotary tables are clamped and unclamped with hydraulics source. They are designed to integrate into a machine’s CNC controller, and operated with Ganro’s M-Mate AC servo control system.

Manual Index Rotary Table: This line of manual rotary tables can be clamped and unclamped either pneumatically or hydraulically. When unclamped, the table is manually indexed to the demanded angle and securely clamped into place.

These rotary tables are designed with a three-piece Hirth coupling for no-table-lift rotation. This design allows for mounting heavy workloads while still getting high rigidity and accuracy. These rotary tables are typically used in applications that incorporate a strong tailstock and tombstone or fixture plate, and can be integrated into the machine"s CNC controls or operated through Ganro"s AC servo controller.

From large to small workpieces, horizontal and vertical applications, 4th and 5th axis work, and manual or automated applications, GANRO has the right rotary tables and machine tools accessories to meet every needs.

8613371530291

8613371530291