cnc rotary table repair in stock

CNC TOOLS provides an exchange credit for most defective items. Our exchange program provides you with savings and keep us stocked for the next time you order. A repairable unit will need to be evaluated to approve full exchange credit.

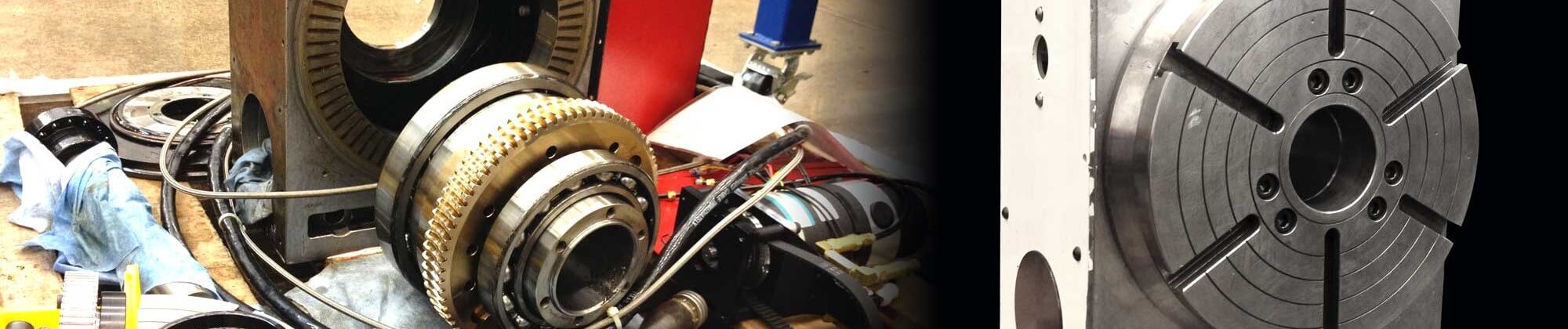

CNC TOOLS can restore your non-working unit to remanufactured conditions. Our Technicians have extensive experience with most manufacturers and apply rigorous testing procedures to ensure parts are fully functional to manufacturer specs.

CNC TOOLS provides 12-Month Warranty to most NEW and Refurbished products unless otherwise specified. If the unit fails within the warranty period we will evaluate, repair or replace no questions asks. We stand behind our products to help customers minimize machine downtime.

CNC TOOLS provides an exchange credit for most defective items. Our exchange program provides you with savings and keep us stocked for the next time you order. A repairable unit will need to be evaluated to approve full exchange credit.

CNC TOOLS can restore your non-working unit to remanufactured conditions. Our Technicians have extensive experience with most manufacturers and apply rigorous testing procedures to ensure parts are fully functional to manufacturer specs.

CNC TOOLS provides 12-Month Warranty to most NEW and Refurbished products unless otherwise specified. If the unit fails within the warranty period we will evaluate, repair or replace no questions asks. We stand behind our products to help customers minimize machine downtime.

We offer quick turnaround and since all repairs and maintenance are performed locally, it reduces your down time. We diagnose, rebuild and repair each machine to restore it to optimal performance. All services are performed by knowledgeable, courteous, local Haas factory-certified service technicians to ensure that your CNC rotary table repair service is done according to manufacturer standards.

Productivity offers rotary table preventive maintenance that includes motor checks, backlash adjustments, flushing and replacement of lubricant and replacement of O-rings and seals. We also offer full service electronic repair of servo control units and cables.

We believe that our wealth of experience and our passion for quality makes Midland Engineering the best choice when it comes to the repair of your rotary table. We understand the need for a quality assured repair service with a focus on keeping downtime to a minimum.

We have experienced engineers based throughout the UK who are available to travel worldwide, we also have a premises here in Chesterfield just off of the M1 where we carry out in house repairs and refurbishments.

And finally, a great deal of attention was devoted to the service friendliness of CNC rotary tables from pL LEHMANN in order to keep downtime as brief as possible. Thanks to sensors and electronic applications, every partner can, in an emergency, receive support directly from headquarters via teleservice. Or the customer is advised in advance to perform maintenance, depending on the usage. Real industry 4.0 / smart factory.

Our dedicated staff with more than 12 years of experience will provide comprehensive service, quality, and craftmanship. Manage downtime! Rental and loaner units are available, so your shop’s workflow can be uninterrupted. Our rotary repair department’s turn around times are the fastest in the industry – your productivity doesn’t have to suffer.

Fill out the form below to contact the repair center. Haas Factory Outlet will efficiently and effectively diagnose and repair your machine according to manufacturer standards. You will be contacted with a return authorization number that must be attached to the indexer/rotary unit before it is shipped for repair.

Has it suddenly stopped working and you"re panicking about downtime? Don"t worry - at CNC we can repair or deconstruct and fully rebuild your device back to its former glory.

At CNC Rotary, we offer a quick, dependable service where we will collect your table, take it back to our workshop, fix it and deliver it back to you as quickly as possible.

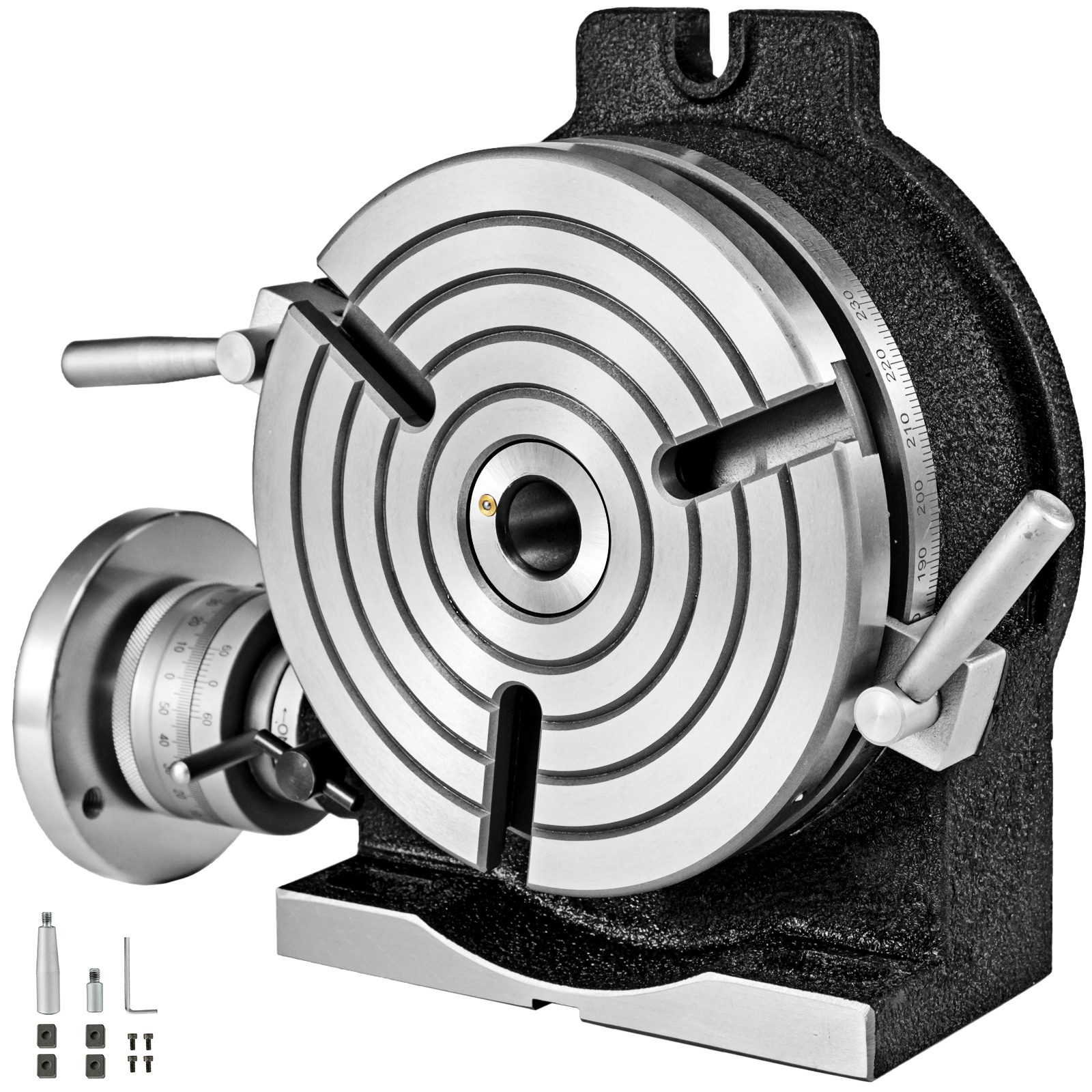

For products that use guide pieces to fix their body in accordance with T-slots of the mating machine, such as CNC rotary tables, tail stocks, side tables and side spindles, step guide pieces are available as well as standard guide pieces.

MMK"s product line has evolved to include a vast selection of CNC rotary tables, power chucks, hydraulic actuating cylinders, and other workholding products. Commitment to high qulaity products and excellent service has earned MMK Matsumoto industry wide attention.

Rusach International & Innovative Rotary Table Solutions are a leading worldwide supplier of small to medium sized compact CNC rotary tables, standard and application oriented designs, high accuracy, compact rotary tables. Thru bore rotary tables, horizontal rotary tables, vertical rotary tables, combination/convertible H-V rotary tables, multi spindle rotary tables, 2-axis tilting rotary tables, direct drive rigid and flexible rotary tables. Production style rotary tables to fit any machine.

Innovative Rotary Table Solutions has a full line of accessories like tail stocks, magnetic plates, rotary supports, steady rests, rotating tail stock supports and controllers, all designed to fit your application. Contact Rusach International today with your application.

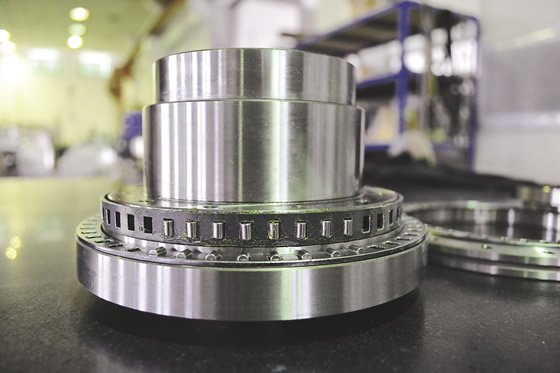

Ganro Industrial Corporation offers large rotary tables in their standard DR series configuration. The large rotary tables are available in a range of 1000mm (40”) to 2500mm (98”) in faceplate diameter. They can be utilized as a full rotating axis incorporated into a machine’s control or as indexers with Ganro’s M-Mate AC servo controller. These rotary tables and indexers are all capable of being mounted in both the vertical and horizontal positions to give manufacturers maximum flexibility. These large rotary tables and indexers utilize a hydraulic brake system to reach high clamping torques. All Ganro DR Series rotary tables and indexers use Ganro’s core technology of a double lead worm shaft and worm wheel system for high precision and reduced backlash. Ganro rotary tables are assembled using cross cylindrical roller bearings with high rotation accuracy capable of bearing heavy loads in every direction.

As the exclusive importer and dealer of Ganro products in the United States, CNC Indexing & Feeding Technologies stocks the most popular Ganro rotary table models, accessories and spare parts. We have certified service technicians for installation and repair of all Ganro and Golden Sun rotary table and indexer models. Please contact us today to learn how adding a Ganro rotary table or indexer can help improve your manufacturing process.

NIKKEN’s world-renowned CNC Rotary Table range provides proven performance, reliability and accuracy benefits for any application or requirement that others simply cannot hope to emulate.

With an extensive range of rotary table sizes, configurations and options available, all fully supported by our extensive global network, you can be sure to find the perfect product to meet any requirement or machine tool.

Single Axis, Twin Axis, Multi-Spindle, Standard Drive, High-Speed Drive, and Direct Drive capabilities are all available from stock. These can be configured and supplied for control directly by the CNC Machine or by integrating our exclusive Alpha 21 and EZ controllers to provide precise positioning and also full Macro B control (Macro B function – Alpha 21 only).

NIKKEN can also provide a complete and expansive range of accessories precisely engineered and customised to suit both the machine tool and the component. These options include a wide variety of chucking solutions, vices, bespoke trunnions & workpiece fixturing along with a wide range of NIKKEN manufactured rotary work supports and tailstocks to cater for all production expectations.

The basic idea behind a rotary table is to hold a workpiece in place and allow for the piece to be rotated along a precise axis so that the piece can be subjected to highly precise tooling. Rotary tables allow for more precise metalwork applications to take place on a workpiece.

Rotary tables can be used for manual applications. However, they can also be attached and used with CNC machines. CNC machines are computerized numerical controlled machines that depend upon the use of codes that are entered into their software systems to determine what the machine does.

CNC machines are not a singular type of machine; this technique can be used with a wide range of machines, from lathes to turning mills, and can be used with a wide range of modification products, such as a rotary table. A person controls the computer and tells it what to do instead of operating the machine manually.

One of the most significant advantages of adding a rotary table to your CNC machine is that the machine is now more adaptable. By adding a rotary table, you can do more with the machine without investing in a new machine. Being able to adapt an existing machine to perform more tasks increases the utility of the machine at a fraction of the cost that it would take to purchase an entirely new machine. You can make your machine more adaptable and efficient by adding a rotary table.

By adding a rotary table onto an existing CNC machine, you will have the ability to undertake more complex tasks with more precision. A rotary table will hold the item being worked on in place, allowing for more precise metalwork tasks to occur. This allows you to craft more advanced pieces that require more detailed work.

Finally, adding a rotatory table to your CNC machine can be a great way to save production time. With a rotary table, you can undertake more complex tasks using the same machine, which means that instead of transferring the item to another machine for finishing tasks, those finishing tasks can take place with the same machine. By taking care of all possible crafting and finishing tasks simultaneously with the same machine, you can save time with the overall production of the item.

If you want to increase the productivity of your CNC machine, adding a rotatory table will increase the functionality of the machine and allow you to undertake more precise metalworking tasks using the same machine. For more information on rotary table products, contact a company such as Koma Precision.

Centroid OEM Machine Tool Manufactures offer a wide variety of Centroid CNC equipped machine tools.. click to to find a Centroid equipped CNC machine tools..

Small Milling Machine CNC Control system: $18,385M400 3 axis with 1Kw AC Brushless Yaskawa servo motors and drivesMedium Milling Machine CNC control system: $22,175M400 3 axis with 2Kw AC Brushless Yaskawa servo motors and drivesLarge Milling Machine CNC Control system: $25,760M400 3 axis with 4.4Kw AC Brushless Yaskawa servo motors and drives

Small Slant Bed Lathe CNC control system: $15,450T400 2 axis with 1Kw AC Brushless Yaskawa servo motors and drivesMedium Slant Bed Lathe CNC control system: $18,795T400 2 axis with 2.2Kw, 2.2kw w/brake AC Brushless Yaskawa servo motors and drivesLarge Slant Bed or VTL CNC control system: $21,597T400 2 axis with 4.4Kw, 4.4 Kw w brake AC Brushless Yaskawa servo motors and drives

Auto part set, Auto tool set, 3D contouring, 4th and 5th axis machining, Available in OEM configurations, Professional Installation with Service & Training and DIY CNC kits for both new machines and retrofit upgrades.

From the May issue of Modern Machine Shop Magazine " A CNC retrofit provides improved reliability and functionality compared to an older machine’s original control, and this is helpful in a number of ways. For example, a more intuitive control interface can help speed setups and minimize the chance for programming and/or setup mistakes, which could possibly damage or scrap a high-value work piece. Similarly, shops are also more confident in quoting work for large, expensive parts knowing the new control won’t hiccup partway through an operation and cause the part to be damaged. Shops also are better-positioned to take in “hot” jobs that require fast turnaround due to the retrofitted machine’s improved"... click here to see the complete article in PDF.

CENTROID Boss series II retrofit customer testimonial"The quality and workmanship of the CENTROID equipment was outstanding and very professional. CENTROID was able to custom tailor the control to allow us to continue to use our rotary milling arrangement as before and even expanded our capability. The short story is that we ended up with a four axis CNC mill for less than half the cost of the three axis Haas. This includes the work that was done by our staff."

C). Face plate spindle damage, we had one unit that actually collapsed part of the spindle shaft. Fortunately, we were able to repair the spindle, potentially saving the customer the cost of replacing the entire face plate spindle.

Your rotary unit is repaired, reassembled and run in for 10 hours. It is then re-inspected, all final adjustments and calibrations are performed to the original manufactures specification.

The original Fadal rotary heads are still one of the best overall designed attachments for the Fadal machine. While there are many imported rotary heads that might "look good" on the outside, it"s the inside that really counts. The simple fact is the Fadal rotary tables were specifically designed to take a crash and keep on working.

Many different rotary heads were made throughout the years of production. A 4th or 5th rotary axis was one of the most popular machine options. In the early 90"s we started shipping all machines "4th axis ready" which means the machine has all the wiring necessary. You basically only needed an amplifier and a axis controller card with software. Contact us if you thinking of adding a 4th axis, we offer all the necessary components.

As you"ll see below, we are the most qualified to repair your rotary table. Having been there from the beginning, we know exactly what your table needs to bring it up to original specifications.

The very first rotary table sold that was sold on the VMC45 in 1981. It was designed and manufactured by Fadal for the VMC45, it never realized full production after production the VMC45 was stopped.

Troyke Mfg. Co. -Afterwards, with the introduction of the VMC40 in 1984, we began offering the TROYKE rotary products as a 4th axis option. The table had an interesting full contact bearing surface using Turcite between the faceplate and the casting with radial bearings support for the faceplate spindle. Few of theses units still remain in the field today. If needed, we can provide complete service for these units.

Soon after 1987, we started adapting many of the popular Japanese rotary tables. Some customers would send us their tables and we adapt our motors and 4th axis interface to them. Eventually we started adding the Tsudakoma, Tecnara and Nikken rotary tables as a direct option to all machines

TR65 - The TR65 (Tilt/Rotate, 6.5" dia. faceplate) had a unique clutch system build into the trunion for the B-axis. One of the biggest problems with 5-axis programming was that is was easier to crash than to program. And a B-axis crash usually resulted in the customer having to return the unit for repair. With this unique design, if the Z-axis crashed into the part, instead of damaging the gears it would simply slip the trunion clutch. The CNC knows the exact position of the B-axis because of the rotary scale feedback that is directly attached to the trunion and not the motor. The addition of the trunion clutch was so important because it virtually eliminated the disruption of operation for a service call.

8613371530291

8613371530291