cnc rotary table repair price

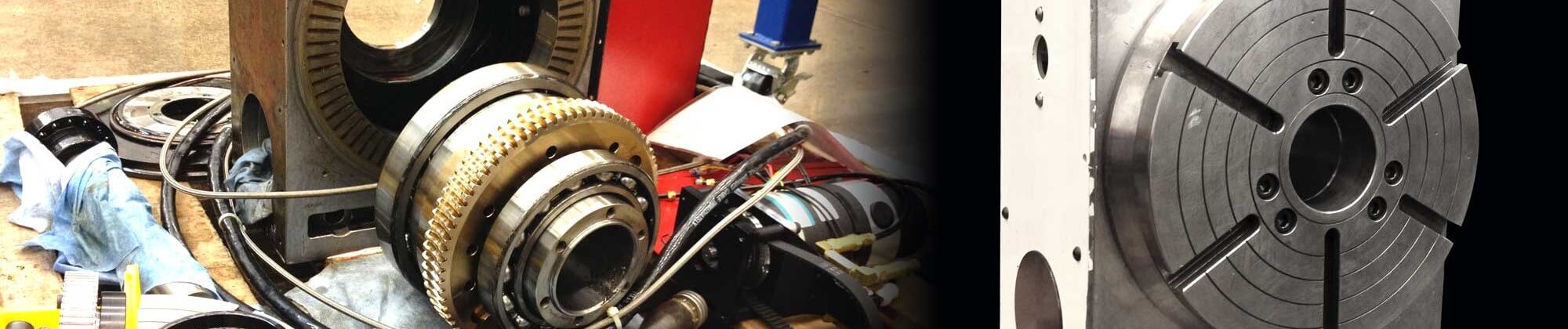

We offer quick turnaround and since all repairs and maintenance are performed locally, it reduces your down time. We diagnose, rebuild and repair each machine to restore it to optimal performance. All services are performed by knowledgeable, courteous, local Haas factory-certified service technicians to ensure that your CNC rotary table repair service is done according to manufacturer standards.

Productivity offers rotary table preventive maintenance that includes motor checks, backlash adjustments, flushing and replacement of lubricant and replacement of O-rings and seals. We also offer full service electronic repair of servo control units and cables.

The original Fadal rotary heads are still one of the best overall designed attachments for the Fadal machine. While there are many imported rotary heads that might "look good" on the outside, it"s the inside that really counts. The simple fact is the Fadal rotary tables were specifically designed to take a crash and keep on working.

Many different rotary heads were made throughout the years of production. A 4th or 5th rotary axis was one of the most popular machine options. In the early 90"s we started shipping all machines "4th axis ready" which means the machine has all the wiring necessary. You basically only needed an amplifier and a axis controller card with software. Contact us if you thinking of adding a 4th axis, we offer all the necessary components.

The very first rotary table sold that was sold on the VMC45 in 1981. It was designed and manufactured by Fadal for the VMC45, it never realized full production after production the VMC45 was stopped.

Troyke Mfg. Co. - Afterwards, with the introduction of the VMC40 in 1984, we began offering the TROYKE rotary products as a 4th axis option. The table had an interesting full contact bearing surface using Turcite between the faceplate and the casting with radial bearings support for the faceplate spindle. Few of these units still remain in the field today. If needed, we can provide complete service for these units.

Soon after 1987, we started adapting many of the popular Japanese rotary tables. Some customers would send us their tables and we adapt our motors and 4th axis interface to them. Eventually we started adding the Tsudakoma, Tecnara and Nikken rotary tables as a direct option to all machines.

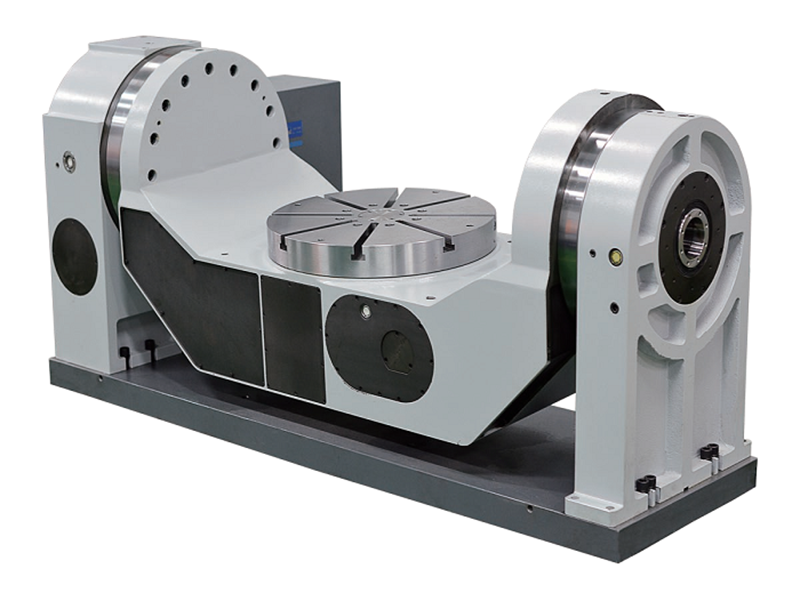

VH65 - After years of installing and also repairing the many various manufactures rotary tables we sold, we learned what different designs worked and didn"t work in the machines. The second rotary head Fadal designed was the VH65. The VH65 stands for Vertical or Horizontal mount and 6.5" diameter faceplate.

TR65 - The TR65 (Tilt/Rotate, 6.5" dia. faceplate) had a unique clutch system build into the trunion for the B-axis. One of the biggest problems with 5-axis programming was that is was easier to crash than to program. And a B-axis crash usually resulted in the customer having to return the unit for repair. With this unique design, if the Z-axis crashed into the part, instead of damaging the gears it would simply slip the trunion clutch. The CNC knows the exact position of the B-axis because of the rotary scale feedback that is directly attached to the trunion and not the motor. The addition of the trunion clutch was so important because it virtually eliminated the disruption of operation for a service call.

C). Face plate spindle damage, we had one unit that actually collapsed part of the spindle shaft. Fortunately, we were able to repair the spindle, potentially saving the customer the cost of replacing the entire face plate spindle.

You will receive an estimate of repair 5-10 days (depending on workload) after receiving rotary unit. Repairs take an average of 10 to 30 working days after receiving approval. Evaluation charge of $500.00 will apply if you do not get it done.

Your rotary unit is repaired, reassembled and run in for 10 hours. It is then re-inspected, all final adjustments and calibrations are performed to the original manufactures specification. We warranty our complete Rebuilds for 1 year.

As you can see we are the most qualified to tune-up or rebuild your rotary table. Having been there from the beginning, we know exactly what your table needs to bring it up to original specifications. Simply call Toll Free 1-800-342-3475 for any questions.

CNC TOOLS provides an exchange credit for most defective items. Our exchange program provides you with savings and keep us stocked for the next time you order. A repairable unit will need to be evaluated to approve full exchange credit.

CNC TOOLS can restore your non-working unit to remanufactured conditions. Our Technicians have extensive experience with most manufacturers and apply rigorous testing procedures to ensure parts are fully functional to manufacturer specs.

CNC TOOLS provides 12-Month Warranty to most NEW and Refurbished products unless otherwise specified. If the unit fails within the warranty period we will evaluate, repair or replace no questions asks. We stand behind our products to help customers minimize machine downtime.

CNC TOOLS provides an exchange credit for most defective items. Our exchange program provides you with savings and keep us stocked for the next time you order. A repairable unit will need to be evaluated to approve full exchange credit.

CNC TOOLS can restore your non-working unit to remanufactured conditions. Our Technicians have extensive experience with most manufacturers and apply rigorous testing procedures to ensure parts are fully functional to manufacturer specs.

CNC TOOLS provides 12-Month Warranty to most NEW and Refurbished products unless otherwise specified. If the unit fails within the warranty period we will evaluate, repair or replace no questions asks. We stand behind our products to help customers minimize machine downtime.

It is when the components are missing tolerance that you realise that the trusty device that has worked so hard, has had enough and needs a holiday at CNCROTARY.COM to recharge its batteries and be ready for battle once again.

With great & continuous support by our valued customers and our top notch quality products makes us most preferable supplier of CNC milling spindles, CNC turning spindles, Grinding spindles, Electro spindles, CNC Rotary Table,Index Tables, 5 Axes Aead, Rack & Pinion, work holding solutions and many more

To upgrade a manual rotary table to CNC-ready, the entire worm housing and the components inside must be replaced with a CNC worm housing. This is done as a factory-only replacement. You will need to ship your manual rotary table back to our factory for the conversion.

Yuasa has been a major provider of CNC rotary products for decades. They can be found in large as well as in small facilities throughout the North American continent. Potomac Electric has recently added Yuasa UDNC-M1 (single-axis) and UDNC-M2 (dual-axis) rotary table programmable controllers to its CNC Repair Services line. Both controllers utilize Delta Tau"s PMAC x/y controller and Delta Tau Geo drive. Potomac Electric has been repairing Delta Tau controllers, drives, and accessories for over 15 years.

We are a small business and we understand the difficulty and cost of maintaining your CNC machinery. Please drop us a note on our Rotary Table Repair Inquiry and Quotes page with any questions.

A large number of specially selected, high-quality second user products are available through our webshop or directly from our technical sales department, providing rotary table products that have been fully rebuilt exclusively by us, to a very high...https://facebook.com/cncrotaryshop/videos/475171379666589/…

Regularly servicing your Rotary Table can make the difference between it running smoothly and the risk of it breaking down incurring unexpected expenses and massively reducing production time.

Removing costs from any business increases profit margins but avoiding servicing your unit may prove to be a false economy, as wear and tear is inevitable and what is picked up during a service as minor maintenance can soon become a costly major repair if left to worsen, again incurring unexpected costs.

After a service is carried out on any CNC Rotary Table, a full report is provided to highlight any early warning signs. This report allows you to schedule planned maintenance, minimising downtime and being able to set budget aside for necessary repairs, ensuring you avoid a costly breakdown or gradual reduction in component quality.

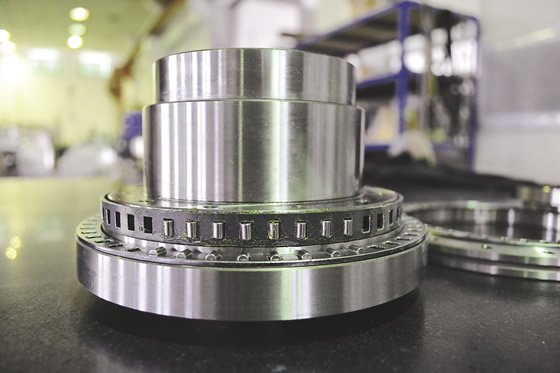

We see many cases of contaminated oil leading to premature bearing failure and accelerated wear, in fact, research shows that over half the number of bearing failures in industrial equipment occur due to the contamination of bearing oil. Just as any car needs regular oil changes, your rotary table will also benefit from regular servicing to protect against damage due to degradation of lubrication.

A Standard Nikken Service entails a full functionality check, adjustment of backlashes etc. where appropriate and oil change & resealing of covers to prevent coolant ingress. We also carry out a range of tests at the same time which give a clear picture of the condition of the bearings, seals, wormscrew and gear, presented in a full report on the current rotary table condition, without the need to remove the table from the machine or strip it down.

Here at Nikken, we have a fully equipped Service Department with over 20 years experience enabling us to offer complete and timely support for all Nikken CNC Rotary Tables, NC Tool Systems and Tool Presetters. We offer one off and annual service agreements to ensure your machine is running at its best performance.

Servicing is a vital part of the up keep and maintenance of all CNC machines. Unfortunately it has become the norm to avoid the rotary tables off of the machines regular service packages due to their complexity and accuracy, but this is the fastest route to high cost repairs / breakdowns.

Midland Engineering carry out full services on all makes/models of rotary tables and can predict issues before they happen. We do this by testing and re calibrating all aspects of the device in order to produce a full report of data. This data is then used to carry out pre-planned preventative maintenance, helping to avoid unexpected breakdowns.

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

8613371530291

8613371530291