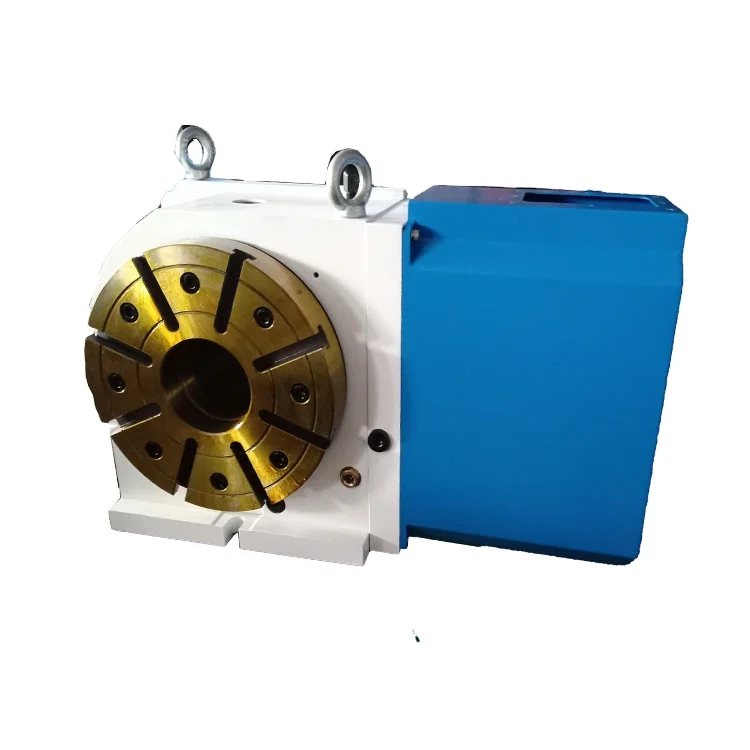

dividing head rotary table manufacturer

Dividing heads allow you to divide a circle into equal fractions conveniently. Anything that involves regular action around a circle is a candidate for a dividing head.

A rotary table has no stops so it is not convenient to do large numbers of things at equal intervals because you would have to painstakingly determine the interval. Also, the rotary table does not divide the circle. For example, if you were making 13 equally spaced operations using a rotary table you would have to calculate some wierd angle for each operation and dial it in--a tedious process. For example, here are the 13 angles for a circle division:

Do you want to manually set each of these values? Have fun doing that. Now, imagine doing it for 53 divisions. You will be there all night. Not only that, the error will be a lot more than a dividing head.

Rotary tables are mounted horizontally, and most can also be mounted vertically. In both cases only at 90° to the mill table. A Dividing Head is always vertical, but can be tilted through 90°.

Dividing heads are always fitted with "indexing plates" (holed wheels and clock hands), allowing a wide range of angles to be turned. The indexing mechanism can do intermediate angles. Rotary tables can be fitted with indexing plates as an accessory, but usually the number of angles supported is limited compared to a dividing head. (A generalisation. And, because rotary tables do all common angles, the limitation may not matter.)

Rotary tables are more convenient for general work because most jobs are mounted at 90° or 180° relative to the milling table. Possibly more robust than a dividing head for rough work. When close accuracy isn"t needed, jobs can be spun rapidly by the rotary table without cranking the handle - a time saver. When accuracy is needed the handle and worm are engaged. Usually there"s a vernier scale sufficiently accurate for most work. The handle is also relatively fast because most simple angles can be produced with it. For example, easy to crank from 0, 60, 120, 180, 240, 300, 0 to cut a hexagon head. Unfortunately not all angles are "simple"!

Indexing plates are so awkward that driving a Rotary Table with a stepper motor and microcontroller is popular. You simply tell the controller how many divisions are needed, press "Go", and the computer does the rest. Apart from reducing brain strain and automating a tedious task, the computer eliminates most mistakes. Computers don"t get sums wrong, have excellent memories, and are hard to distract! Also, a computer and stepper motor will do a good job of angles too complicated for the Indexing plates.

Generalising again, I suggest most people, most of the time, only need a rotary table. I see Dividing Heads as specialist tools and have never felt the need for one. For the same reason I drive an ordinary small car rather than a Land Rover. The closest I get to off-road driving is a supermarket car park! You might live on a farm...

Unless there"s a specific reason for needing a Dividing Head, I wouldn"t spend money on one. My rotary table is used a lot, in contrast a Dividing Head is only "nice to have".

The indexing plate is a machine tool accessory that holds the workpiece on the chuck or between two pinnacles and rotates, indexing and positioning it. Plate connected with rotary indexing table is in Diameter: 4"/100mm and Thickness: 0.28"/7mm, good for rotary tables in Model HV-3, HV-4, HV-5, HV-6, TS160. Perfect to use with dividing head for milling table.

Explore rotary indexing head with simple designs on Alibaba.com for efficient metal cutting and strong support for the workpiece while cutting or grinding. The devices are vital components to various grinding equipment, and they are typically easy to mount. Standard machines that apply rotary indexing head as installable or built-in parts include milling machines, boring tools, and drill presses. Some device applications include gear cutting, devising milling cutter flutes, and making bolt hole circles.

The innovative indexing head features a sturdy head and footstock or indexing centers for steady and reliable operation. Alibaba.com delivers different types of rotary indexing head, including plain, optical, spiral, and universal spiral machines to cater to unique project requirements. The device components may operate as a unit or with extra attachments for enhanced accuracy and precision levels. Explore various direct index heads for fluting taps, milling squares, octagons, and many more.

Shoppers can use rotary indexing head to verify precision angles, proportions and measures up to seconds of a degree using optical lenses for sensitive projects. Universal designs are well-suited for all forms of head indexing since they are configurable at any angle. Make indexing work more comfortable and enjoyable by having these machines in the workshop.

Compare mind-blowing rotary indexing head options and exclusive deals on machinery on Alibaba.com. The quality-assured products come with sustainable warranties and are easy to operate and maintain. Customization for orders and aftersales support is also available from trusted dealers and distributors.

I have used it in the vertical position to cut a 107 tooth gear which isn"t covered by any of the dividing head wheels I"ve got. I set up an excel spreadsheet with the angle required for each tooth which isn"t as easy as it sounds as the rotary table is calibrated in degrees/minutes/seconds rather than decimal degrees so it took a bit of figuring out how to do it.

I have an 8" Rutland horizontal/vertical RT made in Taiwan that is about all I want to carry around without mechanical help. It has done all I ask of it, and a larger fixture plate mounted to the top of the table could be up to any diameter I care to make it. It is a high quality RT, and I am happy with it. Just went out and weighed it on a bathroom scale, said ~55 pounds. I also recently picked up a beautiful old adjustable height tailstock for it. It is also very heavy and solid, maybe 25 pounds.

I also have a 6" swing dividing head (no maker"s mark, WWII?) with two sets of three dividing plates, two D.E. Whiton 1-3/4" 8 tpi mount chucks (3 and 4 jaw, also marked Rivett!}, and #9 B&S spindle tooling for it as well, and a mill mounting table adapter plate that holds the dividing head and the tailstock to it for quick mounting to the mill table. Throw it on the mill, tighten 4 bolts, and it is ready to use, with less than .001" tolerance fit everywhere.

Given the choice between dividing head and rotary table, I vote for both! The jobs they do are mostly quite different, and one does not work for the other very well. In a pinch, yes, it can be done.

These days it"s pretty trivial to create a spreadsheet to figure out the required degrees/minutes/seconds for some arbitrary number of divisions n, so it"s not all that big a deal to use a rotary table for dividing. A dividing head is, as others say, probably a bit more convenient both in ease of dividing oddball numbers of divisions and in less mass to get in the way of what you"re machining...but a rotary table will be more flexible. If you want to substitute for a dividing head, be sure to get a horizontal/vertical rotary table, as you"ll want "vertical" mode for dividing (and making gears).

If the rotary table has a Morse #3 center hole (or whatever), in vertical mode you could probably use Morse taper collets for workholding, which might be pretty handy. The only thing is, as hinted above, in vertical mode there may be a lot of rotary table in the way of what you"re trying to machine, if you need to get in close. It"s do-able, but you may to need to be a bit creative in workholding to arrange necessary clearance to get the tool where you need it.

8613371530291

8613371530291