diy 5th axis cnc rotary table brands

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new 5 axis rotary table or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement 5 axis rotary table, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new 5 axis rotary table are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

KME CNC Rigid Cast Iron Trunnion Tables are one of the leaders in the industry for accuracy, surface finishes and repeatability. Allowing you to speed up your cycle times, these tables are ideal for high volume production applications. Powerful and compact trunnion design ensures smooth operation over the entire travel range.

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

CNC rotary tables are a cost-effective alternative for the shops that cannot afford those high-end multi-axis machining centers. Though less versatile and efficient than a CNC machining center, a typical milling machine that incorporates a rotary table is able to carry out many more intricate tasks. In this article, we will walk you through the basic knowledge of the 4th and 5th axis CNC rotary tables, including how they work and what they can do for the shops.

In essence, it is a mechanical device that offers an additional rotational axis to a machine tool. It is typically designed to work with a milling machine so that the machine has the ability to carry out more complex cuts. Provided with a rotational axis, in a sense it combines a milling machine with a lathe. Besides giving an extra axis, rotary tables are also used for indexing and positioning tasks.

Rotary tables were invented in the early 20th century. The construction has not changed much since the invention except the way they are driven. At first, chains were used. But from 1918 on the shaft-driven mechanisms replaced them. As the technology of powered machines and computer control advanced, NC and CNC models hit the market in the late 20th century. CNC controls facilitated precision positioning and indexing.

The primary benefit is the indexing accuracy. In the past, millimeter-scale accuracy was enough for general-purpose machining applications since the part tolerance requirements were not high. Today, medical equipment, military, and automotive components require higher precision. That is why CNC tables with micrometer precision prevail across industries.

The standard CNC rotary tables are also called the 4th axis or 4-axis rotary tables. The 4th axis refers to the rotational axis, their most important feature. It upgrades an existing machine tool with x, y, z dimensions by adding an additional axis.

As mentioned earlier, the working principle of a 4th axis CNC rotary table is similar to the headstock of a lathe. They are both electrically powered to clamp a workpiece and make turns. The CNC system enables precision positioning so that the milling machine can make cuts on the desired surfaces of a workpiece.

An additional fourth axis is beneficial because it can be adjusted for particular amounts of rotary motion. The degrees the table rotates are pre-programmed and accurately controlled by the computer. The other benefit is that it allows the milling machine to work on cylindrical parts. The milling machine can cut grooves, slots, and planes on the outer diameter of a bar.

The precision indexing ability of the rotary table enables the machine tool to cut equidistant holes in a workpiece around 360 degrees across its surface. Repositioning of the workpiece is not required during such an operation. Similar operations such as arc cuts and curved contours can be performed in a run as well.

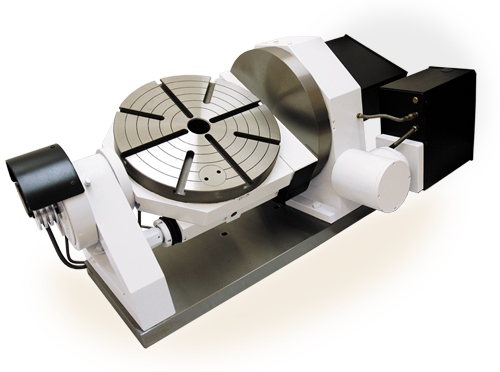

A 5th axis CNC rotary table provides two additional machining axes to a machine tool. Besides the rotational axis, the 5-axis rotaries have another swinging axis. In other words, the table not only turns but also tips. With two more axes, the machine tool is able to perform multi-plane machining.

The working mechanism of a 5-axis CNC rotary table is simple. As you can see in the image above, the rotary is mounted onto a swivel base. In addition to the swivel, other designs such as a swing bed are also available to provide a tilting axis to the table. Here is a video showcasing the moving axes.

A 5th axis CNC rotary table not only features precision positioning but also eliminates multiple setups that are required for complex machining applications. Compared to the standard CNC rotaries, the 5-axis table covers more surfaces on the workpiece. The milling machine can machine a workpiece on any four of the five axes at the same time, which reduces the production lead time significantly.

One of the key applications of 5-axis machining is mold-making. The ability to achieve intricate surface designs on the workpiece allows for the machine to manufacture molds used in industries including aviation/aerospace, automotive, military/defense, and medical.

The 4th and 5th axis CNC rotary tables have their own pros and cons and are suitable for particular applications. The 4th axis rotaries are apt at precision indexing for simpler designs whereas the 5th axis tables excel at complex designs but the rigidity is compromised and chatter or deflection may take place accordingly. The shops should choose a model that meets their actual requirements.

Centroid OEM Machine Tool Manufactures offer a wide variety of Centroid CNC equipped machine tools.. click to to find a Centroid equipped CNC machine tools..

Small Milling Machine CNC Control system: $18,385M400 3 axis with 1Kw AC Brushless Yaskawa servo motors and drivesMedium Milling Machine CNC control system: $22,175M400 3 axis with 2Kw AC Brushless Yaskawa servo motors and drivesLarge Milling Machine CNC Control system: $25,760M400 3 axis with 4.4Kw AC Brushless Yaskawa servo motors and drives

Small Slant Bed Lathe CNC control system: $15,450T400 2 axis with 1Kw AC Brushless Yaskawa servo motors and drivesMedium Slant Bed Lathe CNC control system: $18,795T400 2 axis with 2.2Kw, 2.2kw w/brake AC Brushless Yaskawa servo motors and drivesLarge Slant Bed or VTL CNC control system: $21,597T400 2 axis with 4.4Kw, 4.4 Kw w brake AC Brushless Yaskawa servo motors and drives

Auto part set, Auto tool set, 3D contouring, 4th and 5th axis machining, Available in OEM configurations, Professional Installation with Service & Training and DIY CNC kits for both new machines and retrofit upgrades.

From the May issue of Modern Machine Shop Magazine " A CNC retrofit provides improved reliability and functionality compared to an older machine’s original control, and this is helpful in a number of ways. For example, a more intuitive control interface can help speed setups and minimize the chance for programming and/or setup mistakes, which could possibly damage or scrap a high-value work piece. Similarly, shops are also more confident in quoting work for large, expensive parts knowing the new control won’t hiccup partway through an operation and cause the part to be damaged. Shops also are better-positioned to take in “hot” jobs that require fast turnaround due to the retrofitted machine’s improved"... click here to see the complete article in PDF.

CENTROID Boss series II retrofit customer testimonial"The quality and workmanship of the CENTROID equipment was outstanding and very professional. CENTROID was able to custom tailor the control to allow us to continue to use our rotary milling arrangement as before and even expanded our capability. The short story is that we ended up with a four axis CNC mill for less than half the cost of the three axis Haas. This includes the work that was done by our staff."

Whether your CNC control has AC or DC drives, uses Fanuc, Mitsubishi, Yaskawa, Glentek, Siemens, Baldor, etc. we can build your rotary table with a compatible motor for just about any 4th axis-ready machine on the market! If you need help getting a machine 4th axis ready, we also supply the parts you need; such as amplifiers, drives, cables and connectors. If your application does not require simultaneous 4th axis cutting, we offer an easy-to-program, single-axis control box that can be M-function interfaced to your CNC machine. The control box can either be programmed directly or fed data via RS-232 for fast, accurate indexing to any angle.

The number of axes you need for a machining center depends on the geometry of the part to be machined. Machine tools are most often equipped with 5 axes, but there are also 3-axis and 4-axis machines as well as ones with up to 7 axes. In this section, we will deal with 5-axis machines because they are the most common in the industry. We will go over:

... compact footprints of the Haas UMC-500 Series Universal Machining Centers make them perfect solutions for 3+2 machining and simultaneous 5-axis machining ...

The GM-2-5AX is a 5-axis gantry mill designed for complex, large-part machining, such as airframe components, layup molds, and composite structures. The machine’s rigid ...

... to change. GF Machining Solutions provides these manufacturers with agility for the future with its Mikron MILL P series of five-axis, simultaneous Milling machines.The ...

... Monnalisa is the innovative horizontal 5 axis milling centre specifically developed for machining monolithic, structural, large dimension aluminum parts, particularly ...

PowerMax™ is a large working volume, 5 axes (6 in case the rotary table is selected), horizontal, subtractive manufacturing center for Aluminum and Titanium parts.

... resolution direct measuring systems guarantee maximum repeat accuracy in a working space of 300 x 300mm. KERN Evo can be optionally equipped with a 4th and 5th axis without compromising ...

The MultiTec is the smallest of Waldrich Coburg’s CNC vertical mills, profiling similarly to our TAURUS vertical machining centers but with a fully customizable ...

... column type milling machine entrusted with the important task of reviving the success obtained throughout the world by the moving table milling machine mod. LEM. In line with the last ...

5-Axis, high-speed milling machine for medium sized aircraft structural parts and panels. Designed for processing aircraft structural parts up to 2 x 4 m, such as ribs, ...

Are you looking for an accessory to boost the precision of your modern machining centers? CNC rotary tables provide a versatile tool in expanding the capabilities of your machines. They allow for precision positioning during 4 and even 5 axis cutting operations, thereby transforming 3-axis machinery into CNC machines with heightened accuracy. CNC rotary tables are a cost-effective solution to perform complicated machining tasks, with additional benefits such as increased productivity, efficient use of labor and materials, and better quality control.

Additionally, CNC rotary tables can be used independently to mount other components on a table, including trim attachments and chucks for drilling applications. CNC rotary tables offer considerable advantages that promote their usefulness in a variety of industrial settings.

Looking to sell your CNC Rotary Table? Simply fill out the sell your machine form and we will get back to you with a quote. Interested in one of our used machines for sale? Simply click the “Get Quote” button and a sales representative will contact you shortly.

The normal functioning of CNC machines is done along the three Z, X, and Y axes. The five axes machines have two more axes accessible, which are namely A and B. The addition of the two extra axes makes it easy to cut complex and intricate parts. The increasing usage of five axes machines is because of their capability to reduce the time of production.

The usage of a spinning cutting fitting allows the CNC machines to quickly attain the required part geometries. Since the table positions and rotates from all five axes, the stress amount on the cutting apparatuses is reduced, and that adds to the lifespan of a CNC machine. The figure below represents a five axes CNC machine.

5 Axis Machining is a type of CNC Machining. The electromechanical procedure which manipulates apparatuses around three axes to five axes, with high accuracy and precision, cutting off excess materials to create components and parts is called CNC machining. CAD creates the starting design, which is to be machined by CNC machining process. The design is now translated into several CNC codes to give programmed instructions to the apparatuses in a CNC machine.

The multitasking capability of CNC machines enables the completion of a part or component in a distinct operation with efficiency and ease. The types of applications done by CNC machines involve collars, bushings, fittings, fasteners, inserts, machined washers, machined components, pins, spacers, nuts, spindles, drive shafts, standoffs, and splined shafts just to name a few.

Diamond tools usually used are high precision tools, diamond particles layer cutting surfaces. Figure 1.3 shows the machine table with a spindle utilized for carving gemstone and the motion directions of the diamond tool while machining. Even though diamond particulates are applied all over the surface of the tool, this kind of tool construction is made for cutting edges.

Depending on the cut width and the surface quality after machining, the size of the tool is selected. The diameter of the particulates coated to the tool is also in proportion to the tool head diameter. The main tool oscillates in the three axes Z, X, and Y. In this design, for the T-shape diamond apparatus as seen in Figure 1.3a, the direction of depth of cut Y-axis is the depth of cut direction. Rotation of the B and A axes affects carving curves and arcs on the object.

From the design parameters above, the main parts and components are selected first. The manufacturing of CNC machines has its basis on the primary components, present parts and systems, and then coming up with new systems according to the usage of requirements. In the design, the primary components are selected as shown below.

The movement and spindle of axes are set in the proper directions. Inventor software is used to build, analyze and simulate the components for mechanical systems. The 3 dimensional CAD modeling of a CNC machinery is shown in the image above. In this design, Z, X, and Y axes are run by stepper motors via the ball screws. B and A axes are run from the stepper motors via timing belts. The primary design was based on parts available commercially, other parts were repurposed to meet the utilizing functions. B and A axes are calculated to guarantee strong links and bring effectiveness when the CNC machine is in working. First, it is pertinent to pick the hard machining material, the timing belt’s transmission is utilized to lower the motor’s torque, and then determine dimensions, the dynamics transmission ratio. Full CNC machine assembly is brought together using the 3 dimensional CAD simulations sketching step. Simulations of axis movement are done, resizing the components and then machining.

The electrical system is designed and installed. The power source for the motor and the controller is a DC supply with three voltage levels. Where 5VDC is utilized to give input for controllers and signals, 24VDC is utilized for the operation of stepper motors, and the power supply can be attuned in a range of 12 to 100VDC for controlling spindle speed. The electrical system of the CNC machine is illustrated in Figure 1.5 below.

In CNC machining, a component is made utilizing subtractive machining technology and cutting tools, which cuts off at the component to make the needed shape. The shape is preconfigured by the unique CAD (Computer-Aided Design) file. A program is then made in G-Code layout, which inputs instructions directly to the CNC machinery.

Presently, it is most typical for CNC Milling machinery to have only three axes to work from, Z, X and Y. Nevertheless, 5-axis CNC machinery uses more axes, to put into the cutting operation from added angles, giving bigger scope for more intricate and complicated designs. So, axes A, B, and C may be introduced.

The cutting apparatus of the 5-axis CNC Machine reaches the workpiece from one of the five axes. It moves along the Z, X, and Y linear axes and also rotates on the A, B, or C axes.

These axes work along Z, X, and Y in rotational angles to bring a 5-axis cutting machine able to make complex designs while staying a really high quality to the finished component. A, B and C axis move freely to the Z, X and Y in a rotating fashion. The specific setup of the CAD design or machine determines which 2 of the 3 more rotational axes are utilized. This 5-axis setup comes at a higher cost because of the higher calibration levels and automation technology required to operate the five axis CNC machine and feed the commands.

It must be ensured that the processing power of a CNC control is great enough to calculate, control and compute the number of axes utilized at the same time.

Look ahead function for a four plus one (4+1) axes machine must be 200 blocks minimum. For more complicated 4-axis machine sequences, 400 blocks are better. For a full five axis simultaneous procedure, a faster calculation CNC control is needed. This could be a 1000 blocks voluntary look ahead function, offering extremely high calculation speeds.

Sufficient rigidity and power of the machine spindle are both pertinent factors and are at times overlooked. Nevertheless, a powerful spindle needs an even more firm mechanical design’s support. To ensure error-free and smooth cutting, the heart of the five axis CNC machining center which is the machine spindle needs to not just be adequately powerful to withstand the loads and stresses put on it but also have enough reserves to the limit. Subject to the part to be CNC machined, a not as powerful spindle of 11kW to 15Kw with a max torque of lower than 100 Nm could limit the machine’s abilities. Such machines may be affordable in the short run, in the longer view, not so much.

There are many benefits to the use of 5-axis CNC machines since they produce fewer errors and have higher productivity than traditional machining processes. As with all forms of industrial operations, inspection is a critical aspect of 5-axis CNC machining. Quality control and inspection are included in every stage of the CNC process. In addition to traditional quality control, quality assurance in regard to documentation and processes is also part of CNC inspection.

The quality inspection of 5-axis CNC machining involves three levels of inspection, which are tool accuracy, part test, and process monitoring and control.

Tool Accuracy Test: The tool accuracy test is in reference to the movement, centering, and positioning of the machine tool. The orientation of the spindle, bracket, axis, and other factors such as the perpendicular positioning of the main shaft in relation to the worktable are various aspects of the tool accuracy test. It is essential that the angle and bend of the shaft and the linear axis are accurate and precise.

Regardless of the accuracy and reliability of 5-axis CNC machining, inspection is necessary to ensure that the final product meets a customer’s vision and needs. Although the process is the most sophisticated production method, it still requires oversight, control, and monitoring.

As the core of any CNC machinery – especially for a 5-axis CNC machine tool – it is pertinent to monitor heat control in the frame and the spindle. Doing so does not only help prolong the lifespan of this important mechanism; it will also provide better accuracy and quality for machined parts. To avoid overheating of a spindle, it is necessary that the spindle housing and the spindle nose are cooled effectively. Heat prevention is essential during intense machining tasks, to control and reduce the heat created from the bearings and motor during higher velocities and longer machining cycles.

The main variance between the types of five axis CNC machines is where the rotational axes appear on the machine. Five axis CNC machines can either have the rotation found in motioning the table and, hence an object or in spinning the apparatus head onto a fixed material. Swivel head machinery can accommodate a heavier and larger material because it does not have to move the material at hand. In disparity, a spinning table machine can offer speed and stability for objects with less weight.

This one places a B axis, 360 degree rotary table under the workpiece. The covered machine offers a workspace fifty inches in diameter by fifty inches of height.

The ideal component of this machine is a holed cylinder, particularly angled holes. One instance is turbine housing. On a component such as this, these holes appear at different positions around the OD. In this case, a machine with this construction can set itself from one hole to the other with a motion in one axis only. Any other kind of five axis CNC machine would motion from one hole to the next on a cylindrical component using movements in two axes, or more. But on a pivoting head/rotary table machine, the apparatus only needs to be slanted one time to the accurate angle for the hole, also the spindle head must only be oriented in Z, X, and Y axes one time. Drilling an arrangement of holes then is an issue of retracting, feeding in, and indexing in B only to get to the next hole.

A more repeatable procedure is the result. More axes of positions would only add to the chances for position error to affect the motion. Another benefit of this CNC machine construction relates to material size. The fewer rotational axes motion the material, the improved the machine can facilitate large parts. This machinery does spin the material in B, so the material’s swinging is limited to this axis. Nevertheless, since this is the only material pivoting, the machine operates on tall materials effectively. Five axis CNC machines putting both pivots on the table usually are limited to materials which are small in relation to the linear movements. But this design leaves the material more fixed, enabling the machine to operate on very tall cylindrical materials.

On this CNC machine, the primary table is so big that the A-axis unit may be oriented over a broad range of positions, increasing flexibility. Efficient programming needs the programmer to precisely know where the A-axis table face locates in relation to the B pivot. This at times means the code is programmed to assume a specific position for the A axis, and leaves the operator configuring the machinery with the lengthy step of orienting the A-axis unit to precisely match this need.

An ideal component for this CNC machine is one that gives a holed ring to the spindle, mainly if that material is cylindrical and also needs to be machined around its OD.

This machine is not enclosed, so it cuts away some large parts if the axis part isn’t in place. Prepared for five axis CNC machining, it comes across more restricting limitations on material size. When the A axis part is in position, the volume of the material is limited not only with regards to the swinging about the A axis, but in accordance with how big a material it is practical to hang from the horizontal table surface.

However, the large number of XYZ movement which remains around the smaller five axis unit aids to make this type the best five axis CNC machine for usage of long extensions or tools, mainly at odd angles.

The trunnion setup may also be called a Table-Table configuration since both its rotary axes are in the trunnion table, and the head is stationary always. Most programmers and operators can easily familiarize with this configuration since it is a simple process development from standard three axis CNC machining. Since the two rotary axes are at times utilized to easily position the material; into a needed position, it is simple to picture how the machinery will behave and position during machining.

The trunnion table machine will often give better undercut abilities than other machine setups, since the table can slant farther (in one direction) than the designs of a swivel head. The trunnion setup also gives the operator a big complete practical work amount – since the table easily slants and locks in position, giving the X, Y, and Z axes their complete range of motion. In a swivel head machine construction, some of the total work envelope should be used to facilitate the tool length as the head slants back and forth. This state can be enhanced when machining with long apparatus that can affect the total work envelope extremely.

The trunnion form of the CNC machine may also be a better option for the removal of heavy metal. Since the head does not articulate, hence enabling the usage of belt driven or geared spindles, this machine kind will mostly give more torque at low RPMs. This stationary head construction also eliminates the chance of pushing a head away from orientation during machining.

This kind of machine may be either a head-head setup, where all spins are done by the head, while the table is fixed, or head-table setup which has a rotating table and a tilting head.This head-table, head-head, or construction will often enable machining of much heavier materials than the trunnion construction.

Since the table does not slant, the complete weight of the material is moved down directly through the CNC machine base and onto the ground. This makes this a very stable configuration for larger parts. Also, the construction of the table in comparison to the trunnion design enables for larger material in general regardless of weight. Also, the rotating head enables the usage of short or more average length apparatus when machining since all spins of the apparatus happen above the material.

Although five axis CNC machines were formerly only reserved for the aerospace market, they are now being used in many industries. A five axis CNC machine can be used wherever a three axis CNC machine is in there for a smoother finish and more efficiency. It offers shorter cycles and needs less manual changing of tools or repositioning. In a three axis CNC machine, the user should reposition the component being machined so the tool may reach every one of its faces. This stage may open the procedure up to alignment issues and human error. A five axis CNC machine eliminates that, offering easy access to all faces.

CAM and CAD software for five axis CNC machines may be exceptionally advanced. They offer a multitude of programming choices and at times include collision evasion and post-processors for easy connection to a machine. With the appropriate setup, these programs can even be utilized for “lights-out” CNC machining, where it is left unattended. Five axis CNC machining may be utilized for complicated 3D shapes, also for executing traditional machining on titled or odd surfaces. Some usual industries which make use of five axis CNC machining include:

Aerospace Applications: This machining giant makes the use of five axis CNC machining’s capability to make contoured edges and smooth shapes. Aerospace applications are mainly geometrically intricate and unique. The level of detail that can be achieved from a five axis CNC machine is incalculably valuable — as is its capability to make interior cuts. Another advantage to the aerospace market is that a component does not require repositioning at every pass. Using a five axis CNC machine allows it to remain as accurate as possible by finishing a component in one pass.

CNC Machining in Medical: Five axis CNC machining can give benefits to medical devices manufacturers. The high precision it gives can help the production of implants, devices and other parts in reaching demanding healthcare standards. These outputs are small, with complex detail, and a five axis CNC machine saves time and money through more efficient, accurate production and processes.

Military Uses: Parts for precise military devices are also regularly found in five axis CNC machines. Besides their aerospace applications, they can involve submarine components, compressor blades and turbines, smart weapons, sensors, high-performance engine parts, stealth applications, and even nuclear weapons. While not all of them are military applications, nearly half of all five axis CNC machine buyers buy them for projects or contracts with the American government.

Energy Equipment: A five axis CNC machine can make specific and detailed parts that energy equipment needs. When operating on particularly resistant, rough materials, using a five axis CNC machine may offer stability to a work area, making it easier to shape and cut. It can also make the procedure more efficient, lessening the wear on tools.

A five axis CNC machine allows the working of every surface, beside the bottom and the clamping area. When operating on contoured components or components that need machining on numerous faces, there is need several for setups of the three axis CNC machine to obtain the complex geometries through manual rotations but five axis CNC technology finishes the task in a one setup, lowering the amount of setups and helps with saving time.

The additional motions available with five axis CNC machining enables the achievement of complex designs and shapes. With the five axis CNC machine, there is the ability to machine arcs and angles which were formerly attainable only through manifold setups and numerous special fixtures. Ultimately, five axis CNC machining gets rid of the need to make complex fixtures as the part is held once and rotated in a single procedure to attain the desired geometry.

Every time a component is removed from a machine, the precise alignment that enables superior quality achievement is lost. Unlike three axis CNC machining, five axis CNC machining enhances accuracy by enabling the completion of a job in one set up, and produces multiple and complicated shapes without loss of the precision needed to maintain quality.

In five axis CNC machining, the cutting apparatus stays at a tangent to the cutting surface, enabling low cycling time spans, which helps reduce as more material is removed every time the apparatus passes.

The fifth and fourth axes help with orientation and bring the component closer to the cutting apparatus, allowing the use of a shorter cutting apparatus, which is less vulnerable to vibrations at exceedingly high cutting speeds. This helps achieve an improved surface finish. It also saves time which is not the case when utilizing a three axis CNC machine. Use of really small cuts must be made to attain a better surface finish, longer lead times are then imminent.

An initially higher investment is often required for a 5-axis CNC machine and the necessary software. The total investment cost is often higher than the total cost of a standard 3-axis machining center. Moreover, the maintenance needed is at times more complex.

There are two more rotational movements involved in addition to the three linear movements, making 5-axis CNC machining more complicated than 3-axis CNC machining. Consideration is also required on the coordination of the movement of each of the axes, to evade collision, interference, and the suitable interpolation motion amount. To optimize the needed surface quality and machining precision, complex programming could be a challenge, which could need the services of a qualified programmer.

From the points above, it is clear that the advantages of using a 5-axis CNC machine likely outweigh the drawbacks. However, the variety of challenges imposed when choosing a 5-axis CNC machine should still be considered.

The major benefit of 5-axis machining is the ability to produce intricate and complex parts due to its adeptness. This aspect of the process decreases production time from start to completion. The avoidance of crashing by revolving the cutting tool or work table offers a rapid and efficient approach to various part geometries and avoids the need for reprogramming or extra machining.

The normal machine centers of CNC machining are built around the 3-axis model, which are the X, Y, and Z axes at the center of the machine. The 5-axis configuration adds two machining centers to increase the motion of tools.

Droop Swivel Head Form - The droop swivel head form has the two coordinate axes at the top of the cutter with the rotational axis not perpendicular to the linear axis.

A 5-Axis CNC machine offers industries the chance to undertake jobs that they were formerly unable to complete. For manufacturers who presently use 3-Axis CNC machining, the advancement to a 4+1 or even full 5-axis CNC machine is the next logical step in their investment and production planning. Due to the price of such machines, nevertheless, it is advised that customers fully understand which procedures best meet the specific production requirements. There is also a need to pick the right CNC machine tool to realize the profitability and efficiency of production completely.

Buying a multi-axis CNC milling machine like a 5 axis CNC machine is similar to choosing a car make and model. You will base your decision on the intended use, budget and personality along with many other considerations. The garage of options for 5-axis CNCs is equivalent to a garage of race cars, all-terrain vehicles, buses, and luxury cars. There are more general purpose machines and then there are used 5-axis CNC machines made for specific applications. Smaller shops often start 5-axis machining by adding a single or dual rotary to an existing 3-axis vertical machining center.

Machinists often find that they can begin the learning process for making more complex parts with the addition of a single or dual-rotary unit. You may have started in this area of developing your expertise and now find that more quote opportunities are coming in for even more complex parts which have higher profit margins. This is a great time to buy your first used 5-axis CNC milling machine!

There are many reasons now more than ever why machine shops are replacing their current machines with 5-axis CNC milling machines. Here are a few of the top reasons that drive machine shop owners to add or replace older machines with 5-axis CNC machines:

The business case can be made for replacing standard 3-axis parts machining with 5-axis CNC machining based on both the setup and cycle time improvements. In one example by Hurco, one part that took 7 operations and 5 hours 30 minutes to setup on a standard 3 axis CNC machine needed only 2 operations and 1 hour 30 minutes to setup on a 5-axis machine. The cycle time for that same part also went down by over 30%. If a machine is running, it"s not making money. This kind of savings can quickly improve ROI.

When you buy a used 5-axis CNC machine, you are increasing the complexity of parts that you can make. Some shops like work that others consider to be too difficult. If your company loves to learn from every challenge and become better with each job, this strategy can pay great dividends. 5-axis machining is great for the complex work and shorter running jobs. Your 5-axis machine should be flexible, precise and adaptable for the challenges. Many used 5-axis machines have a swivel head that can articulate cuts in almost every direction.

5-axis CNC machines are built to last. Similar to buying a car, newer years might have some special features, but if you dont need those features, then why buy them? A solid used CNC 5-axis for sale should be able to reliably make parts for many years. The software can be upgraded, sensors can be added, skins on controls can be replaced and the machine will continue to make parts. You can find great bargains on 5-axis CNC machines for sale in our listings.

5-axis CNC machining can do what other machines can do, but machines like Swiss lathes, vertical machining centers and other 3-axis mills cannot do everything that a 5-axis CNC machining center can do. This makes the 5-axis CNC one of the most versatile pieces of equipment that you can buy. Combined with the power of modern CAD/CAM software, you can make a wide range of parts with one piece of equipment.

Buying a 5-axis CNC milling machine gives your operators the opportunity to grow in their abilities to make more complex parts. Parts that you may not want to quote today will become possible as your machinists become accustomed to a new way of thinking about machining.

When a used 5-axis CNC is setup in a work center to allow for automated material loading and parts unloading, it can run unattended with as much as 95% spindle utilization. Compared to other types of milling like vertical machining centers and horizontal machining centers, you get more production simply because the 5-axis machine spindles are running more consistently.

When deciding on the type of used 5-axis machine to purchase, key factors to consider will be part complexity, part mix and the average number of parts to be run per setup. For example, parts that can be made on a 3-axis machine may actually be a better fit on a 5-axis because of a quicker setup on a machine with tools already available on a tool changer. Major options for used 5-axis CNCs include the rotary type and trunnion table type.Part Complexity: Do you want to machine complex parts? Consider the differences between trunnion and swivel head style machines and the table tilting and rotation travel for the A-axis and C-axis. Also consider the number of tool slots available in the tool changer the more stations, the more complexity in one setup.

Physical Size: Youll want to consider the physical size of your used CNC 5-axis machine. This will be dictated by the size of parts that will be machined and the amount of room on your shop floor. Then youll need to determine the rigidity by thinking about the types of materials that you will be machining. Keep in mind that some multi-axis machines are better than others for particular applications. It will be helpful to learn if a particular used CNC machine was used in a similar application before.

We have for sale used 5-axis CNC machining centers with trunnion tables. A few benefits of choosing a trunnion style trunnion table on your 5-axis CNC machine include a better under-cut capability, larger work volume and more torque at low RPM. As compared with a swivel rotate machine which typically is limited to 90 degrees of the head in any direction, a trunnion table allows more than 90 degrees of rotation.

This makes it possible to reach up under a flange, under the edge of a part, or machine an angle hole that points down under the table. Since the part is under the spindle"s Z-axis and the spindle is always vertical, once a workpiece is clamped down you have the full travel of the X and Y as the machining envelope. As compared to a swivel head machining center, there is more torque at lower RPMs on a 5-axis with a trunnion table.

We have used 5-axis CNC machines with swivel heads. A few benefits of choosing a swivel head machine over a trunnion include the ability to run heavier parts, more versatility and fewer tool interference issues. On a trunnion style machine, the part is always rotating and twisting within the work envelope which limits the weight capacity that the axis can handle. Since the table rotates more like a standard 3-axis machine on a 5-axis machining center with a swivel head, the table can handle heavier parts because of better weight distribution.

Often swivel rotate used 5-axis CNC machines have much greater versatility than the trunnion because of table space on the side which allows for some fixturing, 3-axis work, or even 4th axis work using the tilting head. On trunnion table 5-axis CNC, when the part tilts towards the operator, the bottom of the head casting and the trunnion itself which can impede making smaller type parts as compared to the swivel. Standard length tooling works well on swivel rotate machining centers where often longer tooling is needed for trunnion table style 5-axis machines.

CNC Indexing & Feeding Technologies is proud to represent the TJR line of rotary tables, indexers and accessories. TJR originated as a rotary table sales and service agent and established itself as an OEM in 2009.

TJR tables feature an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. All new TJR tables come standard with a 3-year parts warranty.

Standard Rotary Tables. The AR Series is TJR’s standard 4th axis pneumatic brake rotary table. It is offered in both a Right hand motor mounting and Left hand motor mounting option. The HR Series is TJR’s standard hydraulic brake 4th axis rotary table.

CNC Indexing & Feeding Technologies offers a wide range of TJR rotary tables. However, many are unclear about what rotary tables can do for their business, as well as how they work in CNC machining. First, let’s consider the basics about a rotary table and how it works in the machining and manufacturing processes.

In many cases, the work pieces created through CNC machining would be impossible without computer assistance. The code used to communicate between the CNC machine and computer software is specialized. Older machines, or manual machines, used hard wired controllers. However, new CNC machines rely on modern devices like CDs, USB drives, networks and so on.

A rotary table can tilt and rotate. The table makes use of the indexing head in order to cut according to a specific technique. This makes it possible for the machine to create a workpiece with complete flexibility in rotation and angling.

A rotary table can help to create arcs and circles, an important process in part or tool fabrication. Tools can be specially made, such as car parts, machine parts, and many other objects.

The CNC process lets companies make straight cuts even with multiple angles and to cut small objects into even smaller parts. CNC rotary tables can also help in the processes of cutting gears, drilling or cutting holes.

The table can also be used along with a dividing head and index plate, to further concentrate the shaping. Tables are also used to hold certain parts for superior milling techniques.

Adding rotary tables will improve your capacity to produce the parts you want and increase profits. This brings us to the primary advantage of CNC rotary tables: less time and greater accuracy in cutting.

The benefits of using cnc rotary tables include consistency, faster production and increased capacity. Products and work pieces assembled through CNC systems are more reliable than products created manually or through other methods. The process is identical each and every time, so consistency can be guaranteed. This is critical for a company trying to ensure safety protocol.

The capacity of complexity of product is another benefit. Complex motions are made simpler by CNC rotary tables, making them more affordable to produce.

Naturally, such an intricate process cannot be unsupervised, since efficiency depends on optimal performance. A supervisor must oversee a rotary table operating with CNC controls to ensure the machine and software are configured correctly.

We offer a wide variety of rotary tables to meet all of your needs. This includes standard rotary tables with full rotating axis capabilities, and vertical and horizontal mounting positions.

We also offer large rotary tables with hydraulic brake systems, which allow higher clamping torques. You can also find assistance with smaller rear mount rotary tables or tilt rotary tables.

Horizontal rotary tables are specially made for horizontal mounting and carrying a much heavier weight. Horizontal index tables are available, whether in manual or CNC index tables style. Finally, there are face gear rotary tables and rotary table accessories, ideal for projects that need higher degrees of accuracy.

CNC Indexing & Feeding Technologies can help you find the machine tool accessories you need to meet your production demands. This includes simple rotating feature, larger work pieces, vertical and horizontal applications, or even 4 or 5 axis work. With TJR rotary tables, you can improve your cycle and process time, reduce your down time and increase your profits.

#cncmachining #cncmanufacturing #manufacturing #indianmanufacturing #machinist #metalcutting #5thaxis #5axis #cncmill #cncmachine #5axismill #machineshop #5axiscnc #rotarytable

About UCAM: We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others.

8613371530291

8613371530291