diy 5th axis cnc rotary table made in china

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new 5 axis rotary table or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement 5 axis rotary table, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new 5 axis rotary table are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

So I thought, OK, I have to use a trunnion. Then I thought, why build a 3D printer (prior years project) if you are only to use it for fancy stuff. I have to 3D print something really useful: a trunnion table!

The belts though, you can not avoid, you have to buy them. I tried printing some ninjaflex material but it is not suitable for this application, you need the belts to be really stiff in terms of tension to increase the machine"s accuracy.

Albeit only momentarily, I made a new spindle mount to set my machine up for 5-axis: 4962 4963 4964 4965 But I cant think of anything to make with it :lol: Clearly I need to drop the bed down (which is fine, it"s adjustible) to get enough clearance.

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

CNC machining technology has evolved over the last couple of years from simple machine tools to more sophisticated ones. 5-axis CNC machining is one of the most advanced processes available today. It implements subtractive machining technology to provide infinite possibilities in part creation. This technique uses cutting tools that work on five axes to cut workpieces into desired shapes and sizes.

5-axis machining offers increased accuracy and precision, efficiency, and reliability. The increased number of axes also gives 5-axis milling machines more outstanding capabilities than their counterparts. Moreover, the process allows complete automation and management with Computer Numerical Control (CNC). As a result, many reliable CNC machine shops rely on this technology for precision CNC machining services.

This article covers the basics of 5-axis CNC machining. Here, we will explain what’s 5-axis machining and how the process works, breaking down the different axes. You will also learn the pros and cons of using this machining process and its common applications. The information we provide will help you get the most out of the 5-axis technology.

This procedure involves the movement of cutting tools across five axes simultaneously. 5-axis CNC machines offer three linear axes working simultaneously with two rotational axes to achieve intricate parts. This typically adds more tilt to the worktable or tool spindly, allowing for increased rotation and movement.

A 5th axis allows machinists to fabricate up to 5 faces in a single operation. This makes the process highly efficient and precise. It also makes it suitable for creating complex structures and features with minimal setups. Since several parts require consistent machining of 5 faces, this process is becoming more valuable for several industries.

To help understand the axes in a 5-axis CNC milling machine, let’s explain what an axis count entails in CNC machining. A machining axis count is the number of directions the cutting tool (or raw material) can move to create the desired product. For instance, conventional CNC machines have three-axis counts. Consequently, their cutting tools can only move across the X, Y, and Z axes.

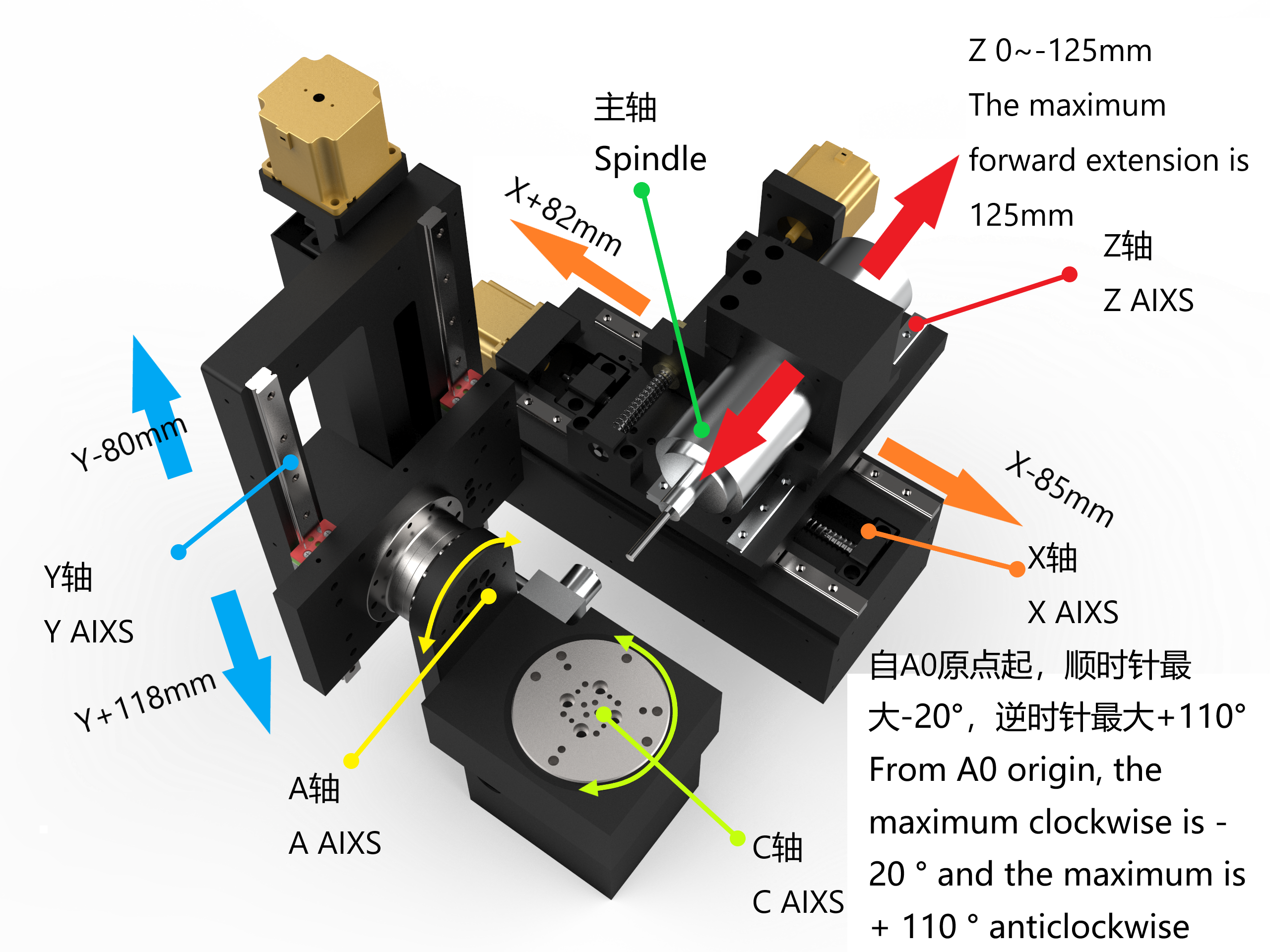

5-axis machining centers increase the functionalities of the linear axes by tilting (and rotating) the worktable. There are two additional rotational axes called the A-axis and the C-axis. The A-axis is also referred to as the tilting table axis, while the B-axis is the table rotation axis. Including these axes allows the machining of more complex geometries than 2-axis or 3-axis CNC machines. The table below summarizes the movement of the axes.

As with other CNC machines, 5-axis CNC millingmachines rely on computer instructions. The programmed instructions for the machine control the movement of the cutting tool and workpiece. The 5-axis machining process starts with creating the 3D CAD model of the desired components.

After this, the CAD model is exported into CAM software, converting it into a computer program (G-code). The G-code contains instructions for the CNC machine. It contains tool paths created according to the geometries of the desired part. The instructions control the movement of cutting tools along linear axes (X, Y, and Z). It also controls the direction of the worktable along rotational axes (A and B) to create the desired part.

The process allows the machining of 5 faces of a workpiece with one setup. Therefore, it saves manufacturing time and cost, helping you get your products to market faster. But note that the speed and direction of movement depend on the type and configuration of the 5-axis machine.

5-axis machines can enhance your machining procedure and improve scalability. These machining centers can come in various types to meet the manufacturing industry.

Head/Head machines have rotational axes located in the head. Their 5-axis apex comes on a platform that moves through a fixed worktable, keeping the workpiece in place. Therefore, you won’t need to worry about tool interference on the machine spindle head.

This way, the apex has a higher chance of moving around a workpiece, making them suitable for producing large, heavy parts. The machine table can withstand heavy weights without compromising the accuracy of the rotational aces. However, the design of these machines limits their movements in the rotary axes.

Head/Table machine setup has one rotational axis in the head and the other in the rotary table. Their revolving axis has a restricted range and is situated in the head. On the other hand, the rotary shaft has a wider (unlimited) range and is located in the table.

This setup is beneficial because it can consistently rotate the workpiece without any limit. However, there is a limit to the number of parts it can produce. This is because the workpiece rests on the rotary axis.

In this setup, the 5-axis machines have their rotary axes situated inside the table. Therefore, all rotations occur on the table, and the head does not move. The design of these machines makes them suitable for machining undercuts. Moreover, since the head does not rotate, machinists can easily see how the cuts will happen during the programming stage.

However, the machine arrangement is less suitable for machining large or heavy components. This limitation is due to the table’s inability to withstand too much weight.

As mentioned earlier, the movement of axes of the 5-axis manufacturing process depends on the instructions of the CNC program. There are fundamentally two CNC machining operation styles that work with 5-axis:

The trunnion-style machine works with the A-axis rotating around the X-axis and the C-axis rotating about the Z-axis. The movement of the table indicates the rotary axes. That is, both rotational axes are located within the table while the head remains stationary (Table/Table). Trunnion-style 5-axis CNC machines are suited to:

The Swivel rotate style 5-axis CNC machine works with the B-axis rotating about the Y-axis while the C-axis rotates around the Z-axis. This movement differs from the Trunnion style because the table remains horizontal throughout the cutting process. As a result, it can support heavier components. Swivel rotate machines are suited to:

A 5-axis CNC machine allows the machining of five surfaces simultaneously. For conventional 3-axis machining, you may need several setups to work on parts with several faces. But the 5-axis technology completes the machining of contoured parts and other parts with many faces in a single structure. This allows you to manufacture components with complex geometries with fewer setups.

The additional rotation in this machining process helps you achieve more complex designs and geometries. The machine allows the seamless machining of arcs and angles that were only previously possible through multiple special fixtures. The 5-axis milling process can rotate parts in a single operation to achieve desired geometries, eliminating the need for complex fixtures.

In addition, the technique pairs excellently with GD&T call-outs to produce datum features in one operation. 5-axis milling is also suited to CNC machining applications requiring surface profile tolerances on complex contoured surfaces.

The extra setups involved with manual machining compared to CNC machining cause machinists to lose precise alignments during fabrication. However, minimal setups involved in 5-axis CNC milling reduce the possibilities for errors and improve the accuracy required to achieve superior quality.

The different types of 5-axis machines available today eliminate the need to re-position workpieces at different angles during machining. Thus, you can be sure of improved machining tolerances. Moreover, some machine configurations allow the use of shorter cutting tools. This increases the lifespan of the tools and ensures repeatability.

5-axis machining ensures that cutting tools are tangential to the cutting surfaces. This arrangement allows the removal of more materials each time the tool rotates. Therefore, it lowers the cycle times and overall machining costs.

5-axis machined parts are often completed in a single operation because of the high-speed advantage of the process. The single setup involved helps save time and money. Moreover, employing shorter cutting tools with longer lifespans eliminates the need for constant tool replacement, saving money and time.

In addition, the 5-axis milling process can be automated, reducing human operations and labor requirements. This reduces labor costs involved with the process. Therefore, 5-axis CNC machining is a cost-effective solution that accelerates your products to market.

The cost of purchasing a 5-axis CNC machine and its essential software is high. It is much higher than what is needed for 3-axis machining centers. Likewise, the maintenance requirements of the machine are also quite challenging than conventional machine tools. This aspect also directly increases the machining costs of 5-axis machined parts.

5-axis CNC milling is an advanced technology involving advanced programming, machine setup, and operations. Therefore, the process requires highly skilled technical operators. This often translates to increased labor costs.

The under-utilization of 5-axis capabilities is a common occurrence. Some operators do not understand the full capabilities of the machine. Others may not have the programming knowledge for a cutting-edge operation.

Before deciding to use the 5-axis technology, try to get enough information. Analyze the data from the customer, checking for accuracy and correctness. Take a close look at the component and check whether there is a need for a pretest.

Simulation software will be useful for verifying the process before translating the CAD design into a CAM model. The software will help monitor the tool’s length, its interference, and the part’s size. It’s needed to invest in programs and software that complement the 5-axis machine’s capabilities. Additionally, it would be best to do a cost analysis to ensure you’re using the most cost-effective process for the job.

Creating 5-axis tool paths often involves a general trade-off between high-speed cutting and reducing risks of crashing. Collisions may lead to defective components, damage the machine, or cause you to scrap parts.

Fortunately, employing certain software tools can eliminate this. The software program will look ahead to check every move of the tool to see if it will run into anything. As long as the CNC machining design is modeled correctly, the software will see the collision before it happens.

5-axis CNC machining ensures high productivity but may also increase the risks of errors. This may be in the form of using the wrong tool or a broken cutting tool. Using a tool-detection system can minimize such errors. This system will help analyze the tool you want to use, ensuring you choose the right one.

The aerospace industry requires components with organic shapes with contoured edges and compound shapes. Aerospace parts are unique and geometrically intricate, making 5-axis machining the ideal technology of choice. This process achieves a high level of detail and reduces the need for re-fixturing of the cutting head. Thus, parts for aerospace applications remain as precise as possible, meeting industry standards.

Quality and precision are non-negotiable when it comes to manufacturing medical equipment. The high-precision capabilities of the 5-axis fabrication process assist in the production of implants, devices, and other equipment to meet rigorous healthcare requirements. Most of the components are small and intricate. Others are complex electrical scanning and monitoring equipment. 5-axis technology offers an efficient and cost-effective means of producing these components.

The energy industry often requires complex and advanced components, including solar power systems and power stations. The rapid emergence of 5-axis machining ensures CNC precision machining of detailed and specific parts for energy equipment. These parts are machined to be durable and provide stability to workspaces.

Deciding between 5-axis machining centers and other techniques can be pretty challenging. There are many factors to consider to ensure you make the best choice. Here’s a comparison between this technology and other methods.

Many people tend to confuse these two techniques. 5-axis CNC machining, also known as continuous 5-axis machining, involves the continuous rotation of cutting tools along five axes. In contrast, 3+2-axis machining executes a 3-axis program. During this process, the cutting tool is locked at an angle. The two rotary axes determine this angle.

The main advantage of 5-axis over 3+2-axis CNC machining is speed. The latter involves constant stopping and starting of the machine between each tool orientation. However, the former completes the cutting in a single operation. Furthermore, 5-axis machining is more suitable for complex surfaces, while 3+2-axis CNC machining works mainly for plane processing.

Since 5-axis machines require lesser clamps and no special fixture, the machining cost is lower than with 3+2-axis counterparts. However, you should note that the programming involved with the 5-axis technology is much more complicated than the 3+2-axis machining.

Unlike the 5-axis CNC machining process, 3D printing is an additive manufacturing process that involves building components one layer at a time. While these technologies differ in their mode of operation, there are more overlaps in their application. They both offer high accuracy, fast turnaround, increased repeatability, and excellent surface finishes.

3D printing does not require special fixturesor tooling. As a result, the initial setup cost is also minimal. However, 5-axis CNC machines offer better dimensional accuracy than 3D printing. They can machine small and very large parts accurately. Getting extremely tight tolerances with 3D printing will require additional post-processing operations.

With 5-axis machining explained, you now comprehensively understand 5-axis CNC machining. It’s time to take charge of your manufacturing experience. 5-axis CNC machines simplify fabrication processes, ensure faster and cost-effective production, and improve precision and accuracy. However, they are not ideal for all designs. For instance, 3- or 4-axis CNC machines may be more suitable and cost-effective for precise cutouts, holes, and cavities.

Therefore, it is important to contact a CNC machining expert before starting your project. RapidDirect is a leading CNC machining services provider across the globe. We own several 5-axis CNC machines, including Hermle C650, C400, C250, C42, and C22. Our strong 5-axis CNC machining services can manufacture high-precision CNC machined parts with high quality, fast lead time, and competitive pricing.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Take a moment to imagine how challenging it would have been for machinists in the early 20th century to fabricate parts and structures. The best machine tools available to them at the time were chisel, hammer, and manually operated lathe machine. But everything changed after Richard Kegg developed the first computer numerical control (CNC) machine in 1952.

And ever since, CNC machining technology has continued to advance, evolving from a mere simple three-axis machine controlled with punch cards to a more sophisticated 5-axis CNC machine.

A 5-axis CNC machine is a machining technology that provides infinite possibilities as to the part size and shapes you can fabricate. It offers high accuracy and precision and is heavily relied on by top-tier machine shops to manufacture pretty much any design you come up with.

In this article, we will cover the basics of 5-axis CNC machines. We will start by explaining what a 5-axis CNC machine is and how it works before discussing its advantages over conventional types of CNC machines.

Machining axis count describes the number of directions in which the CNC cutting tool (or workpiece) can move to produce the desired machined part. For example, conventional CNC machines typically have a three-axis count, meaning their cutting tool can move across the X, Y, and Z axes―sideways on the X-axis, vertical on the Y-axis, and back and forth on the Z-axis (see Figure 1).

A 5-axis CNC machine adds to these three linear axes by being able to also tilt (and rotate) the table holding the workpiece, as shown in Figure 1. These two new rotational axes are typically called the A-axis (or tilting table axis) and the C-axis (or table rotation axis); they allow you to machine more complex geometries than the 3-axis CNC machines.

Like every other CNC machine, a 5-axis CNC machine relies on computer instructions to control the motion of the cutting tool (and workpiece) to fabricate the desired part.

The 5-axis CNC machining process starts with the designer creating a 3D CAD (computer-aided design) model of the desired part using CAD tools like SolidWorks and Autodesk Inventor. Next, the machinist exports this CAD model into a CAM (computer-aided manufacturing) software, which converts the drawing into a computer program (also called G-code).

The G-code contains sets of instructions that control the motion of the cutting tools along the linear axes (X, Y, and Z axes) and the motion of the worktable along the rotary axes (A and C axes) to produce the desired parts.

Now, you might be wondering where did the other two come from. Aside from describing the fly’s position in the space, it is also possible to describe its orientation. So, the fly rolling around X would be the fourth axis, while the fifth axis would be the fly rotating around Y. Some also argue that there’s a sixth axis, rotating around the Z-axis.

The configuration you choose for the 5-axis CNC Milling Machine determines which one of the three rotational axes will be used. There are two main configurations – a trunnion-style machine and a swivel-rotate-style machine.

The trunnion-style 5-axis CNC Milling Machine uses the A-axis rotating about the X-axis and the C-axis rotating about the Z-axis, while the swivel-rotate-style 5-axis CNC Milling Machine uses the B-axis rotating about the Y-axis and the C-axis rotating about the Z-axis.

The main difference between the two is the way in which the rotary axes are expressed – in trunnion-style it happens through the movement of the table, while in the swivel-rotate-style of the 5-axis CNC Milling Machine is done through the swiveling of the spindle. Both of them have their own advantages, so which one will be used depends mostly on what needs to be done.

Over half of the parts produced with CNC require five-sided machining, which is why more and more manufacturers decide to include it in their services. Additionally, 5-axis CNC machining offers many benefits when compared to, for example, 3-axis machining, such as:

Because of its five axes, 5-axis CNC machines allow you to set up your workpiece once; the machine then handles every machining operation needed to create your desired part. This is quite different from conventional 3-axis machines, where you’d need several machine setups to fabricate a complex geometry.

The single-setup nature of 5-axis CNC machines allows you to machine complex parts quickly while reducing costs and mitigating errors prevalent in conventional CNC machines.

The fourth and fifth axes of 5-axis CNC machines allow you to bring the workpiece closer to the cutting tool. This means that you’re able to use shorter cutting tools, which are less susceptible to vibration and allow you to achieve better surface finishes.

Due to movement flexibility, 5-axis CNC machines are much more precise than 3-axis machines, which is why they not only produce smoother parts but they can also produce parts that would be too complex for a 3-axis machine.

5-axis CNC machining can be used to produce parts utilized in plenty of different industries due to their efficiency and the ability to produce complex shapes. Here are a few examples of industries that most commonly take advantage of this technology:

Medical – 5-axis CNC machining can help manufacturers of medical equipment in the production of devices, implants, as well as other pieces of equipment that need to be made with extra precision in order to meet healthcare standards which tend to be rigorous (rightfully so).

Military – another industry that uses 5-axis CNC machining to produce the needed parts. Some of the possible applications include submarine parts, high-performance engine parts, turbine and compressor blades, smart weapons, sensors, stealth applications, as well as, in some cases, nuclear weaponry.

Energy equipment – producing parts for energy equipment often requires using materials that are hard to work with. With 5-axis CNC machining, you can make the whole process easier and more efficient.

Now that you know at least something about 5-axis CNC machining, you can proceed to manufacture pretty much any design you come up with using 5-axis CNC machines, right? Absolutely not!

Without a doubt, 5-axis CNC machines simplify the fabrication of complex parts. However, not all designs are worth creating using 5-axis machines. For example, you might be better off fabricating high-precision holes, cutouts, and cavities using 3- or 4-axis CNC machines. That’s why we always recommend that you speak to a CNC machining expert before you take the plunge with manufacturing.

Gensun Precision Machining is a top-tier CNC machining service provider across Asia and the globe. Not only do we have CNC machining experts and engineers, but we also have a wide range of advanced CNC machining technologies, including 3-, 4-, and 5-axis CNC machines.

5-axis cnc gantry machine center High machining accuracy, high rigidity of the bed, automatic selection of processing volume, high productivity, generally 3~5 times that of ordinary machining centers, can handle the processing of some complex parts, which can be increased by ten times or even dozens of times.

cnc machine center is an important industrial equipment for manufacturing. The five-axis machining center can process various complex surfaces or special-shaped parts, such as turbine engine blades, engine propellers, and some complex surfaces and special-shaped parts.

8613371530291

8613371530291