diy rotary table for milling machine made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

For a corner fillet weld such as those, it may help if you grind off half of each corner on the slotted plates giving a 45 deg V. This will help to ensure the weld gets good penetration and strength at the same time as allowing you to retain the original edges for alignment.

This tailstock was designed for use with my rotary table. This has a centre height of 85 mm. I have made the height fully adjustable from 20 mm to 90 mm since it may be useful a...

Specification Unit XL6436 W Table size mm 1325 × 360 Table travel(X/Y/Z) mm 750/3 1 0/ 390 Max . swivel angle of table 45° Table feed step grade 8 Table feed range(X/Y/Z) mm/min 30-750/20-500/15-375 Table rapid speed X mm/min 1200 Table rapid speed Y mm/min 800 Table rapid speed Z mm/min 600 Spindle hole taper (V) 7:24, IS050; (H) 7:24, IS050 Arm travel mm 550 Distance between horizontal spindle center line and table surface mm (H)3 0 - 420 Distance between spindle nose and table surface mm (V)20 0-590 Distance between spindle center line and arm surface mm 200 Spindle speed range rpm (V) 12 step s, 60-1750; (H) 12 step s, 60-1800 T-slots (NO . /width/pitch) mm 3/18/80 Main motor power Kw (H) 5.5; (V) 4 Overall size mm 1800 × 2100 × 2000 Net weight kg 2 700

OEM Factory table power feed for milling machine in China with low price Using on milling machines Easy to install,no modification needed Highest quality design and construction materials Circuit panel is desighed with easily replaceable insert type connectors Assy-gear (nylon) clutch can be built in torque release to prevent damage to shaft and metal gear is too much resistance is met,anyhow,it is depended on customer"s requirement Applicable voltage:110V, if have to use 220V,please use voltage converter Specifications Model No. TONE902 Description Power feed Surface finishing Paint Color Gray ,Blue Gear Plastic and brass Package Export package MOQ 1set Equipment Our capability

Please refer to the pictures and diagram to be sure the kit will mount to your table. Your rotary table should look similar to the one in the photo- for illustration only, the rotary table is not included with the CNC drive kit.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

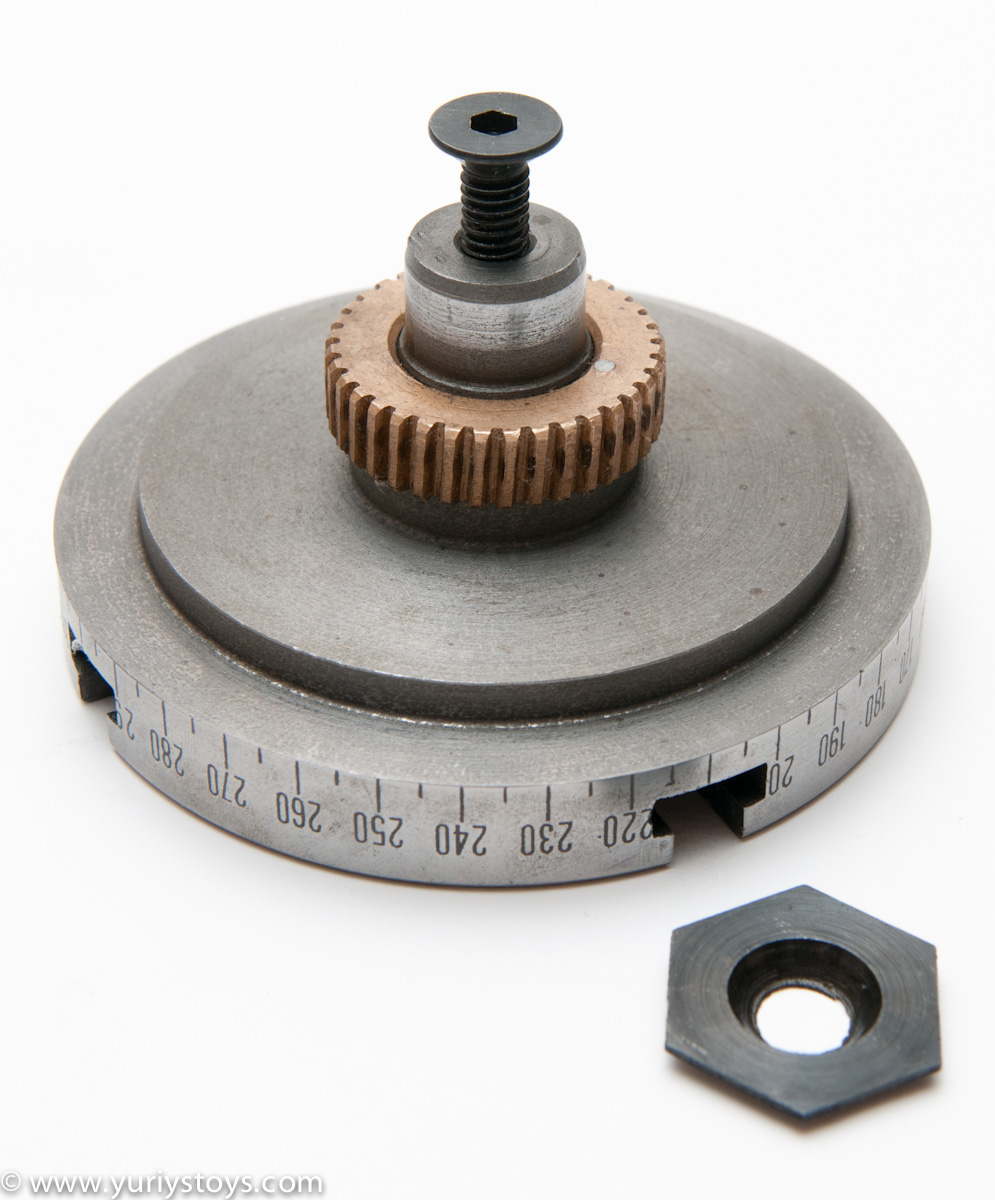

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring and so on.

Our amazing rotary table is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost. They are definitely your best choice!

Our rotary table is both vertical and horizontal with two functions. When the vertical position of the table is used together with the tail part, it is also possible to complete circle cutting, indexing drilling, milling and more complicated work.

HT200 casting has good casting performance, shock absorption performance as well as high strength heat resistance. It ensures the of superior performance the machine and provides you a good sense of use.

It"s not difficult for you to adjust the rotary table milling machine. What you should to do is just adjust the handle to the position where you want. Because the precise scale is marked on the dial.

If you purchase our product, we are going to give you a free wrench, 2 positioning keys and screws. When you install the vertical & horizontal rotary table, these accessories will bring you a lot of conveniences.

This machine is designed for milling, drilling, fixture boring and many common workshop applications. It makes it possible for operators to drill or cut work at exact intervals around a fixed axis in the process of working.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

What are some of the best Rotary table brands you can buy? I only buy tools once so quality of the most important thing. I’ll happily buy vintage if people truly think they are better. I have a Bridgeport (pictured below)

Here"s a mystery for all you hobby milling machine enthusiasts. Help me ID this rotary table. I"m considering purchasing it, but can"t figure out who made it.

So, here"s what I"m wondering. About half the time I use the rotary table I find the hand wheel interferes with where I"d like to clamp it down. Looking at other tables this seems to be the common configuration, where the handwheel interferes with the mounting plane(s) of the table. Why would...

not getting any feedback to a previous post I gotta wonder if there isn"t something wrong with an Advance Rotary Table. I see lots of posts regarding "what to buy" and "I settled for a Chinese knockoff". Just wondering what is the problem? This seems to be an extremely well built and accurate...

I have a vertex 10" Rotary table with mounted chuck, I use it often. There are quite a few occasions I wish it was motorized. Has anyone done a DIY motor on their rotary table and not spent a fortune ? I"ve seen pretty expensive motors so i"m looking for DIY options. I think I may have even...

I"ve become a (happy) owner of a new-to-me 8" Phase II horizontal rotary table. Unfortunately it came with the dividing plate setup and no handwheel, so I need to make one. If you have this model of the table, I would really appreciate if you could post a picture and/or dimensions of...

So I need a rotary table for a couple of projects I have in mind, making round things on my Jet 15 mill/drill. I don"t have a lathe. I"m thinking 6" would be a reasonable size both for the things I need to make and the size of my mill. I see cheap imports on ebay starting around $160, Phase...

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

8613371530291

8613371530291