diy rotary table plans made in china

This tailstock was designed for use with my rotary table. This has a centre height of 85 mm. I have made the height fully adjustable from 20 mm to 90 mm since it may be useful a...

Update 03/19/2020:During this tough time I am offering these plans for free. To download the plans simple click here. Feel free the share the plans with others.

This product includes full detail drawings to construct a custom rotary table. This rotary table allows you to make accurate off-axis acoustical measurements of your speakers. The special design is simple to construct and does not require the purchase of any special hardware other than two regular door hinges.

Not sure I agree with you folks that claim that one needs a rotab in order to make a rotab. However, depending on the size of table you want to make you will need a lathe with a swing at least as large as the rotab. IOW your rotab will be a teensy one.

The way that I was taught is that you have to make up a test bar. Take a piece of 12" by 1" roundbar, drill two centre holes in it"s ends, on your lathe and take a parallel cut between centres. Once you have corrected the error of your lathe and both ends of the test bar measure the same diameter, you can then use the test bar in your milling machine as well, to set the tailstock of the dividing head as well as the alignment of the bar to the table axis.

I recently bought a 8" H/V Phase II RT from MSC. So far I have been quite happy with it, as I needed it for a current project. I can lift it, but genrally prefer to slide it on and off a rolling cart from my milling table. The 10" would have been too heavy to lift. The T-slots are smaller than the mills, so my first job was to make a set for use with the RT. Clamps for milling can also be too large for clamping small pieces to the table, so some fabrication might be in order as well.

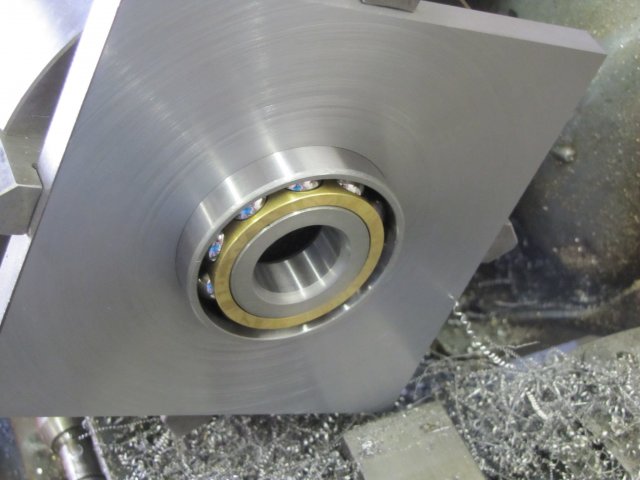

Please refer to the pictures and diagram to be sure the kit will mount to your table. Your rotary table should look similar to the one in the photo- for illustration only, the rotary table is not included with the CNC drive kit.

What are some of the best Rotary table brands you can buy? I only buy tools once so quality of the most important thing. I’ll happily buy vintage if people truly think they are better. I have a Bridgeport (pictured below)

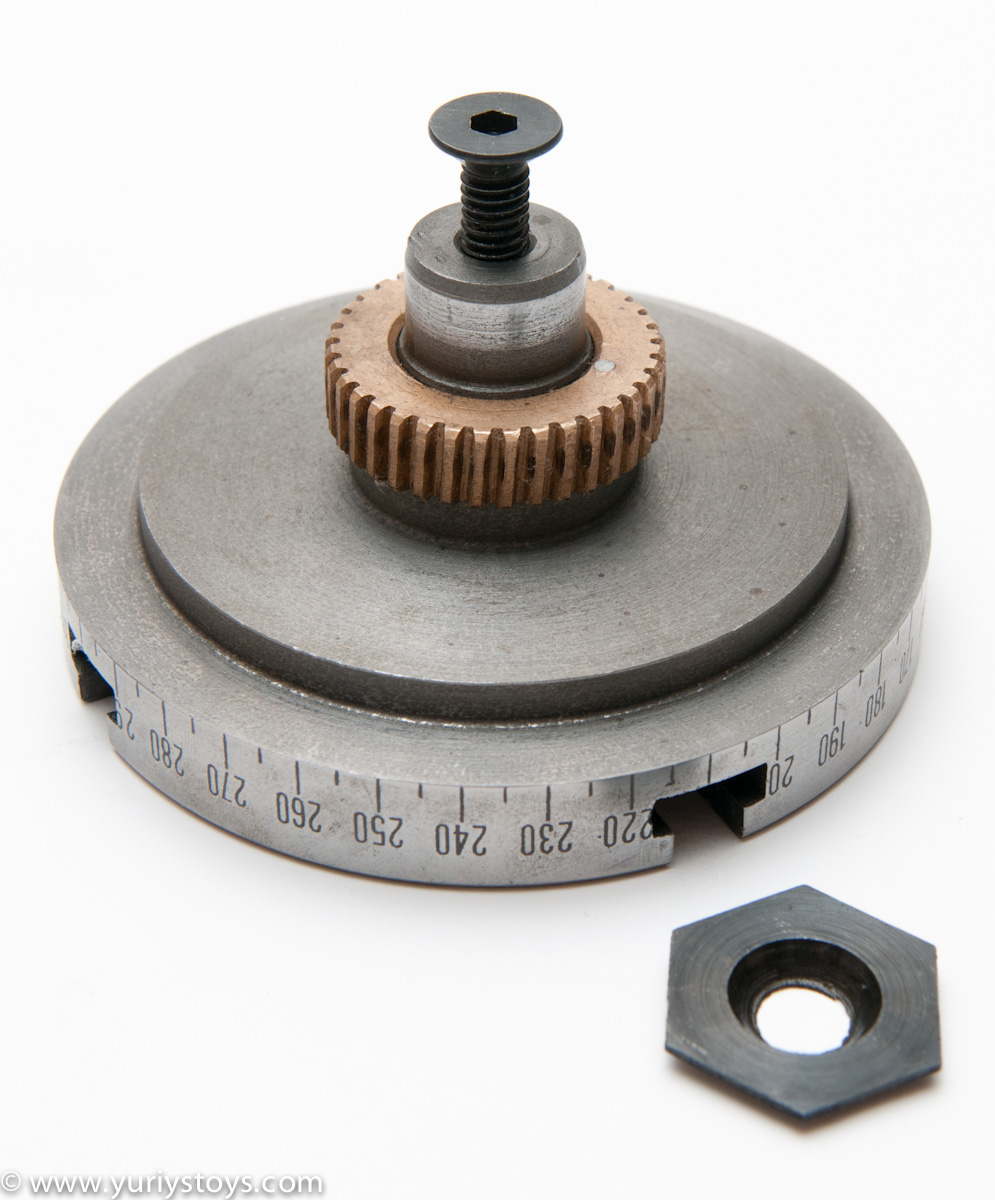

Here"s a mystery for all you hobby milling machine enthusiasts. Help me ID this rotary table. I"m considering purchasing it, but can"t figure out who made it.

So, here"s what I"m wondering. About half the time I use the rotary table I find the hand wheel interferes with where I"d like to clamp it down. Looking at other tables this seems to be the common configuration, where the handwheel interferes with the mounting plane(s) of the table. Why would...

not getting any feedback to a previous post I gotta wonder if there isn"t something wrong with an Advance Rotary Table. I see lots of posts regarding "what to buy" and "I settled for a Chinese knockoff". Just wondering what is the problem? This seems to be an extremely well built and accurate...

I have a vertex 10" Rotary table with mounted chuck, I use it often. There are quite a few occasions I wish it was motorized. Has anyone done a DIY motor on their rotary table and not spent a fortune ? I"ve seen pretty expensive motors so i"m looking for DIY options. I think I may have even...

I"ve become a (happy) owner of a new-to-me 8" Phase II horizontal rotary table. Unfortunately it came with the dividing plate setup and no handwheel, so I need to make one. If you have this model of the table, I would really appreciate if you could post a picture and/or dimensions of...

So I need a rotary table for a couple of projects I have in mind, making round things on my Jet 15 mill/drill. I don"t have a lathe. I"m thinking 6" would be a reasonable size both for the things I need to make and the size of my mill. I see cheap imports on ebay starting around $160, Phase...

The equipment table and robot arm can be directly mounted on the output table of Rotary Table. It can save the time and cost for mechanical design, parts allocation, belt debugging, etc., which compared with the use of mechanical parts such as pulleys and belt.

As for the term "hinge", I made that up. The one I am thinking of is still called a rotary table; there are two parts ... the rotary table, and then the base. The two are connected on one side by the hinges (just two tabs with holes, a rod, and the horizontal hole in the base that the rod goes through). The tab parts fit over the edges of the base and the rod slides through the tab holes and the horizontal hole in the base.

Even with a rotary table that is not hinged, you can mount it vertically and in that position you might call it a dividing head because you can usually buy a tailstock for it, and, for certain ones the dividing plates.

8613371530291

8613371530291