diy rotary table plans price

- hold-downs are 10-32 type cap screws & matching T-nuts kind of unique to Sherline. You could make them yourself, but they are reasonable cost. This lends itself to smallish setups & also the slots come closer to center than common. I"m going to also make some gridded pre-threaded tooling plates to clamp on the table so I can orient odd-ball parts easier yet.

Update 03/19/2020:During this tough time I am offering these plans for free. To download the plans simple click here. Feel free the share the plans with others.

This product includes full detail drawings to construct a custom rotary table. This rotary table allows you to make accurate off-axis acoustical measurements of your speakers. The special design is simple to construct and does not require the purchase of any special hardware other than two regular door hinges.

To rotate the worm blank through steps of 1 degree it is usual to use a rotary table or dividing head. Both these items cost rather more than I am prepared to pay for a tool that I will only use occasionally. Also, a "proper" dividing head or rotary table is designed to allow you to do fairly heavy milling - I don"t need this facility. I decided to make my own homemade DIY dividing head for light work.

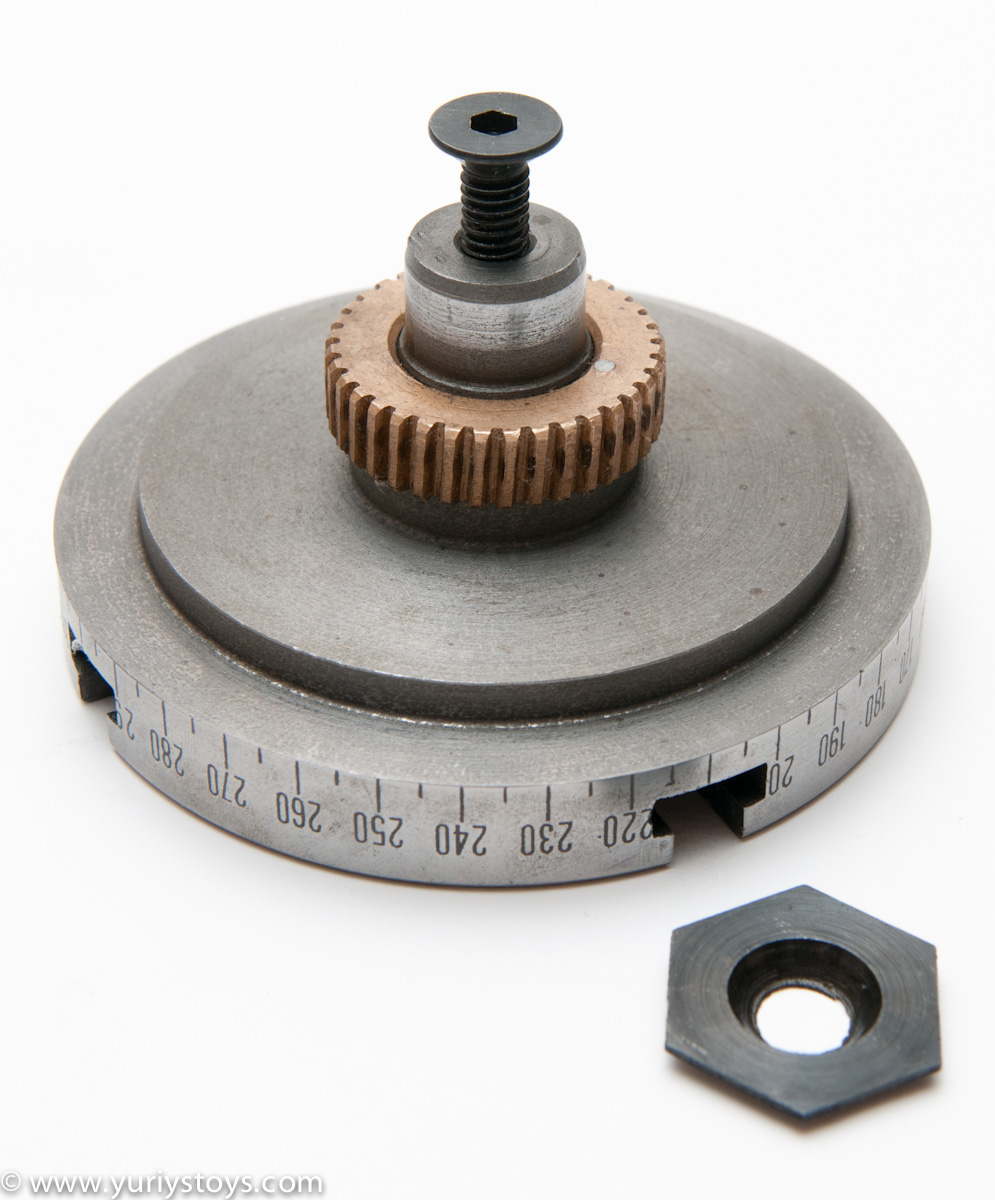

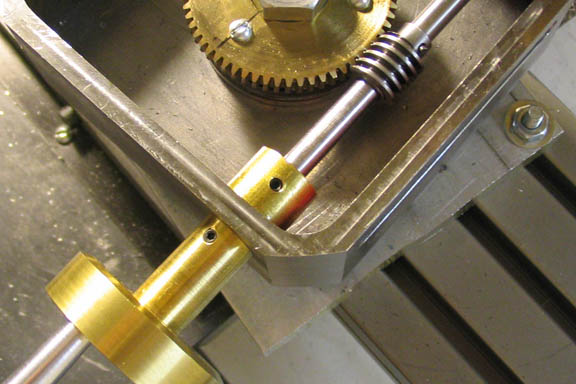

In my capacious parts box I had a small (2 inch diameter) 60 tooth worm wheel gear set. I had been thinking about making this into some kind of rotary table / dividing head / worm wheel gashing gadget. One weekend I decided to see what I could come up with.

First, I found a bearing in my parts box. It was 15mm inner diameter and 32mm outer diameter. This seemed ideal to support the working table end of the gadget. A length of 15mm diameter silver steel (drill rod) fitted it well.

Then I made the work table. This is simply a 20mm long length of 3 inch o/d aluminium barstock. The centre is bored out to be a press fit for the 15mm o/d axle. I made it a very tight fit. I heated the aluminium in the oven to 250C and the frozen steel axle slipped in easily. Now it has cooled, you"ll not get them apart! It always amazes me how much heat the aluminium retains for some time after it has come out of the oven.

Years ago, before I learned CNC, I owned a Phase II 8″ horizontal/vertical rotary table that I purchased from Kap Pullen’s Getmachinetools.com store. He has them at a good price, BTW, and he’s a darned nice fellow to deal with as well as being a frequent HSM contributor. Anyway, its a nice little table, but I hadn’t done a whole lot with it for quite a while after purchasing it. As is so often the case, one day, a project landed on my doorstep and I was glad to have it.

Before I could get started, however, I had to make some accessories for it. Basically, I needed some T-Nuts to fit the table, as well as a little fixture that makes it easy to hold a plate up off the table through a hole in the center so you can machine it. The latter, what I call a “plate machining fixture”, was inspired by something similar I saw the Widgitmaster of CNCZone fame using to make Dremel clamps for his mini-router:

I turned the round spigot using the 4-jaw on the lathe. I’m making the fixture out of MIC-6 aluminum plate, which is pre-ground very flat on the sides. This is a 5 inch by 3 inch piece. I’ve clamped it to the rotab using my T-nuts and the regular mill clamps and step blocks. It is sitting on parallels to make sure I don’t cut into the table. You can also see how I’ve clamped the rotary table to the mill table using a big cast iron V-block I have. You can never have to many blocks with precision faces hanging around!

Having a 4-jaw chuck on your rotary table is mighty handy! Because it’s a 4-jaw, you can dial in the workpiece by adjusting the jaws until it is perfectly concentric with the table’s axis of rotation. The best way is to make an adapter plate that attaches to the back of the chuck in the same way that your lathe does so you can exchange lathe tooling with the rotab. Here is an example:

For the example, the chuck is threaded onto the adaptor plate, and then the holes in the adapter plate’s flange are used to bolt down to T-nuts on the table.

In my case, I bought a 4-jaw from Shars brand new, and simply drilled some through-holes in the chuck to mount to the table directly without an adapter plate:

First, you want to make sure your part is properly centered on the table. To do that, I clamp the table down on the mill table (no special place is needed), put my Indicol indicator holder on the mill spindle, and find some round feature on the part to indicate on. For example, on the plate milling fixture above, indicate on the round boss, or on the center hole. Spin the table and bump the part in until spinning the table doesn’t move the indicator.

Second, locate the center of rotation directly under the mill spindle. You can simply use the X and Y table handwheels to do this. Use that Indicol to indicate off of a circular feature you want centered under the spindle. Turn the indicol around on the spindle and adjust the handwheels until the indicator stays put relative to the spindle position. A Blake Coaxial indicator will make this last even simpler.

When you’re rounding partially by cranking a part around on the rotary table, it’s really easy to go a little too far and screw things up. The answer is to drill the end points to make the exact stopping point on the rotab a lot less sensitive:

Centering with a Blake indicator is really fast, but what if you don’t have a Blake, or worse, what if your mill is too small to accomodate one? Here is a nice solution I found on a German site. This fellow has made an ER collect fixture for his rotary table, and has taken care that when installed on the table, the axis of the collet is aligned with the table’s axis. He can then place a dowel or other straight pin in the collet and line up until it will go into a similarly sized collet on the spindle. Nice trick! It’s similar to how Widgitmaster showed me to align a drill chuck on a QCTP to the lathe centerline with a dowel pin held in the lathe chuck.

Please keep the item in its original condition, with brand outer box, MRP tags attached, user manual, warranty cards, CDs and original accessories in manufacturer packaging for a successful return pick-up. Before returning a Tablet, the device should be formatted and screen lock should be disabled.

8613371530291

8613371530291