dmg mori rotary table brands

Chuck packages offer a convenient and productive turn-key bundle providing the Set-Tru Chuck for increased precision and rigidity, adapter for interface between the DMG Mori Seiki Rotary Table and the chuck and all necessary T-nuts and bolts. HVH offers DDRT200 and DDRT260 types of chucks packages for DMG Mori Seiki Rotary Tables, Indexers and Trunnions.

THIS DMG DMU 125P DUOBLOCK/ 5 AXIS, FEATURES A SIEMENS 840D CONTROL, NEW IN 2014, SIMULTANEOUS FIVE (5) AXIS/ FIVE (5) SIDED MACHINING, FULL B-AXIS, FULL NC SWIVEL/ TILT ROTARY TABLE, 60 ATC AND A ...

THIS DMG MORI DMU 60 EVO LINEAR 5-AXIS VERTICAL, 2016 FEATURES A CELOS SIEMENS 840D CONTROL, NC ROTARY TABLE WITH SWIVEL AXIS, 60 TOOL ATC, AND 18,000 RPM HSK-A63 SPINDLE.

THIS DMG MORI DMU65 monoBLOCK 5 AXIS VERTICAL COMES WITH HEIDENHAIN iTNC 530 CNC CONTROL, 60 TOOL ATC, TRUNNION TABLE, HSK 63/ 18000 RPM SPINDLE AND BLUM LASER.

VERY LOW HOUR 2019 DMG MORI NHX 4000 HORIZONTAL WITH (2) 15.75" PALLETS, UPGRADED 60 ATC, HSK 63/ 15000 RPM SPINDLE, CHIP BLASTER, RENISHAW OPTICAL PROBE AND FANUC FS31I-B W/MAPPS CONTROL.

THIS DMG MORI NLX2500SY/1250 CNC TURNING CENTER WITH SUB-SPINDLE AND Y AXIS, LNS BARFEEDER, PARTS CATCHER, CHIP CONVEYOR AND DMG MORI CELOS CONTROL, 2015.

X/Y/Z 2.500/920/820mm, B-Axes, table 3.100 x 900mm / load max 3.200kg, spindle 10.000rpm / 32-48kW / 196 - 294Nm / ISO 40, 30-Pos-ATC, sub-spindle bore 43mm, CNC Heidenhain TNC 530, LxBxH, ca. 3,8x...

Are you looking for an accessory to boost the precision of your modern machining centers? CNC rotary tables provide a versatile tool in expanding the capabilities of your machines. They allow for precision positioning during 4 and even 5 axis cutting operations, thereby transforming 3-axis machinery into CNC machines with heightened accuracy. CNC rotary tables are a cost-effective solution to perform complicated machining tasks, with additional benefits such as increased productivity, efficient use of labor and materials, and better quality control.

Additionally, CNC rotary tables can be used independently to mount other components on a table, including trim attachments and chucks for drilling applications. CNC rotary tables offer considerable advantages that promote their usefulness in a variety of industrial settings.

Looking to sell your CNC Rotary Table? Simply fill out the sell your machine form and we will get back to you with a quote. Interested in one of our used machines for sale? Simply click the “Get Quote” button and a sales representative will contact you shortly.

Are you looking for an accessory to boost the precision of your modern machining centers? CNC rotary tables provide a versatile tool in expanding the capabilities of your machines. They allow for precision positioning during 4 and even 5 axis cutting operations, thereby transforming 3-axis machinery into CNC machines with heightened accuracy. CNC rotary tables are a cost-effective solution to perform complicated machining tasks, with additional benefits such as increased productivity, efficient use of labor and materials, and better quality control.

Additionally, CNC rotary tables can be used independently to mount other components on a table, including trim attachments and chucks for drilling applications. CNC rotary tables offer considerable advantages that promote their usefulness in a variety of industrial settings.

Looking to sell your CNC Rotary Table? Simply fill out the sell your machine form and we will get back to you with a quote. Interested in one of our used machines for sale? Simply click the “Get Quote” button and a sales representative will contact you shortly.

"description": "Machinery Network Inc. has a wide selection of quality used DMG Mori machines including vertical CNC machining centers, combination lathes and turning centers. Browse our inventory of machines or contact us if you need something that you don"t see.",

"twitter:description": "Machinery Network Inc. has a wide selection of quality used DMG Mori machines including vertical CNC machining centers, combination lathes and turning centers. Browse our inventory of machines or contact us if you need something that you don"t see.",

"og:description": "Machinery Network Inc. has a wide selection of quality used DMG Mori machines including vertical CNC machining centers, combination lathes and turning centers. Browse our inventory of machines or contact us if you need something that you don"t see.",

DMG Mori Gildemeister CTX Gamma 1250 TC CNC Turn & Mill Machining Center, 51" x 27" Travels, 15" Chuck, 4" Bar Cap., Capto 8 Tooling, 4k RPM, New 2015 *5,937 Cut Hours! Located in Santa Fe Springs,...

When your workpieces require the use of 5C collets, the TJR AR-5C Pneumatic Collet Rotary Table from CNC Indexing & Feeding Technologies is an affordable alternative to 3- or 4-jaw chucks.

TJR’s one-piece dual lead wormshaft design is more accurate than split types used by other rotary table manufacturers. The oversize diameter pitch circle reduces pressure on the contact surface, and the worm gear’s full tooth depth engagement and larger gear module allow for a larger surface contact area and a much stronger worm gear system.

Weighing in at 34 kg (75lb), the AR-5C has a table diameter of 125 mm (4.92″), with a thru-hole diameter of 35 mm (1.37″), minimum indexing increment of 0.001˚, maximum table rotation speed of 83.3 rpm, and peak allowable workpiece load of 100 kg (220 lb.). Servo motor models are available for FANUC or Mitsubishi tapers.

CNC Indexing & Feeding Technologies is the exclusive U.S. importer for TJR Precision Technology rotary tables. We stock the TJR line at our Mason, Ohio, location, with full installation and repair services available. All TJR rotary tables come standard with a 3-year parts warranty.

TJR Precision Technology Co., Ltd. has been manufacturing rotary tables since 2009, providing highly advanced tables for top machine tools brands, including Doosan, Mazak, DMG Mori, Hardinge, YCM, Leadwell, Feeler, Bulova and Tongtai.

CNC Indexing offers a wide range of CNC accessories, including rotary tables, indexers, high pressure coolant systems, bar feeders, bar loaders and oil skimmers. Call 513-770-4200 today to learn more about how we can help you!

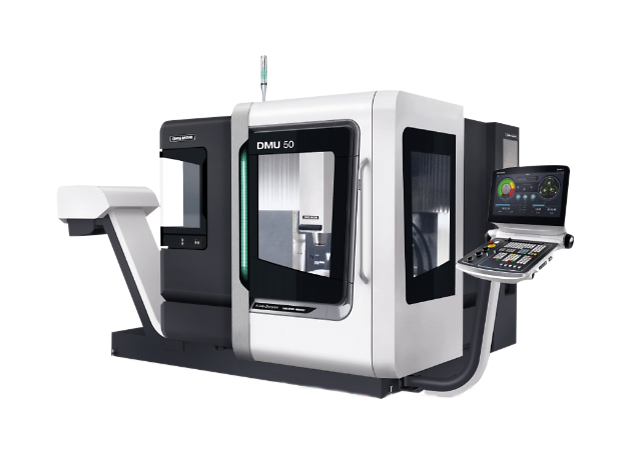

DMG is a sales brand of DMG Mori AG, one of the largest manufacturers of CNC turning and milling machines in the world. Its extensive product range includes universal, vertical, production and automatic lathes, machining centers, laser cutting systems and ultrasonic milling machines. In particular, DMG was instrumental in the development of the innovative ultrasonic cutting technology.

DMG Mori AG emerged from the cooperation between the German manufacturer Deckel-Maho-Gildemeister and the Japanese company Mori Seiki and unites the traditional brands DMG, Gildemeister, Mori Seiki, Sauer and Wasino under the worldwide sales brand DMG MORI as a "Global One Company." With a total of 14 production sites worldwide, DMG MORI is now one of the most important international manufacturers of machine tools.

Due to its broadly based product portfolio and wide range of applications, machine tools from DMG MORI are used in almost all areas of industry, from vehicle and shipbuilding to mechanical and plant engineering and aerospace. DMG high-tech machines can process a remarkable amount of materials, from stainless steel, steel and metal to various plastics, glass and diamond. The efficiency and precision of DMG grinding machines, DMG milling machines and CNC-controlled lathes from DMG are outstanding features of the successful manufacturer..

To meet the diverse needs of its customers, DMG MORI operates a global network with over 150 sales and service locations in 79 countries. With wide-ranging services such as maintenance, repair, spare parts service as well as special training courses, the company offers its customers comprehensive and reliable support..

Due to their widespread use, DMG machine tools can often be found on the used market at favorable conditions. To ensure that you are on the safe side when buying a used DMG machine tool, Stenzel offers you a full all-round service from the joint inspection of the machine at the seller"s premises to insured transport and commissioning. In this way, you receive a reliable used machine from DMG at an attractive price and with full service.

But with so many ways to go about five-axis machining, how do know what is the best buy for your shop? DMG MORI’s general manager of Aerospace Center of Excellence, Jeff Wallace, offers some insight.

Particularly for job shops, five-axis machining enables complex parts to be cut from solid material that otherwise might have to be cast. This enables quick turnaround for short-run and prototype work on high-value parts. It’s a great opportunity to differentiate the shop from lower tech competitors and build a more profitable business.

For example, if the parts are small to medium size, with today’s technology, a tilting-table-type machine is going to be the best bet. If the parts are large and heavy, an articulating head—possibly on a gantry-style machine or a horizontal machining center—may be the only option. This consideration alone will narrow your choices and help you compare features of various machine models within the required range.

The simplest and least expensive way to get at five sides of a part is with a 3+2 machine configuration. For small to medium machines, that typically means a three-axis machining center with a tilting rotary table to position the part. This of course can be accomplished with an auxiliary two-axis table on a standard three-axis machining center. But a machine with an integrated tilt table offers better machining performance and is easier to set up and program.

Higher part precision requirements in production environments place higher demands on a machine’s construction and motion control system. Rising to these demands, DMG MORI’s

Critical to this machine’s performance is the use of direct drive motors on the B and C rotary axes, which sometimes can be a restriction if there is a high demand for rotary acceleration and deceleration during the machining process, such as in the manufacturing of blisks or impellers.

Even though this machining center series uses a tilt table design, it can handle surprisingly large workpieces. With a trunnion-style table supported and driven at each end, the largest model can handle workpieces up to 13,228 lbs. with X-Y-Z travels of 52.6" × 49.2" × 35.4". It can even be equipped with a higher speed table that permits vertical turning and five-axis machining on the same machine.

Handling Cycles aid part- and tool-oriented functions such as adjusting feed rate relative to table load, automatically sorting tools to minimize magazine indexing time, and more. There is also a cycle for B-axis plunging that automatically looks for tool interference which can be a danger point with big parts and long tools.

Machining Cycles include a module just for 5-axis milling and turn/mill with intelligent look-head, gear generation, and grinding. Automatic Tuning Cycle can adjust machining parameters based on user selectable requirements on speed, surface finish and accuracy. There are also a fleet of cycles for DMG MORI’s turning and multitasking machines.

For safety, the CNCs automatically check for interference in 3D for spindles, tables, tools, workpieces and fixtures. Once a problem is detected, the machine will stop operation, whether it is in automatic or manual mode.

Whether you think five-axis machining isn’t for your shop or you’re satisfied with ten-year-old technology, it’s time to take another look. To help visualize which type of machine tool might be best for your shop, browse DMG Mori’s

8613371530291

8613371530291