doosan rotary table manufacturer

In 2022, it is likely you are considering either completely automating your machine tending or looking for avenues to reduce setup time and increase throughput. Our complete workholding packages for DNM series mills are perfect for achieving just that. When purchasing a complete solution from Martin Trunnion Tables, you will be provided with a rotary table, baseplate, trunnion solution, and workholding preassembled and ready to cut chips. Scroll down for more information and package options.

The PUMA VTR with adjustable W-axis comes with some of the largest vertical turning center specs in the industry. Give it your higher profile parts, then sit back and watch the show.

Goodbye wasted time, wasted space and wasted money. Hello NHP Series: unbeatable linear roller guide horizontal machining centers in a compact layout. Built for massive metal removal, these machines can single-handedly change your business.

DN Solutions’ Rotary Pallet System (RPS)—available on NHP, NHM and HC horizontal machining centers—is a one-, two- or three-story standout that grants you productivity your competition can’t touch.

August 30, 2018 Seoul, South Korea – Doosan Machine Tools Co. (CEO: Kim Jae-seop) will participate in IMTS 2018, one of the largest machine tools exhibitions in the world to be held from September 10 to September 15 this year. in Chicago, United States. The International Manufacturing Technology Show is organized every other year, and about 2,000 exhibiting companies will participate in the coming exhibition with about 115,000 registrants.

In the IMTS 2018, Doosan Machine Tools will have an exhibition space of 15,675 ft2 at the front row of the main exhibition hall, side by side with the world top ranking machine tool manufacturers, showing off its presence as a global leader in the industry.

“In IMTS 2018, we will exhibit large numbers of new products meeting the requirements of American customers, together with the solutions for creating productivity and higher added-value through automation and convergence, which is today’s hot issue in the industry. I believe this will increase the sales in the United States, and consolidate our presence as the industry"s leading machine tool manufacturer.”, said Mr. Kim Jae-seop, CEO of Doosan Machine Tools.

At IMTS 2018, Doosan Machine Tools will be featuring the DVF Series of compact 5-axis machining centers. The DVF Series takes its place in the company’s lineup of vertical machining centers specifically designed for cutting diverse and complex shapes.

The DVF 5000 comes standard with an 18,000r/min integral 40 taper spindle. A FANUC 31iB5 CNC controller makes full 5-axis simultaneous control possible, giving complete contouring capabilities. It also features a 500mm diameter (630mm option) built in rotary table. Available table supports allow a maximum weight of 880lbs and minimize any table deflection. The rotary table is designed for user-friendliness and consummate work efficiency, minimizing interference as the part is machined. Doosan also offers a DVF 5000 5 Face version with a FANUC 0iMF CNC controller and a 12,000r/min directly-coupled spindle.

The DVF 8000 is a larger full 5-axis machining center that incorporates many of the features of the DVF 5000, but has a larger (800mm diameter) rotary table which can support a maximum weight of 3,086 lbs.

These VMCs offer a diverse range of tailored options and automation that make them ideal for unmanned machining. They come automation-ready and supplied with an optional/retrofittable AWC (Auto Workpiece Changer) which provides additional productivity by offering up to 12 pallets to feed the machine for unattended machining.

At IMTS 2018, Doosan Machine Tools will demonstrate its PUMA SMX super multi-tasking turning centers, which come with a lower turret for enhanced versatility and productivity. The turret is available on both the 10” chuck (PUMA SMX2600ST) and 12” chuck (PUMA SMX3100ST) models.

Doosan’s PUMA SMX Series is a twin-spindle, multi-tasking turning center built for completing complex parts in a single setup. Both turning spindles feature 0.0001° resolution on the C-axis for high precision contouring, and the 12,000 RPM dedicated milling spindle features 0.0001° resolution contouring B-axis as well. With a Y-axis stroke of 11.8” (300mm) and an orthogonal X/Y structure, part accuracy and machine accessibility are both improved.

At IMTS 2018, Doosan Machine Tools will be showing the DHF 8000, an 800mm twin pallet 5 axis horizontal machining center with a nodding head. This HMC was specifically designed for the processing of large, complex parts such as those used in the aerospace, oil field and automotive industries.

The nodding head spindle and rotary table (axis A and B) allow the DHF 8000 to handle a complete range of machining processes from roughing to finishing in a single setup. This configuration makes quick work of multi-face workpieces and the 5-axis simultaneous machining of complex shapes.

Fanuc 0iMB CNC Control, 4-th Axis Control, SMW Accu-Rock RT 160 8" Programmable Rotary Table and Tailstock, 24 Station Twin-Arm Automatic Tool Changer, 12,000 Max Spindle RPM, Cat 40 Spindle Taper, Remote Jog Handwheel, Coolant System, Thru Spindle Coolant (290 PSI), Chiller

On Machine Enhancements Work Holding Our range of modular work holding integrates seamlessly with our multi axis platform approach as our zero point location and modular base rail technology are available with the NIKKEN standard table interfaces, this allows rapid change over of component fixtures and work holding set ups. Standard clamping modules, centring vices and chucks are all interchangeable with machine bed and additional axes, in addition a wide range of standard and bespoke trunnion set ups are available as options. Productivity Options Feature a complete range of Tool...

Spindle optimisation Rotary Tables Section Machine Enhancements, NIKKEN Rotary Tables Spindle Optimisation NC Tooling System Spindle Optimisation Angle Heads and Turboflex Productivity Options Tool Pre Setters NIKKEN are able to provide a wide range of on Machine enhancements to create a flexible multi-axis machine platform essential for todays highly competitive market. Our range of 4th and 5th axis tables open up the possibilities of part manufacture in a single cycle, improving process flow and productivity! NIKKENs extensive product range combined with technical expertise, training and...

On Machine Enhancements Rotary Tables NIKKEN Kosakusho Works Limited, in Japan annually produces some 3500 rotary tables, it employs a global workforce in excess of 550 and has earned, and maintains, a reputation for producing quality products and demonstrating total commitment to its clients. Our unique table construction delivers unrivalled performance and reliability, our products are fully supported by our team of factory trained service team and our advanced manufacturing specialists. Our Tables are the perfect fit for the Doosan range of machines and offer the opportunity to combine...

Rotary Tables Unique Table Construction Casting NIKKEN Rotary Tables utilize fine grain high-density Grey Cast Iron castings, these castings are stabilized prior to finishing operations and offer long term stability, low distortion, high strength and rigidity. Industry 4.0 NIKKEN are leading the way by utilising the latest, cloud-based technology to access big data during the lifetime of our products. Providing you with full Industry 4.0 compliance. Being able to sense and predict failure is a major aspiration for optimizing machine uptime, with this goal in mind NIKKEN have created our new...

On Machine Enhancements Rotary Tables NIKKEN NC Tables offer unrivalled quality and performance, they optimize production and can be configured for all types of Machining centres, Vertical, Horizontal, twin pallet. NIKKEN can offer a wide range of 4th and 5th Axis Tables that can be easily configured with a variety of work holding solutions such as Trunnion fixtures, built in rotary joints for facilitating hydraulic clamping, chucking and vice systems, the range consists of gear driven and direct drive units and can be controlled by the machine tool direct or via our own Alpha21 control...

Rotary Tables Standard Rotary Tables NIKKEN offer a comprehensive range of tables for Vertical machines, Face plate diameters range from 105mm to 1600mm and Motor positions can left hand, right hand or back mounted to ensure units are able to be mounted in the most efficient position. Options Include: • Built in Rotary Joints • Direct encoders • Zero Point Quick change solutions • Machine Vices • Trunnion systems • Modular Work Holding and clamping • Manual and Power Chuck systems • Manual, Pneumatic and Hydraulic • Tailstocks • TAT end Support Units Servo Specification NIKKEN Tables are...

On Machine Enhancements 5 Axis Solutions NIKKEN are at the forefront in the field of 5 axis tables, we feature a comprehensive range to suit Doosan machining centres, they offer the opportunity to maximise productivity by combining multiple operations, and they are ideally suited for complex multi-faceted parts or components with compound detail to be machined.

A comprehensive range of modular vices and chucking systems are available to compliment NIKKEN 5 Axis solutions. 5 Axis Solutions are an ideal addition to any Doosan machining centre, they are ideally suited to difficult to hold complex parts and by reducing set ups they optimise quality and productivity, in many instances a part can be manufactured and inspected in a single operation. “Sputnik” multi part clamping system Compact 5 Axis units can be mounted along the Y Axis of a vertical Machine to facilitate part manufacture in a single set up. Tables can be mounted along the X axis of the...

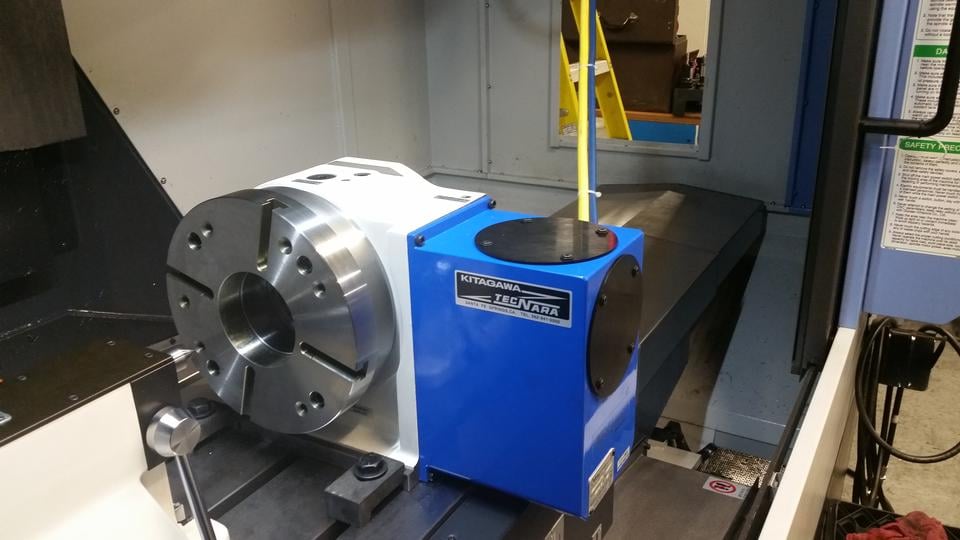

The recently introduced DNM vertical machining centers from Doosan are now equipped with factory-installed Tsudakoma TN161 or TN201 rotary turning tables.

The TN models incorporate specially designed, double-lead worm gears that mesh the full length of the teeth.The machine also features a patent-pending pneumatic clamping device for added power.According to Doosan, these features improve indexing speed by 50 percent and clamping force by 250 percent, and result in faster cycle times and higher accuracy, even when machining far from the tilting axis.

Tsudakoma rotary tables are standard on Doosan’s DNM400-31iA5 vertical machining center with a 36.2-in. by 17.1-in. loading area, and the DNM500-31iA5 vertical turning center with a 47.2-in. by 21.2-in. capacity.Both models are powered by a 30-HP spindle motor capable of driving CAT 40 tools at speeds up to 15,000 RPM and generate up to 1,655 lbs. of thrust along the X and Y axes and 3,611 lbs. along the Z.

8613371530291

8613371530291