drilling rig rotary table components manufacturer

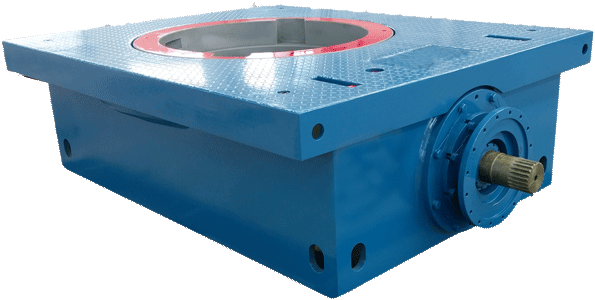

Cameron rotary tables range from 27 1/2 in to 60 1/2 in and feature a large oil capacity that adds to the unit"s durability. The rotary table includes a forged-steel fabricated housing and a heat-treated forged-steel turntable. Each rotary table is supplied with spiral-bevel, induction-hardened gears and two independent ratchet-type locks, with lever access from the top to lock the table in position.

Welcome to Pickett Oilfield’s rotary tables web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used rotary tables and rotary equipment to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including rotary tables to choose from at competitive prices. Browse our inventory of rotary tables and rotary table drilling components for sale at competitive rates.

Explore the various drilling rig parts rotary table products available for wholesale at Alibaba.com. Get a drilling rig parts rotary table for drilling water wells, water exploration holes, geological exploration, coal mines, and other kinds of mining. Some drilling rig parts rotary table options use caterpillar tread to move. Others use rubber tires, while others require a separate means of transport. Caterpillar tread propulsion can climb up to 25 degrees inclination. Some products in the range are capable of drilling over 200 meters, while others are only used for open-pit mining with depths of around 3 meters. Drilling can be done vertically downwards, horizontally, or in a slanting direction. Drilling speed depends on the power of the machine and the general hardness of the surface. The hole diameter can vary from 90mm to 200mm.

drilling rig parts rotary table options also include an air compressor, a mud pump, drilling rods of various sizes, connectors, and a drilling tower. Drilling is done using drill bits of various shapes, sizes, and compositions. You can choose between diamond bits, alloy ring-shaped bits, 3-wing alloy bits, PDC bits, and hammer bits. Each drill bit uses different drilling methods, including rotary, percussion, blast hole, and core drilling.

Smaller products have a lifting power of around 25 kilonewtons and weigh about 2,500kgs. They’re ideal for small-scale drillings such as farms and homes. Larger ones are faster with more power, making them ideal for commercial use. Browse through Alibaba.com and find a drilling rig parts rotary table that’s ideal for your work scope. Buy mine drilling rigs for your wholesale business at competitive prices. Chinese wholesalers provide you with customization options and great after-sales services.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Rotary Tables - 37-1/2 IN. ROTARIES, FG-2A, 500 TON, 14 IN. - 2-3/8 IN. PIPE SIZES USE FOR TRIPPING AND CASING RUNNING. OPTIONAL HPCD AVAILABLE. ALL FG SERIES TOOLS ARE HYDRAULICALLY ACT... More Info

Rotary Tables - 49-1/2 IN. ROTARIES, FG-3A, 750/500 TON, 20 IN. - 2-3/8 IN. PIPE SIZES USE FOR TRIPPING AND CASING RUNNING. OPTIONAL HPCD AVAILABLE. ALL FG SERIES TOOLS ARE HYDRAULICALLY... More Info

Rotary Tables - DEN-CON 49-1/2 IN. HMB BUSHING, 750 TON RATING, AVAILABLE WITH A VARIETY OF INSERT BOWLS INCLUDING CONVENTIONAL API BOWLS, 500 TON BOWLS AND 750 TON BOWLS. More Info

Rotary Tables - 37-1/2 IN. - 49-1/2 IN. ROTARIES, FG-6B, 350 TON, 8-5/8 IN. & SMALLER WORKOVER RISER. PURPOSE BUILT POWER SLIP FOR HANDLING WORKOVER RISER WITH UMBILICALS. IDEAL FOR RENT... More Info

Rotary Tables - POWER SLIPS ARE AVAILABLE FOR 27-1/2 IN., 37-1/2 IN. & 49-1/2 IN. ROTARY TABLES. RATED CAPACITIES FROM 350 TONS TO 750 TONS. 27-1/2 IN. ROTARIES, FG-5A, 350 TON, 9-5/8 IN... More Info

Rotary Tables - ADAPTER RINGS - 750 TON - SOLID & SPLIT RINGS - DEN-CON 60-1/2 IN. X 49-1/2 IN. ADAPTER RINGS. ADAPTER RING OUTSIDE CONFIGURATION AND INSIDE CONFIGURATION CAN BE DONE FOR... More Info

Rotary Tables - ADAPTER RINGS - 750 TON - SOLID & SPLIT RINGS - DEN-CON 49-1/2 IN. X 37-1/2 IN. ADAPTER RINGS. ADAPTER RING OUTSIDE CONFIGURATION AND INSIDE CONFIGURATION CAN BE DONE FOR... More Info

A drillingmast is a construction over a well hole it supports the drilling equipment and all keep it lifted into and out of the well hole. ARK Drilling provides variety of design, engineering, and manufacturing services for water and geothermal drilling rigs masts.

Mast is one of the most important component of a rig. It must be stronger than components on board like drawwork. When we desing our masts we calculate static and hook loads for long term operation safety of drilling staff and rig. Our MS60 & MS50 & MS40 rigs masts are same which is max load capacity 70 ton and its made by 100*100*6mm square profile steel. Why we manufacture same mast for various capacity of these our drilling rigs. Its our priority safety of drilling staff and rig while and trouble at drilling operation like stuck the drill pipe. If a mast of rig is is very strong it gives confident to drilling crew.

EC Tool’s drilling gear includes roller chains, draw-works, and many other items. We are happy to help you find the exact item you need, right down to the model. You can also request custom-made swivels, rotary table drawings, and more.

EC Tool specializes in the manufacturing and sales of oilfield drilling equipment and drilling rig packages. We supply the full line from SCR drive rigs to conventional and fast-moving rigs (truck-mounted, trailer-mounted, and skidding), drilling equipment, and rig accessories and parts.

Supplying drill rig replacement parts has been the specialty of Drilling Supply and Manufacturing (DSM) since it first opened its doors in 1977. Today, it is not only known as a supplier of essential replacement parts, it is also known as a drill rig manufacturer and rebuilder.

“We manufacture and sell parts for Gardner-Denver, Mayhew, Midway and Badger drill rigs, and make custom parts for many other rigs,” Ken Young, DSM general manager, claims. Starting with 12 acres of land and just 3,750 square feet of building space in Austin, Texas, the company has grown to fill three buildings totaling 300,000 square feet. “We still have room to grow,” Ken adds, “but not much.”

In 1977, Young came to Austin to join forces with Palmer and Stanley Martin (father and son) to form DSM. Ken had been a partner and manager of the Midway Supply & Manufacturing in Odessa, Texas, (the manufacturer of Midway Drill Rigs) until he sold out in 1974. As a condition of the sale, he remained with Midway for three years after the change in ownership. At this point in his life, Ken considered a number of options in the drilling business before moving to Austin and forming a partnership with the Martin’s.

Palmer Martin began his career in the drilling business in 1945 and opened his own machine shop, Martin Machine Corp., in 1963. From 1963 to 1977, Palmer manufactured parts for Midway Supply & Manufacturing, where he dealt with Ken Young. Palmer’s son, Stanley Martin, began helping out at the family machine shop at the age of 13 and is today the general shop manager and consulting engineer for the company. “Designing drill rig parts and components is not an easy task, “Stanley notes.

DSM is active in the drill rig manufacturing business today, making and marketing the DSM Bob Cat 1000W, 1500W, and other custom rigs. DSM also manufactures rotary tables, Drawworks, PTOs, floating subs, slips, fishing tools and swivels.

“We do a lot of drill collar and cross-over sub work, too,” Ken says. “We make most of the parts right here in our own shop using special lathes and equipment. We make all of our own kelly bushing and slips. We have our own sand-casting molds, but have the casting done outside.”

Skilled employees are a key component of DSM’s success. “We employ a number of former drillers at DSM,” Ken explains. “Drillers make some of the best mechanics and parts people. They understand the needs of our customers whey they call needing replacement parts in a hurry. Parts people have to know a lot about drill rigs in order to locate the problem area and match up the parts for rigs of a given manufacturer and year model,” he adds. Ken’s son, Randy, is DSM’s parts manager. He’s also involved in outside sales.

In 1986, DSM dedicated a complete hydraulic parts and repair shop – DSM Fluid Power – to serve the needs of drill rig owners and operations. This shop maintains the largest hydraulic test equipment in central Texas.

On Dec. 12, 1991, DSM purchased the Mayhew/Gardner-Denver Water Well Division from Cooper Industries, which included all blueprints, patent rights and molds.

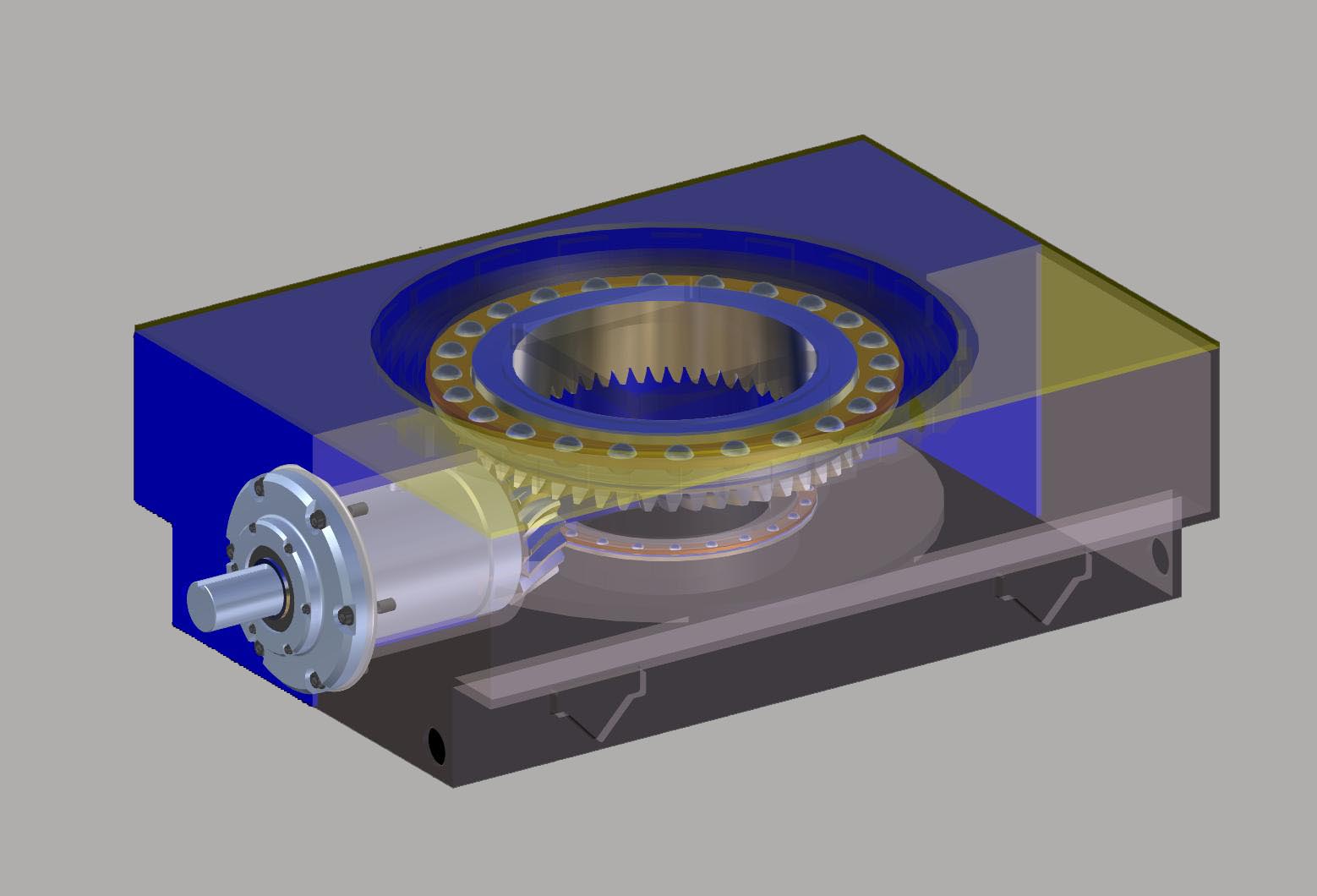

The drilling rig rotary table is an important part of the drilling rig. Its function is to decelerate a pair of bevel gear pairs during drilling operation, so

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

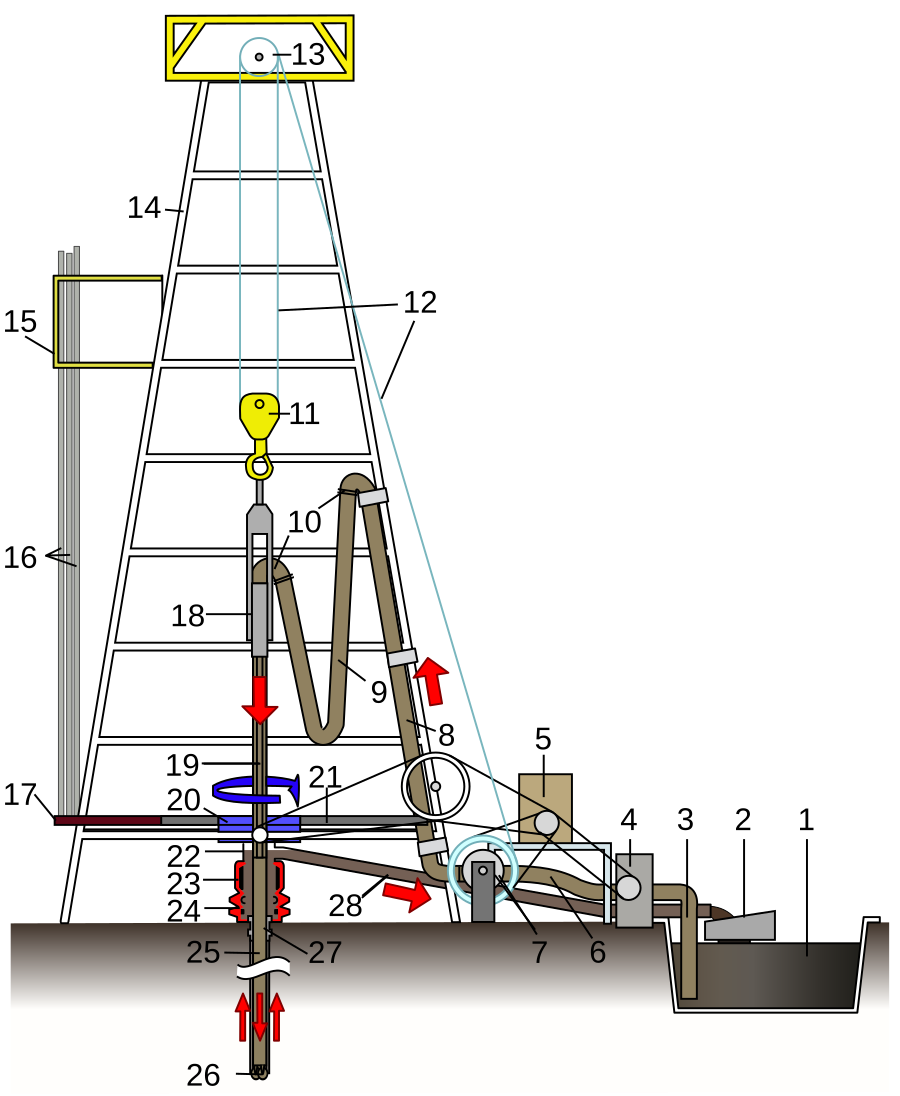

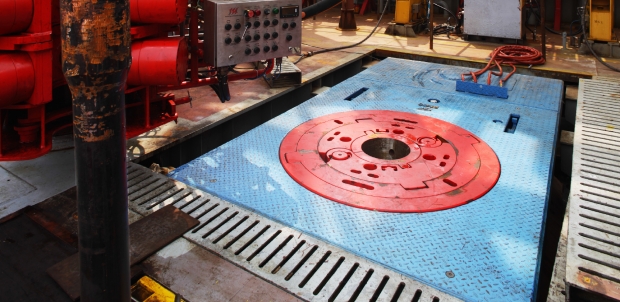

The rotary system includes all of the equipment used to achieve bit rotation. Originally, the main driver in the system of all rigs was the rotary table. The main parts of the rotary system with a rotary table are the swivel, kelly, and drillstring.

The rotary swivel (Fig. 1)serves two important functions in the drilling process. It is a connecting point between the circulating system and the rotary system. It also provides a fl uid seal that must absorb rotational wear while holding pressure. The upper section of the swivel has a bail for connection to the elevator hook, and the gooseneck of the swivel provides a downward-pointing connection for the rotary hose.

The kelly is the fi rst section of pipe below the swivel. The outside cross section of the kelly is square or (mostcommonly) hexagonal to permit it to be gripped easily for turning. Torque is transmitted to the kelly through kelly bushings, which fi t inside the master bushing of the rotary table. The kelly thread is right-handed on the lower end and left-handed on the upper end to permit normal right-hand rotation of the drillstring.

During drilling operations, in every connection, a new pipe is added below the kelly. To avoid premature wear in the kelly’s threads, a kelly saver sub is used between the kelly and the fi rst joint of drillpipe. Kelly cock valves are located on either end of the kelly.

Modern rigs use a topdrive to replace the kelly, kelly bushings, and rotary table. Drillstring rotation is achieved through hydraulic or electric motors. One type of topdrive is shown in Fig. 2

Topdrives are suspended from the hook and can travel up and down the derrick. This will allow drilling to be done with stands of pipes, instead of single joints, which will save considerable time. Comparing with the conventional process, where a new pipe must be added to the drillstring after the length of just one joint has been drilled, using a topdrive system, a new connection will occur only after the length of one stand (two, three, or four pipes) has been drilled.

Fig. 1 —(a) Rotary swivel (Steven M. Hain Company, Inc. 2010); used with permission from Steven M. Hain Company, Inc.; (b) rotary swivel (courtesy of OSHA).

The drillstring connects the surface equipment with the drill bit at the bottom of the well. The rotary table, or the topdrive, rotates the drillstring and, consequently, rotation is transmitted to the bit.

Range 2 drillpipe is used most commonly. Since each joint of pipe has a unique length, the length of each joint must be measured carefully and recorded to allow a determination of total well depth during drilling operations.

The BHA is the lower section of the drillstring. Even though a BHA may have many different tubulars depending on the complexity of the operation, most of the BHA is composed of drill collars (Fig. 3c). The drill collars are thick-walled, heavy steel tubulars used to apply weight to the bit. The buckling tendency of the relatively thinwalled drillpipe is too great to use it for this purpose. The smaller clearance between the borehole and the drill collars helps to keep the hole straight. Stabilizers (Fig. 4)often are used in the drill collar string to assist in keeping the drill collars centralized. Other types of tubulars used include shock absorbers and drilling jars. In addition, heavyweight drillpipes, a type of drillpipe with thicker walls, are commonly placed on top of the BHA to make the transition between the heavier drill collars and the drillpipes.

Huisman manufactured a LOC 5 drilling rig that is used by NewGen Drilling to drill in the gas field of the Whincher Range, near Busselton, in Southwest Australia. The rig is designed with safety foremost but also features other innovations and benefits.

8613371530291

8613371530291